Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Gravotech Laser Workstation LW2

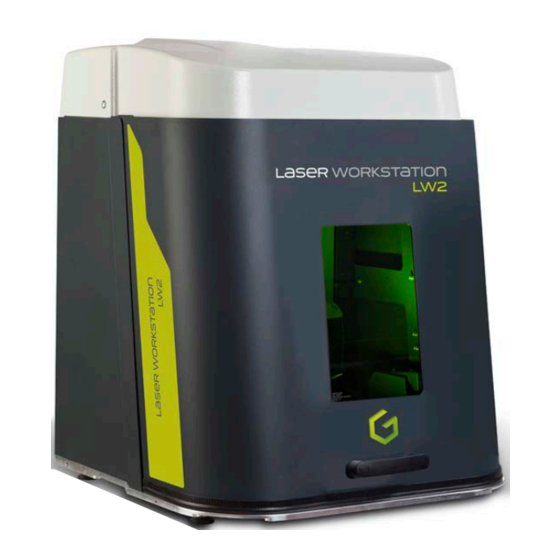

- Page 1 OPERATING AND MAINTENANCE MANUAL INTEGRATION Laser Workstation MARKING LASER...

-

Page 2: Table Of Contents

Table of contents A. Foreword ..............................6 1. Appreciation ............................6 2. Information ............................6 B. Legal notices ............................7 C. Regulation observance ...........................8 D. Required safety labels ..........................9 E. Introduction ............................11 1. Presentation ............................11 2. Instructions for use and warranty limitations ..................11 3. Identification of the marking equipment .................... - Page 3 Installation .............................24 „ Step 1: ............................... 24 „ Step 2: ............................... 25 1. Fiber-Series ............................25 „ Step 3: ............................... 25 „ Step 4: ............................... 26 „ Step 5: ............................... 26 „ Step 6: ............................... 27 J. Connections - Installation ........................29 1.

-

Page 4: Foreword

A. Foreword 1. Appreciation Thank you for choosing LW2 - Gravotech. Gravotech is pleased to count you among the users of its engraving and traceability solutions. For help, contact Gravotech. For more information on products, visit www.gravotech.com website. 2. Information To ensure security and productivity, read this manual before starting-up the equipment. -

Page 5: Legal Notices

User. Gravotech shall not be liable for any damages, that the User or its property, a third party or the Product itself may suffer, caused by the Product and arising from any inappropriate use or misuse of the Product, negligence, carelessness, inadequate supervision or maintenance, failure to observe the safety or usage instructions described herein or otherwise communicated to the User, the use of poor- quality or non-recommended lubricants, fluids and additives or where there is fault on the part of the User or a third party. As provided in... -

Page 6: Regulation Observance

C. Regulation observance Last updated: 02/2018 EC declaration of conformity or declaration of incorporation supplied with the machinery Type of machine Directives - Standards Dot peen marking: Machine - Low voltage: 2014/35/EU XF500p, XF500m, Impact p, Impact eZ p, Impact m, Impact eZ m - EMC: 2014/30/EU P5000PN, P5000EM - RoHS 2: 2011/65/EU... -

Page 7: Required Safety Labels

D. Required safety labels Last updated: 12/2017 Required safety labels Shared labels Warning: Laser beam Warning: Electricity LS100 LS100 Ex Warning: Flammable LS100 Energy materials LS900 LS900 XP LS1000 XP Warning: Hot surface Warning: Flammable materials LS100 Ex Fibre LS900 Fibre Warning: Hot surface LS900 Edge Laser Solution... - Page 8 Required safety labels Required safety labels Laser Solution -Series (Energy) LW1 - LW2 (LaserTop 2000) M_LW2_EN_A...

-

Page 9: Introduction

They must be replaced on a regular basis, according to the application. See: Wearing and spare parts 3. Identification of the marking equipment The marking equipment is identified by: • 1 identification plate on the rear face Have the model and serial number of the equipment available when contacting Gravotech. 4. Work station safety • Turn off the machine before beginning any cleaning, maintenance or repair procedure. • Never unplug a cable while the Control Unit is turned on. -

Page 10: X84; Marking Head

In the event of an extended period of non-use, unplug the power cable and protect the machine. • Never pour or spill liquid on the machine (drinks, cleaning products, etc.) except where recommended by Gravotech. Gravotech will not be held responsible for injuries resulting from disregard for the above operating instructions or other general safety rules applicable to the use of this equipment or resulting from misuse. Furthermore, disregard for the instructions will void the warranty. M_LW2_EN_A... -

Page 11: Unpacking

F. Unpacking 1. Packaging: LW2 Wedge Strapping protection angle LW2 (maximum: 60 kg (132.277 lb)) Contents of the box: marking head (maximum: 20 kg (44.092 lb)) Contents of the box: Control Unit (maximum: 25 kg (55.116 lb)) Wedge Pallet HM6 screw (x 4): prior to handling or lifting, unscrew the screws fixing 4 lifting rings M6. 10. Door retaining strap This equipment includes a Laser source and must be handled with care to avoid damage to the equipment (misalignment) which may reduce its effectiveness. -

Page 12: Recommendations

Unpacking Lasertop MC (weight: 60 kg (132.277 lb)) Unpack the machine with 3 operators Handles (x 6) 2. Recommendations • Check the optical fiber was not damaged during transport. • When unpacking the CCU, hold the optical head to prevent it from falling. Remove the CCU's protective packing at the last moment. Quickly connect the optical head to the marking head with the 3 screws provided. • Remove the protective plugs only when installing. • Keep the packing in case the machine has to be returned. To pack the machine, use its original packaging. -

Page 13: Laser Safety

The area in which the machine is used must be limited to authorized and protected personnel only. Only trained personnel aware of the risks posed by the machine are authorized to use it. Only Gravotech personnel, or persons authorized by Gravotech may service the elements that constitute the marking machine. -

Page 14: Labels

Laser safety 2. Labels „ Warranty labels These labels guarantee the laser was not opened or dismantled. Opening without prior written consent voids warranty. DO NOT OPEN LASER COVER WARRANTY VOID IF SEAL IS BROKEN * * DO NOT OPEN THE LASER COVER WARRANTY VOID IF SEAL IS BROKEN „... -

Page 15: X84; General Instructions

Laser safety Regulation in the restricted area Access to the restricted laser area is regulated. Only competent personnel having attended proper training can remain during the operation: this implies medical aptitude and laser safety training. Any person authorized access to the restricted area is to observe the rules provided by the employer. (1) To be filled in or crossed out. -

Page 16: Potential Hazards Related To Materials Worked With

Laser safety 4. Potential hazards related to materials worked with „ Fumes and toxic particles Laser marking certain materials emits dangerous fumes and particles that may be toxic and/or damage the equipment. In this case, adapt an extraction system (with filtration if necessary) to the marking station. The processing of parts using this type of Laser causes thermal and photo-electric (molecular) deterioration of the material. Even micro-quantities of the by-product (soot or fumes), created during Laser marking, may accumulate over a long period. -

Page 17: X84; Examples Of Secondary Radiation Risks

Laser safety „ Examples of secondary radiation risks The use of a class 4 laser device can generate: • a risk of fire or explosion due to materials or inflammable substances • UV radiation • X rays • high intensity visible light when marking on certain materials „ Reflected beam Special integration is required when marking some materials to prevent the beam reflecting. • copper, copper-based materials (bronze, brass) • gold • silver • polished materials M_LW2_EN_A... -

Page 18: Description Of The Machine

H. Description of the machine „ Global view of the marking area To access the marking area, lift the door handle. Door - Door motorization (optional) Marking head Motorized Z-axis Door locking latch Marking area according on the lens used Multi-function remote control Laser protection glass Numerical counter: indicates the Z position of the marking head. It can be reset to zero according to the equipment used. M_LW2_EN_A... -

Page 19: X84; Multi-Function Remote Control

Description of the machine „ Multi-function remote control Emergency stop Marking area lighting (On/Off) Z-axis raising Marking in progress Stop marking "Extractor fault" indicator light (optional) Activation/deactivation of the extractor Door opening/closing Z-axis lowering 10. "Marking ready" indicator light 11. Start marking 12. "Door opening" automatic mode indicator light 13. Door opening/closing: automatic mode M_LW2_EN_A... - Page 20 Description of the machine Switches the marking field lighting on or off. Marking area lighting (button(s) 2) When the LW2 machine is powered on, the light indicates program start-up. Used to raise or lower the marking head in order to adjust focus. These buttons are disabled if the "programmable Z axis" option is selected (motorized Z-axis piloted by the Lasertrace program).

-

Page 21: X84; Marking

Description of the machine „ Marking The marking program works in both millimeters and inches. All values pertaining to length are expressed in the chosen unit. Reset button Units (mm or inches) M_LW2_EN_A... -

Page 22: Installation

I. Installation The different elements of the equipment must be connected with the power off. The power supply should be connected last. To install the equipment in complete safety, follow the stages below. „ Step 1: Opening the casing: 1. Unscrew the 4 screws at the top of the housing. 2. -

Page 23: X84; Step 2

Installation 4. Tilt the cover until vertical. 5. Lift off the cover, pressing its sides lightly. „ Step 2: Remove 2x2 screws CHc M5x45 in order to release the counterweights. Retain the screws for any future shipping operation (maintenance, after-sale service, etc.) 1. Fiber-Series „ Step 3: Open the flange at the back. Remove the laser, if present. -

Page 24: X84; Step 4

Installation „ Step 4: Place the laser in the LW2, on its support (Z axis). Do not touch the other screws in the marking head. „ Step 5: Never hold or manipulate the optical head by the fiber. Always use the aluminium isolator mount to manipulate. Optical head connection: 1. -

Page 25: X84; Step 6

Installation „ Step 6: Do not touch the other screws in the optical head. See below. Connection of the marking head to the CCU: 1. Connect the 17 point connector. 2. Connect the 19 point connector. Do not touch the optical head. Marking head - View of connectors 17 point connector - Head/CCU connecting cable 19 point connector - Head/CCU connecting cable Optical head M_LW2_EN_A... - Page 26 Installation 3. Place the appropriate split seals over the lower flange (the small diameter to the left). Tip: use adhesive tape to attach the upper flange to the sheet metal arc or use a reusable cable tie to facilitate this operation. 4. Re-close and lock the upper flange. Tip: if closing the flange is difficult, unplug the laser connectors or tighten the flanges using locking pliers, protecting the bellows (thick plastic or cardboard). No light must be allowed to pass between the flange, the laser and the cables. 5. Connect the laser. Close the housing (reverse of the disassembly operation). M_LW2_EN_A...

-

Page 27: Connections - Installation

J. Connections - Installation 1. Connecting the Control Unit The different elements of the equipment must be connected with the power off. The power supply should be connected last. Control Unit - LW2: View of connectors 19 point connector Head/CCU connecting cable (cable supplied): marking-head signals 17 point connector Head/CCU connecting cable (cable supplied): X-Y signals Profinet/Ethernet IP module (optional) 7 point connector (DIN F) - Not available 3 point connector (DIN F) - Not available DB15F connector Ethernet connection (RJ45) - Page 28 Connections - Installation • Connection of the marking head to the CCU 1. Connect the marking head to the CCU with the two connection cables provided (17 points - 19 points). 2. Push the connectors into the socket and tighten the locking rings. 3.

- Page 29 Connections - Installation • RS232 connection for communication with PC (programmable Z axis) • Connection RD1/RD2 Cable + flange kit • Fume extractor connection: ES30 1. The different elements of the equipment must be connected with the power off. The power supply should be connected last. 2. Remove the cover. M_LW2_EN_A...

- Page 30 Connections - Installation 3. Attach the exhaust tube adapter. 4. Connect the tube to the LW2 (diameter 100). Tighten the hose clamp. 5. Connect the tube to the extractor (diameter 100). Tighten the hose clamp. 6. Connect the cable ES30 / LW2. M_LW2_EN_A...

-

Page 31: Dismantling The System

Connections - Installation • Power supply connection 2. Dismantling the system See the user manual of the machine. M_LW2_EN_A... -

Page 32: Installation

Connections - Installation 3. Installation „ Possible integration and operating positions for the LW2 Position the Control Unit horizontally, in a dry, ventilated area, at least 20 cm (7.874 in) from the floor. Always leave a free space of 50 mm (1.969 in) in front of the CCU and of 150 mm (5.906 in) in back for good air circulation. As components are air-cooled, air circulation in the CCU must not be perturbed. Version rack 19" 4U-5U: used to integrate the CCU in a cabinet. Vertical position possible Analyse the CCU's integration in order to avoid problems due to the fiber's minimum bend radius. -

Page 33: Accessories Available Upon Request

K. Accessories available upon request Please give the item codes with your order to speed processing. 1. List of accessories and options available upon request T-slot table The aluminum table with t-slots for mounting standard Ref. 68980 accessories or specific tooling. Caster - diameter 50 (order 4 pieces for a complete kit) Ref. 73048 Ref. Description 66660 Door motorization 66658 Door locking 66661 Motorized Z-axis piloted by the Lasertrace program 68634 Table protection 66648... -

Page 34: Preventive Maintenance

L. Preventive maintenance 1. Visual inspection of the bellows (rear of LW2) Upper bellows Lower bellows Check the condition of the bellows in the event of burning or perforation. M_LW2_EN_A... -

Page 35: Dimensional Drawings

M. Dimensional drawings „ Dimensional drawings • LW2 dimensional drawing Laser protection glass: 180 mm (7.087 in) x 280 mm (11.024 in) Handle: door opening/closing 4 support feet (adjustable) Cover Door - Door motorization (optional) Control interface board Fuse carrier Handles (x6): handling the machine Mobile protective shutters 10. - Page 36 Dimensional drawings • Fiber-Series dimensional drawing Laser protection glass: 180 mm (7.087 in) x 280 mm (11.024 in) Handle: door opening/closing 4 support feet (adjustable) Cover Door - Door motorization (optional) Handles (x6): handling the machine Cable transit (optional) Fume extractor connection (optional) Z axis (travel distance 300 mm (11.811 in)) 10.

- Page 37 Dimensional drawings • Dimensional drawing of the table: Fiber series Marking area (x 4) Origin 27 fastening holes Handles (x4) 65 mm (2.559 in)x 65 mm (2.559 in) 110 mm (4.331 in)x 110 mm (4.331 in) 180 mm (7.087 in)x 180 mm (7.087 in) 240 mm (9.449 in)x 240 mm (9.449 in) M_LW2_EN_A...

- Page 38 Dimensional drawings • Max. volume of the part: 100 Focal lens Max. volume of the part 100 mm Focal lens Marking area: 65 mm (2.559 in) x 65 mm (2.559 in) M_LW2_EN_A...

- Page 39 Dimensional drawings • Max. volume of the part: 160 Focal lens Max. volume of the part 160 mm Focal lens Marking area: 110 mm (4.331 in) x 110 mm (4.331 in) M_LW2_EN_A...

- Page 40 Dimensional drawings • Max. volume of the part: 254 Focal lens Max. volume of the part 254 mm Focal lens Marking area: 180 mm (7.087 in) x 180 mm (7.087 in) M_LW2_EN_A...

- Page 41 Dimensional drawings • Max. volume of the part: 330 Focal lens Max. volume of the part 330 mm Focal lens Marking area: 240 mm (9.449 in) x 240 mm (9.449 in) M_LW2_EN_A...

-

Page 42: Noise Emission Of The Machine

N. Noise emission of the machine 1. Test code „ Measurement method The measurements were taken according to the regulations of standard ISO 12001:1996. „ Material used for marking • Machine: LW2 + Fiber-Series • One electronic command unit • An interface computer (used by the operator) „ Definition of the microphone position The microphone is positioned 1 m (3.281 ft) in front of the machine and 1.4 m (4.593 ft) from the floor. The measurements were taken according to the regulations of standard ISO 12001:1996. „ Test conditions •... -

Page 43: Technical Specifications

O. Technical specifications See the user manual of the machine. • Motorized Z-axis: max. path 300 mm (11.811 in) • Class 1 (EN 60825-1 standard) 1. Laser beam • Class 4 (EN60825-1) (class 1 with suitable protection) Fiber Series Hybrid Series Green Series CO2 Series Wavelength...

Need help?

Do you have a question about the Laser Workstation LW2 and is the answer not in the manual?

Questions and answers