Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Tar River BWC-040EC

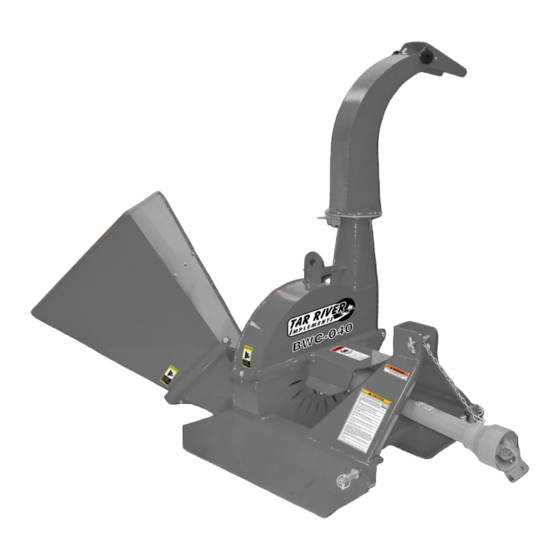

- Page 1 Wood Chipper BWC-040EC, BWC-040, BWC-060 Operator’s Manual Rev. 08/21...

- Page 2 BWC-040, BWC-040EC, BWC-060 Wood Chipper Page left blank intentionally...

- Page 3 BWC-040, BWC-040EC, BWC-060 Wood Chipper TO THE DEALER: Assembly and proper installation of this product is the responsibility of the Tar River dealer. Read manual in- structions and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check Lists in the Owner’s/Operator’s Manual are completed before releasing equipment to the owner.

-

Page 4: Table Of Contents

BWC-040, BWC-040EC, BWC-060 Wood Chipper Table of Contents Introduction …………………………………………………………………………………………….. 5 Technical Specifications ……………………………………………………………………………….. 5 Safety …………………………………………………………………………………………………… 6 Safety Signal Words ……………………………………………………………………………………. 6 General Safety Guidelines ……………………………………………………………………………… 7 Safety Decal Care ………………………………………………………………………………………. 7 Before Operation ……………………………………………………………………………………….. 8 During Operation ……………………………………………………………………………………….. 9 Highway And Transport Operations ……………………………………………………………………... -

Page 5: Introduction

BWC-040, BWC-040EC, BWC-060 Wood Chipper Introduction Thank you for purchasing your BWC Wood Chipper. It is important to properly maintain and keep in place all safety guards and shields that came with you machine. The BWC Wood Chipper is the perfect tool to help clear your land of fallen limbs and branches. Use your wood chips to create beautifully covered flowerbeds and natural areas in the yard. -

Page 6: Safety

BWC-040, BWC-040EC, BWC-060 Wood Chipper Important Safety Information Safety It is important that you read the entire manual and to become familiar with this product before you begin using it. This product is designed for certain applications only. The manufacturer cannot be responsible for issues arising from modification. -

Page 7: General Safety Guidelines

BWC-040, BWC-040EC, BWC-060 Wood Chipper Important Safety Information General Safety Guidelines Safety of the operator is one of the main concerns in designing and developing a new piece of equipment. De- signers and manufacturers build in as many safety features as possible. However, every year many accidents occur which could have been avoided by a few seconds of thought and a more careful approach to handling equipment. -

Page 8: Before Operation

BWC-040, BWC-040EC, BWC-060 Wood Chipper Important Safety Information How to install Safety Signs: Be sure that the installation area is clean and dry. • Decide on the exact position before you remove the backing paper. • Remove the smallest portion of the split backing paper. -

Page 9: During Operation

BWC-040, BWC-040EC, BWC-060 Wood Chipper Important Safety Information During Operation Children should not be allowed on the product. • Clear the area of small children and bystanders before moving the feeder. • If using a towing unit, securely attach feeder by using a hardened 3/4” pin, a metal retainer, and safety •... -

Page 10: Highway And Transport Operations

BWC-040, BWC-040EC, BWC-060 Wood Chipper Important Safety Information Highway and Transport Operations Adopt safe driving practices. • Keep the brake pedals latched together at all times. Never use independent braking with machine in tow • as loss of control and/or upset of unit can result. - Page 11 BWC-040, BWC-040EC, BWC-060 Wood Chipper Important Safety Information Highway and Transport Operations Maneuver the tractor or towing vehicle at safe speeds. • Avoid overhead wires or other obstacles. Contact with overhead lines could cause serious injury or death. • Avoid loose fill, rocks and holes, they can be dangerous for equipment operation or movement.

-

Page 12: Operating Instructions

Operating Instructions Operation It is important that each operator of the Tar River Wood Chipper read and understand the operational proce- dures and all related safety precautions outlined in this section. The following pre-operation checklist is provid- ed for the operator. It is important for both the personal safety and maintaining good mechanical condition that this checklist is followed. - Page 13 BWC-040, BWC-040EC, BWC-060 Wood Chipper Operating Instructions Attaching the PTO shaft: Before installing the PTO shaft make sure that the RPM rating and the direction of rotation match those of the tractor. Carefully read the PTO shaft and tractor instructions. Before operation, make sure that the guards are installed on the power take off of the tractor and PTO shaft.

- Page 14 BWC-040, BWC-040EC, BWC-060 Wood Chipper Operating Instructions Start up Although there are no operational restrictions on the Wood Chipper when used for the first time, it is recom- mended that the following mechanical items be checked: Maintenance Section Before your first start and after operating for 1 hour and every 5 Hours of operation Torque all fasteners and hardware.

- Page 15 BWC-040, BWC-040EC, BWC-060 Wood Chipper Operating Instructions Feeding The BWC may be available in either gravity or hydraulically feed. Danger: If gravity feed be careful not to reach into the feed hopper further than the curtain. To reach further, use a stick or branch to push any material into the disc that does not go in on its own. To begin operations, slowly slide the material to be chipped into the hopper.

- Page 16 BWC-040, BWC-040EC, BWC-060 Wood Chipper Operating Instructions The stationary blade is designed with 4 sharp corners that can be utilized. When the corner facing the rotor blade rounds over, remove the blade and re-install with a different corner facing the rotor blade. Use the anvil to set the clearance to the rotor blade when re-installing.

-

Page 17: Trouble Shooting

BWC-040, BWC-040EC, BWC-060 Wood Chipper Trouble Shooting PROBLEM CAUSE SOLUTION Obstructed discharge Shut down and clear debris. Rotor not turning. Rotor plugged. Clear rotor. Broken shear pin. Replace shear pin. Knives are dull. Sharpen knives. Slow feeding. Blade angle wrong, Re-sharpen knives to improper angle. -

Page 18: Torque Specifications

BWC-040, BWC-040EC, BWC-060 Wood Chipper Notes: This chart is an approximate estimate of torque values. Always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific application. Fasteners must always be replaced with the same grade as specified in the manual. - Page 19 BWC-040, BWC-040EC, BWC-060 Wood Chipper Page left blank intentionally...

- Page 20 BWC-040, BWC-040EC, BWC-060 Wood Chipper Page left blank intentionally...

-

Page 21: Parts Breakdown

Wood Chipper BCW-040EC, BCW-040, BCW-060 Parts Manual Rev. 08/21... - Page 22 BWC-040, BWC-040EC, BWC-060 Wood Chipper BWC-040...

- Page 23 BWC-040, BWC-040EC, BWC-060 Wood Chipper BWC-040 Item Part # Description Qty. BX4-0601 Deflector SSM0812530 Socket screw M08-1.25x30 NM08125 Nut- M08-1.25 BX4-9313 Knob - deflector BX4-0600 Discharge chute BM061020 Bolt HH M06-1.00x10 BX4-0605 Spacer ring BX4-0603 Ring - fastener rear BX4-0501...

-

Page 24: Bwc-060

BWC-040, BWC-040EC, BWC-060 Wood Chipper BWC-060... - Page 25 BWC-040, BWC-040EC, BWC-060 Wood Chipper BWC-060 Item Part # Description Qty. BM061020 Bolt HH M06-1.00x20 BX6-0607 Support - flap BX6-0903 Flap BX6-0101 Chute BM1217535 Bolt HH M12-1.75x35 BX6-0901 Anvil BM121525 Bolt HH M12-1.50x25 BM142045 Bolt HH M14-2.00x45 BUCF210 Bearing UFC 210...

-

Page 26: Bwc-040

BWC-040, BWC-040EC, BWC-060 Wood Chipper BWC-040EC Discharge Chute... - Page 27 BWC-040, BWC-040EC, BWC-060 Wood Chipper BWC-040EC Discharge Chute Item Part # Description Qty. BX52G-03-01 Discharge latch LNM08125 Locking nut M08-1.25 BX52G-01-+ Chute deflector BM0812530 Bolt HH M08-1.25x30 BX52G-01 Discharge chute BX4-0007 Latch assembly BM061030 Bolt HH M06-1.00x30 LNM0610 Nut lock M06-1.00...

-

Page 28: Bwc-040Ec

BWC-040, BWC-040EC, BWC-060 Wood Chipper BWC-040EC Frame... - Page 29 BWC-040, BWC-040EC, BWC-060 Wood Chipper BWC-040EC Frame Item Part # Description Qty. BX52G-05-01 Chipper frame Chute BX52G-01 Chute - folding BX52-07-01 Disc BX52G-07-02 Blade LNM1015 Nut locking M10-1.50 SSM101530 Socket screw countersunk M10-1.50x30 BM061020 Bolt HH M06-1.00x20 LNM0610 Nut locking M06-1.00 BM101525 Bolt HH M10-1.50x25...

-

Page 30: Bwc Pto Assembly

BWC-040, BWC-040EC, BWC-060 Wood Chipper PTO Assembly Item Part # Description Qty. DP1075-40 PTO yoke series 40 DP1078-40 Male yoke and tube (Implement end) Series 40 DP1079-40 Female yoke and tube (Tractor end) Series 40 DP1074M-40 Complete male end PTO shielding (implement end) Series 20-40... - Page 31 BWC-040, BWC-040EC, BWC-060 Wood Chipper Page left blank intentionally...

-

Page 32: Decals

BWC-040, BWC-040EC, BWC-060 Wood Chipper Decals... - Page 33 BWC-040, BWC-040EC, BWC-060 Wood Chipper Decals Item Part # Description Qty. D1015 Decal Logo “Tar River” small Decal Model # “BWC-040” Decal Model # “BWC-040EC” Decal Model # “BWC-060” RT1007 Decal Danger Rotating Driveline D960 Decal Warning, “Cancer” Z940006 Decal Caution “Read Manual”...

- Page 34 BWC-040, BWC-040EC, BWC-060 Wood Chipper Decals RT1007 Danger Rotating Driveline Z94007 Danger Rotating Blades Qty. 1 Qty. 1 Z94008 Danger Object Hazard Qty. 1 D960 Warning Cancer Qty. 1 9270112 Caution Avoid Crushing Qty. 3 RT1004 Warning Safety Shield Qty.1 Z94006 Caution Read Manual Qty.

-

Page 35: Warranty

BWC-040, BWC-040EC, BWC-060 Wood Chipper Warranty LIMITED WARRANTY Belco Resources Equipment warrants to the original purchaser of any new piece of machinery from Belco Re- sources Equipment, purchased from an authorized Belco Resources Equipment dealer, that the equipment be free from defects in material and workmanship for a period of one (1) year for non-commercial, state, and mu- nicipalities’... - Page 36 DRL-048, DRL-072 Crop Seeder 401 Jeffreys Road Tel: 252-822-7140 Rocky Mount, NC 27804 Fax: 252-787-5855 www.tarrivermfg.com Sales@tarrivermfg.com...

Need help?

Do you have a question about the BWC-040EC and is the answer not in the manual?

Questions and answers