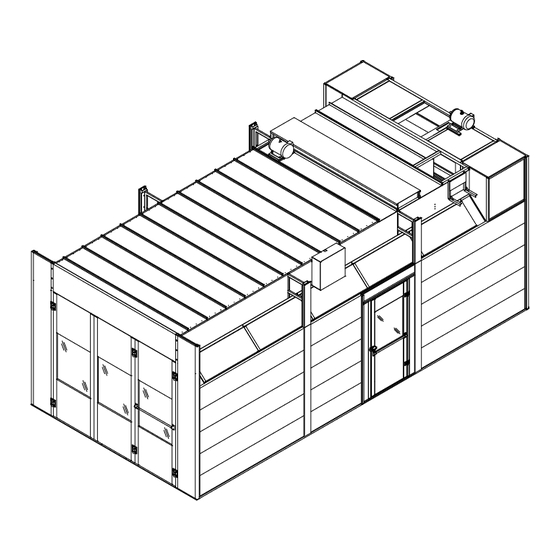

Summary of Contents for Garmat Chinook II

- Page 1 Operations and Maintenance Manual Garmat USA,Inc. Chinook II Paint Spray Booths Garmat USA, Inc. 1401 W. Standford Ave. Englewood, CO 80110 (800) 442-7628 ph. (303) 781-2683 www.garmat.com...

-

Page 2: Table Of Contents

OPERATIONS AND MAINTENANCE INSTRUCTIONS OPERATIONS INSTRUCTIONS…………………………………………. Page 3 MAINTENANCE INSTRUCTIONS………………………………………. Page 7 MAINTENANCE SCHEDUAL.………………………………………….. Page 8 TROUBLESHOOTING…………………………………………………….. Page 10 OPERATION SEQUENCE………………………………………………… Page 10 FILTER CHANGE RECORD……………………………………………… Page 12 WARNING LABLES……………………………………………………… Page 13... -

Page 3: Operations Instructions

PERSONAL INJURY, AND/OR DEATH. Paint Booth will assist you in your pursuit of the finest finish with a minimum of work. The Garmat® Tier 1 Paint Booth is designed and manufactured in the United States. The Garmat® PREPARATION OF THE PAINTER Tier 1 Paint Booth provides the optimal environment for the application of fine automotive finishes. - Page 4 HALF FULL BEFORE MOVING THE FRONT ENTRY VEHICLE INTO THE BOOTH. THE DRIVE-THROUGH PROPANE (LPG) TANK MUST HAVE Always center vehicle side-to-side, and front to back ROOM FOR EXPANSION WITHIN THE on the floor. TANK DURING BAKE CYCLE. NOTE: THE BOOTH FANS MUST BE WARNING: DO NOT ENTER THE BOOTH RUNNING WHENEVER A CAR IS MOVED DURING THE BAKE CYCLE.

- Page 5 first 40 hours of use and every three months after 42104(X) Intake & Exhaust, No Heat: that. In addition to adjustments explained in the maintenance instructions, you may attempt repairs your self. However, if you are not sure how to repair the unit, be sure to request service from a qualified technician or your local distributor.

-

Page 6: Maintenance Instructions

To assure that the optimum-finishing environment designed into your Garmat® Tier 1 Paint Booth is WARNING: THE MAIN ELECTRICAL maintained, filter replacement at recommended PANEL IS SUPPLIED BY TWO SOURCES OF intervals and regular cleaning of the booth and the ELECTRICAL POWER. - Page 7 The quality of finish produced by your Garmat® SUSEPTIBLE TO SPONTAINOUS paint booth is affected by the following: COMBUSTION. DISPOSE OF PROPERLY. a. The filter media used and the timeliness of filter CEILING FILTER CHANGE AT 1000-1200 replacement. HOUR INTERVALS b.

-

Page 8: Maintenance Schedual

CHECK booth pressure and make sure the booth pressure is operating in the proper range. CONTROL AIR - The air supplied to the Garmat USA, Inc. paint spray booth must be clean and dry SWEEP the floor while the booth is in operation. - Page 9 MAINTENANCE OF INTERNAL AND EXTERNAL SURFACES To clean, use a soft, dry cloth. If the surfaces are extremely dirty, use a soft cloth, dipped into a soap and water solution or a weak detergent solution. Wring the cloth before wiping the surface. Wipe again with a soft, dry cloth.

-

Page 10: Troubleshooting

Pilot manual gas valve turned off. marked FIREYE. Turn manual valve ON. AT FIREYE IS ON). High limit, low gas and/or high gas If lockout repeats, call a Garmat USA pressure switch tripped. proof of closure authorized service-technician. Touch alarm Open. - Page 11 overload condition, all booth operations quit. COOL DOWN MODE. Breakers protect control voltages, 110v and 24v. When the bake timer completes cycle, the Pressing the SPRAY button gives input “2”to the timer will input “8” at the PLC. The plc will PLC and the PLC outputs “Q1”...

-

Page 12: Filter Change Record

FILTER HOURS DATE COMMENTS SPEC/ACTUAL EXHAUST EXHAUST 100/ EXHAUST 150/ EXHAUST 200/ EXT & INT 250/ EXHAUST 300/ EXHAUST 350/ EXHAUST 400/ EXHAUST 450/ EXT & INT 500/ EXHAUST 550/ EXHAUST 600/ EXHAUST 650/ EXHAUST 700/ EXT & INT 750/ EXHAUST 800/ EXHAUST...

Need help?

Do you have a question about the Chinook II and is the answer not in the manual?

Questions and answers