Summary of Contents for Baruffaldi CE Series

- Page 1 .CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 1 / 59 USE AND MAINTENANCE MANUAL CE 2-Speed Gearboxes...

- Page 2 .CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 2 / 59...

- Page 3 .CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 3 / 59 WARNINGS Before setting at work, carefully read instructions for use and follow them! Only qualified personnel, that has carefully read instructions, is allowed to operate on BF gearboxes.

-

Page 4: Table Of Contents

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 4 / 59 1 Structure of the Gearbox ___________________________________________________ 6 1.1 Delivery conditions _________________________________________________________________ 7 1.2 Data label ________________________________________________________________________ 8 1.3 Handling and lifting the Gearboxes ___________________________________________________ 9 1.4 Technical data ___________________________________________________________________ 10 1.5 Ordering code ____________________________________________________________________ 12 1.6 Motor flange dimensions ___________________________________________________________ 13... - Page 5 .CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 5 / 59 4.10 Assembling Positions & Lubrication - CE 16 & 18 ______________________________________ 50 4.11 Assembling Positions & Lubrication - CE 20 ___________________________________________ 52 4.12 Assembling Positions & Lubrication - CEA13 & CEA 13+ _________________________________ 54 4.13 Assembling Positions &...

-

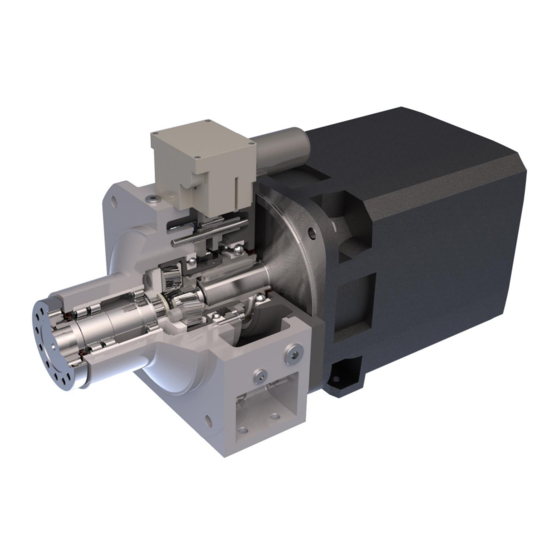

Page 6: Structure Of The Gearbox

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 6 / 59 TRUCTURE OF THE EARBOX Flange Output Shaft Output Actuator Motor Fixing holes for "flange mounting " Centering diameter for Fixing holes for "flange mounting" "feet mounting"... -

Page 7: Delivery Conditions

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 7 / 59 1.1 D ELIVERY CONDITIONS All Gearboxes are delivered with: • Test report • Electrical connector complete with plug and relevant pins • Balancing insert for motor shaft balancing (if necessary) •... -

Page 8: Data Label

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 8 / 59 Additional components only for Gearboxes type CE 20 • Drain fitting • Vent fitting 1.2 D ATA LABEL Gearbox Size Code (see Ordering Code on page 10) Serial Number Transmission ratio... -

Page 9: Handling And Lifting The Gearboxes

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 9 / 59 1.3 H ANDLING AND LIFTING THE EARBOXES GEARBOX Size 13-13+ 14 - 15 Eyebolt hole dimension Approximate weight (kg) 190/230 190/230 190/230 (depending on motor flange) Use the holes shown below for gearbox lifting CE 20 CE 11-12-13-13+-14-15-16-18... -

Page 10: Technical Data

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 10 / 59 1.4 T ECHNICAL DATA Size CE11 CE12 CE13 CE13+ CE14 Taglia Ratio I=4.48 I=4.4 I=4.9* I=5.5 I=5.5 Rapporto Nominal power Potenza nominale Nominal speed 1500 Velocità... - Page 11 .CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 11 / 59 Size CE15 CE16 CE18 CE20 Taglia Ratio I=5.5 Rapporto Nominal power Potenza nominale Nominal speed 1500 1250 1000 Velocità nominale S1 Nm Nominal input torque Coppia nominale entrata S6 Nm Nominal output torque...

-

Page 12: Ordering Code

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 12 / 59 1.5 O RDERING CODE Version Motor Shaft Balancing Code Code Versione Bilanciamento albero motore Version Standard Versione standard Ratio Code Rapporto With oil sensor and actuator at 180° Con sensore olio e attuatore a 180°... -

Page 13: Motor Flange Dimensions

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 13 / 59 1.6 M OTOR FLANGE DIMENSIONS 2 3 . Motor dimensions provided by the manufacturer CE11 Dimensioni del motore fornite dal produttore Motor Code Diameter Lenght Centering Pitch holes... -

Page 14: Functioning Principle

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 14 / 59 UNCTIONING PRINCIPLE 2.1 M AIN DESCRIPTION The actuator (02), acting on the fork (06), moves the sliding sleeve (11) to engage either the pinion (09) or the fixed ring (13). -

Page 15: Gearbox In High Speed Mode (1:1)

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 15 / 59 2.2.1 Gearbox in high speed mode (1:1) In this operating mode, the sliding sleeve (11) is engaged with the pinion (09). Motion coming from the motor goes to the planetary unit both through the ring gear (10) and the sun gear (12), so the planet carrier (08) turns at the same speed of the motor. -

Page 16: General Operating Rules

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 16 / 59 2.2 G ENERAL OPERATING RULES Planetary gearboxes can be used in the three positions described above. Low speed mode (chapter 2.2.2) can be used without time limitations, the gearbox can operate continuously, provided all parameters are within the gearbox specifications. -

Page 17: Gearbox Start-Up

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 17 / 59 EARBOX START 3.1 M OTOR SPECIFICATIONS 3.1.1 Dimensions and tolerances The motor applied to the gearbox should comply with the following specifications: • Size and power admitted by the gearbox •... -

Page 18: Matching Motor - Gearbox Balancing

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 18 / 59 3.1.3 Matching motor - gearbox balancing ➢ If the motor shaft is straight (no key), there is no balancing problem because both the motor shaft and the gearbox pinion are balanced: the gearbox can be fitted directly to the motor by means of the clamping unit provided, see chapters 3.2.2/3.3.2. -

Page 19: Assembling The Motor On The Gearbox - Gearbox Ce 11 - 13 - 13+ - 16 - 18 - 20

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 19 / 59 3.2 A CE 11 - 13 - 13+ - 16 - 18 - 20 SSEMBLING THE MOTOR ON THE GEARBOX EARBOX 3.2.1 Motor shaft with key Always check the full motor code and the gearbox code before proceeding. -

Page 20: Motor Shaft Without Key (Straight Shaft) - Conical Clamping Unit

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 20 / 59 3.2.2 Motor shaft without key (straight shaft) - conical clamping unit This assembling operation is rather delicate. Carefully follow the procedure described below! • REMOVE FLANGE (3) + PINION CLAMPING UNIT (100) FROM THE GEARBOX Step 1 Loosen the screws that fix the motor flange to the gearbox housing and gently pull the flange... - Page 21 .CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 21 / 59 Fasten the flange to the motor with the screws supplied g) Insert and tighten n°2 set screws (99) on the threaded holes in order to fasten the pinion onto the motor shaft avoiding axial sliding of the pinion during the clampers (15) tightening (pay attention at this step, in fact the axial slidings of the pinion might generate troubles at the bearing 98) h) Tighten the screws (9a) by hand after removing set screws (14), if present...

- Page 22 .CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 22 / 59 • ASSEMBLE THE GEARBOX UNIT WITH MOTOR+ PINION CLAMPING UNIT (100) Step 3 O-ring k) Check that the O-ring is in place l) Gently push the gearbox towards the motor flange, until they get in contact. Turning the output shaft by hand can help engage the sun gear (12) with the planets (07) m) Tighten the screws: see chapter 3.2.1 - d) for the possible configurations When inserting the sun gear (12) inside the planetary unit, pay attention not to damage the...

-

Page 23: Disassembling The Clamping Unit (100) From Motor Shaft

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 23 / 59 3.2.3 Disassembling the clamping unit (100) from motor shaft During maintenance operations, it may be necessary to remove the motor from the gearbox. If the pinion is locked by means of a clamping unit, you should follow the instructions below. a) Remove the screws that fix the motor flange to the gearbox b) Pull the gearbox unit away from the motor+flange+pinion, until the sun gear is out of the gearbox... -

Page 24: Assembling The Motor On The Gearbox - Gearbox Type Ce 12 - 14 - 15

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 24 / 59 3. 3 A CE 12 - 14 - 15 SSEMBLING THE MOTOR ON THE GEARBOX EARBOX TYPE For gearboxes type CE12 and CE14-CE15, the procedure is different from all other gearboxes. 3.3.1 Motor shaft with key •... - Page 25 .CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 25 / 59 • SCREWING THE PINION ON THE MOTOR SHAFT Step 3 After fitting the pinion, it is necessary to screw it to the motor shaft. Before this operation, check the dimension Y according to the drawings/chart below.

-

Page 26: Motor Shaft Without Key (Straight Shaft) - Conical Clamping Unit

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 26 / 59 3.3.2 Motor shaft without key (straight shaft) - conical clamping unit motor shaft end (motor side) Motor shaft a) Assemble the bush (21) with relevant gaskets (21a) on the motor shaft, until shaft end b) Clean motor shaft and pinion (22) hole c) Oil the pinion/shaft contact surfaces on both pinion and motor shaft (**) d) Assemble the pinion (22) with the clamping ring (23) on the motor shaft, against bush (21) -

Page 27: Assembling The Gearbox On The Motor

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 27 / 59 3.3.4 Assembling the gearbox on the motor Check that the O-Ring (01a) is in place. Assemble motor + flange + pinion to the gearbox, so that the free end of the pinion (09 or 22) fits the spline of the sun gear (12). -

Page 28: Motor-Gearbox Assembling Options

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 28 / 59 3.4 M OTOR GEARBOX ASSEMBLING OPTIONS Motor and gearbox can be assembled on the machine in different ways, according to the design of the machine. All gearboxes, except CE20, have a centering diameter + fixing holes on the front flange (for "flange mounting") and feet with holes (for "feet mounting") - see Chapter 1. -

Page 29: Gearbox Output

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 29 / 59 3.5 G EARBOX UTPUT 3.5.1 Verifying gearbox output loading capacity Gearboxes can be supplied in shaft-output or flange-output configuration. Shaft-output is normally used when the gearbox is assembled coaxial to the machine or connected to it by means of a timing belt or a gear (1). -

Page 30: Gearbox Output Bearings: Position And Loading Capacity

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 30 / 59 3.5.2 Gearbox output bearings: position and loading capacity Bearing R Bearing F Second bearing Cuscinetto R Cuscinetto F Secondo cuscinetto Table 1 Loading Loading Loading Type Type... -

Page 31: Assembling Positions And Lubrication

It is also used in some assembly positions, even if the speeds and operating times are not high, because it is the only way to lubricate all the inner parts properly. -All Baruffaldi gearboxes are designed for operation with inner pressure equal to outer (atmospheric) pressure. -

Page 32: Splash Lubrication

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 32 / 59 4.2 S PLASH UBRICATION Splash lubrication is used when there are frequent shifting operations, frequent speed changes, variable turning speeds and frequent machine downtimes such as, for example, rests for tool changes. This lubrication system is suitable only for applications with maximum input speed 4500 rpm and in the assembling positions indicated below. - Page 33 (chapter 4.1) is only approximate. In order to keep the oil level under control over time, it is strongly suggested to use an additional oil level sensor (c) assembled on the gearbox; upon request, Baruffaldi can supply a suitable sensor (code 999.912.06547).

-

Page 34: Oil Recirculating Lubrication (Forced Lubrication)

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 34 / 59 4.3 O ECIRCULATING UBRICATION ORCED UBRICATION Using oil recirculating lubrication, in any assembling position, improves heat dissipation in the gearbox. In case of continuous use at high rotation speed and with short downtimes, oil recirculating lubrication is necessary. -

Page 35: Monitoring The Oil Flow: Oil Flow Rate Switch

In order to monitor the oil flow over time, the use of a Flow Rate Switch is strongly suggested, to be connected to the oil supply circuit. Upon request, Baruffaldi can provide a suitable Flow Rate Switch, as shown below. -

Page 36: Gearbox Assembling Designation

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 36 / 59 4.4 G EARBOX ASSEMBLING DESIGNATION The different assembling positions on the machine are identified with a specific code, ase described below Horizontal Horizontal turned Vertical downward Vertical upward 4.5 L... -

Page 37: Ce 13 - Horizontal Assembly - Forced Lubrication With Suction Pump

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 37 / 59 4.5.1 CE 13 - Horizontal assembly - Forced Lubrication With Suction Pump 4.5.2 CE 13 - Horizontal assembly - Forced Lubrication With Oil Return By Fall Down... -

Page 38: Ce 13 - Vertical Down Assy - Forced Lubrication With Oil Return By Suction

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 38 / 59 4.5.3 CE 13 - Vertical Down Assy - Forced Lubrication With Oil Return By Suction 4.5.4 CE 13 - Horizontal Assy - Forced Lubrication With Oil Return By Fall Down... -

Page 39: Ce 20 - Horizontal Assembly - Forced Lubrication With Suction Pump

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 39 / 59 4.5.5 CE 20 - Horizontal Assembly - Forced Lubrication With Suction Pump 4.5.6 CE 20 - Horizontal Assembly - Forced Lubrication With Oil Return By Fall Down... -

Page 40: Ce 20 - Horizontal Assembly - Forced Lubrication With Oil Return By Fall Down

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 40 / 59 4.5.7 CE 20 - Horizontal Assembly - Forced Lubrication With Oil Return By Fall Down 4.5.8 CE 20 - Horizontal Assembly - Forced Lubrication With Suction Pump... -

Page 41: Ce 20 - Vertical Down Assembly - Forced Lubrication With Suction Pump

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 41 / 59 4.5.9 CE 20 - Vertical Down Assembly - Forced Lubrication With Suction Pump 4.5.10 CE 20 Vertical Down Assy - Forced Lubrication With Oil Return By Fall Down... -

Page 42: Assembling Positions & Lubrication - Ce 11

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 42 / 59 4.6 A & L - CE 11 SSEMBLING OSITIONS UBRICATION... - Page 43 .CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 43 / 59...

-

Page 44: Assembling Positions & Lubrication - Ce 12

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 44 / 59 4.7 A & L - CE 12 SSEMBLING OSITIONS UBRICATION In position B and B1, injectors are fitted for lubrication oil. Do not remove or turn, seizing danger! - Page 45 .CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 45 / 59 In position B and B1, injectors are fitted for lubrication oil. Do not remove or turn, seizing danger!

-

Page 46: Assembling Positions & Lubrication - Ce 13 & Ce13

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 46 / 59 4.8 A & L - CE 13 & CE13+ SSEMBLING OSITIONS UBRICATION... - Page 47 .CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 47 / 59...

-

Page 48: Assembling Positions & Lubrication - Ce 14 & Ce 15

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 48 / 59 4.9 A & L - CE 14 & CE 15 SSEMBLING OSITIONS UBRICATION In position B and B1, injectors are fitted for lubrication oil. Do not remove or turn, seizing danger! - Page 49 .CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 49 / 59 In position B and B1, injectors are fitted for lubrication oil. Do not remove or turn, seizing danger!

- Page 50 .CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 50 / 59 4.10 A & L - CE 16 & 18 SSEMBLING OSITIONS UBRICATION...

- Page 51 .CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 51 / 59...

-

Page 52: Assembling Positions & Lubrication - Ce 20

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 52 / 59 4.11 A & L - CE 20 SSEMBLING OSITIONS UBRICATION... - Page 53 .CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 53 / 59...

-

Page 54: Assembling Positions & Lubrication - Cea13 & Cea 13

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 54 / 59 4.12 A & L - CEA13 & CEA 13+ SSEMBLING OSITIONS UBRICATION 4.13 A & L - CEA14 & CEA 15 SSEMBLING OSITIONS UBRICATION... -

Page 55: Electrical Section

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 55 / 59 LECTRICAL ECTION 5.1 A CTUATOR The gearbox actuator (02) is an electro-mechanical shifting unit used to switch between the low speed/high speed/neutral positions. The unit is designed according to the easiest and most durable solutions for the speed change. Cable Pin Out (a) Actuator (02) 5.2 C... -

Page 56: Flow Chart & Iso Program Example

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 56 / 59 5.3 F & I HART ROGRAM XAMPLE... - Page 57 .CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 57 / 59 This program shows a customer implementation of speed change sequence. ISO PROGR. EXAMPLE IF M42 is „on“ (request of second gear step from CNC side) THEN Attempt=0 Spindle stop command IF spindle is stopped THEN...

-

Page 58: Gearbox Layout Views

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 58 / 59 EARBOX AYOUT IEWS 6.1 G CE 11 - 13 - 13+ - 16 - 18 - 20 EARBOX TYPE 01 Housing 02 Actuator 03 Motor flange 04 Output flange or Output shaft 06 Fork 07 Planetary gears... -

Page 59: Gearbox Type Ce 12 - 14 -15

.CE.GEN.ENG.DOCX USE AND MAINTENANCE MANUAL Issued 2018 Rev.03 2-Speed Gearboxes Series CE Page 59 / 59 6.2 G CE 12 - 14 -15 EARBOX TYPE 01 Housing 02 Actuator 03 Motor flange 04 Output flange or Output shaft 06 Fork 07 Planetary gears 08 Planetary gears carrier 09 Pinion...

Need help?

Do you have a question about the CE Series and is the answer not in the manual?

Questions and answers