Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for FMC M12-HD

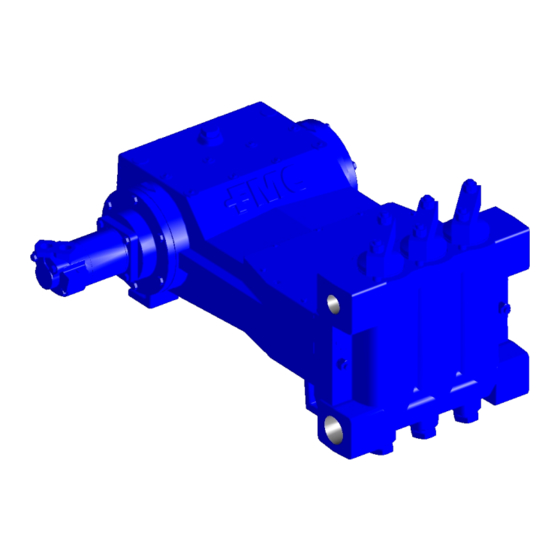

- Page 1 M12-HD Piston Pump Operation & Maintenance Manual...

-

Page 2: Safety Instructions

Always contact FMC or your FMC equipment dealer for the most complete and current information before starting any repair job. Contact FMC any time if you are unsure about any procedure involving FMC equipment. -

Page 3: Table Of Contents

F M C M 1 2 - H D O P E R A T I O N A N D M A I N T E N A N C E M A N U A L Table of Contents Safety Instructions ....................2 General Features......................4 Storage Requirements... -

Page 4: General Features

The FMC M12-HD pump is a high performance pump specially designed for the demanding duties of horizontal drilling. The M12-HD is a piston style pump that utilizes high performance rubber pistons running in a hardened liner for maximum component life between service. The pump also features abrasive service valve assemblies with a special seating elements designed to seal even when sand and other particulates are present in the fluid. -

Page 5: Storage Requirements

M A N U A L Storage Requirements FMC pumps come from the factory prepared for storage periods of up to six (6) months in proper environmental conditions. Indoor storage in a dry, temperature-controlled location is always recommended. If pumps are to be stored short term (less than six (6) months) in a severe environment, they should be prepared using the procedures outlined in the “Short Term Storage... -

Page 6: Precautions During Freezing Weather

M A N U A L removed for storage. Once these steps have been completed, fill with oil and follow normal start-up procedures. Note that FMC can factory prepare units for extended storage for a nominal fee if specified at the time of order. -

Page 7: Lubrication Requirements

M A N U A L Lubrication Requirements FMC pumps are supplied without oil in the crankcase and must be filled with oil prior to startup. The FMC M12-HD pump requires 12 quarts (11.4 liters) of oil. Any anti-wear gear, turbine, or hydraulic oil of the proper viscosity will work. -

Page 8: Periodic Maintenance Schedule

F M C M 1 2 - H D O P E R A T I O N A N D M A I N T E N A N C E M A N U A L Preventative Maintenance Schedule Interval Component... -

Page 9: Service Procedures

This section covers all normal service procedures on the fluid end of the pump. FMC drive ends do not require routine maintenance and overhaul procedures may require special tools, equipment, or training. - Page 10 F M C M 1 2 - H D O P E R A T I O N A N D M A I N T E N A N C E M A N U A L • Use a 1-1/8” socket wrench to remove each of the cylinder clamp hex nuts (46) and washers (47).

- Page 11 F M C M 1 2 - H D O P E R A T I O N A N D M A I N T E N A N C E M A N U A L • Install new piston (42) and piston o-ring (45) into the piston sub-assembly as shown (70).

-

Page 12: Valve Replacement

For maximum uptime between service, FMC recommends that all 6 complete valve assemblies be replaced whenever this service is performed, not just the valve (or components of the valve) that show visible signs of damage. - Page 13 F M C M 1 2 - H D O P E R A T I O N A N D M A I N T E N A N C E M A N U A L • Assemble the puller guide (19) and puller eccentric (18) on one end of the puller stem (15) as shown.

- Page 14 M A I N T E N A N C E M A N U A L Note: FMC M12 valves are held in place using a self-locking taper. The tapered portion of the valve seat and the tapered portion of the fluid cylinder must be clean and dry prior to assembly to insure proper operation.

-

Page 15: Oil Seal Replacement

F M C M 1 2 - H D O P E R A T I O N A N D M A I N T E N A N C E M A N U A L Oil Seal Replacement •... -

Page 16: Special Tools

A N D M A I N T E N A N C E M A N U A L Special Service Tools FMC AR Valve Puller Tool Part Number 5276358 Kit Includes the following parts: Puller Bolt Slide Hammer... -

Page 17: Trouble-Shooting Guide

Trouble-shooting Guide No flow from pump Tank is empty Inlet valve is closed Inlet strainer is clogged with debris Crankshaft is not turning Insufficient pressure from pump ONLY Pump speed is too slow Relief valve improperly adjusted and by-passing fluid Oversize or worn nozzle on equipment Worn pump valves Excessive leakage from pump seals... - Page 18 Short piston seal life High abrasive particle content in fluid Wrong style or type of piston for service Piston liner is damaged Pump is cavitating (cylinders may run hot) Piston assembly o-ring is damaged Poor quality water used Pump is allowed to run dry for extended periods of time Liner wash system not properly maintained (if equipped) Short valve life High abrasive particle content in fluid...

- Page 20 Division Headquarters FMC Fluid Control Division 6677 North Gessner Road Houston, TX 77040 Phone 713.510.6800 • Fax 713.510.6806 Manufacturing & Customer Service FMC Fluid Control Operation 2825 West Washington Avenue Stephenville, TX 76401 Phone 800.643.6254 or 254.968.2181 • Fax 254.965.8278 Internet &...

Need help?

Do you have a question about the M12-HD and is the answer not in the manual?

Questions and answers