Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for RNA FP 15 E

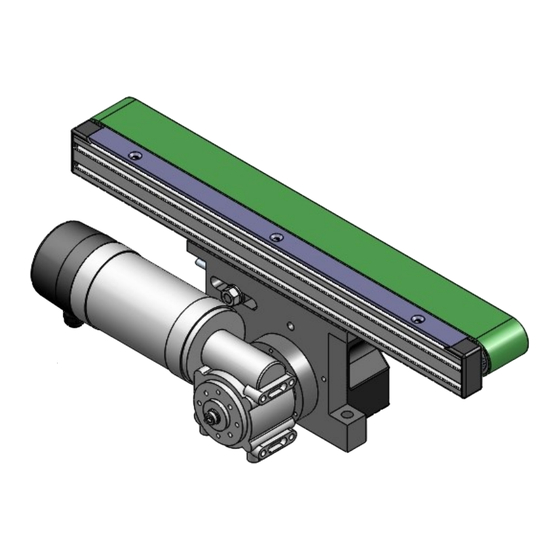

- Page 1 Installation instructions relating to Belt conveyors FP 15 E FP 15 D...

-

Page 2: Table Of Contents

Table of Contents Technical data ........................4 1.1. Table ........................... 4 1.2. Motor connection diagrams ....................4 1.2.1. Dunker / Rotek three-phase motor ................4 1.2.2. Dunker / Rotek AC motor ..................... 6 1.2.3. Engel DC motor ......................7 Safety directives ........................7 2.1. - Page 3 Declaration of Incorporation according to Machinery Directive 2006/42/EC We hereby declare that our product is intended to be incorporated into or assembled with other machinery to constitute one machine in terms of the Directive indicated above (or parts thereof) and that it must not be put into operation until the relevant machinery into which it is to beincorporated has been declared to be in conformity with the EC Machinery Directive.

-

Page 4: Technical Data

1. Technical data 1.1. Table Belt lengths = shaft center distance (mm) 200 to 2,000 Belt widths (mm) 10, 20, 30, 40 and toroidal driving cords Ø3 Conveyor load max. 100 total load depending on motor, belt width and mode of operation (conveyance or accumulation) the total load may be much higher Belt speed +/- 20% constant... - Page 5 Connection of Rotek three-phase motors Connection to three-phase supply Connection to three-phase supply High voltage Low voltage 3x400V 3x230V For reversing the sense of rotation change two phases of the supply line Fig. 1 Fig. 2 Fig. 3 Fig. 4 The protective earth conductor PE is to be connected by user.

-

Page 6: Dunker / Rotek Ac Motor

1.2.2. Dunker / Rotek AC motor Connection of Dunker AC motors Connection to a.c. supply Connection to a.c. supply 1x230V 1x230V CCW rotation CW rotation Connection of Rotek three-phase motors Connection to a.c. supply Connection to a.c. supply 1x230V 1x230V CW rotation CCW rotation The protective earth conductor PE is to be connected by user. -

Page 7: Engel Dc Motor

1.2.3. Engel DC motor Connection of Engel DC motors To reverse the sense of rotation change the feeder connection. 2. Safety directives We have taken great care in design and manufacture of our conveyors in order to ensure smooth and safe operation. You, too, can make an important contribution towards safety at work. - Page 8 Attention Risk of injury and electric shock hazard! • The equipment user and operators shall ensure that only authorized personnel works at the conveyor. • Any changes that have occurred on the feeding system affecting safety shall immediately be reported to the user.

-

Page 9: Applicable Directives And Standards

Authorized personnel refers to qualified personnel that has been assigned a clearly defined task by the user of the belt conveyor. Qualified electrical worker According to IEC 364 and DIN VDE 0105 Part 1, the term 'qualified electrical worker' refers to persons who, through their professional training, know-how and experience and through their knowledge of applicable standards are able to assess the work assigned to them and to recognize potential hazards. -

Page 10: Shipment And Installation

4. Shipment and installation 4.1. Shipment Shipment ex works The belt conveyors are delivered ex works in cardboard or box packaging. Handling on site The belt conveyor weight depends on its dimensions and motor rating. Please refer to the shipping documents for the weight of your specific equipment. -

Page 11: Commissioning

5. Commissioning Attention Electrical connection of the belt conveyor must be made by trained professional electricians only! When making any change to the electrical connection be sure to observe the operating instructions for the motor circuit-breaker / control unit. The belt conveyor is started and stopped on the motor protection breaker. Fig. -

Page 12: Maintenance

Move tensioning roller towards drive roller to increase belt tension Move tensioning roller away from drive roller to decrease belt tension Correct belt tension is obtained when the belt conveys a load of 5 to 10 kg (depending on belt width) without slipping. Caution Too high belt tension may overload both the belt and the motor. -

Page 13: Return, Drive And Supporting Rollers

6.4. Return, drive and supporting rollers Clean soiled rollers with spirit and a clean non-linting cloth. Where belts are used for food applications use an approved substitute for the spirit. Caution Take care to provide sufficient ventilation! Wear protective clothing. 6.5. - Page 14 RNA Group Headquarters Manufacturing and Sales Rhein-Nadel Automation GmbH Reichsweg 19-23 -52068 Aachen Further manufacturing sites of the RNA Group Phone: +49 241/-5109-0 Fax: +49 241/-5109-219 Manufacturing E-mail: vertrieb@RNA.de Lüdenscheid branch www.RNA.de Rhein-Nadel Automation GmbH Nottebohmstraße 57 D-58511 Lüdenscheid Phone: +49 2351 41744...

Need help?

Do you have a question about the FP 15 E and is the answer not in the manual?

Questions and answers