Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for BHV XRot-Pro

- Page 1 RADI O -CONT R OLLED G RASSL AND MOWER U s e r M a n u a l MODEL: XRot-Pro...

-

Page 2: Safe Operation

SAFE OPERATION SAFETY QUICK REMIND Safe and Danger area Replacing parts for safety SAFE AREA TORQUE 130 Nm 96 lbf ft 314813 Danger 6202542 Gefahr Pericolo 6201855 Peligro 6202543 SAFE AREA SAFE AREA Danger Gefahr Pericolo Peligro SAFE AREA 45° 35°... - Page 3 A - INTRODUCTION A - INTRODUCTION INTRODUCTION This handbook must be considered as part of the machine. The seller of new and second-hand machines must record in the selling document that this booklet has been given along with the machine. PICTURES USED IN THE HANDBOOK Before starting use this machine, it is necessary to read carefully this hand-book, learn and observe all the safety rules indicated with the...

-

Page 4: Improper Uses

B - CONDITIONS AND LIMITS OF USE B - CONDITION AND PROPER USE DEFINITION OF PROPER USE • This machine have been designed for grass cutting and weed control in agriculture and public green, flat and sloped areas. • The exact observance of use conditions, maintenance and reparation are the essential element for a correct use. - Page 5 C - INDEX C - INDEX OF CONTENT SECTION 6 - TROUBLESHOOTING A- INTRODUCTION B- CONDITIONS AND PROPER USE SECTION 7 - MAINTENANCE C- INDEX OF CONTENT Main Maintenance components D- MACHINE IDENTIFICATION Lubrification Points Chassis number Electric scheme Type and serial number of the engine Tests before use Dimensions 7.1.1 Control of the engine oil...

- Page 6 D - IDENTIFICATION NUMBER Tiller B70 D - IDENTIFICATION NUMBER In case of a trouble, when You contact Your dealer for a reparation or to ask for spare parts, it is necessary to identify the machine with the following data: •...

- Page 7 121 - 132 Max Slope 35°Uphill - Longitudinal 45° Crawler contact area (17,5x75/80x2) = 2625-2800 cm² Tilt ang/h-gravity point 65° / 15cm Motor type Brushless Perm. Magnetes Power supply 3 Phases - 4Kw Motor power 1.5 kW Driver BHV - 48V 100A...

- Page 8 SECTION 1 - TECHNICAL DATA Tiller B70 1.2 Noise The noise level was obtained during the equipment in action, in neutral position and the results are the following: Honda engine GXV 390 (4 strokes) with original muffler Acoustic pressure level (LpAm) ..92,7 dB(A) Acoustic power level (LwA)...107,3 dB(A) Kawasaki engine FS481V (4 strokes) with original muffler Acoustic pressure level (LpAm) ..

-

Page 9: Safety Devices

SECTION 2 - SAFETY NORMS I. SAFETY 2 - SAFETY NORMS Engine STOP Rear Flap-Guard Debris Chain & Side rubber debris guard Belt Cover Left Rear Blade support Blade Front Right Fig 5 Blade fasteners Front Flap-Guard 2.1 SAFETY DEVICES The terms “FRONT”... -

Page 10: Section 2 - Safety Norms

SECTION 2 - SAFETY NORMS 2.2 WARNING LABELS AND SAFETY ADVICES The most important warning labels are placed near to the danger around the machine. Be sure to understand the meaning of the lables in order to use a proper behavior to avoid any danger action. - Page 11 SECTION 2 - SAFETY NORMS I. SAFETY Before starting the engine, be sure that the SAFETY DEVICES are well working and fitting. Without these cares the operator might work in a danger situation. This machine has been designed and manufactured for being used by one operator only who hold the Radiocontrol.

- Page 12 SECTION 2 - SAFETY NORMS Tiller B70 14) Use only genuine spare parts and accessories especially the safety parts (chap.2.1) to guarantee the safety and the function of the machine. 15) Stop engine before refuelling 16) Handle the fuel with care to avoid spilling on the machine; clean any spillage immediately.

- Page 13 SECTION 2 - SAFETY NORMS I. SAFETY 30) Whenever possible, stop the machine on a flat ground. 31) Park the machine in an unaccessible place for children or unauthorized persons: stop the machine and remove the Start key from the dashboard.

-

Page 14: Machine Preparation

SECTION 3 - MACHINE PREPARATION 3 - MACHINE PREPARATION 3.1 PACKAGING AND ENDOWMENT Fig 6 The machine is supply with: 1 x Basic Unit X-Rot 1 x Radio Control 2 x Lithium battery for Radio control 1 x Battery charger 1 x Radio control’s hanging belt 1 x User Manual &... -

Page 15: Components And Controls

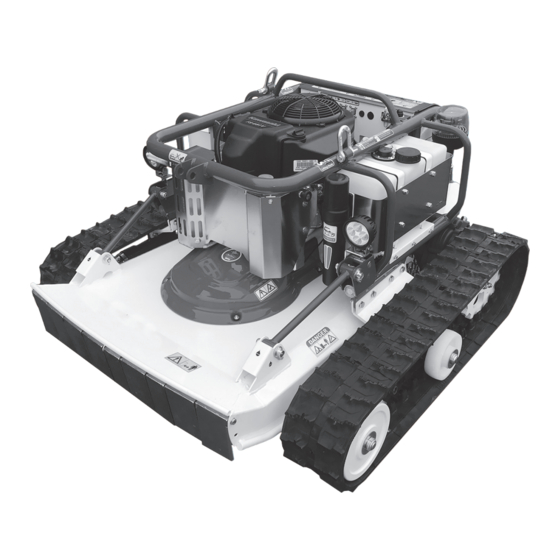

SECTION 4 - COMPONENTS AND CONTROLS I. SAFETY 4 - COMPONENTS AND CONTROLS 4.1 NAME OF MAJOR COMPONENTS (fig.7) Fig 7 Basic Unit: Identification of the main components. A) Tensor wheels H) Battery case & Start key Q) Remote control B) Crawler’s roller I) Engine - Air inlet R) Front Flap-guard... - Page 16 SECTION 4 - CONTROLS Tiller B70 4.2 ENGINE (fig.7 - I) The machine is equipped by a high quality petrol engine made in USA and designed to assure a long operating life. The engine is provided by an electric start. To start the engine follow the procedure of Cap. 5.2. The engine is also provided by a forced lubrication system which help to work in a sloping areas, nevertheless it is highly recommend not to exceed the 35°.

-

Page 17: Electric System

SECTION 4 - CONTROLS I. SAFETY 4 - CONTROLS 4.3 MOWER DECK (fig.7 - p) The mower deck has a special design to reduce the power required. It is connected directly to the engine by belt and disconnected by an EM clutch. The engagement of the Mower is only possible if the engine is running at suitable speed. -

Page 18: Section 4 - Controls

SECTION 4 - CONTROLS Tiller B70 4.6 REMOTE CONTROL The remote control is a heavy duty and reliable unit which allow to carry out all the controls and the adjustment of the machine. It works on a frequency of 2,4 GHz with the Transmission technology AFA (Automatic Frequency Adjustment) that automatically shift to a new free channel in case of noise on the transmission. -

Page 19: Section 5 - How To Use The Machine

SECTION 5 - HOW TO USE THE MACHINE 5 - RULES FOR A SAFE USE 5.1 CONNECTING THE RADIO CONTROL Turn the Starting Key switch to ON position. The buzzer will start to sound to warn that the Radio control is not connected. - Page 20 SECTION 5 - HOW TO USE THE MACHINE 5.3 ENGINE STOP (fig. 11) To stop the engine push anytime the Red STOP Button (Fig 11 - f) and the engine will suddenly stops. Just after stopping, remind to release the emergency Button (f) in its normal position.

-

Page 21: Auxiliary Port

SECTION 5 - HOW TO USE THE MACHINE 5.6 BRAKE SYSTEM AND PARKING The machine is supplied with an automatic passive brakes which stops the machine while not driving. Nevertheless it is recommend to stop the engine only on a flat ground to avoid that for any reason the machine could move downhill. -

Page 22: Loading Onto Or Unloading From A Truck

SECTION 5 - HOW TO USE THE MACHINE 5.10 CONTROLS DURING THE USE The electric drive transmission have been design to be maintenance free. Nevertheless as the machine is equipped by one engine it is necessary to mantein it and to make some controls everytime you use it. These maintenance operations include safety devices which are crucial to assure the safety. - Page 23 SECTION 5 - HOW TO USE THE MACHINE Hitch point Fig 17 Center of Gravity Fig 18 5.12 SAFETY IN THE WORK FIELD It is mandatory to follow these rules to not create danger for the operator and for people, pets or things around the operation area. a) Operate if you have a perfect control at your sight of the area of 20m radius around the machine, only.

-

Page 24: Troubleshooting

SECTION 6 - TROUBLESHOOTING 6 - TROUBLESHOOTING... -

Page 25: Maintenance

SECTION 7 - MAINTENANCE 7 - MAINTENANCE Main Maintenance points Fig 20 a) Engine oil Drain cap e) Air Filter i) Blade b) Fuel Filter f) Battery l) Blade fasteners c) Fuel tank cap g) Mower Blade belt d) Engine oil filling cap h) Mower Flap-guards Lubrication Points k Grease Nipple... - Page 26 SECTION 7 - MAINTENANCE Electric scheme (Honda only Kawasaki General Key Switch Solenoid Stop Starter Emergency Switch Choke 1260 0000 TAB (1) - FUSE BOX - R6 - R5 - R4 STOP Buzzer Solenoid - R3 - R2 - R1 STOP Sparks START...

- Page 27 SECTION 7 - MAINTENANCE Kawasaki Emergency Buzzer Switch AC/DC AC/DC L1.1 Fuel level XC1 (17VAC) L2.1 L3.1 XC2 (68VAC) Superseal 2P Speed adjusting Superseal 2P Height adjusting Deutch 2P L1.2 L2.2 See Fuse Box L3.2 Beacon Superseal 2P Pin 18 122OPT Pin 14 Hours...

-

Page 28: Test Before Use

SECTION 7 - MAINTENANCE 7.1 TEST BEFORE USE 7.1.1 Control of the engine oil (Fig 20 (e)) To check the engine oil it is necessary that the machine is on a on a flat hard ground. Remove the oil dipstick (e) and check that the oil level is near the upper mark. - Page 29 SECTION 7 - MAINTENANCE the machine that allow the tensor block to compensate for the play and return to do its function. Their assembly is very simple and is represented in Fig. 23 Fig 23 7.1.5 Radio Control battery charge The battery of the radio control is a critical component of the machine.

- Page 30 SECTION 7 - MAINTENANCE 7.1.6 Control of the Cutting blades The blades are the most stressed element of the machine and are subject to frequent impacts with stones or other objects that can compromise both the cutting efficiency (loss of the cutting edge) and the integrity itself (breakage of the blades or fixing bolts ).

-

Page 31: Maintenance And Adjustment

SECTION 7 - MAINTENANCE I. SAFETY 7.2 MAINTENANCE AND ADJUSTMENT 7.2.1 Maintenance schedule and Lubrication program Replacement or servicing at authorizedservice facility recommended Clean or wash Inspect replenish or adjust Replace Engine Oil Mantein specific level Air cleaner Fuel Keep fuel tank always full Fuel filter No dust or water inside Battery condition... - Page 32 SECTION 7 - MAINTENANCE Tiller B70 Fig 24 7.2.2 Changing engine oil and filters For the engine oil always refer to the instruction manual of the engine manufacturer. The first oil replacement has to be done after the first 50 working hours which represents the engine running- in period.

- Page 33 SECTION 7 - MAINTENANCE 7.2.4 Lubrication of Joints Following the lubrication program, Fill up the joint with grase every 50 hours. The Lubricatio point are shown in on the Fig. 21 and marked in the machine by a stickers. 7.2.5 Air filter cleaning (See Cap. 4.2.1) Clean the air filter and all the engine's air cooling inlet anytime.

- Page 34 SECTION 7 - MAINTENANCE To adjust the belt, remove the belt cover. Check the tension applying 5 Kg force on the belt. The bended depth of the belt should not be more than 10 mm. If it is required, adjust the belt tension following these instruction.(Fig.29) Fig 29 - release the nuts (1) of the engine's slide - release the locking nuts (2)

- Page 35 SECTION 7 - MAINTENANCE 7.2.8 Crawler replacement The Crawlers are wearing parts and their lifetime depend from the enviroment where the machine have been working. To replace the crawlers it is necessary to lift the machine and positioning 4 props under the mower deck.

- Page 36 SECTION 7 - MAINTENANCE 7.2.10 Debris chain, Rubber and Metal guards The debris chains as well as the Rubber and Metal flap-guards which are in the front and rear side of the mower deck are safety components. They must be always efficient to assure the safety around the mower. They should be checked before starting the daily operations and in any case every 50 hours as recommended by the maintenance schedule.

- Page 37 SECTION 7 - MAINTENANCE 7.3 Notice for disposal Li-NH Battery The symbol of the crossed-out waste container on the device means that it must be handled separately from normal waste. The owner is responsible for handing over scrapped equipment to the designated points of collection for the recycling of electric or electronic waste material.

-

Page 38: Warranty Claim

SECTION 8 - WARRANTY WARRANTY CLAIM SECTION 8 - COMPLAINTS AND WARRANTY The basic principle of the guarantee provisions is compliance with and observance of the relevant operating instructions. Never attempt unauthorized modification of the mower as this could be very hazardous. Damaged or worn parts should be replaced with manufacturer genuine spare parts. - Page 40 XRot MADE IN ITALY BARBIERI Srl Overseas Business Division P.le D. Luigi Sturzo, 15 00144 Roma - Italy Phone +39-0444-885-722 Fax: +39-0444-885-482 Parts code: OM - 6200 - 64 - V2 - GB Publishing date: 15 August 2021 (rev.HSE) Printed in Italy...

Need help?

Do you have a question about the XRot-Pro and is the answer not in the manual?

Questions and answers