Summary of Contents for Centa CENTAX-G

- Page 1 CENTAX-G Assembly and operating instructions 020G-00050…00090-F.10 M020-00009-EN Rev. 4...

-

Page 2: Table Of Contents

Positioning the membrane (1.2.1) ............30 Positioning the ring (1.4) inside the rubber element (1.1) ......31 Mounting the rubber element and the adapter ........31 Mounting the pre-mounted rubber element (F) to the flywheel ....32 CENTA Antriebe Kirschey GmbH 2 / 52... - Page 3 (4) ..........46 9.7.2 Dismantling the adapter (4) from the flywheel ......46 9.7.3 Removing the rubber element (1.1) with the ring (1.4) ....47 Removing the ring (1.4) ..............47 Dismantling the membrane (1.2.1) .............47 CENTA Antriebe Kirschey GmbH 3 / 52...

-

Page 4: Centax-G Rev

Wearing and spare parts............... 50 Annex ....................51 11.1 CENTA data sheet D013-013 (lubricated screw connections) ....51 11.2 CENTA data sheet D020-900 Declaration of incorporation according to the EC Machinery Directive 2006/42/EC, Appendix II B ......52 CENTA Antriebe Kirschey GmbH... - Page 5 Index of tables Table 2-1 Shape and size of ventilation holes ..........9 Table 5-1 Permissible radial alignment tolerance .......... 17 Table 5-2 Permissible angular alignment tolerance ........19 Table 7-1 Troubleshooting table ..............42 CENTA Antriebe Kirschey GmbH 5 / 52...

-

Page 6: General Remarks

In the interests of further development, CENTA reserves the right to make technical changes. IMPORTANT CENTA is unable to accept liability for damage and operating faults caused by failure to observe the operating instructions. These operating instructions are protected under copyright to CENTA Antriebe Kirschey GmbH. -

Page 7: Safety

Denotes a potentially dangerous situation. CAUTION If not prevented, minor injuries and/damage to property may result. Denotes application tips and particularly useful information. This is not IMPORTANT a signal word denoting a dangerous or damaging situation. CENTA Antriebe Kirschey GmbH 7 / 52... -

Page 8: Pictograms

Injury and material damage can occur as a result of: Application not in compliance with the intended use The couplings are intended exclusively for use in accordance with the relevant design. They may only be used under the specified conditions. CENTA Antriebe Kirschey GmbH 8 / 52... - Page 9 Shield the coupling in accordance with the applicable accident prevention regulations with an enclosure. Exception: The coupling is encased by the driving and driven units. The scope of delivery provided by CENTA does not include a protective enclosure. This enclosure must fulfil the following criteria: ...

-

Page 10: Application Not In Compliance With The Intended Use

Only use the coupling for the specified application. CENTA bears no liability for damage resulting from application not in compliance with the intended use of the equipment. Should there be a change of plant parameters, the coupling design must be reviewed by CENTA (address see chapter 1). -

Page 11: Delivery, Transport, Storage And Disposal

IMPORTANT Rubber parts are marked where possible with their production date. From this date, they may only be stored for a maximum of 5 years. CENTA Antriebe Kirschey GmbH 11 / 52... -

Page 12: Storage Location

Ensure safe, environmentally responsible disposal of operating supplies and exchange parts. For this, locally provided recycling facilities and regulations must be utilized. For disposal, the coupling parts must be separated where possible and sorted according to material type. CENTA Antriebe Kirschey GmbH 12 / 52... -

Page 13: Technical Description

Suitable dimensioning of bolts and clamping forces for torque transmission by friction. Available with or without failsafe device. Specifications The specifications can be found in the catalogue and the dimensions in the installation drawing. CENTA Antriebe Kirschey GmbH 13 / 52... -

Page 14: Alignment Of The Units Being Connected

For alignment, this has to be taken into account. After completion of assembly, check the alignment of the coupling again and if necessary correct. CENTA Antriebe Kirschey GmbH 14 / 52... -

Page 15: Axial Alignment

Determine the axial misalignment (see Fig. 5-1). Take installation length L from the installation drawing. Align the units (installation dimension = L±∆K A max Permissible axial alignment tolerance: ∆K =0.5 mm A max CENTA Antriebe Kirschey GmbH 15 / 52... -

Page 16: Radial Alignment

alignment During vertical alignment, take into account the extent by which the engine mounts settle. Please enquire about specifications for the degree of settling from the engine manufacturer or engine mounts manufacturer. CENTA Antriebe Kirschey GmbH 16 / 52... - Page 17 50 / 60 ±0.82 ±0.25 50 / 60 ±0.9 ±0.3 50 / 60 ±1.05 ±0.33 50 / 60 ±1.05 ±0.37 82 - 90 50 / 60 ±1.2 ±0.37 Table 5-1 Permissible radial alignment tolerance CENTA Antriebe Kirschey GmbH 17 / 52...

-

Page 18: Angular Alignment

Assembly and operating instructions M020-00009-EN Rev. 4 CENTAX-G 020G-00050…00090-F.10 Angular alignment Fig. 5-3 Angular misalignment Item Info Designation Remark If scope of supply Adapter If scope of supply Flywheel Customer part Flange Customer part CENTA Antriebe Kirschey GmbH 18 / 52... - Page 19 Size W max [mm] [mm] 50 - 64 0,20 66 - 70 0,22 71 - 72 0,26 0,28 0,31 0,35 0,37 82 - 85 0,44 0,51 0,55 Table 5-2 Permissible angular alignment tolerance CENTA Antriebe Kirschey GmbH 19 / 52...

-

Page 20: Mounting

Always cushion parts when supporting them from below. CAUTION Material damage can occur as a result of: Soiled joint surfaces The surfaces that are to be joined must be free of dirt, preservatives and lubricants. CENTA Antriebe Kirschey GmbH 20 / 52... - Page 21 This type of screw locking medium may not be in contact with rubber parts. IMPORTANT Screw preparation and tightening torque levels in accordance with CENTA data sheet D013-013 (see chapter 11.1). Use suitable lifting devices for assembly. The following assembly stages are described for coupling 020G-00070-F.10.

-

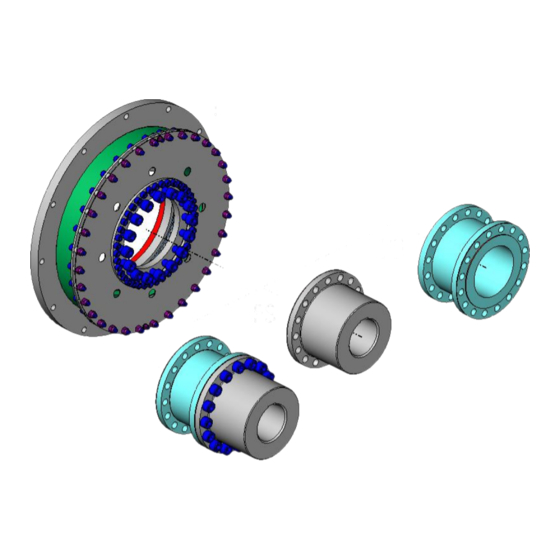

Page 22: Mounting Overview

Rubber element 1.2.1 Membrane Ring Ring Design and size see installation drawing If scope of supply Adapter Adapter If scope of supply Ring If scope of supply Rubber element assembly Pre-mounted by CENTA CENTA Antriebe Kirschey GmbH 22 / 52... - Page 23 Mounting the ring (1.4), see chapter 6.11. Mounting the membrane (1.2.1), see chapter 6.12. Connecting the rubber element (1.1) and the membrane, see chapter 6.13. After completed mounting, see chapter 6.14. CENTA Antriebe Kirschey GmbH 23 / 52...

-

Page 24: Mounting The Hub (3; If Existing)

Material damage can occur as a result of: Incorrect heating of the hubs/flange hubs Heat the hubs/flange hubs steadily in an oil bath, a fan oven, on an electric hot plate, either inductive or with a flame (ring burner). CENTA Antriebe Kirschey GmbH 24 / 52... - Page 25 Face of shaft must not protrude to face of hub. Otherwise radial replacement of other coupling parts is not guaranteed. CAUTION Material damage can occur as a result of: Hot hubs/flange hubs Before further mounting of hubs/flange hubs, allow them to cool to ambient temperature. CENTA Antriebe Kirschey GmbH 25 / 52...

-

Page 26: Mounting The Hub With Conical Oil Interference Fit

G¼ or G¾ see installation drawing Lightly oil the cone of the shaft (A). Push the hub (3) onto the shaft (A). Remove the screw plug (19) from the hub (3). CENTA Antriebe Kirschey GmbH 26 / 52... - Page 27 Remove the pump for expanding the hub from the hub (3). Maintain the oil pressure for pushing on the hub for one hour. Decrease the oil pressure for pushing on the hub. CENTA Antriebe Kirschey GmbH 27 / 52...

- Page 28 IMPORTANT Do not place a load on the hub for 24 hours. IMPORTANT Face of shaft must not protrude to face of hub. Otherwise radial replacement of other coupling parts is not guaranteed. CENTA Antriebe Kirschey GmbH 28 / 52...

-

Page 29: Mounting The Adapter (17; If Existing)

IMPORTANT Tightening torques for elements to connect couplings with customer parts could deviate from CENTA data sheet D013-013. Consider specifications on installation drawing. Aligning the units Align the units to be connected (see chapter 5). -

Page 30: Positioning The Membrane (1.2.1)

(E/3/17; see installation drawing). The radius (r) of the ring (1.9) must point towards the membrane (1.2.1). Positioning the membrane (coupling sizes 00078…00090) Place the membrane (1.2.1) on the flange/hub/adapter (E/3/17; see installation drawing). CENTA Antriebe Kirschey GmbH 30 / 52... -

Page 31: Positioning The Ring (1.4) Inside The Rubber Element (1.1)

Mounting the pre-mounted rubber element (F) to the flywheel, see chapter 6.9. Mounting the rubber element (1.1), the ring (20; if existing) and the adapter (4) to the flywheel, see chapter 6.10. CENTA Antriebe Kirschey GmbH 31 / 52... -

Page 32: Mounting The Pre-Mounted Rubber Element (F) To The Flywheel

(30) and the washers (31). The ring (1.4) remains inside the pre- mounted rubber element (F) for later mounting. IMPORTANT Tightening torques for elements to connect couplings with customer parts could deviate from CENTA data sheet D013-013. Consider specifications on installation drawing. CENTA Antriebe Kirschey GmbH 32 / 52... -

Page 33: Mounting The Rubber Element (1.1), The Ring (20; If Existing) And The Adapter (4) To The Flywheel

Remark Rubber element Ring If scope of supply Adapter If scope of supply Flywheel Customer part Flange Customer part Place the rubber element (1.1) with the ring (1.4) on the flange/hub/adapter (E/3/17). CENTA Antriebe Kirschey GmbH 33 / 52... -

Page 34: 6.10.2 Mounting The Adapter (4) To The Flywheel

Screw the adapter (4) to the flywheel (C) using the screws (30) and the washers (31). IMPORTANT Tightening torques for elements to connect couplings with customer parts could deviate from CENTA data sheet D013-013. Consider specifications on installation drawing. CENTA Antriebe Kirschey GmbH 34 / 52... -

Page 35: Mounting The Rubber Element (1.1) And The Ring (20; If Existing) To The Adapter (4)

(4) Item Info Designation Remark Rubber element Ring If scope of supply Adapter Adapter If scope of supply Ring If scope of supply Screw ISO4762-10.9 Washer ISO7089-300HV Flywheel Customer part Flange Customer part CENTA Antriebe Kirschey GmbH 35 / 52... - Page 36 Push the rubber element (1.1) onto the centring of the adapter (4). Screw the rubber element (1.1) to the adapter (4) using the screws (34) and the washers (35). The ring (1.4) remains inside the rubber element (1.1) for later mounting. CENTA Antriebe Kirschey GmbH 36 / 52...

-

Page 37: Mounting The Ring (1.4)

Mounting the membrane (1.2.1) Mount the membrane as appropriate for the coupling size supplied: Mounting the membrane (sizes 00050…00075), see chapter 6.12.1. Mounting the membrane (sizes 00078…00090), see chapter 6.12.2. CENTA Antriebe Kirschey GmbH 37 / 52... -

Page 38: Mounting The Membrane (Coupling Sizes 00050

Push the membrane (1.2.1) onto the centring of the flange/hub/adapter (E/3/17). Push the ring (1.9) onto the centring of the flange/hub/adapter (E/3/17). Screw the ring (1.9) and the membrane (1.2.1) to the ring (1.4) using the screws (1.10). CENTA Antriebe Kirschey GmbH 38 / 52... -

Page 39: Mounting The Membrane (Coupling Sizes 00078

(1.4) using the screws (1.10). The radius (r) of the ring (segmented; 1.9) must be on the side of the membrane (1.2.1). Repeat the mounting section above, until the ring (segmented; 1.9) is completely mounted. CENTA Antriebe Kirschey GmbH 39 / 52... -

Page 40: Connecting The Rubber Element (1.1) And The Membrane

Assembly and operating instructions M020-00009-EN Rev. 4 CENTAX-G 020G-00050…00090-F.10 6.13 Connecting the rubber element (1.1) and the membrane Fig. 6-14 Connecting the rubber element (1.1) and the membrane Fig. 6-15 Detail X CENTA Antriebe Kirschey GmbH 40 / 52... -

Page 41: After Completed Mounting

Injury and material damage can occur as a result of: Loose screw connections Before commissioning, the tightening torque levels of all screws must be checked and corrected if necessary. Before commencing long-term operation, the plant must successfully complete a test run. CENTA Antriebe Kirschey GmbH 41 / 52... -

Page 42: Operation

In case of uncertainty or if you have questions, please contact our head office (address see chapter 1). Admissible overall misalignment of the coupling The overall misalignment values can be found in the catalogue. CENTA Antriebe Kirschey GmbH 42 / 52... -

Page 43: Care And Maintenance

Exchange the rubber elements / rubber segments in the event that: The wear specifications given in W000-00002 are exceeded Assess the rubber elements / rubber segments as described in CENTA guidelines W000-00002. 8.1.4 Inspection of the screw connections ... -

Page 44: Dismantling

Contact with sharp-edged objects Protect coupling components for transportation. Only hoist coupling components with nylon belts or ropes. Always cushion parts when supporting them from below. IMPORTANT Use suitable lifting devices for dismantling. CENTA Antriebe Kirschey GmbH 44 / 52... -

Page 45: Disconnecting The Rubber Element (1.1) And The Membrane

Loosen and remove the screws (8) of the connection flange/hub/adapter (E/3/17) and ring (1.4). Pull the ring (1.4) off the centring of the flange/hub/adapter (E/3/17) and place it inside the rubber element (1.1). CENTA Antriebe Kirschey GmbH 45 / 52... -

Page 46: Dismantling The Rubber Element And The Adapter

Loosen the screws (30) of the connection adapter (4) and flywheel (C) and remove with the washers (31). Pull the adapter (4) out of the centring of the flywheel (C) and remove. CENTA Antriebe Kirschey GmbH 46 / 52... -

Page 47: Removing The Rubber Element (1.1) With The Ring (1.4)

Dismantling the hub with conical oil interference fit, see chapter 9.11.2. 9.11.1 Dismantling the hub with cylindrical bore and keyway See Fig. 6-1: Remove the hub (3) from the shaft (A). CENTA Antriebe Kirschey GmbH 47 / 52... -

Page 48: 9.11.2 Dismantling The Hub With Conical Oil Interference Fit

Reduce the oil pressure for expanding the hub. Repeat the above mounting section until the hub is completely released from the shaft. Remove the pump for holding the hub from the shaft (A). CENTA Antriebe Kirschey GmbH 48 / 52... -

Page 49: Reassembling The Coupling

Screw the screw plug (19) into the hub (3). Remove the hub (3) from the shaft (A). 9.12 Reassembling the coupling Reassemble the coupling as described in chapter 6. CENTA Antriebe Kirschey GmbH 49 / 52... -

Page 50: Wearing And Spare Parts

A stock of the most important wearing and spare parts is the most important condition to ensure that the coupling is functional and ready for operation at all times. We only provide a warranty for CENTA original parts. Wearing parts of this coupling: ... -

Page 51: Annex

CENTAX-G 020G-00050…00090-F.10 Annex 11.1 CENTA data sheet D013-013 (lubricated screw connections) Validity: For all non-dynamically stressed screw connections with lubricated shank bolts in accordance with ISO 4014, ISO 4017 and ISO 4762 (DIN 912) with metric standard thread in accordance with DIN ISO 262, unless other specifications are given on CENTA documents. -

Page 52: Centa Data Sheet D020-900 Declaration Of Incorporation According To The Ec Machinery Directive 2006/42/Ec

+49-2129-2790 Bergische Strasse 7 centa@centa.de 42781 Haan / GERMANY www.centa.info We herewith declare that the incomplete machine Product: Highly elastic coupling CENTAX-G Model / series code: CX-G / 020G Installation size: 50…90 Design: Serial number: according to shipping documents, if applicable...

Need help?

Do you have a question about the CENTAX-G and is the answer not in the manual?

Questions and answers