Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Flowsafe F88 Series

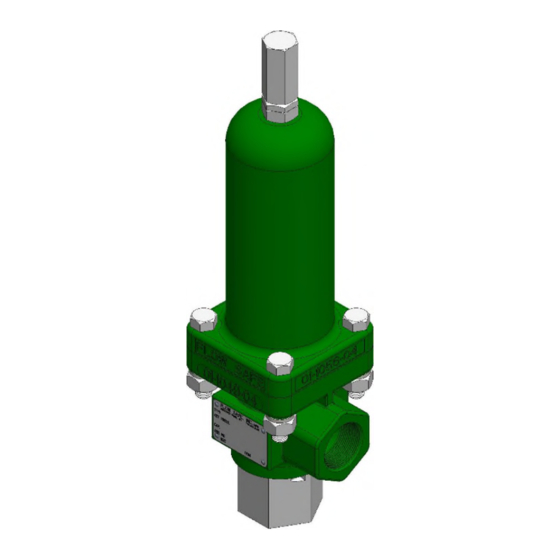

- Page 1 F88 SERIES SPRING-OPERATED SAFETY RELIEF VALVE (GAS/LIQUID) PLASTIC-SEATED -3, -4, -8, -G, -J Orifices INSTALLATION, OPERATION, & MAINTENANCE MANUAL Revision: Date of Issue: Oct. 6, 2021 Approved by: Engineering Projects Dir. Sr. Design Eng.

-

Page 2: Table Of Contents

INSTALLATION, OPERATION, & MAINTENANCE MANUAL TITLE: F88 Series Safety Relief Valve Rev. E Page 2 of 16 TABLE OF CONTENTS Topic Page General ..................... 3 Description, Operation, Service Envelope, Installation, & Startup Description / Operation ..............4 Service Envelope ................5 Installation .................. -

Page 3: General

This manual is intended to provide users with direction and guidance for the maintenance of FLOW SAFE F88 Series safety relief valves. This manual indicates the proper method of valve disassembly, soft goods replacement, and valve reassembly. FLOW SAFE provides this manual as a guideline and reference only. -

Page 4: Description, Operation, Service Envelope, Installation, & Startup

CLOSED OPEN The FLOW SAFE F88 Series safety relief valve is a direct-acting spring-loaded relief valve, suitable for gas and/or liquid service. The Type F88 is plastic-seated with a plastic seal. Orifice sizes are available in -3, -4, -8, -G, and -J with set pressures as referenced in 2.2. -

Page 5: Service Envelope

Prior to installation, check that the set pressure on the nameplate is as required, and meets the system requirements. The F88 Series safety relief valve should be installed in the upright position per the figure on the next page, as close as possible to the pressure source, to minimize pressure losses between the system and the valve. -

Page 6: Startup

INSTALLATION, OPERATION, & MAINTENANCE MANUAL TITLE: F88 Series Safety Relief Valve Rev. E Page 6 of 16 F88 SERIES TYPICAL INSTALLATION VENT STACK w/ RAINCAP OUTLET OUTLET INLET INLET BLOCK VALVE BLOCK VALVE LIQUID SERVICE GAS SERVICE Make sure that the inlet piping/flanges have an opening equal to or greater than the valve's inlet diameter. -

Page 7: Valve Maintenance

INSTALLATION, OPERATION, & MAINTENANCE MANUAL TITLE: F88 Series Safety Relief Valve Rev. E Page 7 of 16 VALVE MAINTENANCE WARNING: It is extremely dangerous to disassemble any valve while it remains in service with incoming line pressure. Also, improper assembly of the valve may result in leakage or failure of the valve when returned to service. -

Page 8: Valve Testing And Adjustment

INSTALLATION, OPERATION, & MAINTENANCE MANUAL TITLE: F88 Series Safety Relief Valve Rev. E Page 8 of 16 Insert the spindle assembly into the body, making sure that it travels freely on the guide surface. Position the bushing seal on the appropriate shoulder of the bushing. -

Page 9: Set Pressure Adjustment

INSTALLATION, OPERATION, & MAINTENANCE MANUAL TITLE: F88 Series Safety Relief Valve Rev. E Page 9 of 16 SET PRESSURE ADJUSTMENT NOTES: 1. If the set pressure is being changed, then the spring, spring washer, PA screw, and bonnet may need to be changed. Consult the factory or an authorized FLOW SAFE assembler for the correct parts. -

Page 10: Accessories

INSTALLATION, OPERATION, & MAINTENANCE MANUAL TITLE: F88 Series Safety Relief Valve Rev. E Page 10 of 16 ACCESSORIES Softgoods Kits NOTE: Provide valve serial number(s) whenever possible when ordering softgoods kits Orifice Std. Kit P/N Lift Lever Kit P/N - 3 / - 4 / - 8... -

Page 11: Troubleshooting Guide

INSTALLATION, OPERATION, & MAINTENANCE MANUAL TITLE: F88 Series Safety Relief Valve Rev. E Page 11 of 16 TROUBLESHOOTING GUIDE: Symptom Possible Cause Remedy The valve leaks around Inadequate bushing torque. Tighten until the bushing bottoms firmly the bushing. on the body. - Page 12 INSTALLATION, OPERATION, & MAINTENANCE MANUAL TITLE: F88 Series Safety Relief Valve Rev. E Page 12 of 16 TROUBLESHOOTING GUIDE (continued): Symptom Possible Cause Remedy The valve does not Spindle is stuck closed. Disassemble the valve and examine the open. sliding surfaces. If damaged, replace.

-

Page 13: F84L-3 / -4 / -8 Series "C" Body Assembly (Bolted Bonnet, Std.)

INSTALLATION, OPERATION, & MAINTENANCE MANUAL TITLE: F88 Series Safety Relief Valve Rev. E Page 13 of 16 F88 SERIES VALVE ASSEMBLY ILLUSTRATION F88-3 / -4 / -8, “C” Body (Low Pressure, Bolted Bonnet) PRESSURE ADJUSTMENT (PA) SCREW LOCKING SPINDLE CAP... -

Page 14: F84L-3 / -4 / -8 Series "X" Body Assembly (Bolted Bonnet, Xl)

INSTALLATION, OPERATION, & MAINTENANCE MANUAL TITLE: F88 Series Safety Relief Valve Rev. E Page 14 of 16 F88 SERIES VALVE ASSEMBLY ILLUSTRATION F88-3 / -4 / -8, “X” Body (High Pressure XL, Bolted Bonnet) PRESSURE ADJUSTMENT (PA) SCREW LOCKING SPINDLE CAP... -

Page 15: F84L-3 / -4 Series "Z" Body Assembly (Bolted Bonnet, Xxl)

INSTALLATION, OPERATION, & MAINTENANCE MANUAL TITLE: F88 Series Safety Relief Valve Rev. E Page 15 of 16 F88 SERIES VALVE ASSEMBLY ILLUSTRATION F88-3 / -4, “Z” Body (Extra High Pressure XXL, Bolted Bonnet) PRESSURE ADJUSTMENT (PA) SCREW PA SCREW CAP... -

Page 16: F84L-G / -J Series "D" "E" "X" Body Assembly (Bolted Bonnet)

INSTALLATION, OPERATION, & MAINTENANCE MANUAL TITLE: F88 Series Safety Relief Valve Rev. E Page 16 of 16 F88 SERIES VALVE ASSEMBLY ILLUSTRATION F88-G, “D” or “X” Body (Bolted Bonnet) F88-J, “E” or “X” Body (Bolted Bonnet) PRESSURE ADJUSTMENT BUSHING HOUSING...

Need help?

Do you have a question about the F88 Series and is the answer not in the manual?

Questions and answers