Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for G-WEIKE LF1390

- Page 2 G.Weike Laser Profession Laser Manufacturer more than 15 Years.

- Page 3 G.Weike Laser Profession Laser Manufacturer more than 15 Years. Jinan G.Weike Science & Technology Co.,Ltd Preface Thank you for you choose our company products. We will provide you with perfect after-sales service and solutions, please properly save the specification and other accessories, so that you can better use. This specification is only applicable to the standard configuration of our products, for special customized products, please read the attached notes carefully.

- Page 4 G.Weike Laser Profession Laser Manufacturer more than 15 Years. As the function of the product is constantly updated, the products you receive may differ in some respects from the statements in this manual. This user manual can satisfy the basic demands of installation and adjustment, more details please refer the user manuals of the machine .Any distribution please contact with our engineers parts and apologize for this.

-

Page 5: Table Of Contents

G.Weike Laser Profession Laser Manufacturer more than 15 Years. CATALOGUE Chapter 1 Safety Instructions and Precautions............1 1.1 Overview......................1 1.2 The machine safety standards..............1 1.3 Safety identification..................1 1.4 Security management warning..............2 1.5 Laser safety notice..................2 1.7 Fire and high temperature protection.............3 1.8 Electric safety....................3 Chapter 2 Introduction....................6 2.1 Products features.................. - Page 6 G.Weike Laser Profession Laser Manufacturer more than 15 Years. 4.4 Fiber Special Cutting Head..............23 4.4.1Fixing of cutting head..............23 4.4.2 Height controller connection............23 4.4.3 Installation of ceramic part & nozzles........25 4.4.4 Piping....................25 4.5 The connection of the gas............... 28 4.6 Air filter Installation...................

- Page 7 G.Weike Laser Profession Laser Manufacturer more than 15 Years. 6.5.1 Lubrication of gear and rack............64 6.5.2 Linear slide rail lubrication............64 6.6 Maintenance when you stop use the machine during long-time.. 64 6.7 Storage conditions, storage period and matters needing attention .........................64 6.8 Quick-wear parts list.................

-

Page 8: Chapter 1 Safety Instructions And Precautions

G.Weike Laser Profession Laser Manufacturer more than 15 Years. Chapter 1 Safety Instructions and Precautions 1.1 Overview Before operate machine and do daily maintenance, operator must read this chapter carefully, with learn safety measures and requirements of machine, and comply with the relevant safety precautions. 1.2 The machine safety standards Laser processing equipment and operation shall be in accordance with user guide EN ISO 12100:2010,EN 60204-1:2006+A1:2009+AC:2010,EN ISO 11553-... -

Page 9: Security Management Warning

G.Weike Laser Profession Laser Manufacturer more than 15 Years. Warning: Be care of the high temperature The laser head will produce a high temperature in its surface, please don’t touch the laser head when its working or shortly after its working. Warning:Be care of the low temperature When using the liquid nitrogen to cutting the materials ,the user’s hand may hurt by the lower... -

Page 10: Fire And High Temperature Protection

G.Weike Laser Profession Laser Manufacturer more than 15 Years. 1.6 Eyes and skin’s protection Caution :When the machine’s door is open in processing.All operators must be strictly wear 1064 nm laser protective glasses!(the model can choose SD - 4) Don't wear glasses for operation and observation prohibited! 1.7 Fire and high temperature protection a).Fire protection of laser cutting processing, often use oxygen, and spark... - Page 11 G.Weike Laser Profession Laser Manufacturer more than 15 Years. Notice: Comprehensive careful reading machine manual and electric schematic diagram, in order to be familiar with the various functions and the corresponding key operation method. The operator can’t repair the electrical parts and laser parts by himself .This machine must be repaired by professional engineers .

- Page 12 G.Weike Laser Profession Laser Manufacturer more than 15 Years. processing room, laser light brake should be closed.

-

Page 13: Chapter 2 Introduction

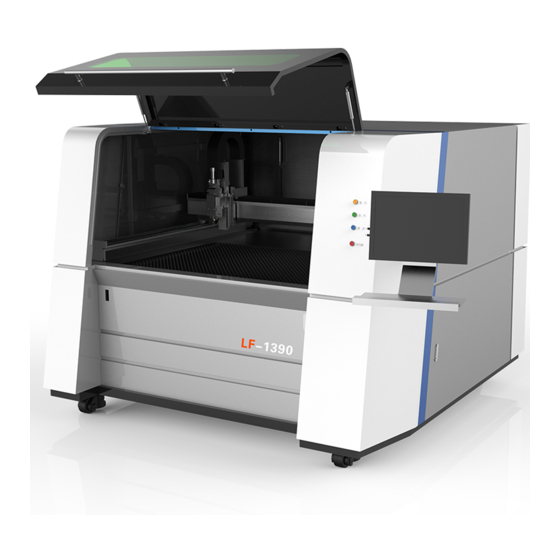

2.2 Main purpose and application scope Laser cutting is a more advanced machining method in cutting materials. LF1390 series fiber cutting machine adopt high quality fiber laser source, equipped with precision linear guide, and other transmission mechanism, optical fiber cutting head, humanized operation interface. It is mainly used for metal crafts, metal products, precision machinery, auto parts and other industries. -

Page 14: The Impact On The Environment And Energy

2.5 Products Construction and working principle 2.5.1 Overall structure and its working principle, working characteristic LF1390 series fiber cutting machine, the main components are: host machine parts, control system, laser, water chiller, transformer, gas equipment, etc. Host machine parts: host machine parts is the main part of the laser cutting machine, main engine parts consistent of lathe bed, beams, workbench, gas path and water path. -

Page 15: Function, Structure And Working Principle, Working Characteristic Of The Auxiliary Device

G.Weike Laser Profession Laser Manufacturer more than 15 Years. Lf1390 series fiber cutting machine’s electric control system is mainly composed of servo system, control system, movable system and low voltage electrical system. Picture 2-1 Software operating main interface Picture2-2 servo system... -

Page 16: Water System

G.Weike Laser Profession Laser Manufacturer more than 15 Years. stainless steel, alloy steel and aluminum alloy. User should choose different cutting gas according to different materials. In the cutting gas system, due to installed pressure sensor inside, make sure that machine stop work in time when gas pressure is not enough, avoid the abandonment of cutting parts. -

Page 17: Chapter 3 Transportation, Shipment And Storage

G.Weike Laser Profession Laser Manufacturer more than 15 Years. Chapter 3 Transportation, Shipment and Storage 3.1 Machine tool transportation Spare trucks transport to the final installation site, the work must be conducted by users in the preparation and implementation. Must be declared machine in time before delivery to the installation place of course. -

Page 18: Delivery Check

G.Weike Laser Profession Laser Manufacturer more than 15 Years. machine landing leg basement and the ground must always less than 100mm 5.Crow bar (1 m), and extension. 1.Using the pliers to cut off the fixing band. 2.Using the crow bar to unclench the wooden box. 3.2 Delivery check 3.2.1 Attentions of open the wooden case Please open according to prompt in outside wooden case, in order to avoid to... -

Page 19: Ground Requirements

G.Weike Laser Profession Laser Manufacturer more than 15 Years. Picture 3-2 Installation location drawing Caution:Be careful of the sharpen edges of the packages and edges of the machine. 3.3.1 Ground requirements 1) The ground where install the equipment should be flat .The laser, bed and the working area height difference should not exceed 10 mm. -

Page 20: The User Of The Measures Should Be Taken

G.Weike Laser Profession Laser Manufacturer more than 15 Years. 1) Forklift, land transport, etc. 2) Directly beside the equipment install or remove other machines. 3) Machines which will cause vibration in operation, such as punching machine, bending machine, shearing machine, etc. 3.3.4 The user of the measures should be taken 1. -

Page 21: Attention

G.Weike Laser Profession Laser Manufacturer more than 15 Years. protect it from external objects damaged parts of laser cutting machine. 3.3.6 Attention Machine transportation environment should avoid the rain, moisture, tilt, rat, potholes, such as damage, and ensure the well ventilated, transportation environment temperature in the range of - 10 ℃... -

Page 22: Chapter 4 Installation And Connection Of Laser Cutting Machine

G.Weike Laser Profession Laser Manufacturer more than 15 Years. Chapter 4 Installation and Connection of Laser Cutting Machine Installation steps summarize Connect the electric line→ connect the water cooling machine with the main machine body →connect the laser source with the machine body →connect the laser head with the machine body →Inset the laser cable into the laser head and lock the connection port →connect the laser source with the laser machine body →connect the gas line, water line with the laser head →connect the air filter with the machine... - Page 23 G.Weike Laser Profession Laser Manufacturer more than 15 Years. -An external laser pipe: fiber laser special pipe (laser attached). If the pipe length of the water cooling machine is more than 10 meters, need to increase the pipe size, must make sure the pressure difference which laser need to. Various laser, each tube connection size also varies .Other cooling water pipe, Pay attention to pipe joint sealing.

- Page 24 G.Weike Laser Profession Laser Manufacturer more than 15 Years. line according to the direction signed on the picture4-1 According to the sign of chiller shell connect the import and export pipe with laser imports (A1) and export (A2), and pay attention to the import and export direction, to avoid put connection wrong with import and export pipe.

- Page 25 G.Weike Laser Profession Laser Manufacturer more than 15 Years. whether each indicator light is green or not. Use again after a long downtime, should power on unit above 2 hours in advance ,to make the oil heater which at bottom of the compressor start oil preheating automatically inside the compressor refrigeration (preheat state means: after electrify chiller control panel in the electricity outage state) and then can normal boot operation.

- Page 26 G.Weike Laser Profession Laser Manufacturer more than 15 Years. After power on, the chiller displays software edition first, for example, “r1. 0” means software edition is 1.0. Then enter setting status automatically. As shown below: Parameter’s setting Chiller set parameter recommend value(he user is subject to change as per practical condition)...

- Page 27 G.Weike Laser Profession Laser Manufacturer more than 15 Years. Attentions: 1) When water temperature reach the temperature controlled, water chiller will start constant temperature control automatic, and water pump within the unit works as usual. 2) Before open machine in the first time, must open the drain valve of the pump gas to valve the air, otherwise easy to damage the pump, at the same time, to adjust well the opening of the valve in the water system.

-

Page 28: Debugging Install Of Fiber Laser Machine

G.Weike Laser Profession Laser Manufacturer more than 15 Years. 4.3 Debugging install of Fiber laser machine 1.AC INPUT: The socket for supply input that can be only mated with the plug on the power cord we provided.(”1” on the Picture 4-8) 2. - Page 29 G.Weike Laser Profession Laser Manufacturer more than 15 Years. One end of the power cord is a plug; insert it in to the socket 'AC INPUT' on the rear panel .Notice that the plug is wrong-side preventing. After insert it, lock it with the lever.

-

Page 30: Fiber Special Cutting Head

G.Weike Laser Profession Laser Manufacturer more than 15 Years. cleaning paper clean head of QBH dust and other dirt! Must ensure that the QBH head clean pollution-free, then can insert cutting head in the expanded beam! Adjust the cutting head of coaxial and focus of the lens, then try to cut! Caution:Install fiber must demand trained professionals to install fiber, it is forbidden to non-specialists plug QBH! Lens using considerations... - Page 31 G.Weike Laser Profession Laser Manufacturer more than 15 Years. Picture 4-11 Picture 4-1...

-

Page 32: Installation Of Ceramic Part & Nozzles

G.Weike Laser Profession Laser Manufacturer more than 15 Years. Picture 4-13 Picture 4-14 4.4.3 Installation of ceramic part & nozzles Picture 4-15 1. Put the ceramic part into the sensor component carefully, the locating pins which on the sensor part should insert into the ceramic part.The nozzle should put into the connecting ring by hand to avoid some damage if you use any tools. - Page 33 G.Weike Laser Profession Laser Manufacturer more than 15 Years. The water inlet and a water outlet pipe structure. Please refer picture 4-16. Caution :Cold Water Only pure water or distilled water are available, conductivity< 20μS/cm. It must keep a certain temperature in water circulation access to avoid mist condensation on the lens.

- Page 34 G.Weike Laser Profession Laser Manufacturer more than 15 Years. Please be sure that all the laser head connectors are locked and tightened by screw-plug before using, or the laser head will not work if there are gas or liquid entering into it. Picture 4-18 Cutting gas G1/8 connector(depth 8mm) Caution: cutting gas...

-

Page 35: The Connection Of The Gas

G.Weike Laser Profession Laser Manufacturer more than 15 Years. Fiber laser : we suggest you clean the fiber part on the laser head to avid dust enter into fiber connector, and insert the fiber plug in horizontal state. More details please refer the water cooling machine user manual. 1. - Page 36 G.Weike Laser Profession Laser Manufacturer more than 15 Years. The machine equipped fiber laser,no need any dedicated laser gas! b)The connection of auxiliary gas 1) Cutting gas requirements of purity Laser Gas Purity Application Material Pressure limit(BAR) 99.99% Carbon steel 0<=P<=10 99.99% Stainless steel...

- Page 37 G.Weike Laser Profession Laser Manufacturer more than 15 Years. The diameter of nozzle The cutting pressure The laser cutting time Cutting gas consumption estimates: the following is a list of cutting consumption when cutting in the standard pressure and high pressure , so as to estimate about the cutting gas consumption, use machine of the accumulation of data to estimate the determine material varieties and different material thickness.

-

Page 38: Air Filter Installation

G.Weike Laser Profession Laser Manufacturer more than 15 Years. This supply way applies to N high pressure cutting under the condition with some premises. Change gas method and points for attention Cutting gas should be chosen high quality gas that production from a formal company,supply by one single gas bomb. - Page 39 G.Weike Laser Profession Laser Manufacturer more than 15 Years. strictly in accordance with the relevant regulation, please understand machine performance before debugging and reading relevant random technical data. Correct debugging is the basis of guarantee machine normal work, please contact with our company if you’re not sure, we will give you a satisfactory answer in the fastest time.

-

Page 40: Chapter 5 Testing And Operation Of The Machine

G.Weike Laser Profession Laser Manufacturer more than 15 Years. Chapter 5 Testing and operation of the machine 5.1Summarize and operation guide Boot steps Turn on the power---Open water cooling machine---Open the emergency stop button---Turn on the laser source---Turn on the software---Back to the origin---Selective cutting gas---standardization---adjust the light---Drawing set cutting parameters---Go frame--- Cutting 1.Check equipment as a whole: before electricity mainly to check the... -

Page 41: Raycus Optical Fiber Signal Line Connection Method

The state of force table is normal. Note: the water cooler may be modified, with its own independent specification shall prevail; this manual is only for reference. 5.2 RAYCUS Optical fiber signal line connection method Please refer the LF1390 FIBER LASER CUTTING MACHINE ELECTRICAL DIAGRAM. -

Page 42: Adjusting Laser Head Height And Turn On The Software

G.Weike Laser Profession Laser Manufacturer more than 15 Years. 5.3 Adjusting laser head height and turn on the software 5.3.1 Standardization Plates will be put to the cutting table, through the operation handle above the laser head to move to a board, [NC] button at the top of the click software, the pop-up dialog box, use the mouse to click on [F1] calibration - Calibration [2] floating, mouse the left key long press down arrow of the laser head moves to the plate 1 cm above the place, click OK, until after the calibration is complete... - Page 43 G.Weike Laser Profession Laser Manufacturer more than 15 Years. Adjust the cutting parameter .As show in Picture 5-14. Picture 5-9...

- Page 44 G.Weike Laser Profession Laser Manufacturer more than 15 Years. Picture 5-10 Picture 5-11 Picture 5-12...

- Page 45 G.Weike Laser Profession Laser Manufacturer more than 15 Years. Picture 5-13 Picture 5-14 Adjust the focal length and cutting parameters According to the plate and the thickness of the adjusting the cutting parameters (click on the software right "craft" icon, input parameters); regulation of laser and nozzle concentricity;...

-

Page 46: Regulating Gas Pressure

G.Weike Laser Profession Laser Manufacturer more than 15 Years. emergency to stop operation of the equipment. After the completion of the processing reference" 4.2 machine shutdown procedures " 5.4 Regulating gas pressure Open the pressure table: first loosen(t u r n l e f t t h e k n o b ) the pressure adjusting knob and then open the gas bottle,then adjust the valve to insure the pressure is in the safety range(please refer(chapter4.5) the finally according to gas pressure button on the operation system to adjust outlet pressure. - Page 47 G.Weike Laser Profession Laser Manufacturer more than 15 Years. If the device manufacturer has no other proposal, you can adjust like follow procedure: 1. Choose a wide opening nozzle, its opening diameter should be larger than the beam diameter, if the nozzle’ s opening size is too small, then remove it. 2.

-

Page 48: Nozzle Function And Central Adjustment

G.Weike Laser Profession Laser Manufacturer more than 15 Years. 5. Put a piece of gummed paper on the nozzle again, use low power laser to penetrate again and check the hole round and center position for 2-5 times until the laser beam is centering in the nozzle opening. Then change a small opening nozzle and do the ways again till laser beam is in the center of nozzle opening. -

Page 49: Adjusting Laser Beam Focus

G.Weike Laser Profession Laser Manufacturer more than 15 Years. cutting quality: 1) Affect the cutting section, when the cutting gas spewing, cause uneven gas, make the cutting section is prone to side has fused stains, on the other side of the phenomenon of no, or parts of all round quality is inconsistent, sometimes resulting in not normal cut. - Page 50 G.Weike Laser Profession Laser Manufacturer more than 15 Years. During laser cutting process, relative location between laser beam focus and cutting materials surface has big influence on cutting effect. It is very important to adjust the focus position. This kind laser cutting machine is equipped with automatic following adjusting device, when material height changes, control system could adjust automatically to make sure the distance between nozzle...

- Page 51 G.Weike Laser Profession Laser Manufacturer more than 15 Years. Picture 5-22: Adjusting laser focus3 E) Focus setting principle: distance between cutting month and material surface is A, it is called nozzle cutting height or punch height. Focus position definition: distance between focus to material above surface, see picture 5-23,B is the focus height.

-

Page 52: Set Distance Between Nozzle And Work Piece

G.Weike Laser Profession Laser Manufacturer more than 15 Years. Form 5-2 Relationship between focus and cutting material 5.6.3 Set distance between nozzle and work piece Picture 5-24: Distance between nozzle and work piece After adjusting sensor adjustment box, the follow-up distance between nozzle and work piece is adjusted by YRC Cutting head box of teaching. - Page 53 G.Weike Laser Profession Laser Manufacturer more than 15 Years. 4).With the work-piece or cutting head movement, small transverse and cut into a seam, continue along the seam at the forefront of laser beam irradiation, the melt material in continuous or pulse from the seam was blown off. For sheet material, cutting speed too slow will make the most of the laser beam directly through incision throw energy, speed increase more beam material, increase the coupling power and material, to obtain wider parameter adjustment...

-

Page 54: The Choice Of Laser Cutting Gas And Pressure

G.Weike Laser Profession Laser Manufacturer more than 15 Years. oxygen and the quality of the plate have serious influence on the quality of the cutting. Laser oxygen cutting mainly uses in easy oxidation of metal materials such as carbon steel, as well as stainless steel, but the cutting section is black and coarse, and the cost is lower than inert gas cutting. - Page 55 G.Weike Laser Profession Laser Manufacturer more than 15 Years. According to the different cutting plate material, laser cutting select the different cutting gas. The choice of cutting gas and pressure has a great influence on cutting quality. Cutting gas mainly function: combustion and heat dissipation, timely blow molten stains produced by cutting, and prevent the cutting of molten stains to rebound into the nozzle, protecting the focusing lens.

-

Page 56: The Influence Of Laser Cutting Power In Cutting Quality

G.Weike Laser Profession Laser Manufacturer more than 15 Years. applications need to choose different cutting parameters according to the specific situation. 5.7.3 The influence of laser cutting power in cutting quality When laser cutting, laser power size selection on cutting quality also affected, cutting power can be determined according to the thickness of the plate material and plate cutting. - Page 57 G.Weike Laser Profession Laser Manufacturer more than 15 Years. and steam. 5. Operators are not allowed to leave the post without permission to bring the tube. 6. Fire extinguishers should be placed in readily accessible places; do not process to turn off the laser; not in the absence of a protective laser beam placed near the paper, cloth or other flammable materials.

-

Page 58: Note On The Use Of Temperature In Spring And Winter

G.Weike Laser Profession Laser Manufacturer more than 15 Years. 17. Air temperature at 0 degrees Celsius for a long time down, should be the water cooler, laser and water pipelines in the cooling water discharge, so as to avoid the temperature is too low to freeze water, causing damage to equipment and pipelines. -

Page 59: The Machine Shutdown Procedure

G.Weike Laser Profession Laser Manufacturer more than 15 Years. Please refer technical sheets provided by our company the use manual of the machine parts and operation system.Any question please contact with our engineers,We would provide you the solution as soon as possible. 5.10 The machine shutdown procedure 1. - Page 60 G.Weike Laser Profession Laser Manufacturer more than 15 Years. Turn the button from “ON” to “OFF” position as shown in the picture 5-25 to picture 5- 4. Turn off the air compressor valve and power supply A. To manually drainage, discharge of oil, air compressor, will be at the bottom of the air compressor air tank drain valve open drainage, after the treated waste water discharge, close the drain valve.

-

Page 61: Chapter6 Maintain And Trouble Shooting

G.Weike Laser Profession Laser Manufacturer more than 15 Years. Chapter6 Maintain and trouble shooting 6.1 Summarize In order to ensure the normal use of laser cutting machine, it must be for daily maintenance and maintenance equipment. Because of the whole machine adopts high precision parts, must be very careful in the process of daily maintenance, in strict accordance with the operating rules of each part, and shall be maintained, and shall not be barbaric operation, so as not to damage the components. -

Page 62: The Peripheral Equipment Daily Maintenance And Maintenance

G.Weike Laser Profession Laser Manufacturer more than 15 Years. Cotton swab: two packs. Multimeter: 1. Basic maintenance operation according to the following table: 6.2 The peripheral equipment daily maintenance and maintenance About cold water machine, voltage stabilizer and laser and other peripheral equipment routine maintenance, please refer to the corresponding operating instructions, the following will only do general description. - Page 63 G.Weike Laser Profession Laser Manufacturer more than 15 Years. mainten Maintenance content Maintain the target ance period To ensure the supply of 1.Check the temperature setting is normal cold the laser cooling water water machine(Set temperature 20±1℃) temperature is normal Ensure normal 2 .Check whether the chiller water seal, water...

- Page 64 G.Weike Laser Profession Laser Manufacturer more than 15 Years. 1 .Check the electric parts (such as switches, To ensure the electric terminal blocks, etc.), with a clean dry cloth to parts surface is clean, wipe. cold water to lengthen service life Caution: Make sure the power is off when check the electric parts.

-

Page 65: Laser Source And Laser Head Module Maintenance

G.Weike Laser Profession Laser Manufacturer more than 15 Years. Picture 6-3 6.2.2 Laser Source and laser head Module maintenance Fiber laser source can do basically free maintenance, the main daily observation of cooling water and cooling air conditioning is normal; The voltage is normal! If there is abnormal alarm immediately bond after-sales service! Caution: Don’t dismantle or fix the laser source on your own, Please contact with our company when the... - Page 66 G.Weike Laser Profession Laser Manufacturer more than 15 Years. when dismantle the laser head from the machine body. And the dismantle of the laser head are totally reverse with the install process. So we just list the dismantle in this manual. Dismantle of Focal Lens 1.Turn left the instrument to loose the four nuts 2.Remove the dismantled parts then loose the other four nuts...

- Page 67 G.Weike Laser Profession Laser Manufacturer more than 15 Years. 4.Use the wrapping paper to cover the lens,when clean another lens to avoid the pollution of the dust or water in the air. Collimator Lens Installation Clean the surface of laser head with anhydrous ethanol and then loose four nuts 2.Using the wrapping paper to cove the focal lens.

- Page 68 G.Weike Laser Profession Laser Manufacturer more than 15 Years. Caution:Please put the different kinds of lens in the right position as the picture 6-4. Protection lens dismantle Picture 6-5 Picture 6-4 1.Turn left the switches on picture 6-5 Picture 6-6 Picture 6-7 2.

-

Page 69: The Steps Of Cleaning Lenses

G.Weike Laser Profession Laser Manufacturer more than 15 Years. from inside the box reflection lens and focus lens, should wear clean gloves, picking it from the side of the lens; Take off the lens on the wrapping paper, should avoid the content such as dust falling on the lens; Remove the lens, after spray gun to remove the dust on the mirror, and then put the lens on the optical lens from;... - Page 70 G.Weike Laser Profession Laser Manufacturer more than 15 Years. Check the air filter once a month.When the filter screen and filter elements getting black, please clean them in the following ways: Please wear dust mask,dust glasses and gloves when cleaning the air filter.

-

Page 71: Machinery Lubrication

G.Weike Laser Profession Laser Manufacturer more than 15 Years. 6.5 Machinery Lubrication 6.5.1 Lubrication of gear and rack Use rust inhibitor (WD-40) to clean up the gear and rack Use hand spray type butter(dinosaurs 192) to lubricate the gear and rack 6.5.2 Linear slide rail lubrication ... - Page 72 G.Weike Laser Profession Laser Manufacturer more than 15 Years. 6.9 Waste treatment Waste metal materials could be recycled. You can sold it to the local recyclable waste collectors. The waste water in the water cooling machine can be discharged to the sewers.

- Page 73 G.Weike Laser Profession Laser Manufacturer more than 15 Years. Chapter 7 Laser metal cutting machine warranty <Laser metal cutting machine warranty> First, thank you very much for the purchase of our products, in order to ensure the smooth progress of the service work of the product, especially as follows: General 1.

- Page 74 G.Weike Laser Profession Laser Manufacturer more than 15 Years. the environment, such as reasons), will give in order to free repair or replacement, also by our bear hair to the purchaser of the freight. Repair parts should be returned to the factory inspection, by the division of customer service department detection, maintenance and then return to the buyer (buyers for various reasons in arrears with my spare parts, will cancel the guarantee of its equipment).

- Page 75 G.Weike Laser Profession Laser Manufactory more than 13 Years. www.wklaser.com Postscript This manual final interpretation is owned by our company, we will try our best to ensure the accuracy of the contents of this manual. Because of the editor’s limited level, there maybe inappropriate or omissions,hoping to obtain the general readers and colleagues criticism and corrections.We don’t assume any form of liability for all the consequences .All rights reserved, without authorization,the document...

Need help?

Do you have a question about the LF1390 and is the answer not in the manual?

Questions and answers

What type of grease normally applied in LF3015 E model machine