Summary of Contents for RIEXINGER BSM 630

- Page 1 Translation of the original operating manual Operating manual Band-saw machine for plastic pipes Type BSM 630...

- Page 2 Status 11/2015 © Eugen Riexinger GmbH & Co. KG...

-

Page 3: Table Of Contents

2.9.4 Mechanical hazards 2.9.5 Heat hazards 2.9.6 Environmental hazards 3. Technical data 3.1 General information 3.2 Delivery contents 3.3 Dimensions and weight 3.4 Equipment 3.5 Workpieces 3.6 Electrical connection 3.7 Emissions 4. Setup and function 4.1 Overview 4.2 Functionality BSM 630... - Page 4 6.5 Connect to electrical power supply 6.6 Initial operation 7. Operation 7.1 Before start-up 7.2 Protective equipment 7.3 Turning the BSM 630 on and off 7.4 Setting the sawing angle 7.5 Loading the machine 7.6 Sawing 8. Finding an reparing malfuncitons 8.1 Repair saw-band malfunctions...

- Page 5 9.5.2 Saw band guide rolls 9.6 Adjust end stops and handle 9.7 Check safety equipment 9.8 BSM 630 maintenance 10. Dismantling and disposal 10.1 Deactivation 10.2 Final shutdown 10.3 Disposal 11. Annex 11.1 Contact form 11.2 EC Conformity Declaration 11.3 Spare part list 11.4 Circuit diagram...

-

Page 7: Important Basic Information

The company Eugen Riexinger GmbH & Co. KG is not liable for damages resulting from non- or partial compliance with the operating manual. -

Page 8: Used Notation Styles

German Social Accident Insurance (electrical facilities and manufacturing equip- ment) of the Professional Association for Health and Social Welfare Roule 3 Band saw machine Polyethylene (thermo-plastic synthetics) Polypropylene (partial crystalline thermo-plastic synthetics) Polyvinylidene fluoride (opaque, partial crystalline thermo-plastic fluorine syn- PVDF thetics) Accident Prevention Regulations BSM 630... -

Page 9: Location Of Objects In The Room

1. Important basic information 1.6 Location of objects in the room The spatial information about locations of objects in the room in relation to the BSM 630 always refer to the image below. View from above Fig. similar BSM 630... -

Page 10: Labelling On The Machine

Warning of dangerous elec- trical voltage when opening Switchboard cabinet the door of the switchboard Control panel cabinet or the control panel casing Type label and CE marking of Saw frame the BSM 630 BSM 630... -

Page 11: Basic Safety Instructions

(see Chap. 3.5 on p. 16). Proper usage also includes: Observing all guidelines from the operating manual and Adhering to maintenance intervals The BSM 630 is exclusively intended for usage in industry, craft and trade. It is not intended for private usage. BSM 630... -

Page 12: Improper Usage

BSM 630 as e.g. wood or metal; work on the machine without the personal protective gear prescribed in this operating manual. -

Page 13: Informal Safety Measures

In addition to this operating manual, adhere to general and local accident prevention- and environmental protection regulations. Ensure that all safety instructions and danger notices attached to the machine (see Chap. 1.7 on p. 8) are legible and replace them if necessary. BSM 630... -

Page 14: Properly Functioning Of Protective Devices

2.9 Other hazards In the following you will find the overridingly valid safety instructions that are relevant for sev- eral of the BSM 630 life phases. Specific safety instructions are listed in the relevant sections of this operating manual. 2.9.1 Fire hazard... -

Page 15: Electrical Hazards

The machine may only be operated by one person. Before running the saw band or lowering the saw bow, the operator must ensure that the area behind the workpiece and the work area are clear. BSM 630... -

Page 16: Heat Hazards

Wear protective gloves during repair work or allow the saw band to cool down before touching it. 2.9.6 Environmental hazards Attention! Plastic waste and used saw bands contaminate the environment! Dispose of all shavings, plastic waste and used saw bands according to locally applicable legal stipulations. BSM 630... -

Page 17: Technical Data

Mitre area of 45 degrees on one side with swivel-mounted saw bow Special Equipment (optional) Visual cutting indicator for quick positioning of workpiece 3.2 Delivery contents The delivery contents consist of: BSM 630 switch box 2 saw bands 9 screw feet 1 operating manual... -

Page 18: Dimensions And Weight

200 mm (with special V-table to minimum of 50 mm possible - optional) 630 mm (with special V-table to maximum of 200 mm possible - Max. diameter optional) The workpiece must be tensioned with both tension belts at two loca- Min. length tions. BSM 630... -

Page 19: Electrical Connection

The BSM 630 may not be used to saw transparent or perforated pipes! The BSM 630 adapts the saw-band guide to the profile of the pipe while sawing. Malfunctions of the active optical sensors may occur when sawing transparent or perforated pipes and may result in damage to the workpiece or the machine. - Page 20 3. Technical data The BSM 630 complies with protection requirements in regard to interference immunity accord- ing to EN 61000-6-2:2005 (Interference immunity for industrial areas). The BSM 630 complies with protection requirements in regard to interference emission accord- ing to EN 61000-6-3:2007 (Interference emission for living-, commercial- and trade areas as well as for small business).

-

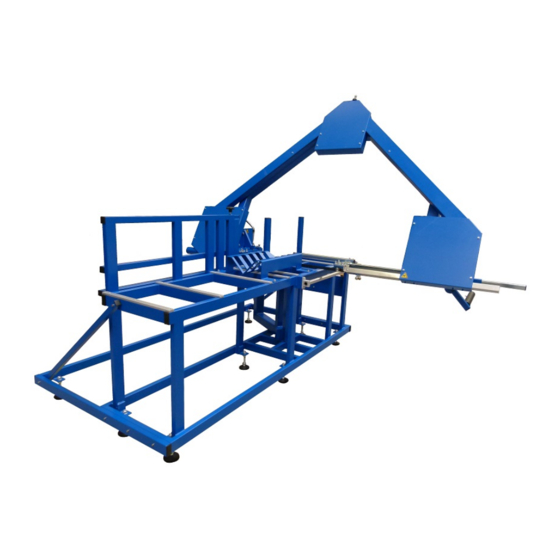

Page 21: Setup And Function

V table for workpiece (optional - avail- able as special equipment) Handle with safety push buttons (adjust- able) Slidable saw band cover Saw bow Tensioning device for saw band extensible workpiece support extraction nozzle extensible stop for workpiece Saw band Saw band guide (2x) BSM 630... -

Page 22: Functionality

4.3 Safety concept 4.3.1 Push buttons According to valid APR the BSM 630 must operate in jogging mode during processes that are dangerous for the operator. This means that the operator must press the pressure switches of the hand grip with both hands while sawing. As soon as the buttons are released, the motor of the saw band stops. - Page 23 Warning! Crushing hazard during operating of machine! Crushing hazard of limbs during pulling down saw bow. When starting the work process, make absolutely sure that there are no parts of the body (arms, hands etc.) in the danger zone. BSM 630...

-

Page 25: Delivery, In-Company Transport And Storage

2) Check also if the delivery contents of the BSM 630 are complete (see Chap. 3.2 on p. 15). 5.2 Environmental conditions for storage and transport... - Page 26 Attention! Improper transport may cause damage to machine! The BSM 630 may not be lifted and transported with lifting devices that are attached to machine parts (e.g. the saw bow) but only with a suitable forklift that lifts the frame of the machine.

-

Page 27: Setup And Activation

The surface of the floor must have the following characteristics: Easy to clean Skid resistant 6.1.2 Lighting The nominal lighting power at the setup location of the BSM 630 must comply with valid work- place regulations. 6.2 Environmental operating conditions Operating temperature... -

Page 28: Setup Plan

Improper environmental conditions may cause damage to machine! Protect the machine, and especially the electrical equipment, from mois- ture, rain and dust. The BSM 630 may not be set up or stored outside. The proprietor is obligated to setup a properly dimensioned ventilation sys- tem at the setup side for sawing of glass fibre-reinforced plastics (GFP) or similar dusty work materials;... -

Page 29: Mounting And Setting Up The Machine

(see Chap. 2.5 on p. 10) according to valid APR. Also ensure that no persons are in the transportation path or in the setup area and wear safety shoes with toe-protection caps. 6.4.1 Mounting saw bow If the saw bow was removed for transportation, mount it as follows. BSM 630... -

Page 30: Place Machine

(see Chap. 4. on p. 19). 5) Remove the underlying wooden blocks. 6) Slowly place the BSM 630 on the ground until it fully rests on the screw feet. 7) Horizontally align the machine frame lengthwise and across with a water level. The slope of the machine frame can be adjusted by screwing the machine feet in or out. -

Page 31: Connect To Electrical Power Supply

Do not reach into the danger zone. Attention! Avoid short switching cycles! Because of the enormous thermal stress during the frequent starting and braking the motor, the electrical box and the electronic brake can be damaged. BSM 630... -

Page 32: Initial Operation

2) Ensure that the phase sequence of the outer cable turns clockwise in the receptacle. 3) Connect the BSM 630 to the power supply by connecting the machine's plug to a receptacle. We assume no liability for damages resulting from failure to comply with the above points. - Page 33 7) Check all safety equipment (see Chap. 9.7 on p. 58). 8) Check whether all protective equipment is installed and connected (see Chap. 7.2 on p. 33). 9) Activate the BSM 630 by turning the main switch on (see Chap. 7.3 on p. 33). Danger! Running saw band may cause serious severance injury! The machine may only be operated by one person.

-

Page 35: Operation

How to check whether all protective equipment is properly installed and closed off: All saw-band covers mounted and fastened with screws? (see Chap. 9.3 on p. 50) 7.3 Turning the BSM 630 on and off Turning the BSM 630 on... -

Page 36: Setting The Sawing Angle

The Operator must ensure that saw bow is in the rear home position. Mitre cuts The BSM 630 has a mitre range of 45 degrees. on one side. This allows mitre cuts to one side. 1) If not yet done, push saw bow in its rear home position. -

Page 37: Loading The Machine

V-table for workpieces (special equipment) Attention! Tensioning the tension belt may cause pinch point injury! While tensioning the tension belts, make sure that your hands or your assistant's hands are not pinched by the belts. BSM 630... - Page 38 2) Place the workpiece onto the support table of the machine with the help of a suitable lifting device and possibly another person. 3) Push the workpiece into the desired postition. 4) To do this, use the sliding stop. BSM 630...

- Page 39 7) Secure workpiece offcut that is not clamped in (e.g. with suitable lifting gear) so that these pieces do not fall from the table after sawing. 8) Open saw bow cover only in cross-sectional size of the workpiece. BSM 630...

-

Page 40: Sawing

Secure workpiece offcuts that are not clamped in (e.g. with suitable lifting gear) so that these pieces do not fall from the table after sawing. It is not permissible for the operator or the assisting person to hold or catch the offcut piece. BSM 630... - Page 41 Do not burden machine and sawband with excessive feed rate. Only use sharp saw bands. 7) If the workpiece is completely cut, release the push buttons. The saw band drive stops. 8) Push saw bow back in rear home position. BSM 630...

-

Page 43: Finding An Reparing Malfuncitons

Consultation with the man- rial type (see Chap. 3.5 on p. 16) ufacturer (see Chap. 8.5 on p. 46) Saw band jammed in Consultation with the man- Used wrong saw-band type workpiece ufacturer (see Chap. 8.5 on p. 46) BSM 630... -

Page 44: Repair Electrical Malfunctions

Turn phases by phase incorrectly inverter in plug The motor is buzzing after Missing phase in power supply, Check power supply, check switching on and does not error motor connection, plug, motor connection come up to rated speed supply line BSM 630... - Page 45 (complete with all cables, without motor) with a short description of the error to us. Information Repairs to electrical boxes older than 3 years is not economical. Please do not return in this case. Otherwise, electrical boxes are free to send in for repair. BSM 630...

-

Page 46: Check Saw-Band Motor

7) Re-tighten the Allen safety screws after preforming the adjustment. 8) Mount the removed saw-band cover at the right location. 9) Turn on the machine with the main switch. BSM 630... -

Page 47: Guarantee

Wearing parts such as drive belts, saw bands and carbon brushes of the motors The manufacturer of the BSM 630 is not liable for the quality of manufactured parts.The pro- prietor alone is responsible for quality control and the quality of parts manufactured with the machine. -

Page 48: Error Report

□ □ □ Dust exposure Temperature range from ....degrees C to ....degrees C □ □ □ Error occurs Constantly Seldom Only when ........□ Probably lightning strike or surge damage Date Name / Technician Phone number BSM 630... -

Page 49: Maintenance

For reasons of personal safety and to ensure the proper functioning of the machine, you should only use original spare parts. It cannot be ensured that spare parts from other manufacturers are constructed with the necessary strain-bearing- and safety capabilities. BSM 630... -

Page 50: Cleaning The Machine

2) Remove shavings from machine parts with a hand broom, brush or vacuum cleaner. 3) Use a brush to remove the shavings in the guide rolls at the back saw-band guide. 4) Open the back saw band cover. Remove shavings with a hand broom, brush or vacuum cleaner. BSM 630... -

Page 51: Tensioning The Saw Band

2) If the saw band tension is too weak (bad saw cut quality, saw band jumps off of the diver- sion-wheels etc.), turn the star grip clockwise until it is tensioned optimally. 3) If the saw band tension is too strong (saw band tears), turn the star grip counter-clockwise until it is tensioned optimally. BSM 630... -

Page 52: Removing The Saw Band

Wear protective gloves when working with the saw band and let the saw band cool down before touching it. 1) If you have not already done so, execute the steps in Chap. 9. on p. 47. 2) Relax the saw band. 3) Disassemble all covers and remove them. BSM 630... -

Page 53: Inserting The Saw Band

1) If you have not already done so, execute the steps in Chap. 9. on p. 47 . 2) If the covers of the saw band have not already been removed, do so (see Chap. 9.3 on p. 50). 3) Operator and assisting person are required to wear work gloves and safety glasses. BSM 630... -

Page 54: Adjusting Saw Band

The saw band poses an injury risk! Wear protective gloves when working with the saw band and let the saw band cool down before touching it. First check the saw band tension (see Chap. 9.2 on p. 49) BSM 630... -

Page 55: Diversion Wheels

9. Maintenance 9.5.1 Diversion wheels Ideally, all three diversion wheels are in the same plane. BSM 630... - Page 56 Please note that the adjustments always have an interaction with the other wheels. Most minimal changes are already successful. After completing the adjustments always counter set screws and tighten the fixing screws E. To protect your machine check the running behavior always initially by manually moving the saw blade. BSM 630...

-

Page 57: Saw Band Guide Rolls

Most minimal changes are already successful. Too strong inclination results in increased bearing pressure and thereby increased wear of bearings and saw band. To protect your machine check the running behavior always initially by manually moving the saw blade. BSM 630... -

Page 58: Adjust End Stops And Handle

Attention! After sawing the hot saw band may burn the operator! The saw band poses an injury risk! Wear protective gloves when working with the saw band and let the saw band cool down before touching it. BSM 630... - Page 59 2) Loosen with a suitable tool the locknut and turn the adjusting screw (2) to the desired direc- tion and lock it with the nut. 3) Note that in lowest position saw band don't collide with the table. 4) Then perform a functional test. BSM 630...

-

Page 60: Check Safety Equipment

4) If sawing does not stop immediately or if sawing starts while the push buttons are not acti- vated, turn off the machine with the main switch and contact the manufacturer's customer serv- ice (see Chap. 8.5 on p. 46). BSM 630... -

Page 61: Bsm 630 Maintenance

9. Maintenance 9.8 BSM 630 maintenance Serial number of BSM 630: ........Please record the maintenance activities in the table according to the sample entry! Next Date Activity Name: maintenance 07-05-2012 Machine greased according to grease plan 07-06-2012 Maier BSM 630... - Page 62 9. Maintenance Next Date Activity Name: maintenance BSM 630...

-

Page 63: Dismantling And Disposal

Running saw band may cause serious severance injury! Only an authorised person may deactivate the machine (see Chap. 2.5 on p. 10). How to deactivate the BSM 630: 1) If a workpiece is still in the machine, remove it (see Chap. 7.5 on p. 35). - Page 64 Information The BSM 630 does not contain dangerous materials The following rules must be observed when disposing of the machine at the end of its lifecycle: Adhere to the country-specific regulations regarding disposal of industrial machines...

-

Page 65: Annex

Tell us about your experience with the BSM 630 or make some suggestions for improving either the BSM 630 or this operating manual. Copy, fill out and send us this contact form. We want to thank you in advance for your assistance! Serial number of deployed BSM 630........... -

Page 66: Ec Conformity Declaration

Egartenring 2 75378 Bad Liebenzell / Germany Person authorised to compile the technical file: Markus Theobald (Business Manager), Eugen Riexinger GmbH & Co. KG, Egartenring 2, 75378 Bad Liebenzell Description of machine: Band-saw machine for plastic pipes of type BSM 630 A conformity declaration is also made for other valid product-relevant guidelines. -

Page 67: Spare Part List

Switch box 310184 Button 300399 Belt pulley Ø 70 300429 Fan belt 300425 Motor 300395 Drive wheel 306507 Tension spring 300397 Diversion wheel 306508 Saw band guide 313087 10 Saw band 0,9 x 25 x 6140 4Z 302443 BSM 630... - Page 68 11. Annex BSM 630...

-

Page 69: Circuit Diagram

11. Annex 11.4 Circuit diagram BSM 630...

Need help?

Do you have a question about the BSM 630 and is the answer not in the manual?

Questions and answers