Advertisement

Quick Links

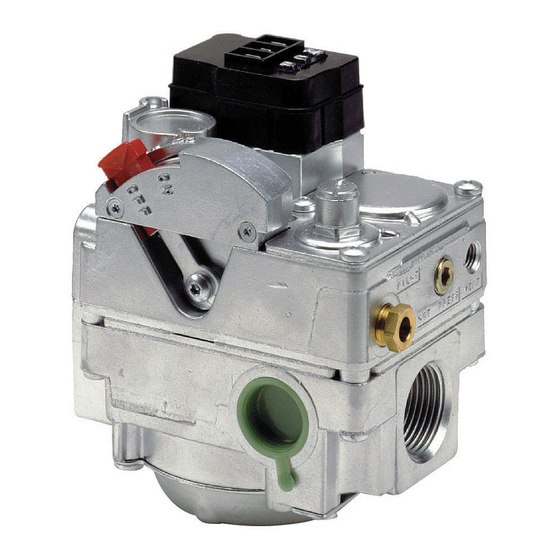

The Robertshaw® 720 Series Gas Controls are designed for a wide

variety of heating applications and can be used to replace most dual

(six function) valves. They are available only in a 24 volt model used

with a constant pilot. Models are available with and without a pressure

regulator. Uni-Kits® are factory set at 3.5" W.C. for natural gas, but can

be converted to L.P. by installing the regulator conversion kit included.

(See Regulator Conversion section.)

The 720 Series, used with a constant pilot, is a six function valve

incorporating a manual valve, safety shutoff magnet, dual automatic

valves (hence the term "dual valves"), main gas regulator, and pilot

adjustment. It features an integral manual selector used to select from

four gas flow positions - off, on, pilot and "set." The "set" position

provides pilot only gas flow during magnet energizing and lock up.

Built-in stops serve to prevent accidental setting to the "off" position.

Wiring connections, manual selector and adjustments are easily

accessible on the top of the valve. With a 3-9/16" swing radius, the 720

Series lends itself well to replacing many OEM valves. Controls are

multiposition and can be mounted in any position (except upside down).

To prevent unsafe attempts at repair, special screws are used and

replacement parts are NOT available.

SPECIFICATIONS

Electrical Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24V AC, .5 amps

Pressure Regulator

Natural Gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .factory set at 3.5" W.C.

L.P. Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . factory set at 11.0" W.C.

Pilot Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/4" tubing

Ambient Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -40° to 175°F

Maximum Inlet Pressure . . . . . . . . . . . . . . . . . . . . . . 7" W.C. - natural gas

REGULATION CAPACITIES (BTU'S)

NATURAL

SIZE

MIN.

3/8" x 3/8"

15,000

1/2" x 3/8"

15,000

1/2" x 1/2"

15,000

1/2" x 3/4"

15,000

3/4" x 3/4"

15,000

INSTALLATION INSTRUCTIONS

Turn off gas supply and electrical power to equipment

before servicing.

PIPING

1. Check replacement valve for multiple outlets (side outlets). If it has

them, be sure all unused outlets are plugged using the socket plugs

provided.

2. Pipe or tubing must be clean and free of scale and dirt.

3. Make sure gas piping is pressure tested before control is connected.

High pressure can damage control causing a hazardous condition. Do

not subject control to more than 1/2 PSI, (14" W.C.) inlet pressure.

4. If it is not already installed, a drip leg (sediment trap) must be

added to the gas supply line to the control. (See figure to the right).

All piping must comply with local codes and ordinances and with

National Fuel Gas Code (ANSI Z223.1/ NFPA, No. 54).

DUAL VALVE GAS HEATING CONTROLS

TYPE GAS

L.P.

MAX.

MIN.

MAX.

175,000

15,000

280,000

175,000

15,000

280,000

200,000

15,000

300,000

200,000

15,000

300,000

200,000

15,000

300,000

INSTALLATION DATA

THIS DEVICE SHOULD BE INSTALLED BY A QUALIFIED

TECHNICIAN WITH DUE REGARD FOR SAFETY AS IMPROPER

INSTALLATION COULD RESULT IN A HAZARDOUS CONDITION.

5. Using pipe thread compound suitable for the gas being used, apply a

small amount on the male pipe threads. (Do not use Teflon tape or

Teflon compound.) Leave the first two threads clean. Never use

compound on female threads as it might be pushed into the control

body.

6. The gas valve is multiposition and can be mounted in any position

(except upside down) without affecting its operation.

7. Install gas valve so gas flow conforms with the inlet and outlet of

the control.

8. DO NOT insert any object other than suitable pipe or tubing in the

inlet or outlet of this control. Internal damage may occur and result

in a hazardous condition. A backup wrench should only be used on

the wrench boss provided for this purpose (see drawing), never on

body of the control, as this could distort the casting. NOTE: Do not

overtighten any pipe connections, as this could crack the valve body.

A valve with a cracked valve body will not be warrantied.

720 SERIES

CAUTION

Advertisement

Summary of Contents for Robertshaw 720 Series

- Page 1 L.P. by installing the regulator conversion kit included. (See Regulator Conversion section.) The 720 Series, used with a constant pilot, is a six function valve incorporating a manual valve, safety shutoff magnet, dual automatic valves (hence the term “dual valves”), main gas regulator, and pilot adjustment.

- Page 2 2. Smell all around the appliance area for gas. If the appliance uses LP (bottled) gas, be sure to smell next to the floor because The 720 Series when equipped with a pressure regulator, has a standard LP gas is heavier than air.

- Page 3 CAUTION: Main burner and pilot orifices must be changed when regulator is converted from one type gas to another. The 720 Series valves can be converted from natural to L.P. by installing the enclosed conversion kit. 4. Follow standard lighting procedure.

- Page 4 Bubbles indicate leaks that must be corrected. 15. Attach label to show control has been converted to L.P. 16. Set room thermostat to desired temperature. Robertshaw®, Ranco®, Paragon® and Uni-Line® are www.uni-line.com For Technical Service Customer Service Telephone 1.800.304.6563 Telephone 1.800.445.8299...

Need help?

Do you have a question about the 720 Series and is the answer not in the manual?

Questions and answers