Table of Contents

Advertisement

Advertisement

Chapters

Table of Contents

Summary of Contents for Bernhard EXPRESS DUAL 3000MC

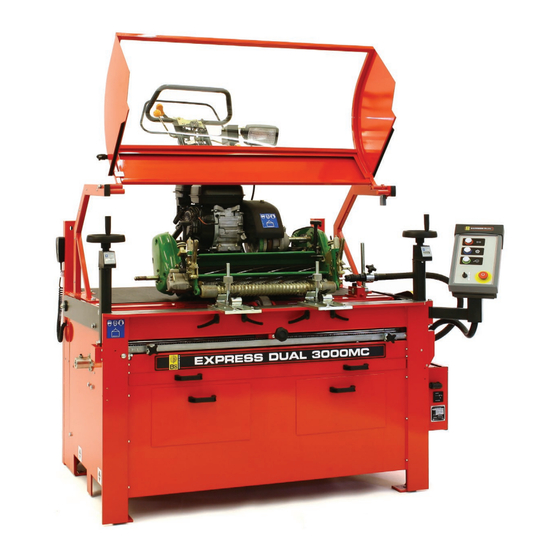

- Page 1 EXPRESS DUAL 3000MC EXPRESS DUAL 3000MC Manual Control Spin Grinder User s Guide & ’ Instruction Manual Please read this manual carefully before using the Express Dual. This manual should be kept in a safe place so that it can be used for future reference.

- Page 2 EXPRESS DUAL 3000MC NOTES ..............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................© Bernhard and Company Limited...

-

Page 3: Table Of Contents

EXPRESS DUAL ED3000MC Manual Control Reel Grinder Welcome to the Bernhard Express Dual 3000MC. If cared for and operated correctly this machine will give you years of good service. This manual will enable you to obtain the best results from your Express Dual so please read it thoroughly before using your machine. -

Page 4: Identification Of Pictograms

TRAPPING FEET OR OTHER OBJECTS WHEN LOWERING LIFT PLATFORM BEWARE! HIGH VOLTAGE MAXIMUM GRINDSTONE DIAMETER 150mm MAXIMUM SPEED 2200 Rev/Min BEWARE! MOVING GRINDSTONE AND SHAFT REEL ROTATING AT BETWEEN 147 AND 255 Rev/Min TOTAL WEIGHT OF MACHINE (KG) © Bernhard and Company Limited... - Page 5 LIFTING EYES BEWARE! MOVING COMPONENTS KEEP HANDS AND OTHER OBJECTS CLEAR WEAR EYE, EAR AND BREATHING PROTECTION TRAVERSE START CONTROL GRINDSTONE START CONTROL REEL START CONTROL STOP CONTROL ENGAGE / DISENGAGE (INCREASE / REDUCE) GRINDSTONE FEED © Bernhard and Company Limited...

- Page 6 EXPRESS DUAL 3000MC Traverse On Reel (Spin) Drive On Grindstone On Clamp Up/Down Motor Stop (E-Stop) (Twist to release) © Bernhard and Company Limited...

-

Page 7: Safety

If a lift table is fitted NEVER attempt to lift in excess of the rated capacity, and always ensure that the area is clear before lowering the load. © Bernhard and Company Limited... -

Page 8: Installation

NOTE Ensure that the packing under the feet is correct before tightening the bolts, otherwise twisting of the frame may occur. © Bernhard and Company Limited... - Page 9 The mainshaft should be washed down as instructed in the maintenance section of this manual. The feed control screws are normally coated with molycote, and may be washed down with WD40 if required and recoated with molycote (or similar anti friction coating) when dry. © Bernhard and Company Limited...

-

Page 10: Identification Of Tools And Equipment

A4097 Adjustable Plain Shaft Driver A2712 8mm Long Series Allen Key A6161 1/8” Allen Key A4087 Channels for Multifix Brackets A6342 Backing up/Pressure Plate (not shown) A6737 Diamond Dresser A9500 Adustable Front Roller / Multifix Brackets © Bernhard and Company Limited... -

Page 11: Understanding The Machine

The rear of the unit will be held by the radiused pressure bar at the rear of the grinder. © Bernhard and Company Limited... - Page 12 NOTE The reset button and overload are both variable and should be adjusted, if required, as indicated in the appropriate service bulletins. The reel drive motor, traverse motor and are protected by individual fuses located in the electrical control box. © Bernhard and Company Limited...

-

Page 13: In Frame Grinding

A backing up plate is supplied to protect the rear of the units and to evenly disperse the force of the pressure bar across the width of the mower (see Fig. 6.3). © Bernhard and Company Limited... - Page 14 “set up guide” should be completed and filed for future reference so that the identical multifix brackets positions can be used for all subsequent applications on the same type of unit. © Bernhard and Company Limited...

- Page 15 The drive head of the shaft can also be slid through it’s support for further adjustment or final connection/ disconnection of drive. 6.4.3 Tighten the drive rod via the allen screw in the flexible coupling onto the flat of the drive shaft. © Bernhard and Company Limited...

- Page 16 By loosening the socket screw and allowing the clamp nut, under the table, to twist through approximately 90 degrees, the whole assembly can be lifted clear of the table, and moved to the other side of the mower unit if required. © Bernhard and Company Limited...

- Page 17 Should the reversing bar be dragged by the traverse assembly in the direction of travel during the grinding processes, causing the stone traverse to reverse prematurely, it will be necessary to adjust the reversing bar damper as indicated in the service bulletin. © Bernhard and Company Limited...

- Page 18 Go back to the right hand end and repeat the process and again release the contact only slightly. NOTE It is important that the grinding wheel should clear the highest blade along the full length of the reel before grinding commences. © Bernhard and Company Limited...

- Page 19 Set the grind stone to the reel as with any other Express Dual, adjusting the independent handwheels until there is a light and steady contact between reel and grind stone across the entire length of the reel. © Bernhard and Company Limited...

- Page 20 NOTE NEVER stop the machine while the grinding wheel and reel are in contact except in an emergency. Never allow the grinding wheel and reel to spark out. If this does happen put another cut on for a few more passes. © Bernhard and Company Limited...

-

Page 21: Electrical Fault Finding

This can best be done by detaching the motor drive and ensuring that the mechanism is moving freely. © Bernhard and Company Limited... -

Page 22: Maintenance

Release the 2 allen screws in the bearing flange ring on the left hand end of the main shaft. 8.1.6 Remove the circlip retaining the left hand side arm to the rear shaft. The side arm can now be removed from the machine. © Bernhard and Company Limited... - Page 23 8.1.15 Apply more feed as necessary to true the grindstone. NOTE Dressing in this way should be carried out periodically to keep the grindstone clean and true BUT remove only the minimum material off the grindstone to keep long service. © Bernhard and Company Limited...

- Page 24 NEVER grip the sleeve and nut assembly in a vice. Fully tighten the nut when the assembly is fitted to the mainshaft. Sleeve Mainshaft Remove minimal material from sides and bottom of key 2nd Key © Bernhard and Company Limited...

- Page 25 NOTE Never apply nor leave any oil or grease on the mainshaft during use. For extended periods of down-time spray on “bright” areas with Bernhard’s Protective oil – clean off with Bernhard’s Clean and Lube spray or WD40 before use.

- Page 26 EXPRESS DUAL 3000MC NOTES ..............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................© Bernhard and Company Limited...

-

Page 27: Part Lists And Exploded Diagrams

MAINSHAFT MOUNTING AND MAIN MOTOR DRIVE _________ 30 TRAVERSE ASSEMBLY __________________________________ 32 REEL DRIVE ___________________________________________ 34 CLAMP ASSEMBLY ______________________________________ 36 MULTI-FIX BRACKET ASSEMBLY _________________________ 38 CONTROL BOX __________________________________________ 40 ELECTRICAL CABINET __________________________________ 41 LIFT TABLE _____________________________________________ 42 © Bernhard and Company Limited... -

Page 28: Main Frame

Drawer Handle ................ 2 A6110 Dust Tray ................. 1 A6323 Dust Tray Handle ..............2 A6111 Drawer Runner (Pad) .............. 4 A6742 Drawer Runner (Drawer) ............4 A6741 M5 x 10 Button Socket Screw ..........8 A5129 © Bernhard and Company Limited... -

Page 29: Feed Assembly

A5303 5/8" whit x 5/8" Socket Screw ......2 A5110 5/8" Washer ............4 A5305 Siko LCD Counter FOR ED3000MC ....2 A8105 Feed Nut ............2 A4043 Inner Bush ............2 A9061 FEED ASSEMBLY © Bernhard and Company Limited... -

Page 30: Mainshaft Mounting And Main Motor Drive

Washer M8 ................4 A5321 Motor Bolt Retaining Plate ............2 A4078 Hex. Set Screw M10 x 70 ............2 A5711 Locknut M10 ................2 A5503 Button Head Socket Screw M5 x 10 ........2 A5129 © Bernhard and Company Limited... - Page 31 EXPRESS DUAL 3000MC © Bernhard and Company Limited...

-

Page 32: Traverse Assembly

Hex Head Screw M6 x 18 ............4 A5719 Washer M6 ................4 A5320 Capacitor 3uf for Traverse Motor ........... 1 A8148 Friction Spring for Reversing Bar ..........1 A6746 Socket Screw ¼” Whit x ¼” ............. 1 A5101 © Bernhard and Company Limited... - Page 33 EXPRESS DUAL 3000MC © Bernhard and Company Limited...

-

Page 34: Reel Drive

Ball Spring Plunger ..............2 A5460 Cap Head Screw 5/8” BSW x 5 1/2” ........1 A5109 Socket Screw M6 x 12 ............. 1 A5146 Diamond Dresser ..............1 A6737 Locknut M10 ................1 A5503 © Bernhard and Company Limited... - Page 35 EXPRESS DUAL 3000MC 13 17 REEL DRIVE © Bernhard and Company Limited...

-

Page 36: Clamp Assembly

A5524 C’s’k Socket Screw M10 x 30 ..........4 A5117 Nut M10 ................... 4 A5503 Hex Head Bolt M10 x 45 ............2 A5706 Nyloc Nut M10 ................. 2 A5505 Washer M10 ................6 A5310 © Bernhard and Company Limited... - Page 37 EXPRESS DUAL 3000MC CLAMP ASSEMBLY © Bernhard and Company Limited...

-

Page 38: Multi-Fix Bracket Assembly

Cap Head Skt Screw M10 x 25 ..........4 A5116 Washer M12 ................4 A5315 Washer M10 ................4 A5310 Base Scale ................2 A6601 Button Head Skt Screw M4 x 8 ..........4 A5125 Multifix Channel (not shown) ........... 2 A4087 © Bernhard and Company Limited... - Page 39 EXPRESS DUAL 3000MC Parts List (Continued) © Bernhard and Company Limited...

-

Page 40: Control Box

Control Box Lid ................ 1 Control Box Arm ..............1 A4028 Pushbutton ................3 A8040 B3T10 Contact Block ............... 3 A8039 Emergency Stop Button ............1 A8073 B4T02 Contact Block .............. 1 A8358 Toggle Switch ................1 A8071 © Bernhard and Company Limited... -

Page 41: Electrical Cabinet

Transformer ................1 A8024 Smoothing Capacitor 10000uf ..........1 A8004 Rectifier ................... 1 Hours Meter Door ..............1 A6336 Traverse Motor Capacitor 3uf ..........1 A8148 Reset Button ................1 A8130 Fuse Door ................1 A6329 © Bernhard and Company Limited... -

Page 42: Lift Table

Mains Tail Lift Controller (not shown) ........1 A8904 M6 x 15 Lobed Knobs - for High lift table plate (not shown) ... 2 A3472 Handle for High Lift Table Cover plate (not shown) ....2 A6197 © Bernhard and Company Limited... - Page 43 EXPRESS DUAL 3000MC Parts List (Continued) LIFT TABLE © Bernhard and Company Limited...

- Page 44 EXPRESS DUAL 3000MC © Bernhard and Company Limited...

-

Page 45: Lift Table Manual

EXPRESS LIFT TABLE MANUAL EXPRESS LIFT TABLE for Express Dual Spin Grinders User s Guide & ’ Instruction Manual Please read this manual carefully. This manual should be kept in a safe place so that it can be used for future reference. - Page 46 EXPRESS DUAL LIFT TABLE FIG. 1. - OVERALL VIEW WITH COVER REMOVED FIG. 2. - TABLE HEIGHT ADJUSTING DETAIL ADJUSTER A – Raises/Lowers Left Hand Side ADJUSTER B – Raises/Lowers Right Hand Side © Bernhard and Company Limited...

- Page 47 If you have any service or operational problems contact your distributor, or phone our Technical Helpline (USA only) – 1-888 474 6348 (+44) 1788 811600 Bernhard and Company Ltd, England – or email techsupport@bernhard.co.uk use the technical support feedback form on our web site www.expressdual.com or www.bernhard.co.uk...

-

Page 48: Safety

When not in use always latch the platform into the vertical position or leave it horizontal at ground level. 1.9. When lowering a load ensure that the floor space below the table is clear of all objects. © Bernhard and Company Limited... -

Page 49: General Description

Then from March 1998 units utilised a 24v DC power pack and transformer. From March 2003 the lift power unit is now 220v AC. All are controlled by a hand held push button panel, which controls both the raising and lowering functions. © Bernhard and Company Limited... -

Page 50: Operating Procedure

When the unit has been moved onto the Dual table return the platform to its normal storage position to allow better access to the Dual table and avoid the risk of personal injury on the projecting corners of the platform. Unload the Dual table in the reverse order. © Bernhard and Company Limited... -

Page 51: Maintenance And Adjustments

On DC powered units visually check the motor brushes for wear. NOTE: When any moving parts have been replaced or cleaned with a degreasing agent, ensure that they are re-assembled with an adequate quantity of medium grease. © Bernhard and Company Limited... -

Page 52: Fault Finding

Check dump valve solenoid – could be debris under the seating or a valve failure. TECHNICAL SPECIFICATIONS Hydraulic Oil I.S.O.32 (eg catrol hysol XH) Capacity 0.9litre (2 pints USA) Max Hydraulic Pressure 140 Bar (Full Load) © Bernhard and Company Limited... - Page 53 EXPRESS DUAL LIFT TABLE NOTES ..............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................© Bernhard and Company Limited...

-

Page 54: Parts List

Mains Tail Lift Controller (not shown) ........1 A8904 M6 x 15 Lobed Knobs - for High lift table plate (not shown) ... 2 A3472 Handle for High Lift Table Cover plate (not shown) ....2 A6197 © Bernhard and Company Limited... - Page 55 EXPRESS DUAL 3000MC Parts List (Continued) LIFT TABLE © Bernhard and Company Limited...

- Page 56 USER MANUAL ADDENDUM Safety enclosure (guard) interlocks and “service” switch Express Dual and Anglemaster models ED3000, ED3000DX, ED5000, AM3000, AM3000DX Express Dual and Anglemaster machines are now supplied with safety enclosures as standard. These enclosures are fitted with a safety interlock switch so that the safety enclosure must be in the closed position before the motors can be started.

- Page 57 USER MANUAL ADDENDUM NOTES ..............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................

-

Page 58: Bernhard And Company Ltd

If you have any service or operational problems contact your distributor, or phone our Technical Helpline (USA only) – 1-888 474 6348 (+44) 1788 811600 Bernhard and Company Ltd, England – or email techsupport@bernhard.co.uk use the technical support feedback form on our web site www.expressdual.com or www.bernhard.co.uk...

Need help?

Do you have a question about the EXPRESS DUAL 3000MC and is the answer not in the manual?

Questions and answers