Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for DETROIT GHG17 DD

- Page 1 DDC-SVC-MAN-0192 GHG17 DD Medium Duty Operators Manual Specifications are subject to change without notice. Detroit Diesel Corporation is registered to ISO 9001:2001. Copyright © Detroit Diesel Corporation. All rights reserved. Detroit Diesel Corporation is a Daimler company. Printed in U.S.A.

-

Page 2: Table Of Contents

First Time Start Preparations............... 26 System Checks..................... 26 Starting the Engine..................29 Cold Weather Operation................30 Detroit Diesel Electronic Control System Operation........32 Detroit Diesel Electronic Control System Operation........32 Detroit Diesel Electronic Control System Features........35 Changing the Idle Speed................35 Stop Engine Override Option.............. - Page 3 GHG17 DD Medium Duty Operators Manual Service Record..................... 47 Instrument Panel Lamps................48 Instrument Panel Lamps................48 Diesel Exhaust Fluid Level Warning Lamps..........52 Diesel Exhaust Fluid Level Warning Lamps..........52 Aftertreatment System Driver Notifications and Actions......53 Aftertreatment System Driver Notifications and Actions......53 Preventive Maintenance Intervals..............

- Page 4 Coolants for Detroit™ Engines..............98 Maintenance....................100 Appendix A - Definitions................107 Appendix B - General Coolant Information..........108 Appendix C - Detroit™ Cooling System Maintenance Products....110 Customer Assistance..................113 Availability of Detroit™ Service Outlets........... 113 Detroit Genuine Coolant Engine Products..........114 Detroit Genuine Coolant Engine Products..........

-

Page 5: California Proposition 65 Warning And Engine Idle Notice

GHG17 DD Medium Duty Operators Manual California Proposition 65 Warning and Engine Idle Notice All information subject to change without notice. DDC-SVC-MAN-0192 Copyright © 2022 DETROIT DIESEL CORPORATION... -

Page 6: Forward

Forward Forward Introduction This manual is intended for use by the operator of a Detroit™ engine used in On- Highway Vehicle applications. Non-Genuine and Rebuilt Component Quality Alert Electronic engine controls have aided engine manufacturers to meet the stringent emission requirements of the U.S. Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) and also in meeting the ever-increasing performance demands of the customer. -

Page 7: Engine Conversions And Modifications

Engine Conversions and Modifications The function and safety of the engine could be affected if unauthorized modifications are made to it. Detroit™ will not accept responsibility for any resulting damage. Tampering with the fuel injection system and engine electronics could also affect engine power output or exhaust emission levels. - Page 8 Throttle Position Organization for Sensor Standardization Kilo (1000) Timing Reference Sensor Kilogram Vehicle Identification Number Kilometer Variable Speed Governor km/h Kilometers per Hour Variable Speed Sensor Kilopascal All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

-

Page 9: To The Operator

NOTICES regarding engine performance or service life will appear. To avoid personal injury and ensure long engine service life, always heed these instructions. Whenever possible, it will benefit you to rely on an authorized Detroit™ service outlet for all your service needs from maintenance to major parts replacement. - Page 10 DDC®, Detroit™, DDEC®, Optimized Idle®, Diagnostic Link®, BlueTec®, POWER Trac®, POWER COOL®, and POWER GUARD® are registered trademarks of Detroit Diesel Corporation. All other trademarks used are the property of their respective owners. All information subject to change without notice.

-

Page 11: Caution Summary

GHG17 DD Medium Duty Operators Manual Caution Summary Caution Summary The following cautions must be observed by the operator of the vehicle or equipment in which this engine is installed and/or by those performing basic engine preventive maintenance. Failure to read and heed these cautions and exercise... - Page 12 To avoid injury when working near or on an operating engine, remove loose items of clothing and jewelry. Tie back or contain long hair that could be caught in any moving part causing injury. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

- Page 13 GHG17 DD Medium Duty Operators Manual WARNING: PERSONAL INJURY To avoid injury when working on or near an operating engine, wear protective clothing, eye protection, and hearing protection. WARNING: HOT OIL To avoid injury from hot oil, do not operate the engine with the rocker cover(s) removed.

- Page 14 To avoid injury from flying debris when using compressed air, wear adequate eye protection (face shield or safety goggles) and do not exceed 276 kPa (40 psi) air pressure. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

- Page 15 GHG17 DD Medium Duty Operators Manual Cooling System Observe the following cautions when servicing the cooling system. WARNING: HOT COOLANT To avoid scalding from the expulsion of hot coolant, never remove the cooling system pressure cap while the engine is at operating temperature.

- Page 16 To avoid injury from fire, keep all potential ignition sources away from diesel fuel, including open flames, sparks, and electrical resistance heating elements. Do not smoke when refueling. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

- Page 17 GHG17 DD Medium Duty Operators Manual WARNING: PERSONAL INJURY To prevent the escape of high pressure fuel that can penetrate skin, ensure the engine has been shut down for a minimum of 10 minutes before servicing any component within the high pressure circuit.

- Page 18 Caution Summary All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

-

Page 19: Engine Indentification

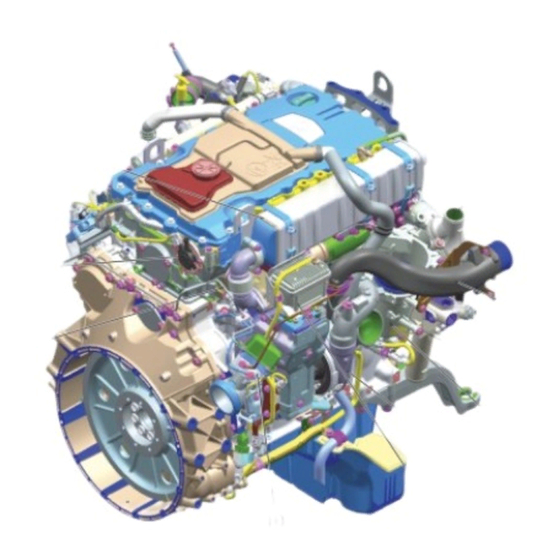

Engine Indentification Engine Components - GHG17 Medium Duty Platform GHG17 Medium Duty Platform engine components are shown below: DD5 Engine Components For general views of the Detroit™ DD5 engine and major components, see the following: Table 3. DD5 Left Side View 1. - Page 20 9. Wastegate Actuator Fuel Doser Injector 5. Charge Air Cooler (CAC) Inlet Pipe Valve DD8 Engine Components For general views of the Detroit™ DD8 engine and major components, see the following: All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

- Page 21 GHG17 DD Medium Duty Operators Manual Table 5. DD8 Left Side View 1. Water Pump 5. Air Compressor 2. Coolant Thermostat 6. Motor Control Module (MCM) 3. High Pressure Fuel Rail 7. Fuel Filter Module 4. High Pressure Fuel Pump 8.

-

Page 22: Engine Model And Serial Number Designation

• 934 = engine model (Medium Duty 4-cyl, for MDEG NAFTA = DD5) • 913 = application/high level identifier • C = assembly plant (C for Mannheim, S for Detroit) • 0043228 = serial number All information subject to change without notice. - Page 23 Using 936913C0043228 as an example: • 936 = engine model (DD8) • 913 = application/high level identifier • C = assembly plant (C for Mannheim Germany, S for Detroit Michigan) • 0043228 = production serial number All information subject to change without notice.

- Page 24 It gives the operating conditions under which certification was made. The following illustration is a GHG17 engine certification label. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

- Page 25 GHG17 DD Medium Duty Operators Manual Figure 7. GHG17 Engine Certification Label All information subject to change without notice. DDC-SVC-MAN-0192 Copyright © 2022 DETROIT DIESEL CORPORATION...

-

Page 26: First Time Start Preparations

1. Make sure all drain cocks in the cooling system are installed (drain cocks are often removed for shipping) and are closed tightly. 2. Fill the coolant overflow surge tank with Detroit™ Genuine Coolant until coolant level stays between the low and full coolant marks on the tank. - Page 27 GHG17 DD Medium Duty Operators Manual 2. Add oil to maintain the correct level on the dipstick. Use only the heavy- duty oils recommended in the "How to Replace the Lubricating Oil and Oil Filter" section in this manual. NOTE: If the dipstick has a positive locking device such as a lever or twist- lock design, this must be disengaged before pulling the dipstick out of the guide tube.

- Page 28 Priming is done by operating the manual hand priming pump located on the frame-mounted fuel filter or connecting an external priming pump to the priming port on the fuel filter module. Authorized Detroit™ service outlets are properly equipped for this type of service.

-

Page 29: Starting The Engine

GHG17 DD Medium Duty Operators Manual • Make sure the transmission is filled to the proper level with the fluid recommended by the gear manufacturer. Do not overfill. • The Diesel Exhaust Fluid (DEF) must be checked and filled regularly with DEF meeting Detroit™... -

Page 30: Cold Weather Operation

Use of a winter front on a DD Platform engine, particularly those that are fully closed, will cause performance issues and is not recommended on DD Platform engines. Winter fronts can result in the following: All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192... - Page 31 GHG17 DD Medium Duty Operators Manual • Excessive fan run time due to higher Charge Air Cooler (CAC) outlet temperatures resulting from low air flow through the CAC • Increased fuel consumption • Failure of the DEF system heaters to turn on when needed due to incorrect...

-

Page 32: Detroit Diesel Electronic Control System Operation

Should the AWL (Check Engine) come on for any reason, the vehicle can still be operated and the driver can proceed to the required destination. This condition should be reported to an authorized Detroit™ distributor or dealer. All information subject to change without notice. - Page 33 GHG17 DD Medium Duty Operators Manual NOTICE: When the RSL (Stop Engine) comes on, the system has detected a major malfunction in the engine that requires immediate attention. It is the operator's responsibility to shut down the engine to avoid serious damage.

- Page 34 Detroit Diesel Electronic Control System Operation If the malfunction is intermittent, the lights will come on and go off as the computer senses the changing engine condition. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

-

Page 35: Detroit Diesel Electronic Control System Features

GHG17 DD Medium Duty Operators Manual Detroit Diesel Electronic Control System Features Changing the Idle Speed The idle speed range of the MD Platform engine is 800 rpm for DD5 and 700 rpm for DD8 if the parameters in the CPC are set to the default range. Change the idle speed as follows: 1. -

Page 36: Anti-Lock Braking Systems

California Engine Idle Limiting All 2010 and newer Detroit™ engines built with the California (50-state) EPA certification are allowed to idle indefinitely when idle speed is below 900 rpm. All information subject to change without notice. -

Page 37: Idle Shutdown Timer

GHG17 DD Medium Duty Operators Manual For California (50-state) EPA certification engines that idle above 900 rpm, the California Engine Idle Limiting feature is enabled. The engine will generally shut down after five minutes of continuous idling when the transmission is in neutral or park and the parking brake is set or after 15 minutes when the transmission is in neutral or park and the parking brake is not set. -

Page 38: Engine Systems

The electrical system consists of a starting motor, starting switch, battery-charging alternator, storage batteries, and necessary wiring. Exhaust System Hot exhaust gas from the exhaust manifolds is used to drive the turbocharger. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192... - Page 39 GHG17 DD Medium Duty Operators Manual Exhaust Gas Recirculation System The Exhaust Gas Recirculation (EGR) system consists of an EGR cooler and EGR valve. The EGR valve allows hot exhaust gas to enter the EGR cooler. Heat is extracted from the exhaust gas, resulting in cooler exhaust gas to the cylinders.

-

Page 40: Ghg17 Medium Duty Aftertreatment System

DEF into the SCR hydrolysis chamber to produce a chemical reaction. This chemical reaction converts nitrogen oxide (NOx), present in the exhaust stream, into water vapor and nitrogen. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192... -

Page 41: Diesel Exhaust Fluid Information

Diesel Exhaust Fluid Availability DEF is available in bulk quantities at roadside truck stop service centers. DEF is also available in various container sizes at Detroit™ service outlets, truck dealerships, and many truck service centers. DEF is available in container sizes as small as 2.5 gallons for convenient storage in your vehicle for emergency use. -

Page 42: Aftertreatment Device Operating Requirements

• Lube oil must have a sulfated ash level less than 1.0 wt %, currently referred to as API FA-4, CK-4 and CJ-4 oil. Detroit™ currently recommends DFS 93K223 (API FA-4) for optimal fuel economy, however, DFS 93K222 (API CK-4) may also be used. -

Page 43: Diesel Exhaust Fluid Tank

(19 mm) than the filler neck of the diesel fuel tank and is fitted with a magnetic insert so that diesel fuel cannot be mistakenly added to the DEF tank. The DEF you should use with your Detroit™ product will be API (American Petroleum Institute) certified and meet the specifications ISO 22241-1 and DIN70700. -

Page 44: Aftertreatment Maintenance

There is a need to periodically remove accumulated ash, derived from engine lube oil, from the filter. This ash does not oxidize in the filter during the regeneration process and must be removed through a cleaning procedure. All Detroit™ ATD equipped engines will illuminate a dashboard warning lamp indicating the need for ash cleaning. -

Page 45: Performing A Parked Regeneration - Ghg17

GHG17 DD Medium Duty Operators Manual Performing a Parked Regeneration - GHG17 Performing a Parked Regeneration - GHG17 Perform a Parked Regeneration as follows: WARNING: ENGINE EXHAUST To avoid injury from inhaling engine exhaust, always operate the engine in a well-ventilated area. Engine exhaust is toxic. - Page 46 2. Set park brake. 3. Hold DPF Switch to the ON position for five seconds and then release (engine speed will increase and DPF lamp will go out). All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

-

Page 47: Diesel Particulate Filter Service Record

GHG17 DD Medium Duty Operators Manual Diesel Particulate Filter Service Record Service Record It is mandatory that customers or distributors maintain a proper record of the particulate filter servicing and cleaning. This record is an agent to warranty considerations. The record must include information such as: •... -

Page 48: Instrument Panel Lamps

• When an electronic system fault occurs. • Flashes when idle shutdown or the (Fault should be diagnosed as soon as optimized idle shutdown occurs. possible.) Red Stop Lamp All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192... - Page 49 GHG17 DD Medium Duty Operators Manual Table 8. Lamp Lamp Name Description Results Red Stop Lamp Indicates a major Move the vehicle to (RSL) engine fault that may the nearest safe result in engine location and shut damage. Engine down the engine. Call derate and/or for service.

- Page 50 • At the start of every ignition cycle (a bulb Never flashes check) • For any emission related fault (light out when the fault is inactive) Fuel Filter Restriction Sensor Lamp: Fuel Filter Failed All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

- Page 51 GHG17 DD Medium Duty Operators Manual Table 12. Lamp Lamp Name Description Results Fuel Filter Restriction Yellow lamp Indicates Service soon Sensor (FFRS) Lamp that the fuel filter is restricted and needs to be serviced. May illuminate at the same time as the...

-

Page 52: Diesel Exhaust Fluid Level Warning Lamps

In an empty or an ignored state and the diesel fuel tank is filled without filling the DEF tank, the vehicle's speed will be limited to 5 mph until DEF is detected in the DEF tank. Figure 8. Driver Card All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192... -

Page 53: Aftertreatment System Driver Notifications And Actions

GHG17 DD Medium Duty Operators Manual Aftertreatment System Driver Notifications and Actions Aftertreatment System Driver Notifications and Actions High Exhaust System Temperature Lamp Table 14. Notifications and Instrument Panel Lamp Driver Action Description • High Exhaust System Temperature (HEST) • No change in driving style lamp required. - Page 54 • Indicates the Diesel exits and the lamps Particulate Filter (DPF) remain on, repeat the has reached system parked regeneration. If limits. the second attempt fails, call for service. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

- Page 55 GHG17 DD Medium Duty Operators Manual Diesel Particulate Filter Regeneration Lamp, Check Engine Lamp, and the Stop Engine Lamp Table 18. Notifications and Instrument Panel Lamp Driver Action Description • A parked regeneration must be performed. Reference model year specific section: "Performing a Parked...

-

Page 56: Preventive Maintenance Intervals

DDCSN for publication Engine Requirements; Lubricating Oil, Fuel and Filters (DDC-SVC-BRO-0001) and publication Coolant Selections for Detroit™ Engines (DDC-SVC-BRO-0002), available from authorized Detroit™ distributors and dealers. Each maintenance table shows which maintenance operation must be performed at the recommended interval (in miles, kilometers, and hours). - Page 57 GHG17 DD Medium Duty Operators Manual WARNING: HOT COOLANT To avoid scalding from the expulsion of hot coolant, never remove the cooling system pressure cap while the engine is at operating temperature. Wear adequate protective clothing (face shield, rubber gloves, apron, and boots). Remove the cap slowly to relieve pressure.

- Page 58 Aftertreatment System (ATS) There is a need to periodically remove accumulated ash from the Diesel Particulate Filter (DPF). All Detroit™ ATS-equipped engines will illuminate a dashboard warning lamp indicating the need for ash cleaning. Once the DPF has reached maximum ash volume, the recommended service for the DPF is to remove the DPF and replace with a Reliabilt®...

- Page 59 GHG17 DD Medium Duty Operators Manual Vibration Damper The vibration damper should be inspected periodically and replaced if damaged. Heat from normal engine operation may, over a period of time, cause the vibration damper to break down and lose its dampening properties. For this reason, the vibration damper must be replaced at time of normal major engine overhaul, regardless of apparent condition.

-

Page 60: Ghg17 Medium Duty Preventive Maintenance Tables

Inspect every 45,000 mi (72,000 km) (1,500 hrs) (18 months)* Air Cleaner Refer to vehicle maintenance procedures Exhaust System Inspect every 45,000 mi (72,000 km) (1,500 hrs) (18 months)* All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192... -

Page 61: Dd5 Long Haul

**Detroit highly recommends exchanging the DPF with a Detroit™ genuine DPF to ensure maximum life. • Currently, only Detroit™ Fuel Filter/Water Separator & Davco 245 or Racor 6600 are the only frame-mounted filtration systems compatible for Detroit™ Engines. • Refer to "Routine Preventive Maintenance" for a description of all items. -

Page 62: Dd5 Severe Service

**Detroit highly recommends exchanging the DPF with a Detroit™ genuine DPF to ensure maximum life. • Currently, only Detroit™ Fuel Filter/Water Separator & Davco 245 or Racor 6600 are the only frame-mounted filtration systems compatible for Detroit™ Engines. • Refer to "Routine Preventive Maintenance" for a description of all items. -

Page 63: Dd8 Short Haul

**Detroit highly recommends exchanging the DPF with a Detroit™ genuine DPF to ensure maximum life. • Currently, only Detroit™ Fuel Filter/Water Separator & Davco 245 or Racor 6600 are the only frame-mounted filtration systems compatible for Detroit™ Engines. • Refer to "Routine Preventive Maintenance" for a description of all items. -

Page 64: Dd8 Long Haul

**Detroit highly recommends exchanging the DPF with a Detroit™ genuine DPF to ensure maximum life. • Currently, only Detroit™ Fuel Filter/Water Separator & Davco 245 or Racor 6600 are the only frame-mounted filtration systems compatible for Detroit™ Engines. • Refer to "Routine Preventive Maintenance" for a description of all items. -

Page 65: Dd8 Severe Service

**Detroit highly recommends exchanging the DPF with a Detroit™ genuine DPF to ensure maximum life. • Currently, only Detroit™ Fuel Filter/Water Separator & Davco 245 or Racor 6600 are the only frame-mounted filtration systems compatible for Detroit™ Engines. • Refer to "Routine Preventive Maintenance" for a description of all items. - Page 66 Inspect every 45,000 miles (72,000 km) (1,500 hrs) (12 months)* Air Cleaner Refer to vehicle maintenance procedures Exhaust System Inspect every 45,000 miles (72,000 km) (1,500 hrs) (12 months)* All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

- Page 67 **Detroit highly recommends exchanging the DPF with a Detroit™ genuine DPF to ensure maximum life. • Currently, only Detroit™ Fuel Filter/Water Separator & Davco 245 or Racor 6600 are the only frame-mounted filtration systems compatible for Detroit™ Engines. • Refer to "Routine Preventive Maintenance" for a description of all items.

-

Page 68: Routine Preventive Maintenance

There are approximately 4.0 L (4.2 qts) from the minimum mark to the maximum mark on the dipstick. Overfilling the oil pan can cause engine damage. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192... -

Page 69: Monitoring The Lubricating Oil Filter

GHG17 DD Medium Duty Operators Manual NOTICE: If the oil level is constantly above normal and excess oil has not been added to the crankcase, consult with an authorized Detroit service outlet for the cause. Fuel or coolant dilution of lubricating oil can result in serious engine damage. -

Page 70: Monitoring The Cooling System

2. Add coolant as required, but do not overfill. Before adding coolant, refer to "How to Select Coolant" for the listing of required intervals using the recommended coolants All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192... -

Page 71: Inspection Of The Radiator

GHG17 DD Medium Duty Operators Manual Checking for Coolant Leaks Perform daily visual checks for cooling system leaks. Look for an accumulation of coolant when the engine is running and when it is stopped. NOTE: Coolant leaks may be more apparent on a engine when it is cold. -

Page 72: Monitoring The Fuel Filters

Adjusting the Valve Lash NOTE: Proper valve lash clearance allows the engine to produce the best possible performance with the lowest emissions. Valve lash adjustments should be performed by an authorized Detroit™ maintenance or repair facility. All information subject to change without notice. -

Page 73: Monitoring The Belt Tensioner

GHG17 DD Medium Duty Operators Manual Perform a valve lash adjustment as scheduled for the appropriate engine duty cycle. Monitoring the Belt Tensioner DD Platform engines are equipped with an automatic tensioning device. No adjustment or periodic maintenance is required. - Page 74 Routine Preventive Maintenance Table 26. Poly-V-Belt Inspection Concerns ABRASION CHUNK-OUT IMPROPER INSTALL CRACKING All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

-

Page 75: Inspection Of The Air Intake System

GHG17 DD Medium Duty Operators Manual Table 27. Poly-V-Belt Inspection Concerns PILLING UNEVEN RIB WEAR MISALIGNMENT GRAVEL PENETRATION Inspection of the Air Intake System Perform the following maintenance on the Air Intake System: 1. Inspect all the connections in the air system to make sure they are tight and leak-free. -

Page 76: Monitoring The Exhaust System

2. Check the exhaust pipe rain cap for proper operation, if so equipped. Monitoring the Aftertreatment System NOTE: All Detroit™ Aftertreatment System (ATS) - equipped engines will illuminate a dashboard warning lamp indicating the need for ash cleaning. Periodically the accumulated ash derived from the engine's lubricating oil needs to be removed from the ATS. -

Page 77: Inspection Of Hoses And Fittings For Fuel Leaks

GHG17 DD Medium Duty Operators Manual 5. Open the drain at the bottom of the fuel tank every 30,000 miles (50,000 kilometers) to drain off any water and/or sediment. WARNING: PERSONAL INJURY To avoid injury from improper use of chemicals, follow the chemical manufacturer's usage, handling, and disposal instructions. -

Page 78: Inspection Of The Turbocharger And Charge Air Cooler

Inspection of the Battery Inspect the battery as follows: WARNING: PERSONAL INJURY To avoid injury from accidental engine startup while servicing the engine, disconnect/disable the starting system. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192... -

Page 79: Steam Cleaning The Engine

GHG17 DD Medium Duty Operators Manual 1. Check for cracks in the battery cases (1), for tightness of the cable clamps (2) at the terminals, and for corrosion of the terminals (3). Service or replace as needed. 2. Keep the terminal surface clean. -

Page 80: Inspection Of The Battery-Charging Alternator

(50,000 km). Re-tighten if necessary. Checking the Vibration Damper Check the vibration damper as follows: 1. Inspect the viscous vibration damper periodically and replace if dented or leaking. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192... - Page 81 GHG17 DD Medium Duty Operators Manual 2. Heat from normal engine operation may, over a period of time, cause the fluid within the damper to break down and lose its dampening properties. For this reason, replace the viscous vibration damper at time of normal major engine overhaul, regardless of apparent condition.

-

Page 82: How To Procedures

How to Select Lubricating Oil Refer to DDC-SVC-BRO-0001 for more information. Detroit Fluids Specification (DFS) DFS 93K223 (API FA-4) or DFS 93K222 (API CK-4) oils are recommended for use in the engine. For optimal fuel economy, use DFS 93K223 approved API FA-4 engine oil. -

Page 83: How To Replace The Lubricating Oil And Oil Filter

GHG17 DD Medium Duty Operators Manual Synthetic oils may be used in Detroit™ engines provided they are approved by a DFS. The use of synthetic oils does not necessarily ensure the extension of the recommended oil drain intervals beyond the limits. - Page 84 To avoid injury before starting and running the engine, ensure the vehicle is parked on a level surface, parking brake is set, and the wheels are blocked. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

-

Page 85: How To Select Diesel Fuel

How to Select Diesel Fuel All Detroit ™ engines equipped with Selective Catalyst Reduction (SCR) are designed to operate on Ultra-Low Sulfur Diesel (ULSD) fuel. For optimal fuel system performance, Detroit Diesel recommends Top Tier Diesel (see figure below). - Page 86 The use of supplemental fuel additives does not necessarily void the engine warranty. However, repair expenses which result from fuel system or engine component malfunctions or damage attributed to their use will not be covered. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

- Page 87 • Used Lubricating Oil Do not use fuel blended with used lubricating oil. Detroit™ specifically prohibits the use of used lubricating oil in diesel fuel. Used lubricating oil contains combustion acids and particulate materials which can severely erode fuel injector components, resulting in loss of power and increased exhaust emissions.

-

Page 88: How To Replace The Fuel Filters

Remove the prefilter as follows: 1. Using a 36 mm socket, unscrew the prefilter cap. 2. Pull the cap and prefilter straight up and out of the fuel filter housing. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192... - Page 89 GHG17 DD Medium Duty Operators Manual 3. Remove the prefilter (1) from the prefilter cap (2) by placing the filter on a solid surface and apply pressure on prefilter cap (2) at an angle. 4. Discard the prefilter. 5. Inspect inside the housing for any large debris; clean housing as needed.

- Page 90 1. Shut off the engine, apply the parking brake, chock the wheels, and perform any other applicable safety steps. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

- Page 91 GHG17 DD Medium Duty Operators Manual CAUTION: ELECTRICAL SHOCK To avoid injury from electrical shock, use care when connecting battery cables. The magnetic switch studs are at battery voltage. 2. Disconnect the batteries. Refer to OEM procedures. 3. Open the hood.

-

Page 92: Engine Out Of Fuel - How To Restart

Use the following procedure to prime the fuel system: NOTE: If a vehicle is on uneven ground, more fuel may be required. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192... - Page 93 13. Shut down the engine. 14. Check for leaks. 15. If engine still fails to start, contact an authorized Detroit™ repair facility. Priming the Fuel System Using the Hand Primer Pump Use the following procedure to prime the fuel system: NOTICE: Prolonged use of the starting motor to prime the fuel system can result in damage to the starter.

- Page 94 12. Reduce engine speed and run at idle for ONE (1) additional minute. 13. Shut down the engine. 14. Check for leaks. 15. If engine still fails to start, contact an authorized Detroit™ repair facility. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

-

Page 95: How To Clean An Engine

GHG17 DD Medium Duty Operators Manual How to Clean an Engine Observance of all environmental protection regulations is required. Use high- pressure equipment as follows: CAUTION: EYE INJURY To avoid injury from flying debris, wear a face shield or goggles. - Page 96 8. Flush the cleaning solution from the cooling system. Immediately after draining the cleaning solution, flush the system with clean water. 9. Once the clean water has drained, fill the system again with clean water. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

-

Page 97: Coolant Selections And Maintenance

All ELC's used must also meet Detroit 93K217 specification. Detroit™ requires that these types of coolants to be free of nitrite and phosphate. Detroit™ has found that ELC's containing nitrite may lead to a breakdown of the coolant and subsequent damage to the cooling system. -

Page 98: Coolant Fill Options

How to Procedures Coolant Fill Options The coolants recommended for use in Detroit™ engines are listed in Table "DD Platform Coolant Fill Options". This publication will give a complete explanation of their use. NOTICE: Required specifications for water, Ethylene Glycol (EG), Propylene Glycol (PG), inhibitor packages, and inhibitor concentration are included in the appendix of this publication. - Page 99 The rest of this section will describe the requirements for the proper usage of the water, antifreeze, and corrosion inhibitors. It will also describe the coolants and additives that are not recommended by Detroit™ and have been proven harmful to Detroit™ engines.

-

Page 100: Maintenance

How to Procedures • Soluble Oils: Soluble oil additives are not approved for use in Detroit™ engine cooling systems. A small amount of oil adversely affects heat transfer. For example, a 1.25% concentration of soluble oil increases the fire deck temperature 6%. - Page 101 GHG17 DD Medium Duty Operators Manual Coolant Change • At the end of a coolant drain interval, remove the used coolant by following the drain procedure provided in the engine service literature and re-fill with fresh coolant. • Note that not all drain procedures for a specific application have the ability to drain all of the used coolant from the cooling system.

- Page 102 To best measure the quality of anti-freeze coolant, a check of the freeze point (glycol concentration), by refractometer, should be performed at each service interval to ensure anti-freeze levels are within specification. Detroit™ requires a freeze point between -31°C and -42°C (-24°F and -44°F) to guarantee optimal engine protection.

- Page 103 GHG17 DD Medium Duty Operators Manual Table 29. Extended Life Coolant Maintenance Intervals (also known as OAT): Service Application Efficient Long Short Action Severe Required Long Haul Haul Haul Engine Series Every Every 70,000 Every 50,000 100,000 miles miles (80,000...

- Page 104 (48,000 km) or that operate under severe conditions. Only one of these conditions needs be met to categorize an application as Severe Service. 5. Whichever comes first. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

- Page 105 GHG17 DD Medium Duty Operators Manual Table 30. Extended Life Coolant Maintenance Intervals (also known as OAT): Service Application Efficient Long Short Action Severe Required Long Haul Haul Haul Engine Series Refer to Every section Every 90,000 Every 70,000 100,000 "Extended...

- Page 106 Only one of these conditions needs be met to categorize an application as Severe Service. 5. Whichever comes first. All information subject to change without notice. Copyright © 2022 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0192...

-

Page 107: Appendix A - Definitions

GHG17 DD Medium Duty Operators Manual Table 32. Extended Life Coolant Drain Intervals (also known as OAT): Engine Series Series 60, 50, 40 MBE4000, MBE900 600,000 miles (965,600 km) or 4 years DD5, DD8, DD13, DD15, DD16 Standard Life Coolant Additive Maintenance Procedures The concentrations of SLC inhibitors will gradually deplete during normal engine operation. -

Page 108: Appendix B - General Coolant Information

The pre-mixed antifreeze is ready to use, while the concentrated coolant must be mixed with water prior to use. All fully formulated coolants used must also meet Detroit 93K217 specification. NOTE: Fully formulated antifreeze does not require a dosage of Supplemental Coolant Additive (SCA) at initial use. - Page 109 GHG17 DD Medium Duty Operators Manual to poor heat transfer, reduced freeze protection, and possible silicate dropout. An antifreeze concentration below 40% (40% antifreeze, 60% water) offers too little freeze and/or corrosion protection and is not recommended. WATER REQUIREMENTS Distilled or de-ionized water, which eliminates the adverse effects of minerals in tap water, is preferred.

-

Page 110: Appendix C - Detroit™ Cooling System Maintenance Products

• Phenols • Phosphorus • Silicon • Toluene Other recycled coolants, especially coolants recycled through filtration processes, are not recommended. Appendix C - Detroit™ Cooling System Maintenance Products Table 34. Detroit™ Extended Life Coolant (Ethylene Glycol-based) Coolant Type Part Number... - Page 111 GHG17 DD Medium Duty Operators Manual Table 35. Detroit Genuine Coolant Plus Extender (for use with Detroit Genuine Coolant Plus) Coolant Type Part Number Description IEG Detroit™ Genuine One Quart Bottle - 6 Per Coolant; Series 50 and OWI 23519400...

- Page 112 Case Coolant PIC 23507856 5-Gallon Pail PIC 23507857 55-Gallon Drum Table 39. Detroit Genuine Coolant 3000 SCA Filters (Series 50 and Series 60 Engines Only) Coolant Type Part Number Description 23507545 4 Ounce (1 Pint Equivalent) 23508425 8 Ounce (2 Pint Equivalent)

-

Page 113: Customer Assistance

Customer Assistance Availability of Detroit™ Service Outlets As the owner of a Detroit™ product, you have a complete network of Detroit™ service outlets in the U.S. and Canada, plus many outlets worldwide that are prepared to meet your parts and service needs: •... -

Page 114: Detroit Genuine Coolant Engine Products

Maintenance of the cooling system requires the chemical makeup of the system to be balanced. Detroit Genuine Fully Formulated Inhibited Ethylene Glycol Coolants The part numbers and sizes of concentrated and pre-blended 50:50 Detroit Genuine Coolants are listed in the following Tables. Table 42. - Page 115 5 Gallon Pail 200155 55 Gallon Drum Twin Pack 201549 Twin Pack – 2 Per Case Detroit Genuine Fluid Analysis Products Detroit Genuine Fluid Analysis Products are shown below. Table 45. Detroit Genuine Fluid Testing and Analysis Products Application Part Number Description Indicates Nitrite, Molybdate &...

-

Page 116: Engine Oil Capacities

Consult with a Detroit distributor to obtain the proper engine oil filters. The engine oil capacities for the DD5 and DD8 applications are listed in the following table. Contact your local Detroit service center if you need more specific information.

Need help?

Do you have a question about the GHG17 DD and is the answer not in the manual?

Questions and answers