Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for DETROIT MBE 900

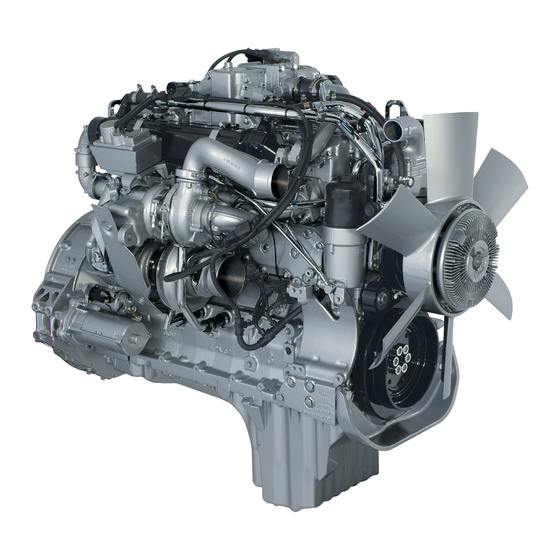

- Page 1 DDC-SVC-MAN-0207 EuroV MBE 900 Operators Manual Specifications are subject to change without notice. Detroit Diesel Corporation is registered to ISO 9001:2001. Copyright © Detroit Diesel Corporation. All rights reserved. Detroit Diesel Corporation is a Daimler company. Printed in U.S.A.

-

Page 2: Table Of Contents

13 Diesel Exhaust Fluid Level Warning Lamps........................27 13.1 Diesel Exhaust Fluid Level Warning Lamps....................... 27 14 Maintenance..................................28 14.1 MBE 900 EuroV Preventive Maintenance Tables - 93K222(CK-4) and 93K218(CJ-4)..........28 14.2 Scheduled Intervals..............................29 14.3 Schedule Use................................30 14.4 Required Maintenance Operations..........................30 14.5 Fuel Prefilter Element Cleaning.......................... - Page 3 EuroV MBE 900 Operators Manual 15.11 Appendix A - Definitions............................56 15.12 Appendix B - General Coolant Information......................57 15.13 Appendix C - Detroit™ Cooling System Maintenance Products................59 15.14 Checking the Hoses..............................60 15.15 How to Service the Dry Type Air Cleaner........................ 61 16 Detroit Genuine Coolanat Engine Products........................

-

Page 4: Forward

Engine Conversions and Modifications The function and safety of the engine could be affected if unauthorized modifications are made to it. Detroit™ will not accept responsibility for any resulting damage. Tampering with the fuel injection system and engine electronics could also affect engine power output or exhaust emission levels. - Page 5 EuroV MBE 900 Operators Manual Acronyms and Abbreviations Check Engine Light Miles per Hour Common Powertrain Controller NOAT Nitrited Organic Acid Technology Detroit Diesel Corporation Nitrogen Oxide DDEC Detroit Diesel Electronic Controls Organic Acid Technology Diagnostic Trouble Code On Board Diagnostic...

-

Page 6: To The Operator

To avoid personal injury and ensure long engine service life, always heed these instructions. Whenever possible, it will benefit you to rely on an authorized Detroit™ service outlet for all your service needs from maintenance to major parts replacement. Authorized service outlets worldwide stock factory-original parts. -

Page 7: Caution Summary

EuroV MBE 900 Operators Manual Caution Summary Caution Summary The following cautions must be observed by the operator of the vehicle or equipment in which this engine is installed and/or by those performing basic engine preventive maintenance. Failure to read and heed these cautions and exercise reasonable care for personal safety and the safety of others when operating the vehicle/equipment or performing basic engine preventive maintenance may result in personal injury and engine and/or vehicle/equipment damage. - Page 8 To avoid injury to skin from contact with the contaminants in used engine oil, wear protective gloves and apron. WARNING: PERSONAL INJURY To avoid injury when using caustic cleaning agents, follow the chemical manufacturers usage, disposal, and safety instructions. All information subject to change without notice. Copyright © 2019 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0207...

- Page 9 EuroV MBE 900 Operators Manual WARNING: PERSONAL INJURY To avoid injury from hot surfaces, wear protective gloves, or allow engine to cool before removing any component. WARNING: PERSONAL INJURY To avoid injury, use care when working around moving belts and rotating parts on the engine.

- Page 10 To avoid injury from accidental engine startup while servicing the engine, disconnect/disable the starting system. Air Intake System Observe the following cautions when working on the air intake system. All information subject to change without notice. Copyright © 2019 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0207...

- Page 11 EuroV MBE 900 Operators Manual WARNING: PERSONAL INJURY To avoid injury from hot surfaces, wear protective gloves, or allow engine to cool before removing any component. WARNING: PERSONAL INJURY To avoid injury from contact with rotating parts when an engine is operating with the air inlet piping removed, install an air inlet screen shield over the turbocharger air inlet.

- Page 12 • To prevent a buildup of potentially volatile vapors, keep the engine area well ventilated during operation. Aftertreatment System Observe the following cautions when servicing the Aftertreatment System (ATS). Be advised that these two labels are attached to the Aftertreatment Device (ATD). All information subject to change without notice. Copyright © 2019 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0207...

-

Page 13: First Time Start Preparations

1. Make sure all drain cocks in the cooling system are installed (drain cocks are often removed for shipping) and are closed tightly. 2. Fill the coolant overflow surge tank with Detroit™ Genuine Coolant until coolant level stays between the low and full coolant marks on the tank. - Page 14 Authorized Detroit™ service outlets are properly equipped for this type of service.

-

Page 15: Starting The Engine

• Make sure the transmission is filled to the proper level with the fluid recommended by the gear manufacturer. Do not overfill. • The Diesel Exhaust Fluid (DEF) must be checked and filled regularly with DEF meeting Detroit™ quality specification. • Make sure cable connections to the storage batteries are clean and tight. -

Page 16: Cold Weather Operation

Winter fronts on Detroit™ engines are seldom necessary due to the modern design of the engine cooling system. The coolant thermostat is on the outlet side of the cooling system on the Detroit™ engine and regulates coolant flow to the radiator into the engine. -

Page 17: Detroit Diesel Electronic Control System Operation

Should the AWL (Check Engine) come on for any reason, the vehicle can still be operated and the driver can proceed to the required destination. This condition should be reported to an authorized Detroit™ distributor or dealer. NOTICE: When the RSL (Stop Engine) comes on, the system has detected a major malfunction in the engine that requires immediate attention. - Page 18 5 Detroit Diesel Electronic Control System Operation NOTE: Continuously holding down the Stop Engine Override Switch will not prevent the engine shutdown sequence. You must continue to reset the automatic shutdown system by pressing the Stop Engine Override Switch at intervals of approximately 15 to 20 seconds.

-

Page 19: Detroit Diesel Electronic Control System Features

EuroV MBE 900 Operators Manual Detroit Diesel Electronic Control System Features Changing the Idle Speed The idle speed can be variable if the parameters in the CPC are set to the default range. Change the idle speed as follows: 1. Turn the cruise control switch to the ON position. -

Page 20: Engine Systems

The electrical system consists of a starting motor, starting switch, battery-charging alternator, storage batteries, and necessary wiring. Exhaust System Hot exhaust gas from the exhaust manifolds is used to drive the turbocharger. All information subject to change without notice. Copyright © 2019 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0207... -

Page 21: Eurov Mbe900 Aftertreatment System

EuroV MBE 900 Operators Manual EuroV MBE900 Aftertreatment System EuroV MBE900 Aftertreatment System The Selective Catalytic Reduction (SCR) catalyst converts a mixture of nitrogen oxides and Diesel Exhaust Fluid (DEF) into nitrogen and water. DEF is pressurized by a pump and is then sprayed into the SCR. -

Page 22: Diesel Exhaust Fluid Information

Diesel Exhaust Fluid (DEF) is stored in the onboard DEF tank. DEF is pulled through the DEF tank header to the DEF pump. DEF is pumped to the dosing unit and is injected into the aftertreatment. DEF circulates back to the DEF tank from the dosing unit. All information subject to change without notice. Copyright © 2019 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0207... -

Page 23: Diesel Exhaust Fluid Tank

• Additional Diesel Exhaust Fluid (DEF) sales locations can be found at www.afdc.energy.gov/afdc/locator/def/ If diesel fuel is added to the DEF tank or DEF is added to the diesel fuel tank, immediately contact your Certified Detroit™ Service Center for further instructions. -

Page 24: Aftertreatment Maintenance

A high amount of black smoke emitting from the vehicle or illumination of the Amber Warning Lamp or Red Stop Lamp are indications of a system problem. Should this occur, consult your local Detroit™ Service Center. Illumination of the Malfunction Indicator Lamp (MIL) Lamp indicates a failure of an emissions control device. The MIL may illuminate along with other ATS warning lamps. -

Page 25: Instrument Panel Lamps

EuroV MBE 900 Operators Manual 12 Instrument Panel Lamps The instrument panel lamps are explained below: Amber Warning Lamp Table 3. Lamp Lamp Name Description Result Amber Warning Lamp (AWL) Indicates a fault with the engine Vehicle can be driven to end of shift. - Page 26 Lamp Solid Lamp Flashing • At the start of every ignition cycle (a bulb check). • Never flashes. • Water separator has reached it maximum capacity. All information subject to change without notice. Copyright © 2019 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0207...

-

Page 27: Diesel Exhaust Fluid Level Warning Lamps

EuroV MBE 900 Operators Manual 13 Diesel Exhaust Fluid Level Warning Lamps 13.1 Diesel Exhaust Fluid Level Warning Lamps A four light bar segment indicates the Diesel Exhaust Fluid (DEF) level in 25% increments. Low DEF levels will trigger a decrease in the engine's performance. -

Page 28: Maintenance

14 Maintenance 14 Maintenance 14.1 MBE 900 EuroV Preventive Maintenance Tables - 93K222(CK-4) and 93K218(CJ-4) NOTE: DFS 93K223(FA-4) oils should not be used in an MBE900 EuroV engine. NOTE: Refer to DTNAConnect.com for most current information. DFS 93K222(CK-4) and 93K218(CJ-4) Oil Service Interval Definitions (applies to the following tables): Long Haul Applies to vehicles that travel more than 100,000 kilometers annually, with an average fuel economy greater than 2.6 km/l, with load factor up to 44%, idle time up to 20%. -

Page 29: Scheduled Intervals

- ***Fuel Economy represents overall fuel economy (including idle time) - ‡Currently, only Detroit™ Fuel Filter/Water Separator & Davco 482/485/487 are the only frame-mounted filtration systems compatible for Detroit™ Engines. - Refer to "Routine Preventive Maintenance" and "How to Procedures" for a description of all items. -

Page 30: Schedule Use

Maintenance Schedule and Interval Operations The three different schedules of vehicle usage (severe, short haul, and long haul) are listed. Refer to section "MBE 900 EuroV Preventive Maintenance Tables - 93K222(CK-4) and 93K218(CJ-4)". For each schedule, the appropriate distance interval (in miles and kilometers) is given for performing and repeating each maintenance operation. - Page 31 EuroV MBE 900 Operators Manual • Visually inspect all lines and hoses. Listen for any sound of leaking. Make sure all pipes and hoses are undamaged, correctly positioned to avoid chafing, and properly secured. Valve Lash Checking and Adjusting Visually inspect all lines and hoses. Listen for any sound of leaking. Make sure all pipes and hoses are undamaged, correctly positioned to avoid chafing, and properly secured.

- Page 32 3. Using the cranking device, turn the crankshaft until cylinder #6 (cylinder #4 on the four-cylinder engine) is at the ignition TDC position (all valves are closed) and cylinder #1 is at the valve overlap position (valves are open). All information subject to change without notice. Copyright © 2019 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0207...

- Page 33 EuroV MBE 900 Operators Manual 4. Using the same procedure, check the valves in the "Valve Overlap" row and adjust them (if necessary), using the procedures under the headings "Checking Valve Lash" and "Adjusting Valve Lash." Table 11. Valve Adjustment- Method Two...

-

Page 34: Fuel Prefilter Element Cleaning

2. Remove the cranking device from the inspection hole in the timing case. 3. Replace the end cover on the inspection hole and tighten the bolts 25 N·m (18 lb·ft). All information subject to change without notice. Copyright © 2019 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0207... - Page 35 EuroV MBE 900 Operators Manual 14.5 Fuel Prefilter Element Cleaning Clean the fuel prefilter element as follows: 1. Open the fuel filler cap to release pressure in the fuel system. Replace and tighten the cap. 2. Clean the outside of the prefilter housing. Keep fuel away from hoses or pipes located beneath the filter Figure 4.

-

Page 36: Main Fuel Filter Element Changing

NOTICE: To prevent damage to the filter housing, do not allow dirt to get into the filter housing. Do not empty the dirt collector into the filter case. 5. Pull the dirt collector out of the filter housing using the tabs on either side. All information subject to change without notice. Copyright © 2019 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0207... -

Page 37: Engine Oil And Filter Changing

EuroV MBE 900 Operators Manual Figure 7. Main Fuel Filter 6. Clean the cap and the dirt collector. 7. Replace the O-ring. 8. Install the new filter element in the cap. Make sure the filter element is securely in place. - Page 38 3. Place a suitable receptacle beneath the oil drain plug on the underside of the oil pan. Carefully unscrew the oil drain plug on the oil pan and allow the oil to drain out. Discard the O-ring on the oil drain plug. All information subject to change without notice. Copyright © 2019 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0207...

- Page 39 EuroV MBE 900 Operators Manual Figure 10. Engine Oil Drain Plug, Oil Pan 4. Remove both the filter cap and the filter element. To release the filter element, twist the lower edge of the filter element to the side. Figure 11. Cap with Oil Filter Element NOTICE: To prevent damage to the filter housing, ensure that no foreign objects get inside it.

- Page 40 NOTICE: Both the primary lube oil filter (front of engine) and the oil centriguge cartridge (side of engine) must be replaced at each oil drain interval. Change the oil centrifuge cartridge as follows: 1. Remove the cover of the oil centrifuge. All information subject to change without notice. Copyright © 2019 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0207...

-

Page 41: Coolant Concentration Checking

EuroV MBE 900 Operators Manual Figure 13. Oil Centrifuge 2. Lift out the dirty cartridge and replace it with a clean one. Figure 14. Centrifuge Cartdirge 3. Replace the centrifuge cover, tighten the cap 40 Nm (30 lb·ft). 14.8 Coolant Concentration Checking... -

Page 42: Coolant Flushing And Changing

3. Drain the coolant from the engine. Coolant system capacity is listed in the "Coolant System Capacity" table below. a. Place a receptacle underneath the coolant drain plug. Choose one that is large enough to hold the expected quantity of coolant. All information subject to change without notice. Copyright © 2019 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0207... -

Page 43: Cooling System Inspecting

EuroV MBE 900 Operators Manual Figure 15. Coolant Drain Plug b. Open the coolant drain plug on the bottom of the radiator. NOTICE: When flushing the radiator, do not apply more than 140 kPa (20 psi) air pressure. Excessive pressure can damage the radiator or heater core. - Page 44 3. Check the outside of the radiator and condenser for blockage by dirt or debris. Make sure the fins are not damaged, and straighten them if necessary. All information subject to change without notice. Copyright © 2019 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0207...

-

Page 45: How To Procedures

NOTE: If the used oil was contaminated by fuel or coolant, it may be necessary to take the vehicle to a certified Detroit Service Center. The Service Center may drain the oil and then remove the oil pan, oil pump, and oil pump intake manifold to drain the remaining oil held back by the backflow valve. - Page 46 8. Inspect the oil filter bypass valve (3) in the end of the standpipe (2) in the oil filter housing. See illustration below. A broken bypass valve (1) is shown on the right. Repair as necessary. All information subject to change without notice. Copyright © 2019 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0207...

- Page 47 EuroV MBE 900 Operators Manual NOTICE: On some chassis models the air filter housing may interfere with installing the oil filter cap and filter element straight into the housing. If this is the case, loosen or remove the air filter housing to allow for proper oil filter installation.

-

Page 48: How To Select Diesel Fuel

All DD Platform engines are designed to operate on Ultra-Low Sulfur Diesel (ULSD) fuel. For optimal fuel system performance, Detroit Diesel recommends Top Tier Diesel (see figure below). For optimum engine operation and maximum service life, diesel fuels meeting the property requirements listed in the table below are recommended for use. -

Page 49: Engine Out Of Fuel - How To Restart

The following fuel additives are not allowed and MUST NOT be mixed with diesel fuel: • Used Lubricating Oil Do not use fuel blended with used lubricating oil. Detroit™ specifically prohibits the use of used lubricating oil in diesel fuel. Used lubricating oil contains combustion acids and particulate materials which can severely erode fuel injector components, resulting in loss of power and increased exhaust emissions. -

Page 50: How To Clean An Engine

12. Return the engine to idle and allow to idle for approximately one minute, then shut down the engine. 13. Check for leaks. 14. If engine still fails to start, contact an authorized Detroit™ repair facility. 15.5 How to Clean an Engine Observance of all environmental protection regulations is required. -

Page 51: Cleaning/Flushing The Cooling System

EuroV MBE 900 Operators Manual 5. When reassembling, ensure that there is no standing water in any electrical connectors before seating the plug. 15.6 Cleaning/Flushing the Cooling System Collect the used coolant, cleaning solutions, and washing liquids and dispose of them in an environmentally responsible manner. -

Page 52: Coolant Fill Options

Concentrated antifreeze coolants should be mixed at 50% (50% antifreeze/50% water). All ELC's used must also meet DFS 93K217 specification. Detroit™ requires that these types of coolants to be free of nitrite and phosphate. Detroit™ has found that ELC's containing nitrite may lead to a breakdown of the coolant and subsequent damage to the cooling system. -

Page 53: Coolant Do's And Don'ts

The rest of this section will describe the requirements for the proper usage of the water, antifreeze, and corrosion inhibitors. It will also describe the coolants and additives that are not recommended by Detroit™ and have been proven harmful to Detroit™... -

Page 54: Maintenance

The following additives should not be used in Detroit™ engines: • Soluble Oils: Soluble oil additives are not approved for use in Detroit™ engine cooling systems. A small amount of oil adversely affects heat transfer. For example, a 1.25% concentration of soluble oil increases the fire deck temperature 6%. - Page 55 Nitrite concentration is an indication of the overall coolant inhibitor concentration in SLC formulations. These coolants must be tested for nitrite concentration at the regular intervals as listed in Table "Standard Life Coolant". Detroit™ Genuine Fluid Analysis 3-Way Test Strips (or equivalent) are recommended. Use these test strips to measure nitrite and glycol concentrations.

-

Page 56: Appendix A - Definitions

In warm climates where freeze protection is not required, water only with corrosion inhibitors is approved for use. Water-only systems need to be treated with the proper dosage of corrosion inhibitors. Detroit™ approved conventional SCA or OAT corrosion inhibitors must be added to the water to provide required corrosion and cavitation erosion protection. -

Page 57: Appendix B - General Coolant Information

In warm climates where freeze protection is not required, water only with corrosion inhibitors is approved for use. Water-only systems need to be treated with the proper dosage of corrosion inhibitors. Detroit™-approved SCA or ELC corrosion inhibitors must be added to the water to provide required corrosion and cavitation erosion protection. - Page 58 Recycled antifreeze coolants of these types are preferred. However, suppliers of these recycled glycols must provide evidence the product is free of contaminates listed below: • Acetates • Acetone • Ammonia • Boron All information subject to change without notice. Copyright © 2019 DETROIT DIESEL CORPORATION DDC-SVC-MAN-0207...

-

Page 59: Appendix C - Detroit™ Cooling System Maintenance Products

Pre-Diluted (50:50) OWI 23519398 55-Gallon Drum OWI 2359084 275-Gallon Tote (Canada) Table 19. Detroit Genuine Coolant Plus Extender (for use with Detroit Genuine Coolant Plus) Coolant Type Part Number Description IEG Detroit™ Genuine Coolant; Series 50 OWI 23519400 One Quart Bottle - 6 Per Case and Series 60 Table 20. -

Page 60: Checking The Hoses

Half Gallon Jugs - 6 Per Case IEG Detroit™ Genuine Coolant PIC 23507856 5-Gallon Pail PIC 23507857 55-Gallon Drum Table 23. Detroit Genuine Coolant 3000 SCA Filters (Series 50 and Series 60 Engines Only) Coolant Type Part Number Description 23507545 4 Ounce (1 Pint Equivalent) 23508425... -

Page 61: How To Service The Dry Type Air Cleaner

2. Replace damaged clamps. 3. Correct all external leaks as soon as detected. NOTE: If Detroit Genuine antifreeze/coolant (or equivalent fully formulated, pre-charged antifreeze is used, a pre- charged element is not required. 4. Check coolant inhibitor levels at the intervals listed in this manual. -

Page 62: Detroit Genuine Coolanat Engine Products

Maintenance of the cooling system requires the chemical makeup of the system to be balanced. Detroit Genuine Fully Formulated Inhibited Ethylene Glycol Coolants The part numbers and sizes of concentrated and pre-blended 50:50 Detroit Genuine Coolants are listed in the following Tables. - Page 63 EuroV MBE 900 Operators Manual Detroit Genuine Fluid Analysis Products Detroit Genuine Fluid Analysis Products are shown below. Table 29. Detroit Genuine Fluid Testing and Analysis Products Application Part Number Description Indicates Nitrite, Molybdate & Glycol Levels 23519401 3-Way Coolant Test Strips (Single Foil Packs) Indicates Nitrite, Molybdate &...

-

Page 64: Engine Oil Capacities

17.1 Engine Oil Capacities - EuroV Consult with a Detroit distributor to obtain the proper engine oil filters. The engine oil capacities for the DD Platform Engine On-Highway Vehicle application are listed in the following tables. Contact your local Detroit service center if you need more specific information.

Need help?

Do you have a question about the MBE 900 and is the answer not in the manual?

Questions and answers