Summary of Contents for Realax IP Series

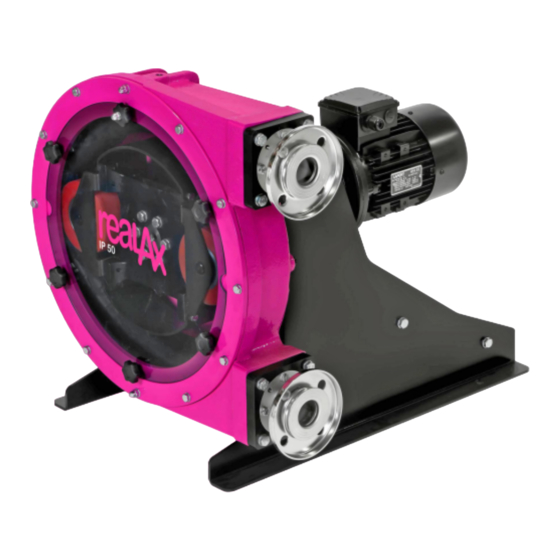

- Page 1 Operating instructions IP Series Peristaltic pump ALL THE HOSE PUMP YOU’LL EVER NEED...

- Page 2 – after all, best is what you want, second best should never be an option. We hope you’ll find using your realax pump simple, trouble- free and that it makes a positive contribution to the success of your process.

-

Page 3: Table Of Contents

Operating instructions Peristaltic Pump IP Series TAbLE Of CONTENTS Introduction .......... -

Page 4: Introduction

Operating instructions Peristaltic Pump IP Series INTRODUCTION This manual forms an integral part of the pump and must accompany it until its demolition. The series IP peristaltic pump is a machine destined to work in industrial areas and as such the instruction manual must... - Page 5 Explanation of the safety information The instructions of this manual, whose inobservance is determined as a failure to meet safety standards, are identified by this symbol . The instructions of this manual, whose inobservance compromises electrical safety. The instructions of this manual, whose inobservance compromises the correct working of the pump, are CAUTION identified with this symbol.

-

Page 6: Safety And Responsibility

Operating instructions Peristaltic Pump IP Series SAfETY AND RESPONSIbILITY General safety information Live parts Possible consequence: Fatal or very serious injuries. - Measure: The device must be disconnected from the power supply before it is opened. - Isolate damaged faulty or manipulated devices from the mains in order to de-energise. - Page 7 Correct and proper use CAUTION Possible consequence: Fatal or very serious injuries. - The unit is not intended to convey or regulate gases or solid media. - Do not exceed the rated pressure, speed or tem- perature for the pump. - The unit may only be used in accordance with the technical data and specifications provided in these operating instructions and in the operating...

- Page 8 Operating instructions Peristaltic Pump IP Series In addition, as the hose has an indeterminate life and due to the possibility of its breakage or deterioration, the user is responsible for the prevention of a possible (although most unlikely) incorporation of particles from the hose into the product being pumped.

-

Page 9: Functional Description

DESCRIPTION The IP Series is a positive displacement pump. The process fluid is con- veyed by the rotor squeezing the hose in the direction of flow. No valves are needed for this. This ensures gentle handling of the process fluid. -

Page 10: Transport And Storage

Operating instructions Peristaltic Pump IP Series TRANSPORT AND STORAGE Transport - The pump is protected by a cardboard packaging. - The packaging materials are recyclable. Storage - The pump should be in a resting position. (The hose should not be compressed). -

Page 11: Assembly And Installation

120* Only available for IP-40 * At max. temperature, the life of hose is drastically reduced. Please contact author- ized realax distributor for high temperature application. Correct installation of the pump 5.2.1 Suction side The pump is to be positioned as near as possible to the liquid container, so that the suction side is kept as short and straight as possible. - Page 12 Operating instructions Peristaltic Pump IP Series 5.2.2 Discharge side The discharge line is to be kept as straight and short as possible, in or- der to avoid performance reduction. The diameter must correspond to the rated diameter of the pump hose. A larger diameter is recommend- ed in the event of viscose liquids.

- Page 13 Fig 3: Squeezing the hose 1. Hose in normal shape. 2. Insufficient squeezing (back flowing media in the cavity will destroy the hose within a short period of time). 3. Perfect squeezing. 4. Excessive squeezing (increased wear and tear to pump and hose). The shims are fitted in the factory.

- Page 14 Operating instructions Peristaltic Pump IP Series 5.3.2 IP-40 Model (Number of shims of 1 mm thickness) a) NR, NBR, EPDM, HYPALON, NR-A and NBR-A: 1/min 0-19 20-39 40-59 60-79 80-99 4.0* – – – – – *Factoring default setting if working pressure is not informed.

- Page 15 5.3.4 IP-60 Model (Number of shims of 1 mm thickness) a) NR, NBR, EPDM, NR-A and NBR-A: 1/min 0-19 20-39 40-59 60-79 80-99 4.0* – *Factoring default setting if working pressure is not informed. 5.3.5 IP-70 Model (Number of shims of 1 mm thickness) a) NR, NBR, EPDM, HYPALON, NR-A and NBR-A: 1/min 0-19...

-

Page 16: Commissioning

Operating instructions Peristaltic Pump IP Series 5.3.6 IP-70D Model (Number of shims of 1 mm thickness) Each of the two pump bodies is fitted with the following configuration: a) NR, NBR, EPDM, HYPALON, NR-A and NBR-A: 1/min 0-19 20-39 40-59... -

Page 17: Maintenance, Repair, Malfunctions Disposal And Spare Parts

MAINTENANCE, REPAIR, MALfUNCTIONS, DISPOSAL AND SPARE PARTS Lubrification Check that the rollers and the hose are sufficiently lubricated. Use only the original realax silicone grease. • Check every 300 operating hours. Model Silicon grace quantity (gr) IP-30 IP-40 IP-50 IP-60 IP-70 Gear reducers. - Page 18 Operating instructions Peristaltic Pump IP Series 7.2.1.2 Model IP-60 1 Close off all valves, in order to prevent leakage of the feed chemical. 2 Dismantle the pipes from both discharge and suction sides 3 Remove the front cover. 4 Remove a roller (the roller that is not touching the pump hose).

- Page 19 Fig 4: Required distance between the end of the hose and the press ring. 6 Fasten the press flange and the connections to the pump casing, tightening progressive the bolts in clock wise (1, 3, 2, 4, 1, 3, 2, 4, etc.), until the flange becomes totally tighten.

- Page 20 Operating instructions Peristaltic Pump IP Series Mount the front cover. Turn the rotor with the help of the motor so that the remaining roller presses against the pump hose. Dismount the front cover. 10 Re-attach the second roller with shims back onto the rotor.

- Page 21 Troubleshooting Problem Possible cause Solution Increased pump Pump hose has no lubricant Lubricate pump hose temperature Increased product tempera- Reduce product temperature ture Insufficient or poor suction Check suction line for block- conditions ages Pump speed too high Reduce pump speed Reduced flow or Valves on discharge and or Open valves...

- Page 22 Operating instructions Peristaltic Pump IP Series Vibrations on Insufficient nominal width Increase nominal width pumps and of the pipes pipelines Pump base plate loose Fasten base plate Pulsation dampers insuf- Install pulsation dampers on suc- ficient or missing tion and / or discharge side...

-

Page 23: Spare Parts

SPARE PARTS Spare parts exploded IP-30 Model Pos. Description Quantity Reference Pump casing 107.00.01 Ball bearing box 107.00.03 Rotor shaft 107.00.04 Rotor 107.00.05 Roller support 107.00.06 Shim 107.00.07 Shaft screw 107.00.08 Roller shaft 107.00.09 Roller 107.00.11... - Page 24 Operating instructions Peristaltic Pump IP Series Pos. Description Quantity Reference Metallic cover 107.00.13 Polycarbonate cover 107.00.14 Press flange 107.00.15 Press ring 100.00.05 Connection SS 1 1/4” BSP 107.00.17 Connection SS 1 1/4” NPT 107.00.34 Connection DIN 11851 NW32 107.00.35 Connection TRI-CLAMP 107.00.36...

- Page 25 Spare parts exploded IP-40 Model Pos. Description Quantity Reference Pump casing 106.00.01 Ball bearing box 106.00.03 Rotor shaft 106.00.04 Rotor 106.00.05 Roller support 106.00.06 Shim 1 mm 106.00.07 Shim 4 mm 106.00.49 Shaft screw 106.00.08 Roller shaft 106.00.09 Roller 106.00.11 Metallic cover 106.00.13 Metallic cover vacuum equipment...

- Page 26 Operating instructions Peristaltic Pump IP Series Pos. Description Quantity Reference Connection SS 1 1/2” BSP 106.00.17 Connection SS 1 1/2” NPT 106.00.34 Connection DIN 11851 NW40 106.00.35 Connection TRI-CLAMP 106.00.36 Connection flange DIN DN40 INOX 106.00.37 Connection flange ANSI DN40 INOX 106.00.38...

- Page 27 Spare parts exploded IP-50 Model Pos. Description Quantity Reference Pump casing 108.00.01 Ball bearing box 108.00.02 Rotor shaft 108.00.03 Rotor 108.01.04 Roller support 108.01.05 Shim 108.00.06 Shaft screw 108.00.07 Roller shaft 108.00.08 Roller 108.01.09 Metallic cover 108.00.10 Polycarbonate cover 108.00.39 Press flange 108.00.11 Press ring...

- Page 28 Operating instructions Peristaltic Pump IP Series Pos. Description Quantity Reference Connection flange DN-50 SS 108.00.13 Connection ANSI flange DN-50 SS 108.00.14 Connection flange DN-50 PP 108.00.16 Connection ANSI flange DN-50 PP 108.00.17 Connection flange DN-50 PVDF 108.00.18 Connection ANSI flange DN-50 PVDF 108.00.19...

- Page 29 Spare parts exploded IP-60 Model Pos. Description Quantity Reference Pump casing 110.00.01 Ball bearing box 110.00.03 Rotor shaft 110.00.04 Rotor 110.00.05 Roller support 110.00.06 Shim 1 mm 110.00.07 Shim 7 mm 110.00.55 Shim 5 mm 110.00.56 Shaft screw 110.00.08 Roller shaft 110.00.09 Separator 110.00.10...

- Page 30 Operating instructions Peristaltic Pump IP Series Pos. Description Quantity Reference Insert S.S 110.00.16 Insert Polypropylene 110.00.46 Insert PVDF 110.00.47 Connection flange DIN 110.00.17 Connection flange ANSI 110.00.41 Connection TRI-CLAMP 110.00.42 Connection DIN 11851 110.00.43 Connection flange DIN (Halar) 110.00.44 Connection flange ANSI (Halar) 110.00.45...

- Page 31 Spare parts exploded IP-70 Model Pos. Description Quantity Reference Pump casing 112.00.01 Ball bearing box 111.00.03 Rotor shaft 111.00.04 Rotor 112.00.02 Roller support 112.00.03 Shim 112.00.04 Shaft screw 112.00.05 Roller shaft 112.00.06 Roller 112.00.07 Front cover 112.00.08 O-ring front cover 112.00.35 Press flange 112.00.09...

- Page 32 Operating instructions Peristaltic Pump IP Series Pos. Description Quantity Reference Connection DIN flange S.S 112.00.11 Connection ANSI flange S.S 112.00.12 Connection DIN 11851 NW-65 112.00.13 Connection DIN flange PP 112.00.14 Connection ANSI flange PP 112.00.15 Connection DIN flange PVDF 112.00.16 Connection ANSI flange PVDF 112.00.17...

- Page 33 Spare parts exploded IP-70D Model Pos. Description Quantity Reference Pump casing 112.00.01 Ball bearing box 111.00.03 Rotor shaft 111.00.04 Rotor 112.00.02 Roller support 112.00.03 Shim 112.00.04 Shaft screw 112.00.05 Roller shaft 112.00.06 Roller 112.00.07 Front cover 112.00.08 O-ring front cover 112.00.35 Press flange 112.00.09...

- Page 34 Operating instructions Peristaltic Pump IP Series Pos. Description Quantity Reference Connection DIN flange S.S 112.00.11 Connection ANSI flange S.S 112.00.12 Peristaltic hose NR 112.00.18 Peristaltic hose NR-A 112.00.19 Peristaltic hose NBR 112.00.20 Peristaltic hose NBR-A 112.00.21 Peristaltic hose EPDM 112.00.22 Peristaltic hose HYPALON 112.00.23...

-

Page 35: Declaration Of Conformity

DECLARATION Of CONfORMITY... -

Page 36: Warranty

WARRANTY We guarantee against all manufacturing defects and guarantee the materials that compose the realax pump for two years from the date of delivery. This guarantee does not cover the hose or the lubricant as these are elements that have a normal function wear, irrespective of their duration. - Page 37 Telefax: +45 7010 3555 www.axflow.fr Bestillinger, forespørgsler og almene spørgsmål kan mailes til os på: axflow@axflow.dk Kontor og lager: For more information about realax AxFlow A/S hose pumps please contact: Kong Svends Vej 65A AxFlow Ltd. DK-2765 Smørum Unit 33, Western Parkway Business Centre www.axflow.dk...

- Page 38 AxFlow GesmbH Austria Seering 2/2 Aby uzyskać więcej informacji na 8141 Unterpremstätten temat pomp realax węża prosimy o Tel.: +43 316/68 35 09-0 kontakt: Fax: +43 316/68 34 92 AxFlow Sp. z o. o. E-mail: office@axflow.at ul.

- Page 39 AxFlow Scotland Unit 3, Harlaw Centre, Howe Moss Crescent, Kirkhill Industrial Estate, Dyce, Aberdeen, AB21 OGN Phone: +44(0)1224 729367 AxFlow Huddersfield Unit 9a, Fieldhouse Business Park, Old Fieldhouse Lane, Huddersfield, HD2 1FA Phone: +44(0)1484 543649 AxFlow Durham Unit 31, Evans Business Centre, Aycliffe Business Park, Newton Aycliffe, County Durham, DL5 6ZF Phone: +44(0)1325 327322...

- Page 40 ALL THE HOSE PUMP YOU’LL EVER NEED www.realaxpumps.com...

Need help?

Do you have a question about the IP Series and is the answer not in the manual?

Questions and answers