Summary of Contents for GE Ajax DPC 2804 LE

- Page 1 GE Oil & Gas ® Ajax Compressor Ajax DPC 2804 LE / Non-LE Operation & Maintenance Manual...

- Page 2 GE Oil & Gas GE Oil & Gas Compression Systems, LLC is the entity owning this Installation, Operating and Maintenance Manual. GE Oil & Gas Compression Systems, LLC can be contacted as follows: Phone: +1-866-754-3562 Website: www.geoilandgas.com Cameron is not affiliated with this manual, and any reference to Cameron or Cameron International...

- Page 3 Initial Release 11/09/2012 Prabhu GE Cover Page Update 7/9/2014 Prabhu GE – Contact Information & Lubrication System (Baffle) Update 09/03/2015 Prabhu Content added in Sections, General Data, Fuel System & Power Cylinder 10/19/2015 Prabhu Sealing Compound Instructions added in Section : 6...

- Page 5 Table of Contents Table of Contents Table of Contents Section 1: Introduction Message from GE Oil & Gas Compression Systems LLC GE Oil & Gas Compression Systems LLC Policies Standards Our Quality Policy Warranties To Original Purchaser (Non-Transferable) Prerequisites Additional Information GE Oil &...

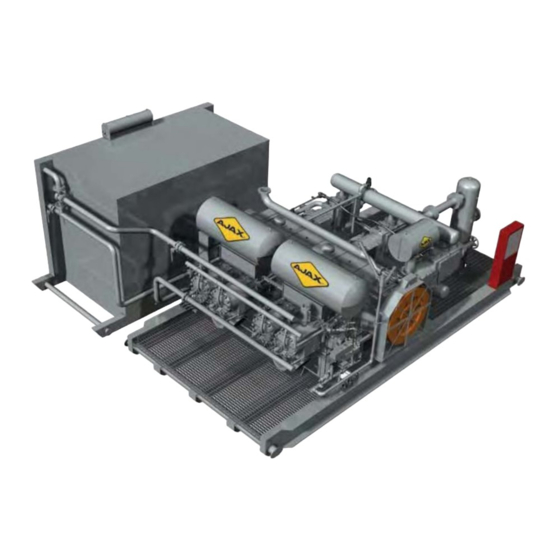

- Page 6 Table of Contents Jet Cell Compressor Cylinder Lubrication System Piston Rods Fuel System Figure 4-1: 2804 Engine Compressor Basic Application Two-Cycle Principle of Operation Figure 4-2: Compression Figure 4-3: Power Figure 4-4: Scavenging Section 5: General Data General Data Table 5-1 General Table 5-2 Power and RPMs Table 5-3 Basic Specifications - Engine Table 5-4 Compressor...

- Page 7 Table of Contents Special Tools Figure 5-5: Special Tools Section 6: Unit Installation Installation Design for Permanent Ajax Compressor Packages Foundation Figure 6-1: Canister Bolt Detail Preparation of the Foundation and Skid for Grouting Setting the Engine Compressor Sheave Alignment Procedure Figure 6-2: Sheave Alignment Procedure Grout Table 6-1: Grout Compressive Strength Requirement Estimates (for reference only)

- Page 8 Table of Contents Field Connections Fuel Gas Piping Figure 6-9: Typical 2804 Starter/Fuel Gas Piping Air Starting System General Information Product Identification Unit Specific Model # and Serial # Table 6-5: Starter Motor Pressure Ratings and Part Numbers Figure 6-10: Starter Motor Diagram Air Starter Motor Precautions Exhaust System Exhaust Pipe and Mufflers...

- Page 9 Table of Contents Crankcase Lubrication System Crankcase Oil Level Control Figure 8-1: Oil Level at the center of the sight glass Oil Control Baffle Figure 8-2: Oil Control Baffle Function and Design Notes and Precautions: Frame Oil Level Baffle Maintenance Figure 8-3: Cylinder 3 Shown, Typical Configuration at Cylinder Locations 1, 2, 4 Table 8-1: Baffle Fastener Torque table Crankcase Oil Maintenance...

- Page 10 Table of Contents Ash Level Viscosity Requirements Figure 8-7: Oil Selection for Ambient Temperature Low Temperature Operation Procedures Table 8-7: Low Overnight Temperature Starting Chart Crossheads Section 9: Fuel System Operating Instructions for plunger type, spill-port gas injection systems General Description Figure 9-1: Fuel System Operation of the system Figure 9-2: Fuel Suction Stroke...

- Page 11 Table of Contents Spark Plugs Fuel Admission Check Valves Section 10: Cooling System Cooling System Figure 10-1 Engine Coolant Temperature Compressor Cylinder Cooling Precautions Figure 10-2: Package Coolant Piping Precautions Belt Tensioning Procedure - Goulds Pump Figure 10-3: Belt Tensioning Procedure - Goulds Pump Figure 10-4: Belt Tensioning Procedure - Goulds Pump Belt Tensioning Procedure Belt Tensioning Procedure - Peerless Pump...

- Page 12 Table of Contents Power Piston Striking Clearance (Non-LE) Engine Piston Rod Stuffing Box Packing ring installation Figure 11-3: Packing ring installation Compressor piston rod stuffing box Packing ring installation Figure 11-4: Packing ring installation Ajax Power Cylinder Balancing Ajax Low Emissions Retrofit Conversions Ajax Low Emissions Retrofit Conversions, 13-1/4 inch and 15 inch Bores - Assembly Procedure Figure 11-5: Clearance Between the Piston and Head Gas Cam Timing...

- Page 13 Table of Contents Gas Injection Valves Preventive Maintenance Section 12: Compressor Cylinder Assembly Performance Clearance Adjustment - Compressor Performance Curves - Compressor Single Acting Operation Hydrogen Sulfide Gas Compressor Cylinder Maintenance Compressor Cylinder Bodies Cylinder Groups Slip Liners Shrink Liners Compressor Pistons Compressor Piston Rings Table 12-1: Piston Ring Clearance...

- Page 14 Table of Contents Secondary Wiring Dual Coils Section 14: IGTB Governor General IGTB Governor Figure 14-1 IGTB Governor Table 14-1: RPM, Voltage, Pressure Problem Diagnostics Table 14-2: Problem Diagnostics Section 15: Servicing for Extended Periods of Storage Preparing For Extended Usage Servicing After Extended Periods In Storage Section 16: Preventive Maintenance Program Preventive Maintenance...

-

Page 15: Section 1: Introduction

PURPOSE STATED HEREIN AND FUTHER AGREE NOT TO DISCLOSE SUCH INFORMATION TO OTHERS EXCEPT IN ACCORDANCE WITH THE PURPOSE STATED HEREIN. All specifications and ratings are subject to change without notice. AJAX is a trademark of GE Oil & Gas Compression Systems LLC. - Page 16 Warranties To Original Purchaser (Non-Transferable) requirements, and identify needed changes. Providing goods, services and communications with ever-increasing quality and value for our customers is a continuous business process in our company. Warranties To Original Purchaser (Non-Transferable) a. "Material and Workmanship Warranty": The Seller warrants to the Purchaser that the Equipment of Seller's own manufacture to be supplied hereunder will be complete in all its parts, and, for the *Warranty Period - The warranty period shall extend for 12 months from date of start-up, but shall not exceed 18 months from date of shipment from factory.

- Page 17 Service personnel should have adequate experience in good maintenance and troubleshooting techniques. GE Oil & Gas Compression Systems LLC recommends that all personnel using this manual should complete GE Oil & Gas Compression Systems LLC’s AJAX Reciprocating Compressor Training.

-

Page 18: Additional Information

Additional Information Unrestricted copies of Service Bulletins are available at the GE Oil & Gas Compression Systems LLC web site. You must have Adobe® Acrobat® Reader (version 6.0 or later) to view the bulletins. GE Oil & Gas Compression Systems LLC Contact Information For parts and customer service, contact by phone: 1-877-300-2550. -

Page 19: Section 2: Safety Information

Do not operate or attempt to repair this equipment unless you have had the proper training approved by Ajax Division, GE Oil & Gas Compression Systems LLC. For training information, contact GE Oil & Gas Compression Systems LLC’s Learning Center by phone: 713-354-1296 or by email: recip.tlc@ge.com. -

Page 20: Safety Decals

Safety Decals Safety Decals Danger, Caution and Note Decals Danger, Caution, and Notice decals will be placed so that they are visible to the operator while the engine is running. The Ajax 2804LE units have the following decals: ® AJAX...

Need help?

Do you have a question about the Ajax DPC 2804 LE and is the answer not in the manual?

Questions and answers