Advertisement

Quick Links

REQUIREMENTS

Ready-to-Use Chemical Solution

Temperature

Pressure

Flow

Supply Line

Hose

Nozzle

OPTIONS

Stainless Steel Hose Racks

Large Stainless Steel Hose Rack

Strainer

Strainer, "Y", SS, 1/2" MF

OVERVIEW

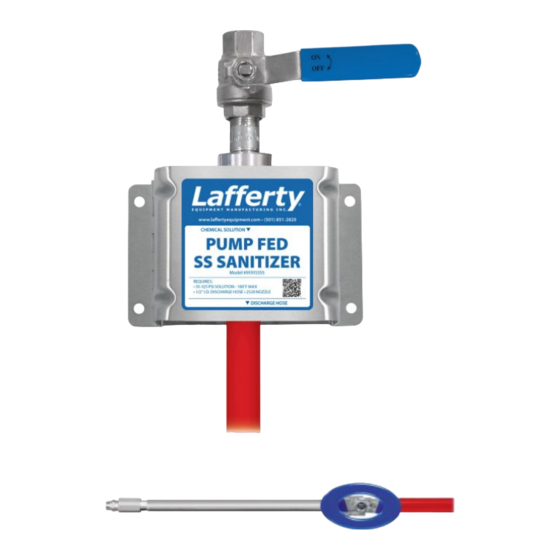

The Pump Fed SS Sanitizer is a spray applicator for applying chemical solutions, such as sanitizers in food processing facilities, to a variety of surfaces at 1.7 GPM @

40 PSI. This stainless steel unit receives ready-to-use chemical solution from a central chemical feed system and projects it through the hose, wand and fan nozzle.

Alternate flow rates are available upon request.

Lafferty Equipment Manufacturing, Inc. • 5614 Oak Grove Road • North Little Rock, Arkansas 72118

Lafferty Equipment Manufacturing, Inc.

Installation & Operation Instructions

Model # 919155SS · Pump Fed SS Sanitizer

up to 180°F

35 to 125 PSI

1.7 GPM @ 40 PSI

1/2"

1/2" ID x 50'

2520

# 224150

# 150350-1

www.laffertyequipment.com

501-851-2820

W A R N I N G ! R E A D A L L

I N S T R U C T I O N S B E F O R E

U S I N G E Q U I P M E N T !

Advertisement

Summary of Contents for Lafferty 919155SS

- Page 1 40 PSI. This stainless steel unit receives ready-to-use chemical solution from a central chemical feed system and projects it through the hose, wand and fan nozzle. Alternate flow rates are available upon request. Lafferty Equipment Manufacturing, Inc. • 5614 Oak Grove Road • North Little Rock, Arkansas 72118...

- Page 2 919155SS • Pump Fed SS Sanitizer SAFETY & OPERATIONAL PRECAUTIONS UNIT FLOW RATES For proper performance do NOT modify, substitute nozzle, hose diameter or length. Manufacturer assumes no liability for the use or misuse of this unit. 1.59 Wear protective clothing, gloves and eye-wear when working with chemicals.

- Page 3 919155SS • Pump Fed SS Sanitizer - Page 3 -...

- Page 4 919155SS • Pump Fed SS Sanitizer Troubleshooting Guide Possible Cause / Solution Problem Startup Maintenance A) Weak pressure or will not spray 1, 2, 3, 4 5, 6 Possible Cause / Solution Startup Maintenance 1. Inlet or discharge not completely open 5.