Advertisement

Quick Links

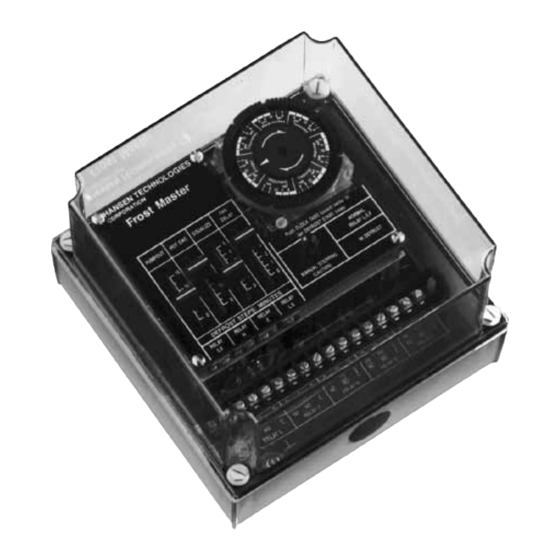

FM-71 Defrost Controller

INTRODUCTION

The Hansen Frost Master

controller for efficient removal of frost accumulation

on evaporator coil surfaces.

simple, reliable solid-state electronics with a precision

quartz time clock and time adjusting slide knobs to

sequentially operate through logical defrost steps for

smooth but complete and effective defrosting. The

SPDT relays facilitate flexible connection of solenoid

valves and control relays. Defrost mode and step

times are easily viewed through the clear cover of the

NEMA 4 enclosure. Typically, one controller is used

per defrost control valve group.

KEY FEATURES

User friendly

SPDT relays, 10 amp switch rating

Entire program always visible

Battery back-up

Terminals for optional sensor defrost initiation

Terminals for optional sensor defrost termination

Staggered defrosting is simple

24 hour or 7-day scheduling

Precision quartz time clock

Remote Initiate only models available

is an easy-to-use defrost

®

This controller uses

Specifications, Applications,

Service Instructions & Parts

FROST MASTER

FROST MASTER

DEFROST CONTROLLERS

for Industrial/Commercial

Evaporator Defrosting

APPLICATIONS

Designed specifically for defrosting industrial and

large commercial refrigeration systems, the Frost

Master

sequences solenoid valves and relays to

®

provide quick and efficient defrosting of evaporator

coils. Because of its SPDT relays and time adjustable

defrost steps, this controller is suitable for almost

every defrost application including: top and bottom

feed unit coolers, blast freezer evaporators, and

ice makers. Whether the evaporator uses hot gas,

electricity, or water to defrost, this controller makes

setting or changing defrost periods simple and easy.

A very precise quartz time clock facilitates accurate

setting of defrost start times. Time clocks include

battery back-up in case of short term power failure to

avoid any nuisance re-setting of clocks after power

interruptions.

Demand initiate and coil temperature terminate devices

may be directly connected to the Frost Master

something other than conventional time-only defrosting

is appropriate. The Frost Master

a built-in temperature terminate feature as well as an

additional defrost step, SOFT GAS, which can help

minimize pressure shock to the evaporator during

defrosting.

TABLE OF CONTENTS

Specifications, Advantages, Installation ........................ 2,3

Initiation, Termination, Wiring ........................................ 4,5

Frost Master

Plus (SOFT GAS) ...................................... 6,7

®

Typical Defrost Applications ........................................... 8,9

Control Valve Selection ...............................................10,11

Remote Initiate Models, Order Info. ................................ 12

Bulletin F100d

JAN 2011

&

®

PLUS

®

when

®

Plus models offer

®

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Hansen FROST MASTER

- Page 1 User friendly interruptions. SPDT relays, 10 amp switch rating Demand initiate and coil temperature terminate devices Entire program always visible may be directly connected to the Frost Master when ® Battery back-up something other than conventional time-only defrosting is appropriate. The Frost Master Plus models offer ®...

- Page 2 Battery Back-Up: 90 hours for quartz time clock from electrical shorts; see pages 5 and 7. Power: 115V 50/60Hz; 230V 50/60Hz The Frost Master® is available, less enclosure, with Terminal Strip: Accepts 14-22 AWG wire sizes metal mounting plate, for installation in electrical panel or approved outdoor enclosure;...

- Page 3 FROST MASTER DEFROST CONTROLLER ® NEMA 4 ENCLOSURE TIME-OF-DAY AT ARROWHEAD LIGHTS FOR DEFROST QUARTZ TIME CLOCK STEPS (24 HOUR OR 7-DAY) DEFROST STEPS TIME TIME CLOCK TABS ADJUSTMENTS “OPTIONAL INITIATE” SPADE TERMINALS CLAMP TYPE TERMINALS “OPTIONAL TERMINATE” SPADE TERMINALS...

- Page 4 DEMAND INITIATE). time the initiate device closed the terminals. The Frost Master® is supplied with a factory installed Typically, no more than a 1/3 of a plant’s evaporators jumper wire which closes the initiate terminals. If a...

- Page 5 This wiring diagram is for illustration purposes only and does not show all controls and safety devices. Final control wiring is the responsibility of the system designer. See above table for relay operation. Relays shown with no power to Frost Master®. See above for relay operation. OPTIONAL DEFROST...

- Page 6 RELAY SG (SOFT GAS) TERMINALS INTRODUCTION TERMINATE (Plus MODELS) This deluxe model, Frost Master® Plus, includes an The defrost terminate feature is built-in to the Frost additional (fifth) defrost step, SOFT GAS, plus a built- Master® Plus models. It consists of an accurate,...

- Page 7 This wiring diagram is for illustration purposes only and does not show all controls and safety devices. Final control wiring is the responsibility of the system designer. See above table for relay operation. Relays shown with no power to Frost Master® Plus. See above for relay operation. OPTIONAL DEFROST...

- Page 8 In most cases, a ½” port soft gas valve should controller. The hot gas supply at the evaporator be sufficient; such as Hansen Type HS8A. A hand should be free of condensate, sufficient in pressure expansion valve (regulator) or globe valve can be...

- Page 9 TYPICAL DEFROST APPLICATIONS These are only examples of possible control valve schemes. As always, they are provided only to assist system designer in applying and selecting valves and controls. Ultimately, designer is responsible for safe and satisfactory operation of any defrost system. BOTTOM FEED EVAPORATOR TOP FEED EVAPORATOR LIQUID SOLENOID VALVE...

- Page 10 Evaporator tons at 10ºF (5°C) temperature differential. Ideal sizing could vary with desired time for defrosting, available supply pressure, amount of ice on evaporator, usage of pre-defrost pumpout, etc. For other control valve sizing, see detailed Hansen bulletins on specific valve types. VALVE SELECTION...

- Page 11 CONTROL VALVES HS8A SOLENOID VALVE Normally spring closed, this valve opens Function of control valves: Provide hot gas to the wide when energized. Ideally suited for coil without liquid slug shocks, close the suction so use as a soft gas, liquid or hot gas supply pressure can build-up, permit condensed refrigerant valve.

- Page 12 Frost Master® with enclosure FM-72 models and the terminate temperature sensor (p/n 67- 7-day clock; 230V, 50/60Hz 0052) for the Frost Master® Plus. To replace clock, Frost Master® with enclosure FM-02 disconnect all power to control unit. Remove each Remote Initiate; 230V, 50/60Hz of three 5/32”...

Need help?

Do you have a question about the FROST MASTER and is the answer not in the manual?

Questions and answers