Advertisement

Quick Links

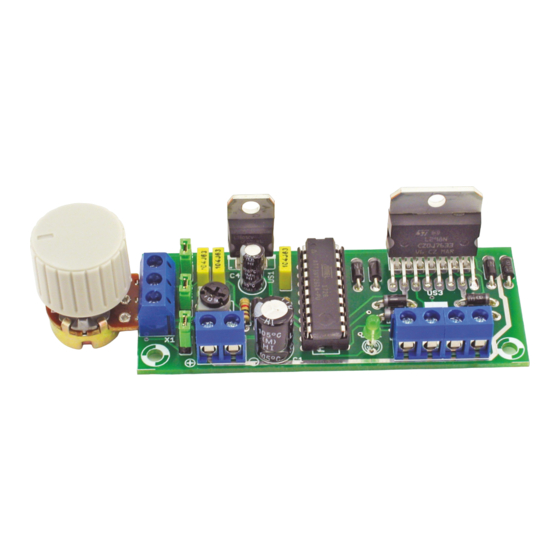

Universal Stepper Motor

kits

Controller

This controller allows the construction of advanced

mock-up mechanisms, extension of machines and

tools such as milling machines or drills but can also

be useful in photography to build a drive for taking

timelapses and 360º photos.

Controller allows stepper motors bipolar (4-wire) and

unipolar (5-, 6- or 8-wire) to be continuously adjusted

in speed and direction using a single potentiometer.

Circuit description

Range of changes in the speed of the motor axis is

divided into two sub-ranges of 1...10 or 7...100 cycles

per second. This selection can be made using the

appropriate jumper. Microstep control with a

resolution of 1/64 or 1/8 step. Microstep operation

involves rotating the magnetic field of the stator in a

much smoother way than in full and half-step control.

By working with the microstep, smaller steps and

more accurate positioning can be achieved. When the

motor is controlled at low frequencies with a full step

Features

• infinitely variable speed and direction of rotation

(with the same potentiometer)

• speed control divided into two ranges

(1 ÷ 10 and 7 ÷ 100 cycles per second)

• microstep control with 1/64 or 1/8 step resolution

• suitable for bipolar (4 wires) and unipolar

(5 or 6 wires) motors

• timer function, time steplessly adjustable

from 0.5 ÷ 70 s

• supply voltage range (rated motor voltage) 8 ÷ 25 V

• output current up to 2 A per channel (coil)

or half-step, the movement becomes discontinuous

and is characterised by high levels of noise and

vibration. With a small step, the energy provided to

the rotor at one step is only a fraction of the energy

of a full step and is so small that it can easily be

absorbed and cushioned by the internal friction in the

motor and its inertia. No vibration is then generated,

and the motor rotor will not run out at any time

beyond its desired position. Microstep control also

enables much quieter motor operation. The controller

PDF

DOWNLOAD

ZOOM

ASSEMBLY DIFFICULTY

1

Advertisement

Summary of Contents for AVT 3225

- Page 1 Universal Stepper Motor kits Controller DOWNLOAD ZOOM ASSEMBLY DIFFICULTY This controller allows the construction of advanced Features mock-up mechanisms, extension of machines and • infinitely variable speed and direction of rotation tools such as milling machines or drills but can also (with the same potentiometer) be useful in photography to build a drive for taking •...

- Page 2 SPEED AND DIRECTION STAT STOP START L-FREQ H-FREQ LED1 Fig. 1. described must be supplied with voltage in the range at a lower resolution of 1/8 step. Absence of a jumper 8...24 VDC and the maximum output current is up to 2 means a lower sequence frequency, i.e., approximately A/channel (coil) with appropriate heat sink.

- Page 3 7805 X1-3 LED1 TIME X2-1 X1-2 X2-2 220uF 100n 100n 10uF X1-1 100n 1N5817 (ADC10/RESET)PB7 (ADC9/INT0/T0)PB6 (ADC8/XTAL2)PB5 TIME (ADC7/XTAL1)PB4 START STOP (SCK/SCL/OC1B)PB2 (MISO/DO/OC1A)PB1 (MOSI/DI/SDA/OC1A)PB0 ENABLE_A SEN_A X3-2 (ADC6/AIN1)PA7 STAT ENABLE_B SEN_B (ADC5/AIN0)PA6 X3-1 (ADC4)PA5 INPUT1 OUT1 X3-4 (ADC3)PA4 INPUT2 OUT2 AVCC (AREF)PA3 INPUT3...

- Page 4 AVT SPV reserves the right to make changes without prior notice.Installation and connection of the appliance not in accordance with the instructions, unauthorised modification of components and any structural alterations may cause damage to the appliance and endanger persons using it. In such a case, the manufacturer and its authorised representatives shall not be liable for any damage arising directly or indirectly from the use or malfunction of the product.

Need help?

Do you have a question about the 3225 and is the answer not in the manual?

Questions and answers