Subscribe to Our Youtube Channel

Summary of Contents for Fisher FERITSCOPE FMP30

- Page 1 Operator‘s Manual FERITSCOPE ® FMP30 Coating Thickness Material Analysis Microhardness Material Testing...

- Page 2 F E R I T S C O P E F M P 30 ® Instrument for measurement of the ferrite content in austenitic and duplex steel. Document order number: 902-097 Issue date: 06-2016 On our home page www.helmut-fischer.com you will find the addresses of our sole agencies and subsidiary companies around the globe.

-

Page 3: Table Of Contents

Table of Contents 1 Safety Information ....... . . 1 Symbols and Conventions Used in the Manual . - Page 4 5 Applications ........37 Setting Up an Application ......37 Selecting the Desired Application .

- Page 5 9 Data Transfer ........131 USB Connection to a PC ......132 Installing the USB Drivers .

-

Page 6: Safety Information

Safety Information Symbols and Conventions Used in the Manual The following symbols and conventions are used in this manual: Indicates safety information referring to danger for persons and warnings regarding damage to the measuring instrument or to accessories. Indicates particularly important information and hints. Indicates a reference to a page or chapter in this manual. -

Page 7: Requirements On The Operating Personnel

Requirements on the Operating Personnel The instrument should be operated only by staff trained for this purpose! In addition, basic knowledge of metrology according to DIN 1319 is es- sential for performing correct -ferrite content measurements and evalua- tions. Basic computer knowledge regarding configuration, operation and pro- graming as well as knowledge of the software in use, which may be ob- tained from respective instruction manuals, is required when using the in-... - Page 8 Ambient Temperature Range During Operation: +10°C ...+40°C Temperature Range During Storage and Transport: +5°C ... +60°C Temperature behind glass panes (e.g., in cars) in direct sunlight easily rise above 60°C! To avoid damage from heat, do not store the instrument or acces- sories in such places.

-

Page 9: Probe Handling

Probe Handling To avoid breakage of the wiring, do not bend the probe connector cable! The radius of rolled up probe connector cables should always be at least 50 mm! Probe- connector cable R 50 mm ! R 1.96 " Fig. -

Page 10: Instrument Repairs

for a correct calibration, and thus for a correct measurement. Observe the following to ensure the proper condition of the calibration stan- dards: To keep wear of the base and the calibration standards during the con- tacting measurements to a minimum, use them for the calibration only and not for test measurements! Do not soil or scratch calibration standards! Replace corroded or scratched calibration standards or those with strong... -

Page 11: Limitation Of Liability

1.10 Limitation of liability The instrument manufacturer accepts no liability and responsibility for any kind of damage resulting from the use of the corrective diagrams and ta- bles provided in the chapter "Appendix", in the operator‘s manual on the support CD. The user uses the corrective diagrams and tables at their own responsibility. -

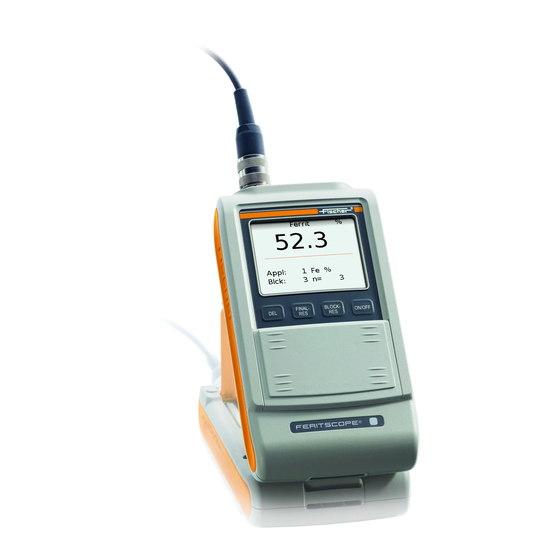

Page 12: Description Of The Instrument

Description of the Instrument Probe connector socket, Page 25 Display, Page 8 Keys for directly retrieving functions, Page 10 USB port for connecting a printer and a PC ON/OFF key to turn the instrument on or off, Page 28 Connector socket for the AC adapter (included) Cover;... -

Page 13: Display

Display The display consists of several display elements. Display element Explanation A normalization is performed (on the base of the calibra- tion standard set) ( beginning on Page 61). A calibration is carried out ( beginning on Page 64). Displays the measurement method Bell: Tolerance limits are enabled ( beginning on Page 91). - Page 14 Display element Explanation Both arrows together: The displayed measurement was recognized as an outlier. -8.8.8.8 Numeric elements for presenting readings, errors and warning messages. Unit of measurement for the displayed reading. Battery: The battery must be replaced or the rechargeable battery must be charged because the voltage dropped below a minimum value ( beginning on Page 22).

-

Page 15: Control Panel Key Functions

Control Panel Key Functions For easier opening of the cover: Press on the corners of the cover and then slide the cover downwards. Fig. 2-2 Opening the cover of the control panel keys The following overview provides a brief description of the functions of the individual control panel keys: Function Deletes the last measured reading... - Page 16 Function FINAL-RES Retrieving the final result ( beginning on Page 124) Repeated pressing of FINAL-RES: Displays the individual components of the final result (mean val- ue, standard deviation, etc.) in succession. .. and then ENTER: Ends the display of the final result (return to the measurement screen) without deleting the stored values (the current measure- ment block will not be closed).

- Page 17 Function BLOCK-RES Retrieves the block result ( beginning on Page 118 Repeated pressing of BLOCK-RES: Displays the individual components of the block result (mean value, standard deviation, etc.) in succession. .. and then Ends the display of the block result (return to the measurement screen) without closing the open measurement block (the current measurement series can be continued).

- Page 18 Function With Application selection and tolerance limit input: Changes the information displayed on the display. With the calibration: Sets the target value of the used calibration standard that will be displayed after the “CAL Target” notifica- tion. With parameter selection: Selects the desired parameters. ...

- Page 19 Function MENU Displaying and entering of the application-specific settings: Tolerance Limits Resolution Block size i individual values Outlier .. and then Selects the settings to be edited .. and then PRINT: Prints or displays a print form of the instrument configuration. ..

-

Page 20: Accessories

Accessories 2.3.1 Probes All probes that can be connected to the instrument are equipped with a memory chip, a so-called EEPROM, in their connector plug. Probe-specific information (such as probe type, production number, measurement method or coefficients of the master characteristic, for example) is stored permanently - even without power supply - in this memory chip, which can be overwritten as many times as desired. - Page 21 2.3.2 Base and Calibration Standards A so-called base is used for the normalization; for the corrective calibration, one, two or three calibration standards are used in addition to the base. Different calibration standards (corrective sets) are available for the correc- tive calibration of the instrument for the different measurement ranges.

- Page 22 Certification of the Calibration Standards FISCHER supplies the calibration standard set and single calibration stan- dards complete with a valid certificate. The certificate includes information about warranties and monitoring of the test devices. 2.3.3 Printer For an overview of printers suitable to be connected to the instrument see the menu Service Functions / PRINT ( Chapter 10.5.1 ‘Printer Selection’, beginning on Page 160).

-

Page 23: Technical Data

Technical Data Instrument model ® FERITSCOPE FMP30 Display Graphical backlit display Measurable coat- Ferrite content measurements in weld seams and clad- ings dings made of austenitic or duplex steel Determination of the portion of deformation martensite in austenitic materials Measuring modes Magnetic induction measurement method... -

Page 24: Contents Of Shipment And Options

Measurement Depends on the connected probe range, trueness and (These and other probe characteristics can be obtained repeatability preci- from the probe data sheet or can be requested from your sion authorized supplier or from FISCHER) Contents of Shipment and Options After receiving the shipment, packaging and content should be checked for potential damage. - Page 25 2.5.2 Options Available options are: AC adapter Various measurement probes Corrective calibration standard set with specified dimensions FN and %Fe Single corrective calibration standards specified dimensions FN and %Fe 1.5 V NiMh rechargeable battery (4 each/unit) ...

-

Page 26: System Setup, Maintenance And Cleaning

System Setup, Maintenance and Cleaning Connect or disconnect plug-type connectors only when the instru- ment is switched off in order to avoid electrical discharge. Connect- ing the AC adapter or inserting a battery should be done carried out with the unit turned off as well! Even a small discharge can delete the instrument memory. -

Page 27: Voltage Supply

Voltage supply Electrical power can be supplied to the instrument in the following ways: with AC adapter (9 V 150 mA, 100 V - 230 V), 4 x 1.5 V batteries (AA or mignon) or 4 x 1.5 V NiMh rechargeable batteries, 2100 mAh (AA or mignon). ... - Page 28 3.1.2 Installing or Replacing Batteries Indicator for battery replacement. Batteries or rechargeable batteries should be replaced. If the battery voltage is too low, the instrument will turn off automatically. Procedure Battery Replacement ) to switch the instrument off (if not yet ON/OFF Page 28 done).

- Page 29 Close the battery compartment cover. Observe the correct polarity when in- stalling the batter- ies. Fig. 3-2 Inserting the batteries and closing the battery compartment cover Use only type MIGNON, 1.5 V, LR6 - AA - AM3 - MN1500 batteries or 4 individual rechargeable batteries NiMH 1.2 V HR6 Type AA.

-

Page 30: Connecting Probes

Connecting Probes Connect probes only when the instrument is off! To turn the instrument off: Press the ON/OFF key on the right side of the control panel. The display is not backlit and no characters are visible. Protect the instrument and accessories from electrostatic charges! Electrical discharges may damage internal components or delete internal memories. - Page 31 When inserting the plug, ensure that the key of the plug fits into the groove of the socket. Otherwise, an erroneous connection between the instrument and the plug may occur or the contact pins of the probe plug may be damaged. Key (plug) Groove (socket) Fig.

- Page 32 Probe connector plug Connector socket Instrument Fig. 3-4 Connecting a probe ON/OFF to turn the instrument on again. The instrument automati- cally recognizes the type of probe connected to it. Exception: A flashing symbol for the measurement method on the display indicates that the instrument does not recognize the connected probe.

-

Page 33: Instrument: On/Off

Instrument: On/Off To avoid erroneous readings, no metallic objects must be in close proximity to the probe tip when powering up the instrument. The minimum distance is 25 mm. 3.3.1 Measurement Method of the Connected Probe After powering up the instrument, the measurement method [Ferrite] pears on the display. - Page 34 3.3.2 Power Up Key sequence Detail of the display Explanation ON/OFF Press the ON/OFF key to power up the in- strument. An audible signal will sound. A monitoring routine will run. At the end of the monitoring routine, the Ap- plication that was used the last time to make measurements with the connected probe will open automatically and the instrument...

- Page 35 Detail of the display Explanation of the displays after power up No reading appears after powering up the instrument be- cause the last not closed block does not contain any read- ings. If the settings in the Service function Storage mode are [do not save] or [delete upon off], no reading will appear upon power up as well because the readings have either not been stored at all or have been deleted when the instru-...

- Page 36 Detail of the display Explanation of the displays after power up The open Application is set to auto-averaging mode ( 5.6.4 ‘Outlier rejection’, beginning on Page 50 and 7.3.7 ‘Measurements With Outlier Rejection Enabled’, be- ginning on Page 93). [i=]: Number of single readings measured using the auto- averaging / set number of single readings to be combined The open Application is set to the “free-running”...

- Page 37 Detail of the display Explanation of the displays after power up This error message appear briefly after power-up if no probe is connected to the instrument, if the probe is not connected properly or if the connected probe is defective. It is not possible to make measurements without a connect- ed probe.

-

Page 38: Cleaning

3.3.4 Switching Off the Instrument Press the ON/OFF key switch the instrument off manually. The instrument shuts down automatically if for about 5 minutes no measure- ments are made or no key is pressed. Cleaning To avoid damage to the instrument due to electrical shock, the line plug of the AC adapter must be pulled before cleaning the instrument or the acces- sories! Soiled instruments or accessories should be cleaned using a plastic care... -

Page 39: Probe Handling

Probe Handling Handling During Measurements Example: Probe FGAB1.3 Always hold the probe at its grip sleeve (right Grip figure). Specimen Always place the probe gently and at a right angle on the specimen surface. Slide the grip sleeve to the specimen surface ... -

Page 40: Assigning A New Probe

Assigning a New Probe The instrument recognizes if the probe connected to the unit is different than the one expected according to the probe identification in the current Appli- cation. Reason: Each individual probe has a name that is comprised of the identi- fication number and the model designation (e.g., FGAB 1.3F). - Page 41 Key sequ. / Detail of the display Explanation Action This warning appears briefly after power-up if a probe other than the last one used is connected to the instrument. After that, the display of the measurement method flashes. Example: FGAB1.3F = Name of the con- nected probe ZERO DEL: Probe assignment starts...

-

Page 42: Applications

Applications All relevant settings and parameters for a measuring application as well as the captured measurement data are stored in a file - we refer to this file as an Application. The instrument has the capability of setting up up to 100 different Applica- tions. - Page 43 As long as the restricted operating mode is enabled (indicated by on the display), only Applications that have already been set up can be selected, i.e., it is not possible to set up new Applications 10.6.1 ‘Restricted Operating Mode’, beginning on Page 166). Procedure Key sequ.

- Page 44 Key sequ. / Detail of the display Explanation Action ENTER if [always ask] is selected from the service function Measurement/Unit 10.7.5 ‘Unit’, beginning on Page 179), select the unit of measurement for making the measurements in the Appli- cation at this point: Use the arrow keys to select the unit.

-

Page 45: Selecting The Desired Application

Selecting the Desired Application To make -ferrite content measurements, a probe must be connected and an Application must be selected that has been set up using the connected probe before measurements can be made. If [Ferrite] flashes on the Display after instrument power-up or after selecting an Application, an Application has not yet been set up using the connected probe. -

Page 46: Deleting An Application

Key sequ. / Detail of the display Explanation Action ENTER Use ENTER to confirm the selected Appli- cation. The selected Application will be re- trieved. The last reading of the last not closed block is displayed. The instrument is ready to make measurements. Deleting an Application As long as the restricted operating mode is enabled (indicated by on the display), the DEL key will not be enabled, i.e., it is not possi-... -

Page 47: List Of Set Up Applications

Key sequ. / Detail of the display Explanation Action Use DEL to start the deletion process. Press- ing DEL again: Deletes the Application. ENTER: Cancels the deletion. It is now possible to select a different Appli- cation ( Page 40) or to set up a new Ap- plication ( Page 37). - Page 48 Fig. 5-1). It is now possible to select a different Appli- cation ( Page 40) or to set up a new Ap- plication ( Page 37). FISCHER FERITSCOPE FMP30 23.07.08 Applications: 0 sheet FGAB1.3Fe Fe % 23.07.08 n= 7 1 face FGAB1.3Fe Fe %...

-

Page 49: Assigning Application Designations

2008-07-23 End of block - Date of the last block closure of this Ap- plication (if no date is shown, the Application does not contain a closed block!). Number of measurements stored in this Application Assigning Application Designations A customer-specific designation that can be comprised of a max. of 16 AS- CII characters can be assigned to every Application. - Page 50 Key sequ. / Detail of the display Explanation Action MENU Selects a menu option by pressing Tolerance Limits ( Page 46) Measurement display resolution Page 48) Automatic block size and block creation Page 49) Outlier rejection ( Page 50) ...

- Page 51 5.6.1 Tolerance Limits Having the tolerance limits enabled allows for a simple and quick determi- nation if the measured -ferrite contents are within specified limits 7.3.5 ‘Measurements With Tolerance Limits Enabled’, beginning on Page 91). Key sequ. / Detail of the display Explanation Action MENU Use MENU to start Settings.

- Page 52 As long as the tolerance limits are enabled, will appear on the display. If the upper and lower specification limits are mixed up when entering the settings, the instrument will automatically select the lower values as the low- er specification limit and the higher value as the upper specification limit. ®...

- Page 53 5.6.2 Measurement Display Resolution The measurement display resolution specifies the resolution for displaying the readings on the display. Example: Reading 18.61 Display with resolution setting “low”:19 Display with resolution setting “standard”: 18.6 Display with resolution setting “high”: 18.61 Resolution 0.0 ...0.999 1.0 ...9.99 10 ...99.99 100 ...999.9 1000 ...9999 9999...

- Page 54 5.6.3 Automatic Block Size and Block Creation “Automatic block creation” must be enabled and a block size must be de- fined for a certain number of readings to be combined in a block automat- ically during the measurement. The block size must be between 2 and 99 7.3.6 ‘Measurements With a Fixed Block Size’, beginning on Page 91).

- Page 55 Key sequ. / Detail of the display Explanation Action Use the arrow keys to set the desired block size. ENTER Press ENTER to confirm the selection and return to the menu to enter additional set- tings. Press DEL to return to the measurement screen.

- Page 56 Key sequ. / Detail of the display Explanation Action ENTER Use ENTER to confirm the selection “Outli- er Reject”. To activate outlier rejection: use the arrow keys to select Outlier Reject “on” or to deactivate outlier rejection: Select Outlier Reject “off”. ENTER Use ENTER to confirm the method “Auto- matic”.

- Page 57 5.6.5 Unit -ferrite content displayed as -Martensit content. The measured -ferrit content in Fe% will be computed into the corresponding -Martensit con- tent. Further information see Chapter Glossary, section -Martensit con- tent. Key sequ./ Detail of display Explanation Action MENU...

- Page 58 Key sequ./ Detail of display Explanation Action MENU Use MENU to start Settings. Press the arrow key , until “Offset” is highlighted on the display. ENTER Use ENTER to confirm the selection “Off- set”. Press the arrow keys to set the desired Off- set value Press ENTER to confirm the selection/entry ENTER...

- Page 59 Explanation of the measured variables: Glossary The measured variable can be set differently in each Application. The settings of the measured variables of the other Applications will not be affected. With every modification of the measured variable, a prompt for delet- ing readings already stored in the open Application will appear because it is not possible to evaluate different types of measured vari- ables statistically.

- Page 60 Measurement Detail of the display Explanation program Fe% / FN Display of ferrite content and saturation and Xs countrate Xs (countrate for probe in air). The ferrite content will be displayed in % or FN corresponding to the set unit 10.7.5 Xn and Xs Displays the normalized countrate Xn of the...

-

Page 61: Linking Applications

Linking Applications 10.6.4 ‘Linking Applications’, beginning on Page 172) If the linking mode is enabled, all applications that have set up using the same probe (identified by the same serial number) will be linked with each other. Applications that have been linked to each use the same normaliza- tion and/or corrective calibration to determine measurements. - Page 62 instrument ( 10.6.4 ‘Linking Applications’, beginning on Page 172). As long as the linking mode is enabled will appear on the display. After disabling the linking mode, all Applications will again be inde- pendent of each other! Each Application can again be normalized and.or calibrated sepa- rately.

- Page 63 Fig. 5-3 Example for linking of applications ® Page 58 Operator‘s Manual FERITSCOPE FMP30...

- Page 64 Immediately following the linking procedure: Because a normalization or a corrective calibration has not yet been carried out immediately following the linking procedure, the normal- izations and corrective calibrations of the linked Applications still dif- fer from each other. Applications 4 and 6 are also linked to each other , because ...

-

Page 65: Normalization, Calibration And Master Calibration

Normalization, Calibration and Master Cali- bration The following factors influence the readings of a -ferrite content measure- ment: Geometry of the specimen (size of the reference area, curvature, dis- tance of the measurement location from the edge of the specimen, sheet thickness, cladding thickness) The correction of these influencing quantities should be carried out based on the correction factors listed... -

Page 66: Normalization

Reference measurements should be performed after every normaliza- tion and calibration to verify the normalization and calibration. It is not possible to start a normalization, corrective calibration or a master calibration as long as the restricted operating mode is enabled (indicated by on the display) ( 10.6.1 ‘Restricted Operating... - Page 67 6.2.1 Normalization Procedure Key sequ. / Detail of the display Explanation Action ZERO Use ZERO to start the normalization of the open Application. ZERO appears and remains on the display while the normalization is performed. [s]: Standard deviation [n]: Number of measurements [Base material (Fe]: The measurements should be made on the base material of the calibration standard set.

- Page 68 6.2.2 Documenting the Normalization with a Printer FISCHER FERITSCOPE FMP30 23.07.08 NORMALIZATION 23.07.08 12:38 Appl.No.: 3 Probe: FGAB1.3Fe fe.= 98.86 Fe% s= 0.321 Fe%...

-

Page 69: Corrective Calibration

Corrective Calibration With a corrective calibration, a new zero point and one additional point (one-point calibration with one calibration standard) or two additional points (two-point calibration with two calibration standards) are established for the calibration curve of the open Application and are stored in the open Application. - Page 70 6.3.2 Corrective Calibration Procedure Key sequ. / Detail of the display Explanation Action Use CAL to start the corrective calibration of the open Application. CAL appears and remains on the display while the corrective calibration is per- formed. [s]: Standard deviation [n]: Number of measurements [Base material (Fe)]: The measurements should be made on base.

- Page 71 Key sequ. / Detail of the display Explanation Action ENTER [Entry: ]: Use the arrow keys to set the rated ferrite content value of the calibra- tion standard. The rated value can be set faster if a mea- surement is performed on a calibration stan- dard that is within the tolerance range, and then the rated value is corrected using the...

- Page 72 Key sequ. / Detail of the display Explanation Action ENTER A confirmation indicating that the corrective calibration has been carried out successful- ly appears. Pressing ENTER confirms the message. PRINT: A print form of the corrective cali- bration will be printed if a printer is con- nected and switched on ( Page 69).

- Page 73 6.3.3 Deleting a Corrective Calibration When deleting the corrective calibration, only the corrective calibra- tion of the open Application will be deleted. The corrective calibra- tions of the other Applications are retained. However, if the linking mode is enabled ( on the display), the corrective calibrations of all Applications that are linked with the open Application will be deleted.

- Page 74 6.3.4 Documenting the Corrective Calibration with a Printer FISCHER FERITSCOPE FMP30 23.07.08 CALIBRATION 23.07.08 12:43 Appl.No.: 3 Probe:FGAB1.3Fe Measurements on Base fe.= 104.2 Fe% s= 1.671 Fe% Fe: 0.680 Fe% Measurements on fe.= 0.646 Fe% s= 0.010 Fe% Calibration stan- dard # 1 Fe: 3.08 Fe%...

-

Page 75: Master Calibration

Master Calibration The master calibration determines the coefficients of the master character- istic and stores them in the EEPROM of the probe plug. These coefficients determine the master characteristic, i.e., the correlation between the mea- surement signal of the probe and the -ferrite content. - Page 76 6.4.1 Selecting the Calibration Standards For the user master calibration, the master calibration standard set avail- able from FISCHER as an option should be used! Only in this manner can the specified trueness be ensured during the subsequent measurements. During the user master calibration, the master characteristic can be deter- mined only if suitable calibration standards are used.

- Page 77 6.4.3 Master Calibration Procedure The probe tip should be checked for potential wear prior to a master cali- bration. Too much probe tip wear becomes noticeable through an increased scat- ter of the readings on a specimen with a homogeneous ferrite content distribution (e.g., a calibration standard).

- Page 78 Key sequ. / Detail of the display Explanation Action ZERO + CAL appear and remain on the ENTER display while the master calibration is per- formed. [s]: Standard deviation [n]: Number of measurements [Base material (Fe)]: The measurements (normalization) should be made on base. [MCL Delete: DEL]: Use DEL to delete an existing master calibration (appears only if a master calibration has already been per-...

- Page 79 Key sequ. / Detail of the display Explanation Action Make about 5 measurements at different lo- cations of the base. The mean value of all readings obtained for the normalization will be displayed. Base [Base material (Fe)]: The measurements should be made on base. [Delete: DEL]: Use DEL to delete the last measurement DEL, 2x DEL to delete all readings obtained for the normalization.

- Page 80 Key sequ. / Detail of the display Explanation Action Make about 5 measurements at different lo- cations of the calibration standard. [Delete: DEL]: Use DEL to delete the last measurement DEL, 2x DEL to delete all Calibration readings obtained for the normalization. standard [OK: ENTER]: Use ENTER to end and store the calibration step.

- Page 81 Please note the information regarding the number of calibration standards under 6.4 on Page 70. To verify a correct master calibration, perform several reference mea- surements. Now, it is possible to make measurements in the open Application. Delete the readings of the reference measurement before starting with the mea- surements on your specimens.

-

Page 82: Key Sequ. / Action

Key sequ. / Detail of the display Explanation Action BLOCK-RES Use BLOCK-RES to display the Xn range for calibration standard #3 [0.5000<Xn<0.0000]. BLOCK-RES Use BLOCK-RES to display the Xn range for calibration standard #4 [0.8000<Xn<0.9900]. BLOCK-RES Use BLOCK-RES to end the display of the Xn range. - Page 83 6.4.5 Documenting the Master Calibration with a Printer FISCHER FERITSCOPE FMP30 23.07.08 MASTER CALIBRATION 23.07.08 13:34 Appl.No.: 4 Probe: FGAB1.3Fe Measurements on uncoated specimen fe.= 104.2 Fe% s= 1.671 Fe% (base material) Fe: 0.680 Fe% Measurements on fe.= 0.646 Fe% s= 0.010 Fe%...

-

Page 84: Determination Of The Normalized Countrate Xn Of A Calibration Standard During A Master Calibration

Mean value of all readings obtained for this step of the calibration. Standard deviation of the readings obtained for this step of the calibration. Determination of the Normalized Countrate Xn of a Cal- ibration Standard During a Master Calibration The normalized countrate Xn of a calibration standard can be determined as described below during a master calibration without affecting the cali- bration. -

Page 85: Measuring

Measuring The information stated in Chapter 1 ‘Safety Information’, beginning on Page 1 must be observed when making measurements! Preparing for a Measurement The instrument and the measurement area must be prepared in the follow- ing manner before measurements can be made: Agreement on the reference areas (determination on where several sin- ... -

Page 86: Parameters That Influence The -Ferrite Content

Parameters That Influence the -Ferrite Content Mea- surement The following factors influence the readings of a -ferrite content measure- ment: Specimen curvature The influence takes effect from following curvature diameters: - diameters less than 50 mm (1.97 ") for convex curvatures, - diameters less than 80 mm (3.15 ") for concave curvatures. - Page 87 content and the influence cannot be stated quantitatively. The influence is relatively small for -ferrite contents of < 10 Fe %. It rises with an increasing -ferrite content and can be reduced best by combining a sufficient number of single readings to one meaningful mean value. For very low ...

- Page 88 Correction curves for measurement values with measurement unit FN Fig. 7-1 Correction values for values with measurement unit FN measured on specimens with different convex curvature diameters ® Operator‘s Manual FERITSCOPE FMP30 Page 83...

- Page 89 Correction curves for measurement values with measurement unit Fe % Abb. 7-2 Correction values for values with measurement unit Fe % measured on specimens with different convex curvature diameters ® Page 84 Operator‘s Manual FERITSCOPE FMP30...

-

Page 90: Making A Measurement

Making a Measurement To make a measurement, place the probe at a right angle on the specimen surface ( Page 34). The probe can be lifted off after the measurement ac- quisition, i.e., after the reading appears on the display. The instrument is ready to make measurements. - Page 91 1. Place the probe: 2. Lift the probe off: Measurement Object Fig. 7-4 Measurement using an angle probe 7.3.1 Measurement Acquisition As long as automatic measurement acquisition is enabled, measurement ac- quisition occurs automatically immediately after the probe is placed on the specimen.

- Page 92 7.3.2 Measurements With External Start Enabled When an automatic measurement acquisition is not desired, e.g., when making measurements in pipes, boreholes or grooves, external start should be enabled and automatic measurement acquisition disabled (Enabling ex- ternally triggered measurement acquisition and disabling automatic mea- surement acquisition: Page 175).

- Page 93 This measuring mode is advantageous if a mean values of the -ferrite con- tent distribution is to be determined quickly within a reference area. This mean value is added to a measurement series as a single reading. With online output of the single readings via the interface port enabled, only this mean value will be output as well.

- Page 94 Measurement Capture Through Automatic Measurements With automatic measurements, a specified number of readings is taken with a selectable time interval between 2 measurements. In contrast to the area measurement, all single readings will be stored ( Page 87). This measuring mode can be advantageous, for example, when the -ferrite content distribution shall be determined along a line.

- Page 95 7.3.4 Audible Signals After the Measurement Acquisition An audible signal will sound after the measurement acquisition (unless it has been disabled). The measurement acquisition signal indicates that a signal arriving from the probe has been recognized and that the probe can be lifted off the specimen.

- Page 96 7.3.5 Measurements With Tolerance Limits Enabled Having the tolerance limits enabled allows for a simple and quick determi- nation if the measured -ferrite contents are within specified limits Page 46). As long as the tolerance limits are enabled, will appear on the dis- play.

- Page 97 the closure of the block is indicated by a long audible signal (if the measurement acquisition signal has been disabled, only the signal to indicated the block closure will sound). With a connected and powered up printer, it is now possible to print the block result automatically after the block closure or upon ( 10.5.3 ‘Block Result’, beginning on Page 162).

- Page 98 7.3.7 Measurements With Outlier Rejection Enabled When making measurements with outlier rejection enabled: the outlier measurements recognized by the instrument will appear on the display and will be indicated acoustically ( 5.6.4 ‘Outlier rejec- tion’, beginning on Page 50), Detail of the display Explanation will appear in front of the reading on...

-

Page 99: Checking The Current Calibration State

Checking the Current Calibration State The CAL-Check function checks whether the mean value of the check mea- surement matches the reference value of the standard to within the scope of measurement uncertainty (in accordance with ISO/IEC guide 98-3). When to perform Acquisition of the current calibration state of the measurement system, ... - Page 100 the standards from the scope of supply of the connected probe. Certificates in which the tolerance or the measurement uncertainty (k=2) for the used standards is specified. Accuracy The calibration accuracy is limited by the measurement uncer- tainty of the standard. The measurement uncertainty of the corrective calibration may not be smaller than the measure- ment uncertainty of the standards used.

- Page 101 Procedure - Checking the Current Calibration State Key sequ./ Detail of the display Explanation Action CAL + Use CAL and to start the intrument fucti- on CAL-Check. Use the arrow keys to set the rated -ferrite content value of the used standard.

- Page 102 Key sequ./ Detail of the display Explanation Action Use the arrow keys to set the uncertainty of the standard. Example: rel. Tolerance ATTENTION: Observe the display unit when entering the uncertainty. ENTER Use ENTER to confirm the entry. Perform a check measurement on standard (1).

- Page 103 Key sequ./ Detail of the display Explanation Action FINAL RES Use FINAL RES to display the check result. You can find additional information on the parameters and measurement uncertainty in chapter Glossary. [Difference:]: Difference between the mean value from the control measurement and the nominal value (= reference value) of the standard used for measurement.

-

Page 104: Documenting The Measurement With A Printer

Documenting the Measurement with a Printer With a connected and powered up printer, it is possible to print individual readings by pressing the PRINT Fig. 7-5 and Fig. 7-6). [Print single readings on] must be set from the Service Functions/Print menu ( 10.5.3 ‘Block Result’, beginning on Page 162). - Page 105 2| | * 3| | * | | 10.3 4|<<| | | 3.1 5| | * | | 10.3 FISCHER FERITSCOPE FMP30 24.07.08 Appl.No. 0 -- Block result -- Block No.: 1 24.07.08 22:05 Mean value fe. = 8.89 +/- 4.04% Std.

- Page 106 The readings and the block results of a single block can be printed during the evaluation of this particular block by pressing the key. PRINT 8.1.1 ‘Documenting the Block Result With a Printer’, beginning on Page 121 FISCHER FERITSCOPE FMP30 24.07.08 Appl.No. 0 -- Block result -- Block No.: 3 24.07.08 12:09 Mean value fe.

-

Page 107: Erroneous Readings

Erroneous Readings 7.6.1 Deleting Erroneous Readings If an erroneous reading is recognized directly after measurement acquisi- tion, the reading can be deleted by pressing The deleted reading will then not be included in the generation of the block and final results. Repeated pressing of will delete all readings of the open block in suc- cession. - Page 108 7.6.4 Overwriting Individual Erroneous Measurements at a Later Time During the evaluation of the current block, individual erroneous measure- ments of the current block or of earlier blocks can be overwritten with new readings. The instrument does not carry out outlier rejection when overwriting stored measurement data (even if outlier rejection is enabled).

- Page 109 Key sequ. / Detail of the display Explanation Action MENU Use MENU to retrieve the display of the sin- gle readings. [Blck:]: Number of the selected block [n=]: Consecutive number of the displayed single reading Use the arrow key to select the sin- gle reading that is to be overwritten.

-

Page 110: Measurements In The Free-Running Display Mode

Key sequ. / Detail of the display Explanation Action Use ENTER to end the block result display. ENTER The last block will be closed automatically and a new block will open. If additional measurements are to be made in the last not yet closed block, do not press ENTER;... - Page 111 7.7.1 Turning the Free-Running Display Mode On/Off To enable the free-running display mode: Press the arrow key. The “free-running” display mode remains enabled until it is disabled; i.e., it does not need to be enabled every time the instrument is pow- ered up.

- Page 112 7.7.2 Procedure For Making Measurements With the Free-Running Dis- play Mode The magnetic poles are subject to increased wear when moving the probe across a surface. Key sequ. / Detail of the display Explanation Action Press the arrow key to enable the free- running display mode.

- Page 113 The audible signals for indicating tolerance limit violations are disabled automatically when making measurements in the free-running display mode. A violation of a tolerance limit will be indicated only through or displayed on the CD display. 7.7.3 Analog Display When making measurements in the “free-running” display mode, the ana- ...

- Page 114 Key sequ. / Detail of the display Explanation Action Press the arrow key to enable the free- running display mode. will appear on the display. [3.00 8.00]: Limits for the analog display (example). Place the probe on the specimen and move it across the surface of the specimen to de- termine the lateral ...

-

Page 115: Measurements In Standard And Matrix Measuring Mode

Measurements in Standard and Matrix Measuring Mode The preparations required for making the actual measurement are indepen- dent of the selected measuring mode and are described in the Chapters “ 7.1 ‘Preparing for a Measurement’, beginning on Page 80 and 7.3 ‘Making a Measurement’, beginning on Page 85. - Page 116 Reference area APPL 1 APPL 2 APPL 3 (for sheet metal) (for pipe) (for profile) Norm 1/ Cal 1 Norm 2/ Cal 2 Norm 3/ Cal 3 Block 1 Block 1 Block 1 Readings sheet 1 Readings pipe 1 Readings profile 1 Block 2 Block 2 Block 2...

- Page 117 7.8.3 The Matrix Measuring Mode When changing to the matrix measuring mode, the number of Applications and the number of blocks must be entered. The same number of blocks is set up for each Application. Each block can receive the same maximum number of readings.

- Page 118 All three Applications contain 20 blocks each. With 3 Applications each with 20 blocks, a maximum of n=318 readings can be stored per block. The matrix measuring mode is suited for -ferrite content measurements when the measurements are to be made on different specimens of the same type in succession, always at certain reference areas, and the measure- ments of corresponding areas are to be combined into blocks.

- Page 119 Automatic Block changing Automatic Block changing must be selected for the next reading to be stored in the next block automatically. Free block selection is not available with automatic block changing! After the audible signal for the measurement acquisition, a long audible sig- nal will sound to indicate block changing ( 7.3.4 ‘Audible Signals After the Measurement Acquisition’, beginning on Page 90).

- Page 120 Key sequ. / Detail of the display Explanation Action Use the arrow keys to select the desired block and ENTER to confirm the block se- lection. The display shown to the left appears if a new block (without readings) is selected. Make the measurement in the selected block on the next specimen.

- Page 121 7.8.5 Assigning Block Designations When making measurements in the Matrix mode, a customer-specific des- ignation that can be comprised of a max. of 16 ASCII characters can be assigned to every Application and every block ( 5.5 ‘Assigning Applica- tion Designations’, beginning on Page 44). Assigning the block designation can be carried out in the following man- ner: Use of the optional software Fischer DataCenter (scope of supply)

-

Page 122: Evaluation

Evaluation The following options are available for evaluating the measured -ferrite contents: Evaluation of the current block (Block result) Evaluation of the open Application (Final result) An evaluation cannot be carried out in an Application, where no measure- ments have not yet been stored or where the measurements have been de- leted! In this case, the display will not change after pressing BLOCK-RES... -

Page 123: Evaluation Of The Current Block "Block Result

Current date 95% confidence interval for the mean value Coefficient of variation V Standard deviation sa (only for the final result if automatic block cre- ation is enabled) Specification limit values LSL and USL Process capability indices Cp and Cpk as well as the estimated value ... - Page 124 When making measurements with a fixed block size and the last block has not been concluded, the next reading will be added to this block (even if ENTER is used to end the evaluation). In this case, the block will be con- cluded only after the number of readings in this block corresponds to the set block size ( 7.3.6 ‘Measurements With a Fixed Block Size’, begin-...

- Page 125 Key sequ. / Detail of the display Explanation Action Notes: [Change block: ] or [Change block: ]: Use to display the block result of the next or previous block. [Single meas: MENU]: Use MENU to display the single readings of ...

- Page 126 1 fe = 10.4% n= 2 fe = 10.4% n= 3 fe = 10.4% n= 4 fe = 10.3% n= 5 fe = 10.2% FISCHER FERITSCOPE FMP30 25.07.08 Appl.No. 0 -- Block result -- Block No.: 3 24.07.08 23:10 Mean value fe.

- Page 127 | | 10.4 3| | | | 10.4 4| | * | | 10.3 5|<<| | | 10.2 FISCHER FERITSCOPE FMP30 25.07.08 Appl.No. 0 -- Block result -- Block No.: 3 24.07.08 12:11 Mean value fe. = 10.33 +/- 0.13% Std.

- Page 128 PRINT . The printout will then include a list of the readings of this block as well. 8.1.3 Computed parameters - Block result FERITSCOPE FMP30 Instrument type: 2008-07-25 Current date Appl. No. Application name/Application number (appears only if a designation has been assigned ( 5.5 ‘Assigning...

-

Page 129: Evaluation Of The Open Application "Final Result

Highest value Highest block mean value (Maximum) LSL/USL Upper / lower specification limit Reading is within the tolerance limits << / >> Reading violates the tolerance limits !/!! The measurement was recognized as an outlier With the Matrix measuring mode enabled (indicated by on the display), the block result will not be printed by pressing BLOCK- RES. - Page 130 Key sequ. / Detail of the display Explanation Action FINAL-RES Use FINAL-RES to start the evaluation of the open Application. [Page: FINAL-RES]: Pressing FINAL-RES again: Displays additional computed quan- tities. [Page: FINAL-RES]: Pressing FINAL-RES again: Displays additional computed quan- tities. [Info: CAL]: Press CAL to display an ex- planation of the computed parameter: appears on the display when the toler-...

- Page 131 Key sequ. / Detail of the display Explanation Action FINAL-RES Notes about finishing the final result using FINAL-RES. [Delete meas.: DEL]: Use DEL to delete all readings of the evalu- ated Application. [Exit: ENTER]: To end the final results function without deleting the readings use ENTER.

- Page 132 FISCHER FERITSCOPE FMP30 27.06.08 Product ......Name ......Appl.No. 0 -- Final result -- from 27.06.08 11:26 to 27.06.08 11:27 Mean value fe..= 39.84% Est.StdDev.. Ã^ = 1.88% COV = 19.11% smallest block= 8.89% largest Block = 10.33% Fig. 8-5 Printout of a final evaluation (example)

- Page 133 8.2.2 Computed Parameters - Final Result FERITSCOPE FMP30 Instrument type: 2008-06-27 Current date Product ..Name ..Appl. No. Number of the Application -- Final result -- Result type from ... to ... Date and time of the last block closure of the first and the last block or the current date and the current time (if the last block is not yet closed).

- Page 134 8.2.3 Histogram A histogram ( Fig. 8-7) will be printed after the final result only if the re- spective histogram mode has been set up in the service functions 10.5.5 ‘Histogram’, beginning on Page 164) and there are least 30 readings stored in the Application ( 10.8 ‘Storage Mode’, beginning on Page 184).

- Page 135 Skewness and kurtosis are printed out only if the evaluated readings do not have normal distribution (with a normal distribution, skewness and kurtosis are Zero!): H I S T O G R A M 10.1| 7 |* 10.2| 12 |* 10.2| 2 |* 10.3|...

-

Page 136: Data Transfer

Data Transfer Basic computer knowledge regarding configuration, operation and pro- graming as well as knowledge of the software in use, which may be obtained form respective instruction manuals, is required when using the instrument in conjunction with a computer. For data transfer you can use the following interfaces: ... -

Page 137: Usb Connection To A Pc

USB Connection to a PC Connect the USB port of the instrument with the USB port of the PC. Use the USB cable supplied with the instrument. Fig. 9-1 Side view of the instrument with the USB port Installing the USB Drivers If there is no USB driver installed for the USB connection on your PC, pro- ceed as follows: If the USB driver was downloaded from a Website of FISCHER: Before... -

Page 138: Com Module (Option, Rs232-Connector)

COM Module (Option, RS232-Connector) RS232 interface, 9 pin Micro-T-plug Pin-out Pin1 not used Pin5 GND Pin2 T x D (Transmit Data, ) Pin6 not used Pin3 R x D (Receive Data, ) Pin7 CTS (Clear To Send, ) Pin8 RTS (Request To Send, ) Pin4 not used Pin9 not used Use FISCHER interface connection set MP (602-341) for connecting the... - Page 139 is connected to the computer during the measurement and the data are out- put immediately (online) via the interface port. If the setting in the service function is “USB/Output/Individual Values”, the single readings are output immediately following the measurement acquisi- tion via the interface port.

-

Page 140: Transmission From The Pc To The Instrument

9.4.2 Offline Operation With offline operation, the data stored in the instrument are output at a later time (offline) via the interface port. The data output is triggered by pressing PRINT If the setting in the service function is “USB/Output/Individual Values”, the single readings are output via the interface port after pressing PRINT If, on the other hand, the setting is “USB/Output/Block mean values”, only... - Page 141 9.5.2 Control Commands The instrument can be remote controlled and can request readings and oth- er data by sending the control commands from the PC to the instrument. The requested readings or the data, respectively, are then transmitted by the in- strument via the interface port and received by the PC.

- Page 142 Command Function Operates the MENU key ESC9 G0 or Trigger a measurement; the measurement reading is saved in the ES or instrument. EN or Response of the instrument: Measurement reading ESC? Requests the number of the current Application. GAN0 Requests the designation of the Application with the number 0 (...

- Page 143 Command Function Request the number of measurement blocks in the open applica- tion file from the instrument. Response of the instrument: Number of blocks IEX0 Checks if the Application with the number 0 (... 99) is set up in the instrument. The instrument outputs “1” if the Application is set IEX99 up and “0”...

- Page 144 Command Function SBN0 Assigns a designation for the Application with the number 1 (... 1000). After receiving the command “SBN”, the instrument SBN999 sends the ASCII character “ACK”. The transfer of the designation that the block is to receive must occur directly thereafter, time-out after 1 second.

- Page 145 Command Function XN or Requests the current normalized countrate. Outputs the current normalized countrate, but does not store it in the instrument. XX or Requests the current count rate Outputs the current count rate but does not store it in the instru- ment.

-

Page 146: Connecting A Printer

Connecting a Printer Connect the USB port of the instrument with the USB port of the Printer. Use the USB cable supplied with the instrument. Fig. 9-2 Side view of the instrument with the USB port You can obtain an overview of printers that are suitable for connection ... -

Page 147: Instrument Settings - Service Function Menu

10 Instrument Settings - Service Function Menu The instrument settings described below are configured from the Service function menu. How to access the “Service function” menu: Key sequ. / Detail of the display Explanation Action ON/OFF Use ON/OFF to turn the instrument on 5 x ENTER After pressing ENTER 5 times, the identifi- cation number 157 appears on the display. -

Page 148: Service Menu Overview

The descriptions below assume that the service functions have been retrieved and not yet exited. 10.1 Service Menu Overview start on Service menu Functions Page System Language Time Date Date format Brightness Light Auto. switch off Initialization Evaluation Block result Histogram USB* Output to port... -

Page 149: System

start on Service menu Functions Page Measurement Audible signal Measurement signal Extern start Measuring Mode - Standard/ Area Measurement/Auto Measurement Unit Measured variable Air value acceptance Storage mode store/do not store/delete at off Master calibration Performing a master calibration About ... Information about the instrument configura- tion 10.2 System... -

Page 150: Time

Key sequ. / Detail of the display Explanation Action ENTER Select the desired language by pressing the arrow keys and confirm the selec- tion with ENTER. 10.2.2 Time Key sequ. / Detail of the display Explanation Action Select System from the service menu. Use ENTER to confirm the selection. -

Page 151: Date

10.2.3 Date Key sequ. / Detail of the display Explanation Action Select System from the service menu. Use ENTER to confirm the selection. ENTER Select the Date by pressing the arrow keys and confirm the selection with EN- TER. -

Page 152: Date Format

10.2.4 Date format Key sequ. / Detail of the display Explanation Action Select System from the service menu. Use ENTER to confirm the selection. Select the Date format by pressing the ar- ENTER row key and confirm the selection with ENTER. -

Page 153: Brightness

10.2.5 Brightness Use the brightness setting to adjust the display brightness continuously. The value can be between 0 (brightest display) and 99 (darkest display). The default brightness setting is 60. Key sequ. / Detail of the display Explanation Action Select System from the service menu. Use ENTER to confirm the selection. -

Page 154: Light

10.2.6 Light The following options are available for the light setting” “off after n sec”: The light turns off after n seconds. “always off”: The light is always off. “always on”: The light is always turned on. “on w. - Page 155 Key sequ. / Detail of the display Explanation Action always on After confirming the selection “always on” ENTER with ENTER, you are immediately returned to the menu in order to enter additional set- tings. on w. power unit After confirming the selection “on w.

- Page 156 10.2.7 Automatic Switch Off Key sequ. / Detail of the display Explanation Action Select System from the service menu. Use ENTER to confirm the selection. ENTER Select Auto. switch off by pressing the ar- row keys and confirm the selection with ENTER.

-

Page 157: Initialization

10.2.8 Re-Initialization of the Instrument The restoration of the default settings of the instrument is called re-initializa- tion. With a re-initialization of the instrument, all Applications are deleted, i.e., the stored measurement data as well as the normalizations and the corrective calibrations of all Applications (thus, after a re-initialization, all Applications must be set up anew!), all readings are deleted, ... - Page 158 Press DEL only if the re-initialization is indeed desired! [Continue: ENTER]: Press ENTER will re- turn you to the System menu. ® Operator‘s Manual FERITSCOPE FMP30 Page 153...

-

Page 159: Evaluation

10.3 Evaluation 10.3.1 Block Result Key sequ. / Detail of the display Explanation Action Select Evaluation from the service menu. Use ENTER to confirm the selection. ENTER Select Block Result by pressing the arrow keys and confirm the selection with ENTER. -

Page 160: Histogram

10.3.2 Histogram A histogram can be presented as well when the final result is displayed.( 8.2 ‘Evaluation of the Open Application “Final Result”’, be- ginning on Page 124.) At least 30 readings are required for this. To dis- play the histogram, proceed as follows: Key sequ. -

Page 161: Usb

10.4 USB 10.4.1 Output Key sequ. / Detail of the display Explanation Action Select USB from the service menu. Instrument with Bluetooth module: Select USB/Bluetooth. Instrument with COM module: Select USB/ COM. Use ENTER to confirm the selection. ENTER Select the desired output mode by pressing ... -

Page 162: Group Separator

10.4.2 Group Separator Key sequ. / Detail of the display Explanation Action Select USB from the service menu. Instrument with Bluetooth module: Select USB/Bluetooth. Instrument with COM module: Select USB/ COM. Use ENTER to confirm the selection. ENTER Select the desired groups separator mode ... - Page 163 10.4.3 Send Free-Running Mode Key sequ. / Detail of the display Explanation Action Select USB from the service menu. Instrument with Bluetooth module: Select USB/Bluetooth. Instrument with COM module: Select USB/ COM. Use ENTER to confirm the selection. ENTER Select the desired free-running mode by ...

- Page 164 Key sequ./ Detail of the Explanation Action display Set the desired data transfer parameters in the menus COM-Baud, COM-Parity and COM-Handshake. Select the menu/parameters by using the ENTER arrow keys and confirm the selec- tion with ENTER. Use DEL at any time to cancel the proce- dure.

-

Page 165: Printing

10.5 Printing 10.5.1 Printer Selection Key sequ. / Detail of the Explanation Action display Select Print from the service menu. Use ENTER to confirm the selection. ENTER Select the Printer by pressing the arrow and confirm the selection with ENTER. - Page 166 10.5.2 Left Margin Setting Key sequ. / Detail of the display Explanation Action Select Print from the service menu. Use ENTER to confirm the selection. ENTER Select Left Margin by pressing the arrow and confirm the selection with ENTER.

-

Page 167: Block Result

10.5.3 Block Result Corresponding to the setting, press BLOCK-RES 8.1.1 ‘Documenting the Block Result With a Printer’, beginning on Page 121) to print the block result. The following setting options exist: Key sequ. / Detail of the display Explanation Action Select Print from the service menu. -

Page 168: Final Result

10.5.4 Final Result Corresponding to the setting, press FINAL-RES 8.2.1 ‘Documenting the Final Result with a Printer’, beginning on Page 126) to print the FINAL re- sult. The following setting options exist: Key sequ. / Detail of the display Explanation Action Select Print from the service menu. -

Page 169: Histogram

10.5.5 Histogram A histogram can be added to the printout of the final result if at least 30 readings are stored in the Application ( 8.2.3 ‘Histogram’, beginning on Page 129). Key sequ. / Detail of the display Explanation Action Select Print from the service menu. -

Page 170: Auto Formfeed

10.5.6 Auto Formfeed Key sequ. / Detail of the dis- Explanation Action play Select Print from the service menu. Use ENTER to confirm the selection. ENTER Select Auto Formfeed by pressing the ar- row keys and confirm the selection with ENTER. -

Page 171: Device Mode

10.6 Device Mode 10.6.1 Restricted Operating Mode When the restricted operating mode is enabled, only the keys necessary for measurement and evaluation are active. This avoids erroneous measure- ments due to unintentional adjustments of instrument parameters. The following keys are active in the restricted operating mode: ZERO ... - Page 172 Key sequ. / Detail of the display Explanation Action Select the desired operating mode by press- ing the arrow keys and confirm the selection with ENTER. [off]: The restricted operating mode is dis- abled, i.e., all functions are enabled ac- cording to their settings.

-

Page 173: Analog Display

10.6.2 Analog Display When making measurements in the “free-running” display mode, the ana- log display facilitates a quick recognition of tendencies in the -ferrite con- tent changes. If analog display is enabled and measurements are made in the “free-running” display mode, the analog display with the set limits will appear in place of the information lines. -

Page 174: Matrix Mode

10.6.3 Matrix Mode Key sequ. / Detail of the display Explanation Action Select Device Mode by pressing the arrow keys and confirm the selection with ENTER. ENTER Select the Matrix mode by pressing the ar- row keys and confirm the selection with ENTER. - Page 175 Key sequ. / Detail of the display Explanation Action ENTER When changing to a different measuring mode, the instrument will b re-initialized 10.2.8 ‘Re-Initialization of the Instru- ment’, beginning on Page 152). [Yes: DEL]: Press DEL to carry out the re- initialization.

- Page 176 ENTER Select the desired block change by pressing the arrow keys and confirm the se- lection with ENTER. [Manually]: The block change must be do- ne manually, i.e., when making measure- ments in the matrix mode, the block where the next reading is to be stored can be se- ...

- Page 177 10.6.4 Linking Applications Key sequ. / Detail of the display Explanation Action Select Device Mode by pressing the arrow keys and confirm the selection with ENTER. ENTER Select Linking by pressing the arrow key and confirm the selection with EN- TER.

-

Page 178: Measurement

10.7 Measurement 10.7.1 Audible Signal The audible signal, i.e., the measurement acquisition signal that sounds af- ter every measurement can be disabled. The audible signals that sound after instrument power-up, after a toler- ance limit violation, after recognition of an outlier measurement or after concluding a block (when making measurements with automatic block creation) cannot be disabled! (Details about the audible sig- nals:... - Page 179 10.7.2 Measurement Signal Key sequ. / Detail of the display Explanation Action Select Measurement by pressing the arrow and confirm the selection with ENTER. ENTER Select Measurement signal by pressing the arrow keys and confirm the se- lection with ENTER.

- Page 180 10.7.3 External Start Key sequ. / Detail of the display Explanation Action Select Measurement by pressing the arrow and confirm the selection with ENTER. ENTER Select Extern start by pressing the arrow keys and confirm the selection with ENTER.

- Page 181 Key sequ. / Detail of the display Explanation Action Select the desired “delay” by pressing the ENTER arrow keys and confirm the selec- tion with ENTER. [0 ms]: no pause after external start [100 ms]: 100 ms pause after external start [2500 ms]: 2500 ms pause after external start [Page : CAL]: Press CAL to leaf through...

- Page 182 10.7.4 Measuring Mode - Standard/Area Measurement/Automatic Measurement Key sequ. / Detail of the display Explanation Action Select Measurement by pressing the arrow and confirm the selection with ENTER. ENTER Select Measuring Mode by pressing the ar- row keys and confirm the selection with ENTER.

- Page 183 Key sequ. / Detail of the display Explanation Action Select the mode for “Automatic measure- ment” by pressing the arrow keys Automatic measurement is possible (en- abled) 7.3.3 ‘Automatic Measurement Acquisi- tion’, beginning on Page 87. Use ENTER to confirm the selection. Use DEL at any time to cancel the proce- dure.

- Page 184 10.7.5 Unit You can specify the unit of measurement for making measurements in the newly set up Application. Key sequ. / Detail of the display Explanation Action Select Measurement by pressing the arrow and confirm the selection with ENTER.

- Page 185 10.7.6 Measured Variable The menu option “Measured variable” appears only when the current Ap- plication is set up. Key sequ. / Detail of the display Explanation Action Select Measurement by pressing the arrow and confirm the selection with ENTER.

- Page 186 Key sequ. / Detail of the display Explanation Action With every modification of the measured variable, a prompt for deleting readings al- ready stored in the open Application will appear because it is not possible to evalu- ate different types of measured variables statistically at the same time.

- Page 187 since this last manual air value capture. When becomes a static air value measurement necessary? If the probe contacts the specimen with very different speeds, or if the touch-down procedure is very slow. If the probe cannot be lifted off sufficiently from the specimen between ...

- Page 188 Key sequ. / Detail of the display Explanation Action Confirming with ENTER will return you to the menu for the measurement. Use DEL at any time to cancel the proce- dure. Manual Air Value Capture To keep the measurement errors with static air value measurements as low as possible, normalizations should be carried out at relatively regular inter- vals.

-

Page 189: Storage Mode

10.8 Storage Mode Key sequ. / Detail of the display Explanation Action Select Storage mode by pressing the ar- row key and confirm the selection with ENTER. ENTER Select the desired mode by pressing the ar- row keys and confirm the selection with ENTER. -

Page 190: About

10.10 About ... Key sequ. / Detail of the display Explanation Action Select About ... by pressing the arrow key and confirm the selection with EN- TER. ENTER Displays the software version, the internal state and the name of the connected probe. Pressing ENTER repeatedly displays the in- strument configuration in succession (cf. - Page 191 FISCHER FERITSCOPE FMP30 25.07.08 Software version : FFA00i18 internal state : 03 00000685 a Probe : FGAB1.3Fe Serial number : 0708V00001 Meas. range : 0.15 - 105 Language : english Date format : european Contrast : 71 Auto. switch off...

-

Page 192: Malfunctions And Messages

11 Malfunctions and Messages 11.1 Malfunctions start Malfunction/Message Cause Correction Page Use ON/OFF to turn the No display Instrument not switched instrument on. Use ON/OFF to turn the Instrument switched off automatically (energy instrument on. savings function during operation without AC adapter Batteries are dis- Replace rechargeable... - Page 193 start Malfunction/Message Cause Correction Page Use ON/OFF + EN- Unable to set up, Restricted operating TER to disable the re- overwrite or delete mode is enabled. Applications. stricted operating mode with the instrument switched off before- hand. Unable to retrieve the “Free-running”...

- Page 194 start Malfunction/Message Cause Correction Page Probe does not mea- Automatic Enable automatic mea- sure measurement acquisition surement acquisition disabled. from the service func- tions or trigger the ex- ternal measurement acquisition by pressing key (or FINAL- RES during the normal- ization or calibration).

- Page 195 start Malfunction/Message Cause Correction Page Wrong readings Wrong voltage due to Connect the correct AC connecting a wrong AC adapter. adapter (e.g., for 110 V instead of 220 V). Probe tip worn. Use a probe with a proper probe tip. Printer prints hiero- Wrong printer setting in Select an appropriate...

-

Page 196: Messages On The Display

11.2 Messages on the Display The error messages (E***) and warning messages (W***) that may occur during instrument operation are contained in the overview on the following pages. start Malfunction/Message Cause Correction Page Reading cannot be dis- Perform the measure- played (because the val- ment correctly (e.g., do - - - -... - Page 197 start Malfunction/Message Cause Correction Page Instrument-internal error. Use ON/OFF to turn the instrument off and then again on. Math Error ! If this error occurs re- peatedly: Inform cus- tomer service. The internal instrument Delete the measure- memory is full. ment data stored in the Application or delete a Appl.

- Page 198 start Malfunction/Message Cause Correction Page Cause: ENTER was Place the probe on the pressed during the mea- specimen and then press ENTER to trig- surement in the “free-run- ning” display mode ger the measurement while the probe was lift- acquisition. ed off.

- Page 199 start Malfunction/Message Cause Correction Page Unable to complete cor- Repeat the corrective rective calibration. calibration and perform Cause: Measurement the calibration measure- Measurements carried out incorrectly. ment correctly (e.g., do not allow the probe to hover over the standard before or after the mea- surement;...

- Page 200 start Malfunction/Message Cause Correction Page Cause: Calibration stan- Repeat the master cali- dards used that did not bration with correct and exhibit the required good calibration stan- dards. ferrite content or are de- fective. Instrument-internal er- Repeat the master cali- ror: Unable to compute bration.

- Page 201 start Malfunction/Message Cause Correction Page Unable to generate the Take additional mea- final result when mak- surements until the first ing measurements with block is concluded and Not enough fixed block sizes if the re-create the final result. measurements ! first block of the evaluat- ed Application is not closed.

- Page 202 start Malfunction/Message Cause Correction Page Instrument-internal error. Delete the faulty Appli- cation and output the measurement data via Error in the interface port. application ! ([Delete Appl.? Yes: DEL N.:EN- TER]: DEL to deleted the Application. [To port? Yes: DEL N.:EN- TER]: DEL to output the measurement data...

- Page 203 start Malfunction/Message Cause Correction Page Current consumption of Check and/or replace a connected USB de- connected USB device. vice too high (max. 100 USB overcur- mA permitted). rent ! The measurement elec- Inform customer ser- tronics has not been bal- vice.

- Page 204 start Malfunction/Message Cause Correction Page Unable to create an ad- Delete the measure- ditional block because ment data stored in the the maximum number of Application or delete a Block memory 4,000 blocks has been complete Application. overflow ! reached. Printer switched off or of- Turn printer on or place fline.

- Page 205 start Malfunction/Message Cause Correction Page Two-point calibration Repeat the corrective performed with calibra- calibration with suitable tion standards with calibration standards. fer- 1-Point The difference of the rite contents that are not calibration ! normalized count Xn of sufficiently far apart (will the two calibration stan- be considered a one- dards must be greater...

-

Page 206: Glossary

12 Glossary 12.1 Terms and Formula Symbols See “Additional Literature” on Page 228. This chapter explains the most common terms and symbols in -ferrite content measurement and related fields (e.g., quality assurance). In some cases, alternate terms or synonyms are mentioned in parentheses. ... - Page 207 Application Measurement Application of the User. In the field of -ferrite content measurement, an Application (memory) re- fers to a memory that stores the coefficients that are determined during the normalization and corrective calibration for each measurement ap- plication as well as the single readings measured in this Application. In addition, the application-specific settings are stored in the applications.

- Page 208 Block result After pressing the BLOCK-RES key, the measurements will be combined into a block and the results of the evaluation of the current block (e.g., mean value and standard deviation of the measurements combined into this block) will be displayed or printed. Block size Number of single readings that are combined to form a block.

- Page 209 The ferrite content Fe is displayed as a function of the countrate Xn in a calibra- tion curve. Xn = 0 Base (ferrite content: 140 FN or 105 Fe%) Xn = 1 ferrite content: 0 FN or 0 Fe% Figure 16.3: Calibration curve ...

- Page 210 Carriage Return (CR) Carriage return. CR is a character of the ASCII character set with the following function: When data or commands are entered, the line one is currently working on will be closed by pressing the CR key (Enter or Return key);...

- Page 211 Countrate Digitized form of the measurement signal, which is proportional to the -ferrite content and is produced in the probe by the -ferrite content. The larger the -ferrite content is, the smaller is the countrate. Calibration curve (characteristics) The numeric values of the normalized countrate Xn range between 0 and 1, and are calculated according to the following equation: –...

- Page 212 the FERITSCOPE ® FMP30, Excess is calculated according to the infor- mation in / 20 / and stated as curvature. Data transfer rate Baud Rate Difference Measurement error to the nominal value (= reference value) of the standard. Parameter in the check result of the instrument function CAL-Check.

- Page 213 --------------------------------------------------------- ------------------------ - where:Fe. = Mean value (block mean value) = single reading N = single readings (of a block) Fe.. Mean value of the block mean values of the evaluated blocks. Standard deviation of the readings that have been taken using a fixed block size. Is output only if fixed block size Block ...

- Page 214 Gaussian normal distribution Normal distribution (Gaussian normal distribution, Gaussian distribution) Gaussian probability paper Probability chart (Gaussian probability paper, sum frequency chart, probability paper) Gaussian distribution Normal distribution (Gaussian normal distribution, Gaussian distribution) Group Separator mark for the end of a block that can be transferred together with the measurement data to the PC.

- Page 215 Kolmogoroff Smirnoff Test Test, which is performed when evaluating the current application with the FERITSCOPE ® FMP30 to determine whether the evaluated measure- ments can be classified as having normal distribution (if up to 40 mea- surements are to be evaluated). Kurtosis Curvature Line feed (LF)

- Page 216 ment. The measurement can be obtained as the result of a single mea- surement or as arithmetic mean of several single measurements (e.g., when auto averaging mode is enabled). Measurement accuracy Tolerance limits (Specification limits) Specification limits (LSL and USL) Measurement block Block Measurement errors...

- Page 217 measurement application. Measurement Series A series of single readings between two block or final results. Measuring Measuring is comparing. The probe signal generated at the measuring position is compared to the probe signal of the calibration standard. Us- ing the calibration curve, the instrument converts the probe signal to the measurement result.

- Page 218 backscatter and X-ray fluorescence methods). During normalization, the calibration curve is adjusted to the individual measurement application that the open Application is calibrated for. The coefficients of the adjust- ed calibration curve are stored in the open Application. The coefficients of the master calibration curve, which are stored in the EEPROM of the probe plug, are not affected.

- Page 219 termined using the standard deviation of the sample mean values (since the sample mean values can be classified as having normal distribu- tion). Whether a quantity can be classified as having normal distribution can be checked in the normal probability chart, since a straight line in the normal probability chart indicates normal distribution.

- Page 220 Parity An error checking method where the digits of a number of error-free transmitted bit groups must add up to an even or an odd number. During data transfer the parity bits are added to the data bits of each character or Byte to be transferred.

- Page 221 – ----------------------------------- - 6 ˆ – Fe.. Fe.. UGW – ------------------------------ - ------------------------------ - 3 ˆ 3 ˆ where:Fe..: Mean vale of the group mean values Cp: process capability index Cpk: critical process capability index USL: upper specification limit...

- Page 222 ˆ d where:R. = mean range ˆ = Estimated value of the standard deviation s of the population = Factor, depends on the random sample size, can be obtained from popular published tables. Rechargeable battery Accumulator (German abbreviation Akku). Rechargeable. Used like any battery.

- Page 223 entire lot (batch, unit of production). Random sample size Number of parts, combined into a random sample. Range Reference measurement Measurement on a reference sample to check the normalization or cal- ibration which was performed before. Reference sample Specimen with a known -ferrite content on a defined reference area ...

- Page 224 conditions is a measure for the repeatability. The smaller the standard deviation of these measurements, the better is repeatability. The repeat- ability is dependent on the test method and the quality of the instrument, but often also on the properties of the specimen (e.g., surface rough- ness).

- Page 225 standard deviations can still have the same mean value. Figure 16.8: Measurement series with the same mean value but different standard devia- tion Standard deviation of the readings that have been taken using a fixed block size. -------- - where:s.

- Page 226 If, for instance, the same number of measurements is performed on sev- eral specimens and the readings on each object are combined into a block (e.g., when making measurements with a fixed block size), s. is a measure for the instrument deviation and sa is the product deviation with the instrument deviation eliminated.

- Page 227 mean value. A negative skewness indicates a distribution whose peak stretches more towards values that are smaller than the mean value. The skewness of symmetric distributions is zero (e.g., for normal distribu- tions). When evaluating the open Application with the FERITSCOPE ®...

- Page 228 used to control the production process. This modern method of quality control ensures constant good manufacturing quality, with a minimum level of rejected parts. Normal distribution of the measurements is re- quired so that statistical process control can be used for quality control purposes.

- Page 229 Check function from the measurement readings of the control mea- surement and the characteristics of the standard on which the control measurement was carried out. The test value is the result of the ratio of difference to uncertainty (k=2). E 1: The measurement accuracy for the opened application file is ok for this standard and cannot be further improved by this standard.

- Page 230 ment result generally obtained under practical conditions. Tolerance limits (Specification limits) Specification limits (LSL and USL); for detailed information, see / 20 /.) The true value is a value known from mathematical theoretical formulations. Since such values are seldom encountered, a value deduced from national or interna- tional standards is taken as “right”.

- Page 231 certainty takes the measurement uncertainty (U ) of the control measurement and the specified measurement uncertainty (U ) of the standard (= reference part) into account for a confidence level of 95.45 %, corresponding to the extension factor k=2. The calculations are made according to ISO/IEC Guide 98-3.

- Page 232 Countrate Normalized countrate. Countrate Countrate obtained when measuring on a measuring object with no ferrite content. Countrate ® Operator‘s Manual FERITSCOPE FMP30 Page 227...

-

Page 233: Additional Literature

12.2 Additional Literature 12.2.1 Statistics and -ferrite content measurement / 1 / American Welding Society 1974: Standard procedures for cali- brating magnetic instruments to measure the delta ferrite content of austenitic stainless steel weld metal (AWS A4.2M); Miami, Florida / 2 / DataMyte Corporation: DataMyte Handbook - A practical guide to computerized data collection for Statistical Process Control... - Page 234 12.2.2 Standards / 12 / DIN 1319, Parts 1, 2 and 3: Basic Concepts in Metrology / 13 / DIN EN ISO 2064: Definitions and Conventions Concerning the Measurement of Coating Thicknesses (previously DIN 50 982, Part 1) / 14 / DIN EN ISO 2178: Measurement of Coating Thicknesses: Magnet- ic Methods (previously DIN 50 981) / 15 /...

- Page 235 ® Page 230 Operator‘s Manual FERITSCOPE FMP30...

-

Page 236: Index

Index automatic 171 manual 171 Block Creation automatic 49 Block mean values 156 AC adapter, connector socket 7 Block size 91 Accessories 15 Brightness 148 Acoustic signals 89 Air humidity 18 Air value Calibration manual capture 183 Deleting corrective -Martensit, display 52 calibration 68 Ambient Temperature 3 Master calibration 70... - Page 237 Driver installation 132 Instrument configuration 185 Print form 185 Instrument mode 166 EEPROM 15 Instrument setting 142 Measured variable 180 EMC 2 Printer 141 Enabled specification limits 91 Service functions 142 Environmental Conditions 2 Instrument settings Error messages 191 Analog display 168 Evaluation Area measurement 177 Print 141...