Table of Contents

Advertisement

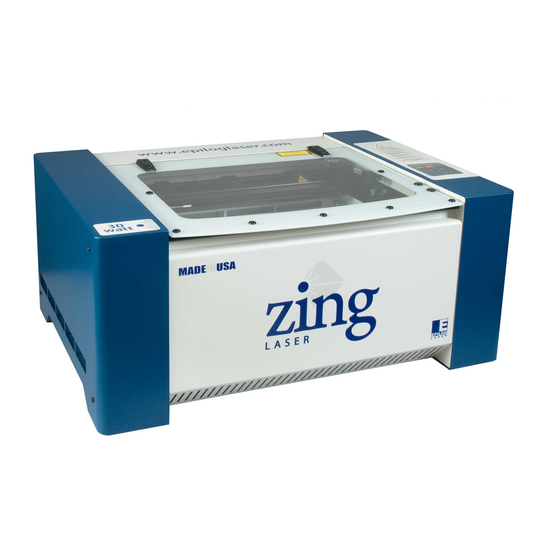

OWNER'S MANUAL FOR EPILOG

Zing - MODEL 10000

This manual can also be found in electronic format on the

Epilog Dashboard Drivers and Documentation

disk that came with your laser system.

April 22, 2010

16371 Table Mountain Parkway

Golden, CO 80403

Phone (303) 277-1188

Fax (303) 277-9669

Technical Support Direct Line: (303) 215-9171

Email Technical Support: tech@epiloglaser.com

Technical Support Online:

www.epiloglaser.com/service.htm

www.epiloglaser.com/downloads.htm

Advertisement

Table of Contents

Summary of Contents for Epilog Laser Zing 10000

- Page 1 OWNER'S MANUAL FOR EPILOG Zing - MODEL 10000 This manual can also be found in electronic format on the Epilog Dashboard Drivers and Documentation disk that came with your laser system. April 22, 2010 16371 Table Mountain Parkway Golden, CO 80403 Phone (303) 277-1188 Fax (303) 277-9669 Technical Support Direct Line: (303) 215-9171...

- Page 2 THIS PAGE WAS INTENTIONALLY LEFT BLANK...

-

Page 3: Table Of Contents

Contents at a Glance Fire Warning!......................ix Lifting Warning! .......................x Introduction ......................xi Epilog Laser Setup ....................1 Section 1: Safety ..........................3 Section 2: Dos and Don’ts ......................13 Section 3: Getting Started ......................15 Section 4: Connecting the Laser to Your Computer..............21 Section 5: Installing the Epilog Dashboard Print Driver ............. - Page 4 Contents at a Glance THIS PAGE WAS INTENTIONALLY LEFT BLANK...

- Page 5 Table of Contents Fire Warning!......................ix Lifting Warning! .......................x Introduction ......................xi How to Use This Owner’s Manual ..................xi Epilog Laser Setup ....................1 Section 1: Safety ..........................3 Laser Safety ..........................3 Electrical Safety ........................5 Fire Safety ..........................6 Safety Features and Regulatory Compliance ................

- Page 6 Table of Contents Basic Operations ....................53 Section 7: Using the Epilog Dashboard Driver................55 General Tab........................... 58 Advanced Tab ........................90 Color Mapping Tab......................103 Additional Dashboard Driver Features ................113 Changing Dashboard Driver Defaults................. 115 Section 8: Using the Front Control Panel .................. 117 Keyboard Commands......................

- Page 7 Table of Contents Section 13: Material Engraving Techniques................173 Acrylic..........................173 Fire Warning!........................173 Anodized Aluminum......................176 Brass - Painted ........................176 Glass............................ 178 Notary Seals - Delrin ......................180 Plastic ..........................181 Rubber Stamps ........................183 Wood........................... 191 Section 14: Material Suppliers....................197 Technical Support, Troubleshooting and Specifications ........

- Page 8 Table of Contents APPENDIX A WARRANTY STATEMENT ..............229 APPENDIX B PRINTING FROM AUTOCAD............. 231 APPENDIX C ADDITIONAL DASHBOARD PRINT DRIVER INSTRUCTIONS ....235 Dashboard Driver Installation for USB Connection Using Windows Vista....... 235 Windows Vista Dashboard driver installation for Ethernet connection ......239 Windows 7 - Driver Installation Instructions - Setting up the TCP/IP Address in the Computer..........................

-

Page 9: Fire Warning

Fire Warning! Your laser system uses a high intensity beam of light that can generate extremely high temperatures when it comes into contact with the material being engraved, marked or cut. Some materials are extremely flammable and can easily ignite and burst into open flame setting the machine afire. -

Page 10: Lifting Warning

Lifting Warning! The Zing 16 laser system weighs 92 lbs. (42 Kg). The Zing 24 is 140 (64 Kg). One person should not attempt to lift either machine. Always use two people for lifting. LIFT LIFT USING TWO PEOPLE WITH CARE The Zing is designed with lift areas at the bottom of the chassis on both the left and right sides of the machine. -

Page 11: Introduction

You will be ready to use the Epilog laser system as soon as you read the first six sections. Then you can refer to topics in the remaining sections, as you work. - Page 12 Introduction Icons Used in this Manual Look for these symbols to help you find valuable information throughout the text: Sometimes the right perspective on a procedure is essential to success. This icon Flags a Quick Note regarding the task at hand. This Icon signifies places to look for additional information to assist with the topic currently being discussed.

- Page 13 Introduction Indicates pages including information regarding connecting your laser system to your computer using an USB connection. Indicates pages including information regarding connecting your laser system to your computer using an Ethernet connection. Indicates the potential for fire danger when operating the laser. xiii...

- Page 14 Introduction THIS PAGE WAS INTENTIONALLY LEFT BLANK...

-

Page 15: Epilog Laser Setup

Manual Epilog Laser Setup... - Page 16 THIS PAGE WAS INTENTIONALLY LEFT BLANK...

-

Page 17: Section 1: Safety

Section 1: Safety In This Section Laser Safety Electrical Safety Fire Safety Safety Features And Regulatory Compliance CE Certification Laser Safety The Epilog Model 10000 Laser System is a Class 3R laser product, as defined in International Standard IEC 60825-1. - Page 18 Section 1: Safety The operator of the Epilog Model 10000 should observe the following general precautions: DO NOT disassemble the machine or remove any of its protective covers while the unit is plugged in. DO NOT attempt to defeat the door interlocks. ...

-

Page 19: Electrical Safety

Section 1: Safety Electrical Safety The AC input power to the Epilog Model 10000 Laser System is potentially lethal and is fully contained within the cabinet. DO NOT open any of the machine’s access panels while the unit is plugged in. -

Page 20: Fire Safety

Section 1: Safety Fire Safety Laser cutting and engraving systems represent a significant fire hazard. Most engraving materials are inherently combustible, and while the objective of most cutting and engraving operations is to vaporize material without burning, it is easy to ignite a flame. -

Page 21: Safety Features And Regulatory Compliance

Section 1: Safety Safety Features and Regulatory Compliance Epilog has incorporated specific safety features into the Model 10000 Laser System in order to meet the requirements of 21 CFR 1040 and the International Standard IEC 60825-1. These safety features include: ... - Page 22 Section 1: Safety Warning Label. This label is located on the rear of the machine’s cabinet. Explanatory Label. This label identifies the classification of the Model 10000 in accordance with IEC 60825-1. It is located on the rear of the machine’s cabinet.

- Page 23 Section 1: Safety Defeatably-interlocked Protective Housing Safety Label. This label is located on the machine’s top access door. CAUTION - CLASS 4 VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED AVOID EYE OR SKIN EXPOSURE TO DIRECT OR SCATTERED RADIATION Aperture Safety Label.

- Page 24 Section 1: Safety Fire Safety Label. This fire hazard label is located on the right side cover of your laser system. Do not cover this label at any time. DANGER FIRE HAZARD DO NOT OPERATE MACHINE UNATTENDED USE EXTREME CAUTION WHEN CUTTING FLAMMABLE MATERIALS SUCH AS WOOD OR ACRYLIC.

-

Page 25: Ce Certification

Section 1: Safety CE Certification... - Page 26 Section 1: Safety THIS PAGE WAS INTENTIONALLY LEFT BLANK...

-

Page 27: Section 2: Dos And Don'ts

Section 2: Dos and Don’ts In This Section Operating Dos and Don’ts DON’T! NEVER operate the machine without a properly operating vent to the outside! Most material will only produce an irritating smoke when engraved. Some materials, including but not limited to paint, varnish, composition board and plastics, produce compounds that can be harmful if concentrated. - Page 28 Section 2: Dos and Don’ts Please allow a few minutes a week for cleaning your machine. Just a small amount of effort at the end of the week will pay off with years of trouble free operation of your machine. See the Engraving Machine Cleaning section of this manual for specifics.

-

Page 29: Section 3: Getting Started

Laser Cooling Requirements And Operating Temperatures Setting Up Your Laser System Setting up your Epilog Laser System is easy to do! If you’ve ever installed a paper printer on your computer, this is almost that easy. You will need to do the following to use your machine: ... -

Page 30: Connecting The Exhaust

Section 3: Getting Started Connecting the Exhaust It is mandatory that an exhaust blower is hooked up and operating whenever your laser system is running a job. The exhaust blower removes the dust, debris and smell from the engraving cavity and exhausts it to the outside of the building. You should never operate your laser system without a properly working exhaust. - Page 31 Section 3: Getting Started Epilog Exhaust Blower Connections Exhaust Port Use flexible aluminum or galvanized sheet metal ducting to connect the laser systems exhaust port to the intake side of your exhaust fan. Then connect the exhaust side of the exhaust fan to the metal duct leading outside. Check your exhaust system for leaks.

- Page 32 Section 3: Getting Started The drawings below show the typical exhaust setup. The top drawing shows the exhaust on the roof and the bottom drawing shows the exhaust fan near the machine. Where the exhaust fan is placed is a choice of personal preference. Some users like the exhaust fan outside because of noise considerations.

-

Page 33: Connecting Electrical Power

Connecting Electrical Power What voltage should be supplied to operate a Zing laser? All Epilog laser systems have an auto-switching power supply that detects the incoming voltage and automatically switches itself to operate properly at any single-phase voltage between 100 and 240 VAC. The power supply will also automatically compensate for either 50 or 60 Hz. -

Page 34: Laser Cooling Requirements And Operating Temperatures

Laser Cooling Requirements and Operating Temperatures Epilog laser systems use air-cooled laser tubes. Laser technology is such that the laser tubes generate heat and the tubes must be cooled in order for them to operate correctly. There are cooling fans located on the bottom left side of the system and cooling vents that are located all along the left side. -

Page 35: Section 4: Connecting The Laser To Your Computer

Ethernet Port Connecting the Laser to Your Computer Your Epilog laser system is designed to be used with either 32-bit or 64-bit versions of Microsoft Windows XP, 2000, Vista, or Windows 7 operating systems. Most of the world is not fully ready for a 64-bit operating system, so you may be better off using a 32-bit version of Windows depending on what else is expected from your computer. -

Page 36: Usb Port

Ethernet port. The Ethernet port is located on the right side of the machine, near the rear. Your Epilog laser has all of the versatility of a Network capable peripheral. As such, there are many different ways that the laser can be connected to a computer or a network. -

Page 37: Section 5: Installing The Epilog Dashboard Print Driver

Dashboard Print Driver Instructions, of this manual The Epilog Dashboard is the print driver that allows your computer to talk to your Epilog laser system when either the Ethernet Crossover cables or USB are connected. The Dashboard is designed for use with Windows XP,... -

Page 38: Installing The Dashboard Driver Using An Ethernet Connection And A Crossover Cable

Note: The following instructions work only for a direct connection from the computer to the Epilog laser using a Crossover cable. This procedure does not work with a hub or a server. For Ethernet connections that require a hub, server or multiple machines/computers, please consult with your network administrator. - Page 39 Section 5: Installing the Epilog Dashboard Print Driver Step 1: Setting the Ethernet IP Address on the Laser In order to set up the laser system with the appropriate IP Address, you will need to set-up the laser through a sequence of steps that are described below. Although it may seem intimidating if this is your first experience setting up Ethernet connections, it’s really quite simple to accomplish.

- Page 40 Section 5: Installing the Epilog Dashboard Print Driver STOP RESET Speed Power Focus Data Config Pointer X/Y Off www.epiloglaser.com IP ADDRESS To set the IP Address, press the POINTER and GO buttons simultaneously. You will see “FUNCTIONS MENU” displayed on the control panel LCD screen.

- Page 41 Section 5: Installing the Epilog Dashboard Print Driver If you want to change the IP Address, please follow these instructions: a) If you want to change the 1 in 192 to any other number, simply press the key for that number. For example, if you want to change the 1 (in 192) to a 4, press the Down cursor key.

- Page 42 Section 5: Installing the Epilog Dashboard Print Driver Subnet Mask Press GO again to see the SUBNET MASK settings. Use the same process of number selection using the keypads to select the appropriate number for the SUBNET MASK. Note: If you are using the cross-over cable provided by Epilog, you can set the “SUBNET MASK”...

- Page 43 Section 5: Installing the Epilog Dashboard Print Driver Step 2: Setting up the Computer’s TCP/IP Address Once you have set the IP Address on the laser you will need to set the TCP/IP Address in your computer. From the Start menu at the bottom of your computer monitor screen select Start | Control Panel | Network Connections.

- Page 44 Section 5: Installing the Epilog Dashboard Print Driver The window below will appear. Select Use the following IP address radio button. Type in the following (leave everything else blank on this page). IP Address 192 168 3 3 Subnet Mask 255 255 255 0 Default Gateway Leave blank...

- Page 45 Step 3: Installing the Dashboard Driver for an Ethernet Connection Insert the Epilog Laser CD into your computer’s CD player. It should Auto-Start and the following window should appear (refer to Appendix C if the AutoRun feature does not bring up the following screen): Click on the Zing Laser…...

- Page 46 Section 5: Installing the Epilog Dashboard Print Driver NOTE - When you Unzip the driver files they will be unzipped into the c:/Epilog_Driver directory. Do not move them from this directory. installation process looks for them in this directory later on in the process. The following window will appear: Click on OK and the following window appears: Click the...

- Page 47 Section 5: Installing the Epilog Dashboard Print Driver Select Local printer attached to this computer Deselect Automatically detect and install my Plug and Play printer Click Next> button to continue. Click on Create a new port: Use the scroll button to select TCP/IP Port Click Next>...

- Page 48 Section 5: Installing the Epilog Dashboard Print Driver Click Next> to continue. Enter the same IP Address that you set using the Zing keyboard (Step 1 in this procedure). It is important that the IP addresses be the same in both places, but the format of the numbers looks a little different.

- Page 49 Section 5: Installing the Epilog Dashboard Print Driver Click on the Custom button, and then Settings. Set Protocol to LPR. This is a very important step. Your download time will be greatly increased if LPR is not selected. Type Legend in the Queue Name box.

- Page 50 Section 5: Installing the Epilog Dashboard Print Driver Click Next to continue. Click Finish to continue.

- Page 51 Section 5: Installing the Epilog Dashboard Print Driver Click Have Disk… Click on Browse...

- Page 52 Section 5: Installing the Epilog Dashboard Print Driver Go to the drive with the Epilog CD. Double click on the drivers folder. Highlight the EpilogWin32Lit.inf file and then click on Open to continue.

- Page 53 Section 5: Installing the Epilog Dashboard Print Driver Click on OK Highlight the Epilog Engraver Win32Zing file and then Click Next>.

- Page 54 Section 5: Installing the Epilog Dashboard Print Driver Name Your Print driver and determine if you want this to be the default driver. Click Next. Do not share. Click Next...

- Page 55 Section 5: Installing the Epilog Dashboard Print Driver Do not print a test page. Click on Finish.

- Page 56 Section 5: Installing the Epilog Dashboard Print Driver Click Continue Anyway. While the driver has not been tested by Microsoft, it will not destabilize your computer. On newer versions of Windows you may see a Window pop up that requests permission to allow installation.

-

Page 57: Section 6: Quick Start & Easy Setup

Artwork Setup Job Setup Your Epilog laser system is ready to use once you have followed the steps in Sections 1 – 5. To get started quickly and run a sample piece of material on your new laser, the following is a very quick setup guide to describe the general steps for running a first job. - Page 58 Section 6: Quick Start and Easy Setup Job:1.Sample.cdr STOP RESET Speed Power Focus Data Config Pointer X/Y Off www.epiloglaser.com The job you sent over most recently is shown in the LCD display. To run that job, just press the GO button on the keyboard. To run a previous job, press the JOB button on the keypad and then scroll through the sent jobs by pressing the UP Arrow key or the Down Arrow Key.

-

Page 59: Artwork Setup

Section 6: Quick Start and Easy Setup Artwork Setup Create your job in the graphics software of your choice, (for example – CorelDraw). There are three different modes of operation for the laser and the way you setup your artwork will determine if you raster engrave or vector cut. Raster engraving can best be described as very high resolution dot matrix "printing"... - Page 60 Section 6: Quick Start and Easy Setup Vector cutting is a continuous path that follows the outline, or profile, of an image. Vector cutting is normally used to cut completely through materials such as wood, acrylic, paper, etc. It can also be used for quick marking of characters and geometric patterns.

- Page 61 Section 6: Quick Start and Easy Setup Note: If your Raster artwork contains thin lines between .001 and .007 inches and you are using Vector or Combined mode, those thin lines will all vector cut. This can be disconcerting when it happens. The most common setup where this occurs is when you have a clipart image with hidden lines that you send to the laser using Combined mode.

-

Page 62: Job Setup

Section 6: Quick Start and Easy Setup Job Setup Your Epilog laser system has a prime reference point that is in the upper-left corner of the laser table. This is the 0,0 (zero, zero), or “Home” position. All artwork and material placement is normally referenced from here. Keep this 0,0 point in mind when measuring and setting up your work. - Page 63 Section 6: Quick Start and Easy Setup Material Orientation Some materials such as wood or plastics that have a grain (brushed look) will look nicer when engraved if the grain of the material runs parallel with the X-stroke of the carriage. The orientation of material without a grain pattern is usually not important.

- Page 64 Section 6: Quick Start and Easy Setup grid uses the exhaust fan to create suction from below the material and hold the piece of material in place. The material can also be held with a variety of materials such as masking tape, PlayDoh, etc. Creating jigs is also an excellent method of holding materials that are high volume, or high value.

- Page 65 Section 6: Quick Start and Easy Setup its holder so it does not touch the engraving material while the job is running. Press the Reset button to exit out of focus mode before starting your job. The focus distance is where the laser beam is at its sharpest point. Many users let the focus gauge swing back and forth while raising the table.

- Page 66 Section 6: Quick Start and Easy Setup THIS PAGE WAS INTENTIONALLY LEFT BLANK...

-

Page 67: Basic Operations

Manual Basic Operations... - Page 68 THIS PAGE WAS INTENTIONALLY LEFT BLANK...

-

Page 69: Section 7: Using The Epilog Dashboard Driver

Section 7: Using the Epilog Dashboard Driver In This Section General Tab Advanced Tab Color Mapping Tab Additional Dashboard Features Changing Dashboard Defaults The Epilog Dashboard is the print driver that allows you to set laser functions from your computer and is the link that prints your data or images from your computer to your laser system. - Page 70 Section 7: Using the Epilog Dashboard Now that you have printed a simple job, you are ready to gain a better understanding of the different printing options available from the Dashboard. Most engraving and cutting jobs can be accomplished by using only the General tab.

- Page 71 Section 7: Using the Epilog Dashboard You can move the little slider box by clicking down, holding and then moving to the desired number before releasing your mouse. You can type the setting into the number box. The following sections provide detailed explanations of the different features in the Print Driver.

-

Page 72: General Tab

Section 7: Using the Epilog Dashboard General Tab Job Type One of the first things new users want to know is how the laser system knows when to engrave and when to cut. The decision is based on several variables: Line weight (or Stroke) as defined in your graphic image from Corel, Illustrator, etc. - Page 73 Section 7: Using the Epilog Dashboard Raster Raster mode is used for marking or engraving materials. Typical uses would be reproducing clipart, scanned images, photos, text and graphic images. The Raster Speed and Raster Power boxes will be enabled when you have selected Raster under Job Type.

- Page 74 Section 7: Using the Epilog Dashboard Example: The rectangle below has a line weight of 0.003 inch. It will not raster engrave at any resolution (see following chart). If you send just this box to the laser in Raster mode and try to run the job, the laser will beep once and be finished because the line is too small to be recognized as an engraving line.

- Page 75 Section 7: Using the Epilog Dashboard Vector Vector mode is used to mark or make a thin line drawing. The Vector Speed, Power and Frequency bars will be enabled when you have selected Vector under Job Type. Note - Artwork, such as scanned images, photos, JPEGs, etc will not vector cut because they do not contain thin lines of any kind.

- Page 76 Section 7: Using the Epilog Dashboard Example: The rectangle below has a line weight of 0.001 inch. It will vector at any resolution (see following chart). Line weight = 0.001 inch. Vector Line Weights Line weights that will vector at different resolutions (DPI) when in Vector or Combined mode.

- Page 77 Section 7: Using the Epilog Dashboard For ease of use, we recommend that you set your vector lines to 0.001 or 0.003 inches. These line weights are the most commonly used in most software applications and as you gain experience, setting them will become second nature. As you can see from the table above, these line weights will vector cut at all resolutions.

- Page 78 The higher the resolution setting, the finer the detail that can be achieved. This Epilog laser system can engrave at resolutions ranging from 100 to 1000 DPI. Keep in mind that engraving resolution is only one factor in determining image quality.

- Page 79 Section 7: Using the Epilog Dashboard Resolution Settings Uses for different resolution settings: 100 – 200 DPI These resolution values are typically used for non-production purposes where you want to experiment with image location, or if you want to quickly produce a rough draft.

- Page 80 Section 7: Using the Epilog Dashboard The diagram below shows the concept of raster lines and dots-per-inch (DPI). The arrows show the change in direction of the carriage between raster lines. The difference in dot density between 250 DPI and 500 DPI resolution is shown. 250 DPI 500 DPI Helpful Hints...

- Page 81 Section 7: Using the Epilog Dashboard The photos below show a CorelDraw clipart image engraved at 250 DPI (top) and at 500 DPI (bottom). This clipart image is full of different shades of gray and you can see that the dot spacing is spread out more on the 250 DPI than it is on the 500 DPI.

- Page 82 Section 7: Using the Epilog Dashboard Piece Size Many users like to create their artwork on a page size in CorelDraw or other software program that matches the size of the piece that is to be lasered. Compensating for beveled edges or placing an image in an exact location is easy when there is a one-for-one relationship between the material and the page size of the artwork.

- Page 83 Section 7: Using the Epilog Dashboard Engrave Direction This feature applies to Raster engraving only and allows you to engrave your project either from the top down, or the bottom up. This is very helpful for some materials like plastic or rubber stamps. In standard top-down engraving there can be a large amount of engraving debris generated.

- Page 84 Section 7: Using the Epilog Dashboard Center Engraving The Center Engraving Option allows you to define the center of your artwork as the primary reference point (Home position) of your engraving or cutting. The Center Engraving Option has been designed to be used in conjunction with the Set Home feature of the laser.

- Page 85 Section 7: Using the Epilog Dashboard Center-Center It’s important to think about setting up your artwork for Center-Center differently than you think about most jobs. Setup for most jobs that do not use the Center- Center feature begin with a determination of page size with the idea that the page size in your graphics package will match the actual size of your work piece.

- Page 86 Section 7: Using the Epilog Dashboard There are some limits to the maximum size page you can use and the placement of your artwork on the page. If you have a mismatch with your artwork placement and your page size you will see a “Position Error” on the keyboard at the laser.

- Page 87 Section 7: Using the Epilog Dashboard To make engraving the name simple, use the Center-Center feature in the driver to quickly and accurately place a name Finished piece Land Lubber Award with engraved name. Fewest Fish Caught! Catfish Joe Why Me??!!!! your Land Lubber Award artwork,...

- Page 88 Section 7: Using the Epilog Dashboard Open a page in Corel. The page size is not very important for using the Center-Center feature, so the page can be almost any size. Note: If you are using a large page size, place your artwork towards the upper left corner of the page.

- Page 89 Section 7: Using the Epilog Dashboard Job:1.Sample.cdr STOP RESET Power Focus Speed Data Config Pointer X/Y Off www.epiloglaser.com Press the X/Y OFF key on the keyboard of the laser system Move the carriage by hand so that the Red Dot Pointer is at the center of the available engraving area.

- Page 90 Section 7: Using the Epilog Dashboard Additional information about using the Center-Center feature: The Center-Center feature is designed to be used in conjunction with the Set Home feature of the laser system. If you do not use the Set Home feature to create a new Home Position at the machine, the Center-Center feature will produce a “Position Error”...

- Page 91 Section 7: Using the Epilog Dashboard Example #2: Laser engraveable pens: The Center-Center feature makes locating the name on a laser engraveable pen very easy to do. First, measure the available engraving area on the barrel of the pen. For our example the engraving area is 2”...

- Page 92 Section 7: Using the Epilog Dashboard Place the work piece in the machine and activate the Red Dot Pointer. We want to set a new Home position by moving the carriage by hand so the Red Dot Pointer is at the center of where you want to engrave. To move the carriage by hand and set a new Home position, use the following instructions: a) Press the X/Y OFF key on the keyboard of the laser system...

- Page 93 Section 7: Using the Epilog Dashboard Left-Center or Top-Center Left-Center and Top-Center are used when you want to use a different starting reference point than the center of the object to start your engraving. These two options are most commonly used in situations when you can easily identify the location in one axis.

- Page 94 Section 7: Using the Epilog Dashboard Page-Center The use of Page-Center option is a difficult concept to explain, but it’s a feature that professional engravers are eager to use. The best way to explain it is to first compare it to one of the other centering options – Center-Center engraving. Page- Center engraving is used most often when engraving text on an arc.

- Page 95 Section 7: Using the Epilog Dashboard For the following example we used a three inch (76 mm) page size to match the three inch medallion size. Use your red dot pointer to find the center of the medallion and then print to a 3” x 3” (76 x 76 mm) page using the Page-Center mode.

- Page 96 Section 7: Using the Epilog Dashboard Raster Settings Speed The Speed setting determines the travel speed of the carriage in Raster mode and is adjustable in 1% increments from 1 to 100%. The slower the speed, the deeper the engraving. Speed settings are heavily dependent on the hardness and the thickness of the material being engraved, with harder materials requiring slower speeds for deeper engraving.

- Page 97 Section 7: Using the Epilog Dashboard If you have a multi-layered material that you can mark easily, but not well, at high speeds, try lowering the speed to see if that produces a better mark. If you’re able to produce a better mark, but it’s overpowered, lower the power also. Power The Power setting determines the amount of laser energy that is delivered to the piece being cut and is adjustable in 1% increments from 1 to 100%.

- Page 98 Section 7: Using the Epilog Dashboard Photograph Modes – Floyd Steinberg, Jarvis and Stucki modes are designed to modify an image by replacing the very structured dot patterns with a more random dot pattern. Engraving in one of these modes can make a photograph engraved on marble or anodized aluminum look more appealing than using an unmodified image.

- Page 99 Section 7: Using the Epilog Dashboard What is Dithering? - The best way to show dithering is with an example. In the example below, we engraved the exact same photo in Standard mode and Stucki mode. Both photos were engraved at 300 DPI. As you can see, the photos look dramatically different.

- Page 100 Section 7: Using the Epilog Dashboard Clipart Modes: Standard - This mode is the default mode and will be used for most engraving jobs that include text and clipart at 500 DPI. Brighten – Many users find this mode good for engraving photographs onto wood or marble at 500 DPI.

- Page 101 Section 7: Using the Epilog Dashboard Vector Settings Speed The Speed setting determines the travel speed of the carriage in Vector cutting mode and is adjustable in 1% increments from 1 to 100%. The slower the speed, the deeper the cut. Most cutting applications require relatively slow speed settings, and the speed is heavily dependent on the hardness and the thickness of the material being cut.

- Page 102 Section 7: Using the Epilog Dashboard Frequency Frequency is the number of laser pulses that the laser fires per inch of travel and is set in the dashboard and can be adjusted from 10 to 5000 pulses per inch. A lower frequency number will have the effect of less heat applied to the material being cut.

- Page 103 Section 7: Using the Epilog Dashboard Vector Sorting A checkmark in the vector sorting box will order the sequence of vector cuts. If sorting is enabled, you have two choices of how the vector lines will be sorted: Optimize and Inside-Out. In Optimize mode, vectors will be cut in the most efficient manner, and will generally vector the next closest line to the one just finished.

-

Page 104: Advanced Tab

Section 7: Using the Epilog Dashboard Advanced Tab The Advanced tab provides more options for controlling your laser system. These advanced functions are an extension of the functions found on the General tab. Raster Type Basic This is the default setting and is by far the most commonly used setting for raster engraving. - Page 105 Section 7: Using the Epilog Dashboard In Basic mode we interpret dots in a couple of different ways depending on the type of artwork that is being used: If the image being engraved is black and white, the laser fires wherever there is black.

- Page 106 Section 7: Using the Epilog Dashboard The image at right will engrave very nicely on acrylic, coated metals or plastics, and will create very nice contrast. This will give the bird better definition and character than if it were just black. The filled areas are 10% and 50%, with a black outline around most areas.

- Page 107 Section 7: Using the Epilog Dashboard 3D Engraving Earlier in the manual we discussed dot patterns and how those patterns are used to create raster images. 3D mode looks at the dots and the dot patterns in a very different way than Basic raster engraving mode, especially where it concerns either color, or grayscale images.

- Page 108 Section 7: Using the Epilog Dashboard box is only a single shade of gray. You need an object that looks something like the circle below to create a 3D image. Engraving this circle in 3D mode will create a dome with center being the high point (because it’s a light shade of gray) and the outside edge being deep (because it’s a darker...

- Page 109 Section 7: Using the Epilog Dashboard 3D engraving usually requires more than one pass to get the depth of engraving necessary to produce the dimensional relief that makes 3D engraving look good. Many users will engrave an image using two or three passes to get the depth they are looking for.

- Page 110 Section 7: Using the Epilog Dashboard Stamp The stamp option automatically converts your artwork into to a format that will produce a laser engraved stamp. This function automatically inverts your artwork so that the background is engraved away while your text and graphic images are left standing.

- Page 111 Section 7: Using the Epilog Dashboard Configurations The “Configurations” feature is a comprehensive data management tool that is used to save all of your Dashboard settings for individual jobs. Saving the Dashboard settings as a database file allows you to retrieve the job parameters at a later time.

- Page 112 Section 7: Using the Epilog Dashboard To establish a configuration file, first set all of the desired settings (Speed, Power, Piece Size, Color Mapping values, etc. for a particular job. To save the settings you have established, go to the advanced tab and click on Save.

- Page 113 Section 7: Using the Epilog Dashboard The Dashboard uses standard Windows protocol to save the configuration files. When you installed the Epilog Dashboard there was a dedicated configurations folder created where you will need to save the configurations. The path for the Configurations folder is shown here: My Documents...

- Page 114 Section 7: Using the Epilog Dashboard Notes on Saving Configuration Settings: If you would like to expand your folder options it is best to make changes from Windows Explorer (My Computer). You can create as many folders under the “engraving_setting” folder as you wish and structure your saved configuration files in a way that best suits your needs.

- Page 115 Section 7: Using the Epilog Dashboard Loading Configuration Files: To load a configuration file, click on the Browse… button. The Browse for Folder window will open. Select the epilog/engraving_setting folder. Click Okay. After selecting your folder all of the configuration files will now show in the Dashboard.

- Page 116 Section 7: Using the Epilog Dashboard Click on the General tab to see the settings that the loaded file brings...

-

Page 117: Color Mapping Tab

Section 7: Using the Epilog Dashboard Color Mapping Tab The Color Mapping feature is an advanced feature that must be checked to activate. While Color mapping is a very powerful tool, most users use it for two main reasons: Using color so that multiple Speed and Power setting can be used in a single print job. - Page 118 Section 7: Using the Epilog Dashboard It’s best to use one of the six basic colors (red, green, A Note About Colors! blue, cyan, yellow, magenta) when color mapping, because the values in Color Mapping MUST match exactly the colors that are used in your graphics package. The RGB color scheme uses numbers to define all colors and the six basic colors have the following numerical definitions: Color...

- Page 119 Section 7: Using the Epilog Dashboard Color Mapping allows you to control the following six laser functions for each color in the Map List: Color – Select the color you want to use or modify. Speed – Sets Raster speed and Vector speed for all objects of the color. Power –...

- Page 120 Section 7: Using the Epilog Dashboard Using Color Mapping Setting up colors to be mapped is a very easy process. The color mapping tab is separated into three functions: 1) The left side of the Advanced tab is used for two purposes: a.

- Page 121 Section 7: Using the Epilog Dashboard Once the values have been defined on the left side of the tab, you will Modify button. want to change them by pressing the Modify button. After pressing the Modify button, the selected color values will be changed and displayed on the right side of the tab.

- Page 122 Section 7: Using the Epilog Dashboard Vector Color Mapping Usually when using Color Mapping in Vector mode users want to both cut and mark a single piece of material in a single job setup. Since the cutting and marking processes have different speed and power requirements, this is a perfect job for Color Mapping.

- Page 123 Section 7: Using the Epilog Dashboard Once your vector outlines are set up in your artwork, Select File/Print and go to the Color Mapping tab in the Epilog Dashboard. Make sure Color Mapping is checked so we can set up our color mapping scheme. In our example we want to mark the green window frames first, so green must be the first color at the top of the list.

- Page 124 Section 7: Using the Epilog Dashboard We will set the green color at a higher speed and lower power than the red color. This will allow us to mark the green and cut the red. For illustration purposes we deleted the other colors so it will be easier to read the values we have set for the colors we are going to use.

- Page 125 Section 7: Using the Epilog Dashboard Raster Color Mapping Raster Color Mapping usually has a different purpose than Vector Color Mapping although the process for setting up colors to be mapped is the same. In Raster Color Mapping mode most users want to reduce the amount of time it takes to engrave a job that uses most of the table but has very little actual engraving.

- Page 126 Section 7: Using the Epilog Dashboard Dashboard you will follow the same process that was used in Vector Color Mapping for setting up the Raster Color Mapping colors, but for this example we will assign all colors the same speed and power (see following diagram). We want all three of the pens to engrave at the same depth, so we have set all of the Speed and Power settings the same (100% Speed and 100% Power).

-

Page 127: Additional Dashboard Driver Features

Section 7: Using the Epilog Dashboard Combined Mode – Color Mapping in combined mode requires a little more planning than Raster only or Vector only modes. Below are the sequencing considerations you will need to account for when using combined mode: Any object that is color mapped will be raster engraved first in the color order from the right side of the tab. - Page 128 Section 7: Using the Epilog Dashboard Multiple Pages CorelDraw allows you to set up and print multiple pages. The screen shot below shows the Corel print window that is set up to print all three pages of a three page document.

-

Page 129: Changing Dashboard Driver Defaults

Section 7: Using the Epilog Dashboard The list below shows the file names a little more clearly: Job:1. File Name Job:2. Page 2 Job:3. Page 3 – This file shows on the LCD when the file is received at the laser. If you already have jobs in the laser system, the naming structure will change. - Page 130 Section 7: Using the Epilog Dashboard THIS PAGE WAS INTENTIONALLY LEFT BLANK...

-

Page 131: Section 8: Using The Front Control Panel

Keyboard Commands Job Storage As you start using your Epilog laser system, you will notice that the Keyboard Commands which are located on the Control Panel are helpful tools for operating your laser system. The keyboard commands make the laser system extremely user friendly. -

Page 132: Keyboard Commands

Section 8: Using the Front Control Panel Keyboard Commands The keyboard is located at the right side of the laser system. All of the keys have specific purposes, but using the laser can be as easy as pressing the “Go” button once a job has been sent to the laser. - Page 133 Section 8: Using the Front Control Panel Once the job starts, the display changes to show a job timer and the engraving resolution. The timer is a useful production tool that displays the elapsed time of engraving. 00:00:12 500 DPI STOP RESET Speed...

- Page 134 Section 8: Using the Front Control Panel SPEED During an engraving job, or when the laser is idle at Home Position, the Speed of the job can be viewed on the control panel by pressing the SPEED button. In Raster mode you can change the speed on the fly.

- Page 135 Section 8: Using the Front Control Panel POWER During an engraving job, or when the laser is idle at Home Position, the Power of the job can be viewed on the control panel by pressing the POWER button. In Raster mode you can change the power on the fly.

- Page 136 Section 8: Using the Front Control Panel X/Y OFF Pressing the X/Y OFF button disables the X and Y motors and allows the operator to move the carriage by hand to any location on the table (be careful to avoid touching the optics while moving the carriage!).

- Page 137 Section 8: Using the Front Control Panel POINTER The POINTER button is a toggle switch that turns the laser systems visible Red Dot Pointer on and off. When the Red Dot Pointer is on, the green indicator light directly adjacent to the POINTER button will be illuminated. General Purpose Buttons This key is used to start a job.

- Page 138 Section 8: Using the Front Control Panel The UP or DOWN buttons will loop continuously through all jobs stored in the laser system. Pressing the GO button will start the job that is displayed on the control panel. Job:1.Sample.cdr STOP RESET Speed Power...

- Page 139 Section 8: Using the Front Control Panel Config The Config key takes you into the factory settings that do not normally need to be reset by the end user. These functions are listed below. To access and move from one Config setting to another use the following instructions: Press the Config key –...

-

Page 140: Job Storage

Section 8: Using the Front Control Panel Job Storage The laser has the capability to store multiple jobs in temporary memory. machine will save any and all jobs sent until there is no free memory left. At that point, the oldest job will be deleted automatically to make room for new jobs. Note: Jobs stored in the laser systems will be erased when the laser system is turned off. -

Page 141: Section 9: Standard & Optional Machine Features

Section 9: Standard & Optional Machine Features In This Section Red Dot Pointer Air Curtain Air Curtain Pump – Optional Feature Vector Grid/Vacuum Table - Optional Feature Pin Table – Optional Feature The laser system is very versatile and has many standard features that are very useful for making engraving and cutting applications easier to perform! Features that are either included with the system or sold separately make the Epilog a high performance tool. -

Page 142: Red Dot Pointer

Section 9: Standard & Optional Machine Features Red Dot Pointer The Pointer setting allows for manually turning ON or OFF the Laser Diode Pointer (Red Dot Pointer). This visible red beam is much like a hand held laser pointer, and has a bright red beam. -

Page 143: Vector Cutting Grid/Vacuum Table

Section 9: Standard & Optional Machine Features Vector Cutting Grid/Vacuum Table The Vector Grid is the ideal tool for vector cutting. The Vector Grid reduces backside burning by lifting the material off the table and supporting it on an aluminum grid. A precise cut and crisp edges are achieved when the laser beam passes cleanly through the material into the air space created below. - Page 144 Section 9: Standard & Optional Machine Features Installation The vector grid is designed to mate to the table so that your rulers and Home position do not change. To install the vector grid, lower the table: There are three oval slots that are cut into the rulers;...

- Page 145 Section 9: Standard & Optional Machine Features To install the vector grid, place it inside the cabinet and move it so that the back of the grid is almost touching the back of the machine. There will only be about a 1/8 inch (3 mm) gap between the vector grid and the back wall of the machine.

- Page 146 Section 9: Standard & Optional Machine Features Always keep the table tray clean! Remove all debris that has fallen through the vector grid. Debris and soot build up in the table tray create a dangerous fire Green thumb screws hazard! Vector grid with front panel removed.

-

Page 147: Zing 24 Rotary Attachment

Section 9: Standard & Optional Machine Features Zing 24 Rotary Attachment The optional Rotary Attachment allows you to mark, engrave or cut cylindrical objects. The Rotary Attachment works in both raster and vector modes. Machine Preparation If you already have a Zing laser system and have just received your rotary attachment, there is a bracket that needs to be installed before using the attachment. - Page 148 Section 9: Standard & Optional Machine Features need to upgrade your firmware by accessing the Epilog web site at www.epiloglaser.com/downloads under the Tech Support tab. Instructions on how to download and then upgrade the firmware can be found on the download page as well as in your owner’s manual.

- Page 149 Section 9: Standard & Optional Machine Features Route the cable through the bracket. Once your rotary is connected you can power-up the laser system. Setting Home (First time use only). New installations may need to set the Rotary Home Position. Install the rotary and power up the system.

- Page 150 Section 9: Standard & Optional Machine Features There is an adjustable numerical setting for both the X and Y axes that allow you to adjust your red dot pointer so it is calibrated to the edge of the bumper. To change the Rotary Home settings follow the instructions below: Press the Config button on your Zing keyboard.

- Page 151 Section 9: Standard & Optional Machine Features -2000 We’ve now moved the red dot in the -4000 +7500 South direction. Next, we want to move it east. +9500 Set the X-axis by moving the red dot to the East (towards +7500), Press the Config button, and then the left or right cursor buttons until you get to the X R Home: menu item.

- Page 152 Section 9: Standard & Optional Machine Features so that the top surface is horizontal (see the flashlight on following pages). Insure your cylinder is positioned so that the left end is close to, but not touching, the black bumper. Using the clamp to hold the glass in place is optional. Some odd shaped glasses rotate better if they are clamped to the drive wheels, but most glasses and other cylindrical objects do not require clamping.

- Page 153 Section 9: Standard & Optional Machine Features Use the scissor jack to raise the right side of the cylinder that engraving/cutting surface is horizontal. Correct Setup – The flashlight is horizontal to the X-Beam. Incorrect Setup – The flashlight is not horizontal. Raise the right side of the flashlight by turning the jack screw.

- Page 154 Section 9: Standard & Optional Machine Features Artwork Layout Because the Rotary Attachment automatically compensates for the diameter of the glass, artwork setup is relatively easy. The most important thing to remember when working with the rotary is that your artwork needs to be rotated 90 degrees to the way it would normally be setup for flat work.

- Page 155 Section 9: Standard & Optional Machine Features For the height (y-direction) of your page, use a flexible tape and measure the circumference of the glass at its largest diameter. For this glass, the height of your page will be 11 inches (279 mm). For the glass used in the prior picture, set up your page size to 6 x 11 inches (152 x 279 mm).

- Page 156 Section 9: Standard & Optional Machine Features Place your artwork near the top of the page. Keeping the white space to a minimum will reduce the distance the glass will rotate before it starts engraving. Eliminating the white space at the top of the page provides the most predictable method of determining where the laser will start engraving on the glass.

- Page 157 Section 9: Standard & Optional Machine Features Visualizing the orientation of the piece The left edge of your page corresponds Imaginary glass. you are engraving as it rests on the to the edge of the black bumper on rotary attachment will help in orienting your rotary attachment.

- Page 158 Section 9: Standard & Optional Machine Features Additional Artwork Tips and Tricks Creating a new Home position for Center-Center engraving. Another way to set up your artwork is by using the Center-Center feature in the Epilog Driver. There are detailed instructions in your Owner’s Manual that describe how to use Center-Center engraving, but one of the most useful methods for the rotary attachment is described here.

- Page 159 Section 9: Standard & Optional Machine Features Press the Go button. You now have a new Home position and the laser is set to engrave in the center of our glass. Note – It can be useful to put a black mark on the center of the glass as a reference point so you can easily see it when you place the glass onto the rotary attachment.

- Page 160 Section 9: Standard & Optional Machine Features Stretching or shrinking your artwork for objects with multiple circumferences. The instructions below show you how to shrink or expand your artwork to accommodate a cylinder where the area being engraved is a different circumference than the circumference at the drive wheels.

- Page 161 Section 9: Standard & Optional Machine Features For objects with a larger middle section – shrink artwork: Middle Section Divide the drive wheel side by the middle diameter Diameter = 4.2” ( 106.7 mm) and multiply by 100 to calculate the percentage of adjustment.

- Page 162 Section 9: Standard & Optional Machine Features For objects with a smaller middle section – expand artwork: Drive Wheel Side Diameter = 3.5” (89 mm) Divide the drive wheel side by the middle diameter and multiply by 100 to calculate the percentage of Middle Section Diameter = 2.7”...

- Page 163 Section 9: Standard & Optional Machine Features Other considerations: In these two examples you’ll notice that the “middle” varies depending on where you measure. Because of this, you’ll never be able to get every piece of artwork perfectly sized. Depending on how much room the artwork takes up, you may want to experiment with the expansion or shrinkage of your artwork to fit your particular glass shape.

-

Page 164: Pin Table

Section 9: Standard & Optional Machine Features Pin Table The Pin Table option offers a method for users to keep all back reflections of the laser beam from marking the sides or back of the material being cut. The Pin Table lifts the cutting material completely off the vector grid and provides a means to eliminate the tick marks that can be created when the laser beam comes into contact with the grid material. - Page 165 Section 9: Standard & Optional Machine Features Assembly Instructions After unpacking the Pin Table, remove the four thumbscrews from the Pin Table assembly. Install the four fences along the two sides using the thumbscrews you just removed. At this point the Pin Table is almost ready to use. The next step involves placing the pins anywhere on the grid so that they support the piece you are going to be cutting, and are out of the laser beam cutting path.

- Page 166 Section 9: Standard & Optional Machine Features The following illustrations show tips on how to easily use the Pin Table. In CorelDraw, set up a 12 x 12 inch (305 x 305 mm) page: Select View, and scroll down click on Grid and Ruler Setup.

- Page 167 Section 9: Standard & Optional Machine Features Set the Frequency to 1.0 per inch (both Horizontal and Vertical), and put a check mark in the Show grid box. Click OK Your Corel page now shows a grid pattern that matches the grid of the Pin Table.

- Page 168 Section 9: Standard & Optional Machine Features Set up your artwork on the grid so that the vector lines do not cross the path of any of the pins. The small black circles within the letter “B” show the location of the pins. Notice that you do not need to place pins in every available space, they just need to be placed where they will support the work piece.

- Page 169 Section 9: Standard & Optional Machine Features The previous example is a relatively simple example of how to use the Pin Table. The following photos show a more complicated Combined Raster/Vector job. This photo shows a job that has been raster engraved and then vector...

-

Page 170: Section 10: Engraving Machine Cleaning

Section 10: Engraving Machine Cleaning In This Section Cleaning Important! Laser Tube Cleaning - Important! Fire Warning! Through normal use your laser system can collect debris and soot that are potentially flammable. Keeping you laser system clean and the area around it clean are important parts of laser maintenance. - Page 171 Section 10: Engraving Machine Cleaning BE CAREFUL! when vector cutting. Many materials have the potential to burst suddenly into flames – even materials that may be very familiar to the user. Always monitor the machine when it is operating. ...

- Page 172 Section 10: Engraving Machine Cleaning each daub to expose clean cotton to the surface, until the optic is free of visible contamination. At that point, prepare a fresh swab and clean the surface with a gentle zigzag motion across it. Avoid any hard "scrubbing" of the surface, especially while there are visible particles on it, and try not to use repetitive circular motions.

- Page 173 Section 10: Engraving Machine Cleaning The photos below show how to clean the plenum, the downdraft ports and the exhaust port at the rear of the machine. While these photos are of a different Epilog model, the concept is identical to the cleaning required of the Zing.

-

Page 174: Laser Tube

Section 10: Engraving Machine Cleaning Laser Tube The laser tube used in your system does have a maximum service life, and there is very little maintenance that is required. At some point in the life of the laser you will need to replace it for gas recharge, electrical repair or mechanical repair. -

Page 175: Section 11: Engraving Machine Calibration / Maintenance

Section 11: Engraving Machine Calibration / Maintenance In This Section Config and Calibration Settings Calibration Settings Using the Keyboard There are a number of factory settings that normally only need to be set once at the factory to calibrate the system. The numerical range of adjustment is shown in the table below. - Page 176 Section 11: Engraving Machine Calibration / Maintenance To access and move from one Config setting to another use the following instructions: 00:00:12 PW=75% Press the Config key – Config Menu: will appear on the keyboard display. Press the Focus key to scroll through the different menu items.

- Page 177 Section 11: Engraving Machine Calibration / Maintenance In addition to the Config key, there are a couple of hidden calibration settings that are accessed through the keys on the front control panel. These settings are accessed by simultaneously pressing a two key combination. The two key combinations are described below as well as the function to be set.

- Page 178 Section 11: Engraving Machine Calibration / Maintenance THIS PAGE WAS INTENTIONALLY LEFT BLANK...

-

Page 179: Section 12: Speed And Power Recommendations

Section 12: Speed and Power Recommendations In This Section Engraving Speed Engraving Power Recommendations Multiple Passes Speed and Power Recommendation Tables Engraving Speed Speed settings determine the travel speed of the carriage as it moves back and forth in Raster Mode and as it profile cuts in Vector Mode. - Page 180 Section 12: Speed and Power Recommendations These files can be used and organized just like the configuration files you create yourself. After clicking the Install button, you can select the files that match wattage of your laser.

-

Page 181: Recommendations

Section 12: Speed and Power Recommendations Recommendations The Epilog Zing Speed and Power guidelines are included on the following pages. Please remember that these are only guidelines. Depth of cut is a matter of personal preference. As such, there is no “correct” setting. Working with the Speed and Power settings becomes fairly intuitive in a very short period of time for most users. -

Page 182: Multiple Passes

Section 12: Speed and Power Recommendations a good mark than the raw speed of the system or the amount of laser power that is output by the laser. The interaction of the laser with different materials is a complex process, and this is especially true for some materials that are actually two different materials that have been bonded together. -

Page 183: 30 Watt - Epilog Zing

Section 12: Speed and Power Recommendations 30 Watt - Epilog Zing 250 DPI 400 DPI 500 DPI VECTOR RASTER RASTER RASTER CUTTING ENGRAVING ENGRAVING ENGRAVING SPEED/POWER SPEED/POWER SPEED/POWER SPEED/POWER/FREQUENCY 40/100 50/100 60/100 ⅛” (3 mm) – 70/70/500 Wood ¼” (6.4 mm) – 15/100/500 Cherry –... -

Page 184: Watt - Epilog Zing

Section 12: Speed and Power Recommendations 40 Watt - Epilog Zing 250 DPI 400 DPI 500 DPI VECTOR RASTER RASTER RASTER CUTTING ENGRAVING ENGRAVING ENGRAVING SPEED/POWER SPEED/POWER SPEED/POWER SPEED/POWER/FREQUENCY 50/100 60/100 70/100 ⅛” (3 mm) – 70/50/500 Wood ¼” (6.4 mm) – 20/100/500 Cherry –... -

Page 185: 50 Watt - Epilog Zing

Section 12: Speed and Power Recommendations 50 Watt - Epilog Zing 250 DPI 400 DPI 500 DPI VECTOR RASTER RASTER RASTER CUTTING ENGRAVING ENGRAVING ENGRAVING SPEED/POWER SPEED/POWER SPEED/POWER SPEED/POWER/FREQUENCY 60/100 70/100 80/100 ⅛” (3 mm) – 70/30/500 Wood ¼” (6.4 mm) – 40/100/500 Cherry –... -

Page 186: 60 Watt - Epilog Zing

Section 12: Speed and Power Recommendations 60 Watt - Epilog Zing 250 DPI 400 DPI 500 DPI VECTOR RASTER RASTER RASTER CUTTING ENGRAVING ENGRAVING ENGRAVING SPEED/POWER SPEED/POWER SPEED/POWER SPEED/POWER/FREQUENCY 50/100 60/100 70/100 ⅛” (3 mm) – 70/25/500 Wood ¼” (6.4 mm) – 50/100/500 Cherry –... -

Page 187: Section 13: Material Engraving Techniques

Rubber Stamps Wood Your Epilog Laser system is very versatile. It can mark and cut many different materials. Following is information regarding some of the materials the laser will mark and cut. Check the Epilog website www.epiloglaser.com periodically for new laser applications, tips, and techniques to use with your laser. - Page 188 Section 13: Material Engraving Techniques Please read the following warnings and recommendations and follow them closely at all times! NEVER let the laser system operate if it will be unattended. KEEP the area around the machine clean and free of clutter, combustible materials, explosives, or volatile solvents such as acetone, alcohol, or gasoline.

- Page 189 Section 13: Material Engraving Techniques Acrylic Engraving Techniques Most acrylic is engraved on the backside to produce a look through effect from the front surface. Remove the back protective cover layer before engraving. Leave the top protective cover layer on so that it remains intact to prevent scratching while handling the acrylic.

-

Page 190: Anodized Aluminum

Section 13: Material Engraving Techniques Anodized Aluminum Anodized aluminum comes in a variety of colors and can usually be easily engraved with a CO2 laser. Black anodized aluminum is great to work with because it turns white when lasered. Black anodize provides the best contrast of all of the colors of anodized aluminum. - Page 191 Section 13: Material Engraving Techniques consuming and most engravers do not want to spend the time and effort necessary to turn this into an acceptable product. Note - Always ask before lasering painted brass if you don’t know what the substrate is! If you are unsure if the piece that you have is brass-coated steel or brass, you can test the material with a magnet.

-

Page 192: Glass

Section 13: Material Engraving Techniques Glass Glass Background When a laser strikes glass it fractures the surface but it will not engrave deeply or remove material. The fracturing of the glass surface will produce a frosted appearance but can cause roughness and chipping depending on the type of glass being engraved. - Page 193 Section 13: Material Engraving Techniques Remove the glass, discard the remaining paper, and clean the glass. If necessary, gently polish the glass with a ScotchBrite pad. Note - You need to be especially careful when laser engraving leaded crystal. The lead in the crystal expands at a different rate than the crystal does and this can cause cracking and breakage of the crystal.

-

Page 194: Notary Seals - Delrin

Section 13: Material Engraving Techniques Notary Seals - Delrin Notary Seals Engraving Techniques Notary seals can be easily manufactured using 1/16-inch (1.5 mm) thick delrin plastic. A seal consists of two pieces - a male die and a female die, both shown below. -

Page 195: Plastic

Section 13: Material Engraving Techniques Plastic Plastic Background Engraving plastics have changed greatly in the past few years. Before lasers, plastic manufacturers designed plastic for rotary engraving systems. A rotary engraving system uses a mechanical spinning bit to remove material. Therefore the depth of the top layer or “cap sheet”... - Page 196 Section 13: Material Engraving Techniques With some plastics it is best to engrave using two passes. The first pass cuts through the cap layer and the second pass cleans away the residue that some plastics leave behind. Another technique that can be useful is to mask the plastic before engraving with transfer or masking tape.

-

Page 197: Rubber Stamps

Section 13: Material Engraving Techniques Rubber Stamps Engraving Rubber Stamps The Dashboard includes settings for producing rubber stamps. Unique stamp attributes are controlled from the driver including, Speed and Power settings, Shoulders, Widening, and more. Processing rubber stamp files requires a two step process. First, the computer must process the file to add the shoulders and widening. - Page 198 Section 13: Material Engraving Techniques Fence Method The Fence method uses a closed outline to define the area to be engraved away. This image shows the stair-step outline of a Fence enclosing the words to be stamped. The laser will engrave away only the background area outlined by the Fence (leaving the letters standing, of course!).

- Page 199 Section 13: Material Engraving Techniques You will tell the engraver which method you are using when you go to the Dashboard to print. After clicking on Stamp mode, you will want to use the Fence box to determine which method you are using. A check in the Fence box tells the engraver you are going to use a fence to define...

- Page 200 Section 13: Material Engraving Techniques Fence The fence defines the outer boundaries of the area to be engraved. The fence must be .001 inch (.025 mm) thick. The fence can be any closed polygon or ellipse. Rectangles, circles, ovals, etc are all acceptable fences, but they must be closed. Multiple stamps, with multiple cut lines can be placed within a single fence.

- Page 201 Section 13: Material Engraving Techniques CORRECT SETUP USING A FENCE IN COMBINED MODE Correct Example #1 – Creating a single stamp with a vector cut line. Correct Example #2 – Creating a single stamp with a vector cut line. Correct Example #3 – Creating multiple stamps with vector cut lines.

- Page 202 Section 13: Material Engraving Techniques INCORRECT SETUP USING A FENCE IN COMBINED MODE Incorrect Example # 1 – The stamp is missing a fence. Incorrect Example # 2 – This setup contains multiple fences. CORRECT SETUP WHEN USING PAGE SIZE IN COMBINED MODE If you are using the page size method, simply...

- Page 203 Section 13: Material Engraving Techniques Select Stamp from the Raster Type: menu. With Stamp mode selected you can change Shoulder Widening settings (explained below). It is best to Mirror your stamp in your software application. The Mirror function Dashboard mirrors everything but lines to be vector cut. Check the Fence box if necessary.

- Page 204 Section 13: Material Engraving Techniques Stamp Match The last setting that you may need to make is made from the laser’s control panel. The Stamp Match setting is defaulted to 0 which is ideal for most stamp applications. If you notice that there is a little jaggedness at the edges of your stamp letters, adjust the Stamp Match by one or two digits (either up to 1 or 2, or down to -1 or -2 etc).

-

Page 205: Wood

Epilog laser systems can engrave in very fine detail. The spot size ranges from .003” (0.08mm) to .008” (0.02 mm) of an inch in diameter, and, if there are large variations in the material that one is engraving into it will greatly affect the quality of the finished piece. - Page 206 Section 13: Material Engraving Techniques The differences between Cherry and Alder are little. The grain, color and densities are nearly identical. The color of these two woods is a light red. We recommend stains that are clear allowing the natural color to show through. Alder isn’t quite as expensive as Cherry and it is a little more readily available.

- Page 207 This will create a shading effect that is almost 3-D in its appearance. Wood Vector Cutting Techniques Epilog Laser Systems are ideal for cutting through solid wood material. thickness of the wood that you can cut varies with the wattage of the laser and the hardness of the wood, but in general you can cut approximately ¼...

- Page 208 Section 13: Material Engraving Techniques ALWAYS keep a properly maintained and inspected fire extinguisher on hand. Epilog recommends a Halotron fire extinguisher or a multi-purpose dry chemical fire extinguisher. The Halotron extinguishers are more expensive than a dry chemical, but offer certain advantages should you ever need to use an extinguisher.

- Page 209 Section 13: Material Engraving Techniques Wood Color Filling Techniques Color filling engraved areas of wood adds either greater contrast or a splash of color to your wood presentation. Normally, color filling is not required for lighter colored wood materials such as maple or cherry, but walnut can often benefit from adding a black color fill to provide more contrast.

- Page 210 Section 13: Material Engraving Techniques THIS PAGE WAS INTENTIONALLY LEFT BLANK...

-

Page 211: Section 14: Material Suppliers

Cermark Metal Coating Color Fill Materials Tapes and Foils The following list contains supplier information for materials typically used with your Epilog laser. Additional suppliers and links can be found on our website at http://www.epiloglaser.com/industry_links.htm Laser Engravable Products LaserBits, Inc. - Page 212 Section 14: Material Suppliers Dimension Espacio S. A. de C.V. Av. Morelos #80 Naucalpan, Mexico 53370 Phone (52)(55) 5312-0333 Fax: (52)(55) 5312-4790 www.dimensionespacio.com.mx Laser Engravable Coated Metals Identification Plates, Inc. 1555 High Point Drive Mesquite, TX 75149-9009 Phone: 972-216-1616 USA Toll Free Phone: 1-800-395-2570 Fax: 1-972-216-1555, 1-800-934-8304 www.idplates.com Victory...

- Page 213 Section 14: Material Suppliers AlumaMark Horizons Incorporated 18531 South Miles Road Cleveland, Ohio 44128 USA Toll Free Phone: 1-800-482-7758 Outside US: 216-475-0555 Fax: 1-216-475-6507 www.horizonsisg.com Leather Tandy Leather Factory, Inc. 3847 East Loop 820 South Fort Worth, TX 76119 For local locations visit their Website (orders also taken online) USA Toll Free Phone: 1-800-433-3201 www.tandyleatherfactory.com Pressboard Plaques - Melamine...

- Page 214 Section 14: Material Suppliers Wood Plaques & Specialty Wood Products Colorado Heirloom 333 E. 4th Street Loveland, CO 80537 USA Toll Free Phone: 1-800-643-8880 Phone: 1-970-667-4222 Fax: 1-970-667-8880 e-mail: cheirloom@aol.com www.coloradoheirloom.com Wood Design/WDI Companies (previously Kentucky Woodcrafts Co.) 908 SW 15 Street Forest Lake, MN 55025 Phone: 651-464-6190...

- Page 215 Section 14: Material Suppliers Marble Laser Sketch, Ltd 12301 New Avenue, Suite E Lemont, Illinois 60439 Phone: 630-243-6360 Fax: 630-243-6908 www.lasersketch.com Engravable Plastics Innovative Plastics Inc. P.O. Box 7065 Algonquin, IL 60102 Phone: 1-815-477-0778 Fax: 1-815-477-1210 e-mail: ipi@mc.net www.inoplas.com Johnson Plastics 9240 Grand Avenue South Minneapolis, MN 55420-3604 USA Toll Free Phone: 1-800-869-7800...

- Page 216 Section 14: Material Suppliers Flat Glass Gold Coast Graphics 15841 Graham Street Huntington Beach, CA 92649 USA Toll Free Phone: 1-888-733-0061 Fax: 1-714-898-9432 www.goldcoastgraphics.com CerMark Metal Coating CerMark Material FERRO Corporation USA Toll Free Phone: 1-800-245-4951 www.cerdecmark.com LaserBits, Inc. 1734 West Williams Drive - Suite 10 Phoenix, Arizona 85027 U.S.A.

-

Page 217: Technical Support, Troubleshooting And Specifications

Manual Technical Support, Troubleshooting and Specifications... - Page 218 THIS PAGE WAS INTENTIONALLY LEFT BLANK...

-

Page 219: Section 15: In Case Of Difficulty

Section 15: In Case of Difficulty In This Section Contacting Technical Support Avoiding Common Print Problems Contacting Technical Support The technical support department at Epilog is available to assist with solving problems you may encounter using your Epilog. Please review first the common problems and solutions as noted below, then if you are still in need of assistance you may contact Epilog’s technical support department at the number or website listed below. -

Page 220: Avoiding Common Print Problems

Section 15: In Case of Difficulty Avoiding Common Print Problems Printing problems are normally related to stopping, resetting or trying to repeat a job before the computer has been allowed enough time to transmit the entire job. If you do interrupt a job while it is being transmitted (printed) to the engraver, there is a good chance that the remaining data is still somewhere between the computer and the engraver, unless you take precautions to clear the print queue. - Page 221 If you are experiencing a double image problem or any other quality issue, it is best to run a sample of what the machine is doing and send it to: Technical Support Department Epilog Laser Corporation 16371 Table Mountain Parkway Golden, CO 80403; USA...

- Page 222 Section 15: In Case of Difficulty Problem: Image at the wrong location on the work piece. Solution: Verify that the page size in your drawing program does not exceed the maximum engravable area of the machine. Verify that the page size in drawing program matches the piece size in the Dashboard.

-

Page 223: Section 16: Specifications

Section 16: Specifications In This Section Zing 16 x 12 Specifications Zing 24 x 12 Specifications Compatibility Recommended PC Other Computer Hardware Recommendations Federal Communications Commission (FCC) Notice Zing 16 x 12 Specifications Maximum Engraving Area 16" x 12" (406 x 305 mm) Maximum Material Thickness 4"... -

Page 224: Zing 24 X 12 Specifications

Section 16: Specifications Zing 24 x 12 Specifications Maximum Engraving Area 24" x 12" (610 x 305 mm) Maximum Material Thickness 7.5" (190.5 mm) Laser Control Display Panel Displays stored file names, speed, power, runtime and more. Intelligent Memory Buffer Store unlimited files up to 64 MB. Rolling buffer allows files of any size (64 MB and larger) to be engraved. -

Page 225: Compatibility

Section 16: Specifications Compatibility The Epilog Zing has been designed as an “open architecture” product. The laser will work with many popular Windows based graphics, engineering and specialty software products. To benefit from all the functionality that was built into the laser, a Windows 32 bit based PC and 32 bit operating system is required. - Page 226 Epilog supplies a network Crossover cable with each laser system that allows one computer to print to a single Epilog laser system. Hard Drive This is the permanent memory in your computer. Many users feel that you can never have a large enough hard drive, but for most laser applications 80 GB’s is going to be...

-

Page 227: Other Computer Hardware Recommendations

Section 16: Specifications predictable, user friendly or functional. Additionally, the technical support staff at Epilog may be less familiar with software other than Corel and less able to help with questions. Consult with your Epilog distributor on software compatibility issues. Epilog does not guarantee compatibility with any software. -

Page 228: About The Laser

About The Laser Your Epilog CO2 laser system uses the latest in laser technology to provide a powerful tool that is simple and safe to setup and operate. The Epilog laser can mark, engrave, and cut a variety of materials. -

Page 229: Federal Communications Commission (Fcc) Notice

Section 16: Specifications Federal Communications Commission (FCC) Notice Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. - Page 230 Section 16: Specifications THIS PAGE WAS INTENTIONALLY LEFT BLANK...

-

Page 231: Section 17: Upgrading The Operational Firmware

Section 17: Upgrading the Operational Firmware In This Section Upgrading Your Firmware Installing New Firmware Onto Your Computer Transferring New Firmware From Your Computer To Your Laser System Upgrading The Epilog Dashboard Print Driver Converting Old .Dat Files To Be Compatible With A New Driver Version: Upgrading Your Firmware Your laser system is capable of having its operation firmware upgraded. -

Page 232: Installing New Firmware Onto Your Computer

Section 17: Upgrading the Operational Firmware Installing New Firmware onto Your Computer Firmware upgrades are available at any time by downloading the firmware file from the Epilog web site - www.epiloglaser.com under the Downloads tab. Or, you can contact Epilog Technical Support and they can e-mail the appropriate file to you. - Page 233 Section 17: Upgrading the Operational Firmware At this time it’s important to know which folder you are unzipping this file to. If you are unsure, use the Browse button to select a folder where you know you can retrieve this file later. Click on the Unzip button.

-

Page 234: Transferring New Firmware From Your Computer To Your Laser

Section 17: Upgrading the Operational Firmware Transferring New Firmware from Your Computer to Your Laser Use the following procedure to transfer the legendZing.hex file to the laser: Create any simple drawing in your graphics package. For this example, we’ve just typed in the text “Firmware Upgrade”. - Page 235 Section 17: Upgrading the Operational Firmware Go to the Advanced tab, check the Update Firmware box and then click on the Load button. Go to the folder that contains the unzipped hex file, select it and then click Open.

- Page 236 Section 17: Upgrading the Operational Firmware The hex file will show in the Update Firmware File box. Click Okay. Click Print. At this point, the .hex file will begin transfering to your laser. The laser knows that it is being upgraded and the simple graphic that you created will not print, nor will it show up as a Job.

- Page 237 Section 17: Upgrading the Operational Firmware DO NOT DISTURB THE LASER DURING THE UPGRADE PROCESS!!! After you have rebooted your laser, the process is complete and you will see the new version number of firmware on your LCD as the laser powers up. Close your Corel page and you are ready for you next job!

-

Page 238: Upgrading The Epilog Dashboard

Section 17: Upgrading the Operational Firmware Upgrading the Epilog Dashboard Occasionally Epilog provides enhancements or upgrades to the Dashboard. Upgrading to the new driver is almost identical to installing a driver for the first time. When upgrading to a new Dashboard, it is best if you first delete the old one, reboot your computer and then install the new one (see the Installing the Epilog Dashboard section of this manual ). -

Page 239: Converting Old .Dat Files To Be Compatible With A New Dashboard

Section 17: Upgrading the Operational Firmware Converting Old .DAT Files to Be Compatible with a New Dashboard Open (double click) the ConfigMerge.exe file that came with the new driver. Click on the Get File button and navigate to the folder where you save your .DAT files. - Page 240 Section 17: Upgrading the Operational Firmware The files that you highlighted and Opened will then show in the ConfigMerge window. Click on the Merge button (you do not need to highlight the files again). Your old .DAT files will be converted to be compatible with the new driver (Version 7.05 in this case).