Table of Contents

Advertisement

Maximum Operating Pressure:

Minimum Filtration Required:

Bulletin HY14-2701-M1/US - TORO Specific

GRESEN

Service Manual

for the Model V10 Directrional Control Valve. If further

assistance is required, contact your Parker Distributor

or Representative.

R

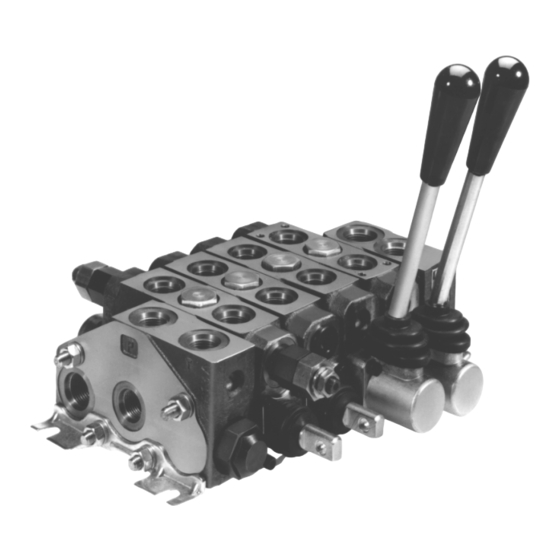

Model V10

Sectional Body

Directional Control Valve

3500 PSI (242 bar)

10 Micron

Rev: 01-01-2005 (Replaces: Revision 8/01/02)

Hydraulics

Advertisement

Table of Contents

Summary of Contents for Parker Hydraulics GRESEN V10

- Page 1 GRESEN Hydraulics Model V10 Sectional Body Directional Control Valve Service Manual Maximum Operating Pressure: 3500 PSI (242 bar) Minimum Filtration Required: 10 Micron for the Model V10 Directrional Control Valve. If further assistance is required, contact your Parker Distributor or Representative. Bulletin HY14-2701-M1/US - TORO Specific Rev: 01-01-2005 (Replaces: Revision 8/01/02)

- Page 2 W A R N IN G FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE. This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized distributors provide product and/or system options for further investigation by users having technical expertise.

-

Page 3: Table Of Contents

Table of Contents Assembly Studs ..................................4 Section Seal Kits ..................................5 Procedures for Removing Model V10 Spool Seals ........................6 Procedures for Installing Model V10 Spool Seals ........................7 Special Note Regarding Back-Up Rings ........................... 8 Power Beyond Sleeve (machines with front loader only) ......................9 Spring Return Spool Positioner ............................... -

Page 4: Assembly Studs

Assembly Studs Torque to Maximum 13 - 15 Ft Lbs (17 - 20 Nm) For Dry Tie Bolts Torque to Maximum 10 - 13 Ft Lbs (13 - 17 Nm) For Oiled Tie Bolts CAUTION If the stud nuts are not tightened to the proper torque, valve spools may bind or stick, or cause O-Ring seals to extrude. -

Page 5: Section Seal Kits

Section Seal Kits Section Seals are located in the Inlet Cover and in the downstream side of all work sections Manual Work Sections Important: Do Not lubricate section seals prior to installation. Install dry. Figure 2. Section Seal Identification Section Seal Kits Ref No. -

Page 6: Procedures For Removing Model V10 Spool Seals

Procedures for Removing Model V10 Spool Seals Handle End Positioner End 1. Remove the handle and positioner hard- ware from the valve section. 2. Insert a punch or screwdriver through the spool clevis. While watching the positioner end, slowly pull the spool toward the handle end. -

Page 7: Procedures For Installing Model V10 Spool Seals

Procedures for Installing Model V10 Spool Seals Handle End Positioner End Install 'Lip' In as Shown. 1. Lightly lube and insert the handle end Spool Seal first. Verify seal fit by carefully running your finger around the exposed edge of the seal. You should have a smooth, perfect ridge with no kinks or twists. -

Page 8: Special Note Regarding Back-Up Rings

Special Note Regarding Back-Up Rings Back-Up Rings in Used Seal Kits (Continuous) Back-Up Ring Many of the plugs and cartridges used in the Parker product line utilize back-up rings. Therefore, many of the seal kits in this Service Manual include back-up rings, some of which are continuous back-up rings. -

Page 9: Power Beyond Sleeve (Machines With Front Loader Only)

Power Beyond Sleeve (machines with front loader only) Torque Option Cavity Cartridge To: 18 - 20 Ft Lbs [24 - 27 Nm] Power Beyond Sleeves (for front loader equipped machines) Figure 5. Power Beyond Sleeve (machines with front loader only) Ref No. -

Page 10: Spring Return Spool Positioner

Spring Return Spool Positioner Torque to: 5 - 6 Ft Lbs (7 - 8 Nm) Torque to: 4 - 5 Ft Lbs (6 - 7 Nm) Figure 6. Spring Return Spool Positioner Ref No. Description Quantity ‘SC’ Spool Positioner Kit, Complete Spring Collar Centering Spring 5/16 - 24 Spool Screw... -

Page 11: 4-Position Float Spool Positioner

4-Position Float Spool Positioner Torque To: 5 - 6 Ft Lbs [7 - 8 Nm] Apply NLGI #2 Heavy Duty General Purpose Grease to Surfaces of Ref. No's. 4, 5, 6 & 8. Insert Spring and Large Detent Ball (Ref. No's. 5 and 6) into spool first. -

Page 12: 5-Position Float Spool Positioner

5-Position Float Spool Positioner Torque To: 5 - 6 Ft Lbs [7 - 8 Nm] Apply NLGI #2 Heavy Duty General Purpose Grease to Surfaces of Ref. No's. 4, 5, 6 & 8. Insert Spring and Large Detent Ball (Ref. No's. 5 and 6) into spool first. -

Page 13: Work Port Cavity Plug

Work Port Relief Cavity Plug Torque Relief Cavity Plug To: 18 - 20 Ft Lbs [24 - 27 Nm] Figure 9. Work Port Relief Cavity Plug Ref No. Description Quantity Plug Seal Kit (Includes Ref No’s. 2 thru 4 Only) NR Plug O-Ring Seal Back-Up Ring... -

Page 14: Extended Handle Assembly

Extended Handle Assembly Coat Flat End, Pin Hole, And Slot Of Handle Rod (Item 2) With Grease (Mobile DTH Or Equivalent) Prior To Installing The Handle Assembly Torque Ref No. 4 to 4 - 5 Ft Lbs [6 - 7 Nm] Press Pin (Item 5) Below The Surface And Stake Both Sides Apply General Purpose... -

Page 15: Joystick Assembly

Joystick Assembly Torque to: 5 - 6 Ft. Lbs. (7 - 8 Nm) Torque to: 4 - 5 Ft. Lbs. (5 - 6 Nm) Torque to: 13 - 15 Ft. Lbs. (17 - 19 Nm) Torque to: 5 - 6 Ft. Lbs. (7 - 8 Nm) Torque to: 4 - 5 Ft. -

Page 16: Joystick Adapter Plate Assembly

Joystick Adapter Plate Assembly Align Both Rod Ends As Shown When Installing Torque to: 35 - 37 Ft Lbs Assemble With Handle Plate and Rod (48 - 51 Nm) End This Way For Right-Hand Joystick Torque to: 11 - 13 Ft Lbs (15 - 18 Nm) Assemble With Handle Plate and Rod End This Way For Joystick...

Need help?

Do you have a question about the GRESEN V10 and is the answer not in the manual?

Questions and answers