Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Azco SUR-PAK FG400

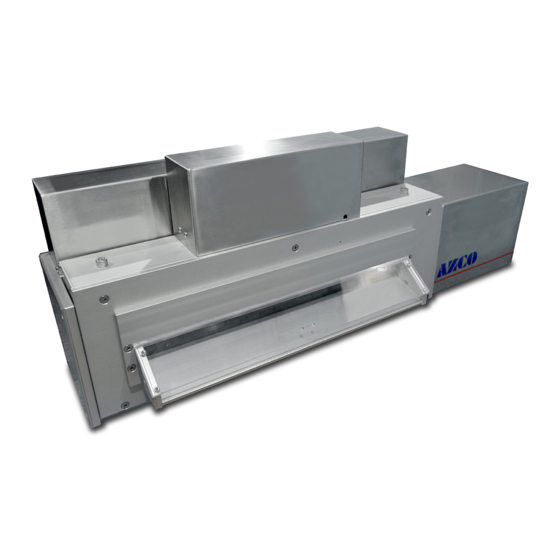

- Page 1 Operation Manual MODEL: FG400 SERIAL #: 203104...

-

Page 2: Table Of Contents

General Maintenance ......................26 Blade Replacement Instructions ................... 26 Blade Setting Instructions ..................... 26 Preventative Maintenance....................27 Troubleshooting ........................ 28 Recommended Spare Parts ....................29 Parameter Default Settings ....................30 Mechanical and Electrical Drawings ................31 Azco Corp. Page 1 10/8/2013... -

Page 3: Introduction

Introduction The AZCO SUR-PAK™, MODEL FG, is a motor fed precision cutting machine. It is designed to cut and dispense a wide variety of materials of varying thickness fed from a continuous web. An optical sensor is used to detect a registration mark on the product web. -

Page 4: Specifications

Supply current Standard (5-phase) units: 10A Air required 40-60 PSI compressed, filtered (non-lubricated) air Accuracy +/ - .047 in. (1.2mm) WARNING: THE UNIT MUST BE PROPERLY GUARDED BEFORE OPERATING! DISCONNECT POWER AND AIR BEFORE SERVICING! Azco Corp. Page 3 10/8/2013... -

Page 5: Installation

220VAC operation, this will be indicated on a label near the AC input receptacle and the machine MUST be connected to a 220V supply. 6. If the unit will accept a trigger from another piece of equipment in the One- Shot Mode for wiring instructions. Azco Corp. Page 4 10/8/2013... -

Page 6: Advanced Setup

Note: If the timer is set to zero (“0”), the knife solenoid will be disabled, and the knife will not operate at all. 5. Set Knife-Up Dwell Time: On a standard machine, the web advance is controlled with the knife home sensor. If additional waiting time is necessary the Azco Corp. Page 5 10/8/2013... - Page 7 Note: If the timer is set to zero (“0”), the signal will be disabled (0 = off, on the display), and no output will occur. Azco Corp. Page 6 10/8/2013...

-

Page 8: Operations

The rollers will index the web until the eye detects the registration mark, then counts a preset offset length, stops and cuts. The machine will run a preset number of pieces. Azco Corp. Page 7 10/8/2013... - Page 9 110 VAC (AZCO will install a mechanical relay in control unit). One- shot mode is found used in systems that require the AZCO unit as a subordinate machine.

-

Page 10: How To Set Up An Automatic Cycle

You will then be asked to press cycle start to begin cycling. To change settings, press cycle stop then main menu. After that enter the standard setup and enter new values when prompted. Azco Corp. Page 9 10/8/2013... - Page 11 The Search Offset value helps the machine ignore any false eye signals between registration marks. This distance should be less than the web’s repeat. NOTE: For best performance, the Search Offset should be larger than the Cut Offset. Otherwise, the motor may not accelerate to high speed. Azco Corp. Page 10 10/8/2013...

-

Page 12: How To Setup The Fg To Run In Eye Mode

STOP until the cycle is stopped by the operator How to Setup the FG to Run in Eye Mode When operating an AZCO unit in the Eye mode, the operator must set three (3) values. These are: Cut Offset, Max Length and Search Offset. - Page 13 MAX LENGTH. If no mark has been detected when the web has been fed this distance, an alarm is generated and feeding stops. Azco Corp. Page 12 10/8/2013...

- Page 14 (the background is much lighter or darker than the mark and there are no wrinkles or stray marks to confuse the eye), the Search Offset can be set to a very small value. A good rule of thumb is to set this value to one half of the piece length. Azco Corp. Page 13 10/8/2013...

-

Page 15: Eye Registration Setup

After the eye is set the machine will be ready to run. Now the product is ready to run. (Helpful Hint: to prevent unwanted tripping or erratic operation, avoid excessive web flutter, wrinkles or background variations.) Azco Corp. Page 14 10/8/2013... -

Page 16: Setup Instructions For Four-Wire "One Shot" Wiring

(relay closure) output for 1500 milliseconds (1.5 seconds) after each cut has been made. Setting the timer to zero turns off the ‘end-of-cut’ output, and no signal will be output. This timer is set to zero at the factory. Azco Corp. Page 15 10/8/2013... -

Page 17: Screen Functions

This is the screen that will appear at the startup of the machine. It allows the operator to enter six different areas of configuration plus a help screen. Some of the areas require a password to enter due to the sensitivity of the settings they hold. Azco Corp. Page 16 10/8/2013... - Page 18 The down dwell is the amount of time allotted for the knife to make a cut. With air pressure ranging from 25-40 PSI, the smallest down dwell possible is 50. Any down dwell that is lower than 50 will result in an incomplete cut. The up dwell is Azco Corp. Page 17 10/8/2013...

- Page 19 These functions do not work while the unit is operating, they will only work when the unit is not running. Azco Corp. Page 18 10/8/2013...

- Page 20 In encoder verify mode the encoder tracks the movement of the product and compares it to the movement of the motor. If the lengths are out of a set value of error the machine gives an error signal. Azco Corp. Page 19 10/8/2013...

- Page 21 SPEED. THERE IS NO NEED TO ADJUST ANY OF THESE SETTINGS. Registration Eye Calibration This screen allows the operator to reset the registration eye in order to create a correct trigger point on the package. First jog the product down until the registration eye is Azco Corp. Page 20 10/8/2013...

- Page 22 After the cycle stop button is pressed, the operator may also use the jog and manual cut buttons to clear any errors or start a new roll of product. Azco Corp. Page 21 10/8/2013...

- Page 23 This is considered the “no mark found” error. Once the unit sees a trigger the unit will then run the cut offset length in order to have the seal in the cut position. Azco Corp. Page 22 10/8/2013...

- Page 24 This screen allows the operator to turn the safety sensors on and off. The sensors available on this unit are the Product Eye (determines whether product is fed into the machine), the Jam Eye (makes sure there is no jam inside the unit), and the Knife Sensor Azco Corp. Page 23 10/8/2013...

- Page 25 The time that is entered is the amount of time that the machine will turn an output on at the end of a cycle. It is used when the operator would like to tell another unit that the AZCO machine is done. Azco Corp.

- Page 26 Whenever there is an alarm fault, the operator must go to this screen and press the alarm clear button in order to start a new cycle. Any error that occurs will be shown by a red light next to the description. Azco Corp. Page 25 10/8/2013...

-

Page 27: General Maintenance

6. Using a piece of 1 to 2 mil plastic sheeting, test the cut quality. If plastic sheeting is not available, paper can also be used. The blade should cut completely along its entire length. If not, repeat the adjustment. Azco Corp. Page 26 10/8/2013... -

Page 28: Preventative Maintenance

The unit is NOT wash down safe and should never be exposed to large amounts of water or fluid. All safety precautions should be followed when cleaning and servicing the unit. Azco Corp. recommend the blades be lubricated once a day using an industrial lubricant (LPS Industrial Lubricant is recommended). -

Page 29: Troubleshooting

Check that the air is supplied. Check that there are no obstructions in the way of the knife assembly. Edges Of The Product Are Tearing: Check that the product roll is in line with the web guides. Azco Corp. Page 28 10/8/2013... -

Page 30: Recommended Spare Parts

Roller FG25041V2 Motor FG25044 Timing Belt E-SOL-3 Solenoid Valve FG40020 Drive Roller E-PS-9 Power Supply 24VDC E-PLC-1 PLC Serial E-MC-13 5 Phase Driver 20600101 Motor, AC 212019D40 Gearhead E-RC-32 Arm Pot E-MC-35 AC Motor Driver Azco Corp. Page 29 10/8/2013... -

Page 31: Parameter Default Settings

FACTORY DEFAULT, AZCO DEFAULT and SECONDARY DEFAULT SETTINGS Model: FG400 Serial #: 203104 Factory Default AZCO Default Customer Custom Settings Settings Settings ADVANCED PASSWORD: 1428 1428 MOTOR HIGH SPEED: 5000 3000 UNIT: JOG SPEED: 2000 ACCELERATION SLOP: MOTOR DIRECTION: CW / CCW... -

Page 32: Mechanical And Electrical Drawings

203104A... - Page 33 UPPER TIE BAR E-SOL-3A SOLENOID PLUG SP25X12 SPRING PIN SHS8X30 SOCKET HD SCREW S.S SK4X6 SET SCREW S.S. AZCO corp. REVISION 2 PLACE DECIMALS +/-.10 DATE HOLES H14, SHAFT h14 ROLL FEED ASSEMBLY ALL OTHERS +/-IT14/2 3 PLACE DECIMALS +/-.005...

- Page 34 AZCO corp. REVISION 2 PLACE DECIMALS +/-.10 DATE HOLES H14, SHAFT h14 ROLL FEED ASSEMBLY ALL OTHERS +/-IT14/2 3 PLACE DECIMALS +/-.005 BY: DS DATE: 2/3/09 2 PLACE DECIMALS +/-.015 FG250B-V3 SHEET 2 OF 2 ANGULAR +/-1/2...

- Page 35 FG400A...

- Page 36 CORP.

- Page 37 203104B...

Need help?

Do you have a question about the SUR-PAK FG400 and is the answer not in the manual?

Questions and answers