Advertisement

9668 Heinrich Hertz Dr # D, San Diego, CA 92154

PH. 619-946-1224

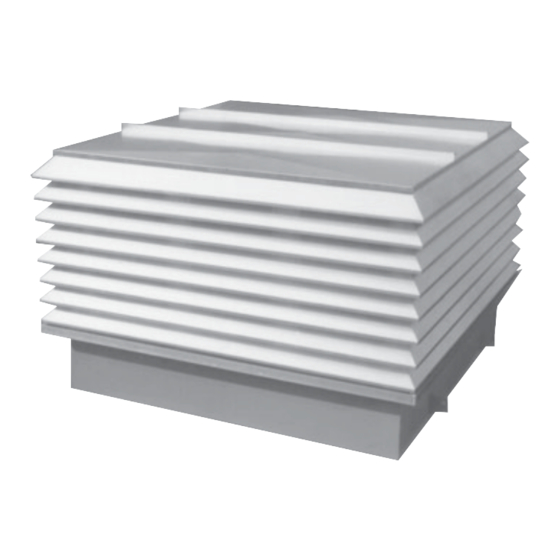

This publication contains the installation, opera-

tion and maintenance instructions for standard

units of the CLS- Centrifugal Filtered Supply

Fans. Carefully read this publication prior to any

installation or maintenance procedure.

The Romlair catalog, CLS, provides additional

information describing the equipment, fan perfor-

mance, and available accessories.

For additional safety information, refer to AMCA

publication 410-96, Safety Practices for Users and

Installers of Industrial and Commercial Fans.

Receiving and Inspection

Inspect the fan and accessories for any damage and

shortage immediately upon receipt of the fan.

• Rotate the blower wheel by hand to ensure it turns

freely. If necessary, shift wheel position and re

tighten.

• Inspect dampers (dampers are optional), for good

operation.

Handling

Lifting Lugs are installed on the base to facilitate

lifting. Never lift by the louver tiers.

WARNING

This unit has rotating parts. Safety precautions

should be exercised at all times during installation,

operation, and maintenance.

ALWAYS DISCONNECT POWER PRIOR TO WORKING

ON FAN.

Storage

Any time the fan is stored for a lenth of time prior to

installation, fill the bearings with grease or moisture-

inhibiting oil. The blower wheel should be rotated

every three to five days to keep a coating of grease

on all internal bearing parts.

The fan should be stored in its original crate and

protected from dust, debris and the weather.

Personal Safety

Disconnect switches are recommended. Place the

disconnect switch near the fan in order that the

power can be cut off quickly in case of an emergency,

and in order that maintenance personnel are provided

complete control of the power source.

READ AND SAVE THESE INSTRUCTIONS

INSTALLATION AND MAINTENANCE INSTRUCTIONS

MODEL CLS

Centrifugal Filtered Supply Fans

Installation

Motor Installation

Most units come with the motors, belts, and drives

installed. No installation of motor and drives are

required.

Duct Installation

Good fan performance requires proper installation of

inlet and discharge ducts. The fan should conform to

the following guidelines.

Free Discharge

Free Discharge

A free discharge into the plenum should be avoided.

Free discharge into the plenum does not allow for a

static regain, resulting in loss efficiency.

Advertisement

Table of Contents

Summary of Contents for Romlair CLS

- Page 1 INSTALLATION AND MAINTENANCE INSTRUCTIONS This publication contains the installation, opera- tion and maintenance instructions for standard units of the CLS- Centrifugal Filtered Supply Fans. Carefully read this publication prior to any installation or maintenance procedure. The Romlair catalog, CLS, provides additional information describing the equipment, fan perfor- mance, and available accessories.

-

Page 2: Wiring Installation

Wheel-to-Inlet Clearance Discharge Duct Turns Wheel-to-inlet clearance is very important for optimal It is good pratice to allow 3 duct diameters between fan performance. This clearance should be checked duct turns or elbows and the fan outlet. Refer to the before initial start-up. -

Page 3: Pulley Alignment

Wheel Rotation Proper Wheel Rotation Test the fan to observe the rotation of the blower wheel and to ensure the rotation is the same as indicated by the direction arrow. On 3 phase motors, If the wheel is rotating in the wrong direction, reverse rotation by switiching two of the supply leads. - Page 4 Pre- Start Up T " 1. Disconnect and lock-out all power switches to fan. See warning below. 2. Check all fasteners, set screws and locking collars on the fan, bearings, drive, motor base and access- ories for tightness. 3. Inspect the V-belt drive for proper alignment and tension.

-

Page 5: Bearing Lubrication

When operating conditions of the fan are to be changed (speed, pressure, temperature, When a bearing failure occurs, it is important that the etc.) consult Romlair to determine if the unit failed bearings be preserved as well as possible and can operate safely at the new conditions. -

Page 6: Troubleshooting

* Always check motor amps and compare to nameplate rating. Excessive fan speed may overload the motor and result in motor failure. Do not exceed the maximum cataloged rpm of the fan. NOTE: Always provide the Romlair Model number and serial number when requesting parts or service information. - Page 7 The roof opening may be made larger. allowing the installer to complete the ductwork 2. Romlair Model CF roof curb (Extra Heavy Duty) are before the fan is set in place. Additional support is designed to accommodate the weight of the Model required for ductwork.

- Page 8 Correction of any verified defects by repair or replacement shall constitute fulfillment of this warranty. ROMLA VENTILATOR COMPANY 9668-D Heinrich Hertz Drive San Diego, California 92154 619/946-1224 • Fax 619/946-1227 Romlair.com...

Need help?

Do you have a question about the CLS and is the answer not in the manual?

Questions and answers