Summary of Contents for Realax IP Series

- Page 1 Operating instructions IP Series Peristaltic pump ALL THE HOSE PUMP YOU’LL EVER NEED...

- Page 2 – after all, best is what you want, second best should never be an option. We hope you’ll find using your realax pump simple, trouble- free and that it makes a positive contribution to the success of your process.

-

Page 3: Table Of Contents

Operating instructions Peristaltic Pump IP Series TAbLE Of CONTENTS Introduction .......... -

Page 4: Introduction

This instruction manual must accompany the pump at all times for as long as it is in use. The IP series peristaltic pump is a machine for fluid handling intended to be used in industrial areas, as such the instruction manual is part of the legislative provisions for the safe and correct use of the pump. - Page 5 Service and support For information with respect to specific adjustments, installation, maintenance or repair jobs which fall beyond the scope of this manual, contact your AxFlow representative. Make sure you have the serial number of the hose pump at hand. Environment and disposal of waste Enquire with your local government about the possibilities for reuse or environment friendly processing of packaging materials, (contaminated)

-

Page 6: Safety

Operating instructions Peristaltic Pump IP Series SAfETY Explanation of the safety information In this manual the following symbols are used: This symbol identifies the instructions of this manual, which must be observed to avoid failure to meet safety standards. This symbol identifies the instructions of this manual, which must be observed to avoid compromising electrical safety. - Page 7 the front cover. Depending on the specific working conditions or accesso- ries used, additional safety instructions can be required. User qualifications Pumps are machines that can present dangers due to moving parts and the presence of a pressurised fluid within the hose. THE fOLLOWING CAN CAUSE SERIOUS DAMAGE AND INJURY •...

- Page 8 Operating instructions Peristaltic Pump IP Series General safety information Live parts Possible consequence: fatal or very serious injuries. - Risk mitigation: the device must be disconnected from the power supply before it is opened. - Isolate damaged, faulty or manipulated devices from the mains in order to de-energise.

- Page 9 - This pump is NOT supplied for use in areas of risk from explosion. ATEX versions of Realax pumps are available and they are supplied with a special ATEX version of the instruction manual.

- Page 10 Operating instructions Peristaltic Pump IP Series - (although most unlikely) incorporation of particles from the hose into the product being pumped. This can be achieved by means of filtration, a hose rupture alarm or other means suitable for the respective process.

-

Page 11: Functional Description

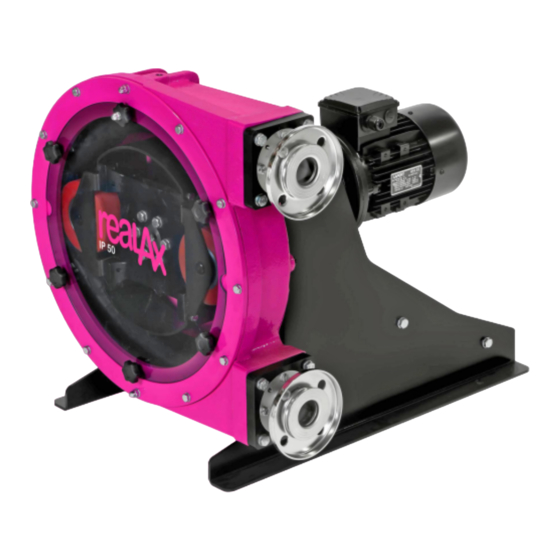

DESCRIPTION The IP Series is a positive displacement pump. The feed liquid is conveyed by the rotor squeezing the hose in the direction of flow. No valves are needed for this. This ensures gentle handling of the metered media. -

Page 12: Description

Operating instructions Peristaltic Pump IP Series Key performance data and noice levels DESCRIPTION UNIT IP 30 IP 40 IP 50 IP 60 IP 70 IP 80 1.55 28.08 Max. Capacity Continuous Duty 6.82 13.2 30.82 41.83 70.45 123.63 2.05 42.12 Max. -

Page 13: Construction

Identification of the gearbox (b) The gearbox has an identity plate with the model, serial number and manufacturer’s details as well as information relevant to its’ function such as reduction ratio. Identification of the electric motor (C) The motor has an identity plate with the model, serial number and manufacturer’s details as well as information relevant to its’... -

Page 14: Pump Hose

Operating instructions Peristaltic Pump IP Series PUMP HOSE General description A: Inner layer B: Nylon reinforcement layers C: Outer layer The pump hose liner material should be chemically resistant with the product to be pumped. Dependent on the specific requirements of your application a corresponding pump hose must be selected. - Page 15 Storage for less than 1 month - The pump should be in a resting position, rotor in horizontal position. - Avoid areas open to harsh weather or excessive humidity and temperatures lower than 0 °C or higher than 30 °C. - Spare hoses should be stored in a dry place away from direct light.

-

Page 16: Assembly, Commissioning & Installation

Operating instructions Peristaltic Pump IP Series Models IP 60, IP 70 and IP 80: Use lifting equipment to elevate the pump. WEIGHTS IP 60 IP 70 IP 80 Total pump 253 kg 574 kg 1,150 kg weight 557 lbs 1,265 lbs... - Page 17 Commissioning 8.2.1 Testing prior to commissioning the pump The following tests are to be carried out: - Check that the rollers are correctly fitted and fastened. - Check that the drive and the pump housing are properly lubricated. The specially formulated lubricant can be obtained from the authorized distributor.

- Page 18 Operating instructions Peristaltic Pump IP Series 8.3.1 Suction side - Install a manometer in the pressure line if the back-pressure value is unknown. Maximum pressure on suction/inlet side is 3 bar (45 psi approx.). - The pump is to be positioned as near as possible to the liquid container, so that the suction side is kept as short and straight as possible.

- Page 19 Maximum permissible loads on the pump flange FORCE UNIT IP 30 IP 40 IP 50 IP 60 IP 70 IP 80 1,000 1,200 1,300 1,500 lb-f lb-f lb-f 8.3.3 Discharge side - The discharge line is to be kept as straight and short as pos- sible, in order to avoid performance reduction.

- Page 20 Operating instructions Peristaltic Pump IP Series Adjusting the roller pressure - The peristaltic pump is equipped with shims, in order to adjust the precise distance from the axis of rotation to the roller for correct hose compression (also dependent on speed and operating pressure).

- Page 21 The shims are fitted in the factory. The number of shims can be adapted to the actual operating conditions according to the following tables. Slight variations in colour of polyurethane rollers is normal. 8.4.1 Model IP 30 Hose materials – NR, NBR, EPDM, CSM and NBR-A: Number of shims of 0.5 mm thickness (part number AX107.00.07) in each location (i.e.

- Page 22 Operating instructions Peristaltic Pump IP Series 8.4.2 Model IP 40 Hose materials – NR, NBR, EPDM, CSM and NBR-A: Number of shims of 4 mm thickness (part number AX106.00.49) and of 0.5 mm thickness (part number AX106.00.83) in each location (i.e. multiply by 4 for total quantity).

- Page 23 8.4.3 Model IP 50 Hose materials – NR, NBR, EPDM, CSM, NBR-A and NR-A: Number of shims of 0.5 mm thickness (part number AX108.00.69) in each location (i.e. multiply by 4 for total quantity). NOTE: for fluid temperatures > 60 ºC: reduce shim quantities by 1. Revolutions/minute and shim thickness 0-19 20-39...

- Page 24 Operating instructions Peristaltic Pump IP Series 8.4.4 Model IP 60 Hose materials – NR, NBR, EPDM, CSM, NBR-A and NR-A: Number of shims of 6 mm thickness (part number AX110.00.58) and 0.5 mm thickness (part number AX110.00.77) in each location (i.e. multiply by 4 for total quantity).

- Page 25 8.4.5 Model IP 70 Hose materials – NR, NBR, EPDM, CSM, NBR-A and NR-A: Number of shims of 0.5 mm thickness (part number AX112.00.65) in each location (i.e. multiply by 4 for total quantity). NOTE: for fluid temperatures > 60 ºC: reduce shim quantities by 1. Revolutions/minute and shim thickness 0-19 20-39...

-

Page 26: Maintenance

Operating instructions Peristaltic Pump IP Series MAINTENANCE Components weights DESCRIPTION IP 30 IP 40 IP 50 IP 60 IP 70 IP 80 82 kg 122 kg 182 kg 253 kg 574 kg 1,150 kg Total weight 108 lb 268 lbs... - Page 27 No other lubrication is necessary. Lubricant quantity table UNIT IP 30 IP 40 IP 50 IP 60 IP 70 IP 80 Lubricant realax realax realax realax realax realax gram Required quantity ounce 14.1 17.6...

- Page 28 Operating instructions Peristaltic Pump IP Series 9.3.1 Changing oil in gearbox The instructions manual of the gearbox is delivered separately attached to this realax manual. Some models of gearbox are lubricated for life, other models of gear reducers require regular maintenance according to the instructions manual of the gear reducer manufacturer.

- Page 29 Remove the front cover. Front covers of IP 30, IP 40, IP 50 and IP 60 can be removed manually (< 20 kg). Lifting equipment must be used to remove the front covers of IP 70 and IP 80. Remove the roller incl. the shims (the roller that is not touching the hose).

- Page 30 Operating instructions Peristaltic Pump IP Series Mount back the front cover. Turn the rotor with the help of the motor so that the hose is pushed out through one of the openings. Remove the pump hose to be exchanged. Dismount the front cover.

- Page 31 Lay the press rings. Between the end of the hose and the press ring, there must be an specific distance (see fig. 1 and fig. 2). realax Approximate distance model outside press ring IP 30 3–7 mm...

- Page 32 Operating instructions Peristaltic Pump IP Series Push the shaft of the connection into the hose (apply a little grease on the shaft if there is too much interference). Tighten the four allen bolts. Way to proceed with the screws tightening...

- Page 33 12. Check that the lower drain plug is assembled correctly. 13. Attach the front cover to the pump housing. 14. Mount the pipes from both discharge and suction sides. 15. Open all of the valves. Replacement of electric motor and/or gear reducer For repair or replacement of the electric motor and the gear reducer they could be disassembled from the pump housing.

-

Page 34: Troubleshooting

Operating instructions Peristaltic Pump IP Series Addition of leak detection sensor The standard drain plug supplied with the IP pump should be removed from the pump housing. Assemble T-fitting and elbow to the pump housing. Screw electro-optical detector to cap, then attach cap to elbow. - Page 35 Check the suction conditions the hoses Abnormal elevation of Check number of shims temperature Unsuitable lubricant Use realax lubricant Insufficient quantity of grease Reapply lubricant High inlet pressure (> 3 bar) Reduce inlet pressure Pump hose Pump hose filled with deposits...

-

Page 36: Spare Parts

Operating instructions Peristaltic Pump IP Series SPARE PARTS 11.1 Spare parts exploded view IP 30 Model... - Page 37 AX107.00.22 Peristaltic Hose CSM IP 30 AX107.00.45 Metallic cover AX107.01.13 Polycarbonate cover AX107.00.14 Base plate Contact realax distributor Base plate S.S. Contact realax distributor Drive O-Ring front Cover IP 30 AX100.00.17 O-Ring Press Ring IP 30 AX106.01.16COM DIN 913 Socket Set Screw Flat Point M16x12 Grade 8.8 AXTORDIN913M16X12PAV DIN 912 Socket Cap Screw M6x10 Grade 8.8...

- Page 38 Operating instructions Peristaltic Pump IP Series 11.2 Spare parts exploded view IP 30 Model - NORPRENE...

- Page 39 AX107.00.56 Connection S.S. DIN 11851 NW32 IP 30 Norprene AX107.00.52 Peristaltic Hose Norprene IP 30 AX107.00.54 Metallic cover AX107.01.13 Polycarbonate cover AX107.00.14 Contact realax Base plate distributor Contact realax Base plate S.S. distributor Drive O-Ring front Cover IP 30 AX100.00.17 O-Ring Press Ring IP 30 AX106.01.16COM...

- Page 40 Operating instructions Peristaltic Pump IP Series 11.3 Spare parts exploded view IP 40 Model...

- Page 41 AX106.00.22 Peristaltic Hose CSM IP 40 AX106.00.48 Metallic cover AX106.01.13 Polycarbonate cover AX106.01.14 Base plate Contact realax distributor Base plate S.S. Contact realax distributor Drive O-Ring front Cover IP 40 AX104.00.17 O-Ring Press Ring IP 40 AX106.01.16COM DIN 912 Socket Cap Screw M8x12 Grade 8.8 AXTORDIN912M8X12 DIN 933 Hexagonal Head Cap Screw M10x40 Grade 8.8...

- Page 42 Operating instructions Peristaltic Pump IP Series 11.4 Spare parts exploded view IP 40 Model - NORPRENE...

- Page 43 AX106.00.36 Connection S.S. DIN 11851 NW40 IP 40 AX106.00.35 Peristaltic Hose NorprenE IP 40 AX106.00.50 Metallic cover AX106.01.13 Polycarbonate cover AX106.01.14 Contact realax Base plate distributor Contact realax Base plate S.S. distributor Drive O-Ring front Cover IP 40 AX104.00.17 O-Ring Press Ring IP 40 AX106.01.16COM...

- Page 44 Operating instructions Peristaltic Pump IP Series 11.5 Spare parts exploded view IP 50 Model...

- Page 45 AX108.00.22 Peristaltic Hose EPDM IP 50 AX108.00.24 Peristaltic Hose CSM IP 50 AX108.00.25 Metallic cover AX108.01.10 Polycarbonate cover AX108.00.39 Contact realax Base plate distributor Contact realax Base plate S.S. distributor Drive O-Ring front Cover IP 50 AX108.00.35 O-Ring Press Ring IP 50 AX108.00.64...

- Page 46 Operating instructions Peristaltic Pump IP Series 11.6 Spare parts exploded view IP 50 Model - NbR-A...

- Page 47 AX108.00.56 Connection S.S. DIN 11851 NW50 IP 50 NBR-A AX108.00.52 Peristaltic Hose NBR-A IP 50 AX108.01.23 Metallic cover AX108.01.10 Polycarbonate cover AX108.00.39 Contact realax Base plate distributor Contact realax Base plate S.S. distributor Drive O-Ring front Cover IP 50 AX108.00.35 O-Ring Press Ring IP 50 AX108.00.64...

- Page 48 Operating instructions Peristaltic Pump IP Series 11.7 Spare parts exploded view IP 50 Model - NORPRENE...

- Page 49 AX108.00.68 Connection S.S. DIN 11851 NW50 IP 50 Norprene AX108.00.57 Peristaltic Hose Norprene IP 50 AX108.00.45 Metallic cover AX108.01.10 Polycarbonate cover AX108.00.39 Contact realax Base plate distributor Contact realax Base plate S.S. distributor Drive O-Ring front Cover IP 50 AX108.00.35 O-Ring Press Ring IP 50 AX108.00.64...

- Page 50 Operating instructions Peristaltic Pump IP Series 11.8 Spare parts exploded view IP 60 Model...

- Page 51 AX110.00.19 Peristaltic Hose CSM IP 60 AX110.00.54 Peristaltic Hose NR IP 60 AX110.00.18 Metallic cover AX110.01.13 Polycarbonate cover AX110.00.14 Contact realax Base plate distributor Contact realax Base plate S.S. distributor Drive O-Ring front Cover IP 60 AX110.00.33 O-Ring Press Ring AX114.00.13...

- Page 52 Operating instructions Peristaltic Pump IP Series 11.9 Spare parts exploded view IP 60 Model - NORPRENE...

- Page 53 AX110.01.42 Flange Connection S.S. DIN 11851 NW50 IP 60 AX110.00.81 Peristaltic Hose Norprene IP 60 AX110.00.67 Metallic cover AX110.01.13 Polycarbonate cover AX110.00.14 Contact realax Base plate distributor Contact realax Base plate S.S. distributor Drive O-Ring front Cover IP 60 AX110.00.33 O-Ring Press Ring AX114.00.13...

- Page 54 Operating instructions Peristaltic Pump IP Series 11.10 Spare parts exploded view IP 70 Model...

- Page 55 AX112.00.22 Peristaltic Hose CSM IP 70 AX112.00.23 Peristaltic Hose NR-A IP 70 AX112.00.19 Metallic cover AX112.00.40 Polycarbonate cover AX112.00.41 Contact realax Base plate distributor Contact realax Base plate S.S. distributor Drive O-Ring Front Cover IP 70 AX112.00.35 O-Ring Press Ring AX114.00.10...

- Page 56 Operating instructions Peristaltic Pump IP Series 11.11 Spare parts exploded view IP 70 Model - NbR-A...

- Page 57 AX112.00.58 Connection S.S. TRI-CLAMP 3” IP 70 NBR-A AX112.00.59 Peristaltic Hose NBR-A IP 70 AX112.01.21 Metallic cover AX112.00.40 Polycarbonate cover AX112.00.41 Contact realax Base plate distributor Contact realax Base plate S.S. distributor Drive O-Ring front Cover IP 70 AX112.00.35 O-Ring Press Ring AX114.00.10...

-

Page 58: End Of Life

Operating instructions Peristaltic Pump IP Series END-Of-LIfE WARNING! Danger from hazardous substances! Possible consequence: Fatal or very serious injuries. Customer must decontaminate the pump with suitable agents (refer to the material safety data sheet for the fluid). 12.1 Recycling Once cleaned the following components can be scrapped/recycled:... -

Page 59: Declaration Of Conformity

DECLARATION Of CONfORMITY... -

Page 60: Warranty

WARRANTY We guarantee against all manufacturing defects and guarantee the mate- rials that compose the realax pump for two years from the date of deliv- ery. This guarantee does not cover the hose or the lubricant as these are elements that have a normal function wear, irrespective of their duration. -

Page 61: Where To Buy

E-mail: info@axflow.de E-mail: office@axflow.at Service-Stützpunkt und Werkstatt www.axflow.at AxFlow Service Süd Kiryat-Shmona-Straße 11 87700 Memmingen, Deutschland For more information about realax Tel. +49 8331 3309 hose pumps please contact: service.sued@axflow.de AxFlow Ltd. 27 Prof. Kiril Popov Street, ground floor Sofia city Tel.: +359 (0) 879 380 202... - Page 62 Operating instructions Peristaltic Pump IP Series A realax tömlőszivattyúkkal Aby uzyskać więcej informacji na kapcsolatos további temat pomp realax węża prosimy o információkért forduljon: kontakt: AxFlow Kft. AxFlow Sp. z o. o. Bilk Centre, B1 ép. ul. Floriana 3/5 Európa utca 6.

- Page 63 För mer information om realax For service and support to your slangpumpar vänligen kontakta: realax hose pumps please contact: AxFlow AB AxFlow Services Ostmästargränd 12 Phone: +44 1484 543649 120 40 Årsta Fax: +44 1484 512608 (Box 90162, 120 22 Stockholm) E-mail: service@axflow.co.uk...

- Page 64 CUSTOMER: PHONE: CONTACT: FAX: INTENTION: Repair Warranty Return MATERIAL DELIVERED: Pump only Complete unit Spare part UNITS: PUMP TYPE: PUMP REFERENCE: SERIAL NUMBER: OPERATION TIME (Years): OPERATING HOURS (h/day): APPLICATION DATA (* Indicate units): PRODUCT VISCOSITY * DENSITY * FLOW * DANGEROUS Corrosive Flammable...

- Page 65 Operating instructions Peristaltic Pump IP Series...

- Page 66 ALL THE HOSE PUMP YOU’LL EVER NEED www.realaxpumps.com...

Need help?

Do you have a question about the IP Series and is the answer not in the manual?

Questions and answers