Subscribe to Our Youtube Channel

Summary of Contents for Pall Palltronic Flow Check II

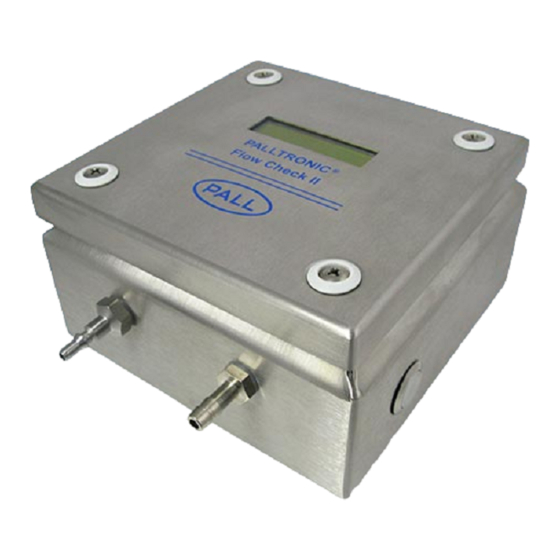

- Page 1 Instructions For Use USD 2642 Palltronic ® Flow Check II Unit Part numbers: FC02, FC02M and FC02H...

-

Page 2: Table Of Contents

Contents Safety and Information Symbols ...................3 1. Safety Instructions ......................3 1.1 Personal Safety ......................3 1.2 Safe Use of the Palltronic Flow Check II Unit..............3 2. Introduction ........................4 2.1 Key Features and Benefits ....................4 2.2 Standard Functions ......................4 3. Using the Palltronic Flow Check II Unit ................5 3.1 Features ........................5... -

Page 3: Safety And Information Symbols

Palltronic Flow Check II unit. Please also read the Operating Instructions for the applicable integrity test instrument which will be used with the Palltronic Flow Check II unit to ensure safe use. The list of literature is as follows: Table 1... -

Page 4: Introduction

Palltronic integrity test instrument is working correctly. The Palltronic Flow Check II unit is used in place of a filter for the purposes of the ‘Flow Check’ test and is available in three flow ranges:... -

Page 5: Using The Palltronic Flow Check Ii Unit

Using the Palltronic Flow Check II Unit Features The Palltronic Flow Check II unit provides two pneumatic ports, as follows: Figure 1 1 = Specification label 2 = ‘IN’ port 3 = ‘Vent’ port The specification label attached to the enclosure displays the certified flow rate using air at an atmospheric pressure of 1000 mbar (14.5 psi), the associated test pressure and the unit serial... -

Page 6: Display Function

• Connect the ‘OUT’ port of the integrity test instrument to the male Stäubli ‘IN’ connection on the Palltronic Flow Check II unit. If an upstream volume is required (see Section 2) then this should be connected between the integrity test instrument and the Palltronic Flow Check II unit. -

Page 7: Performing A 'Flow Check' Test

• Ensure that the ‘VENT’ connection on the Palltronic Flow Check II unit is open to atmosphere. • It is recommended that the red pneumatic tubing supplied with the Palltronic Flow Check II unit be used exclusively for this purpose. -

Page 8: Maintenance

5 seconds to switch the unit off. Used batteries should be discarded in accordance with relevant local and national regulations. The battery will be replaced as part of a standard service and calibration at a Pall facility. Troubleshooting... -

Page 9: Continued Difficulties

• Ensure that the Palltronic Flow Check II unit is dry – if you suspect that the moisture is present in the internal capillary, it is recommended to blow clean, dry air at 2 bar (29 psi) -

Page 10: Appendix A - Atmospheric Pressure Correction Table

Appendix A – Atmospheric Pressure Correction Table The flow value measured with the Palltronic Flow Check II unit is dependent on atmospheric pressure and is given as a reference value normalized for an atmospheric pressure of 1000 mbar (absolute), using air. The unit measures the actual atmospheric pressure which is influenced by the altitude and the actual atmospheric conditions and displays a corrected “expected”... - Page 11 Portsmouth – Europe The information provided in this literature was reviewed for accuracy at the time of publication. Product data may be subject to change without notice. For current information consult your local Pall distributor or +44 (0)23 9230 3303 phone contact Pall directly.

Need help?

Do you have a question about the Palltronic Flow Check II and is the answer not in the manual?

Questions and answers