Advertisement

Quick Links

RENEWAL PARTS IDENTIFICATION

Boiler Serial No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power Circuit Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . No. of Power Circuits . . . . . . . . . . . . . . . Amps. . . . . . . . . . . . . . . . . . . .

Electrical Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Control Circuit Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

National Board No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Total Amps . . . . . . . . . . . . . . . Phase . . . . . . . . . . . . Cy . . . . . . . . . . . . .

IMPORTANT – This data file contains the National Board Registration Certificate approving your generator. It must be kept near the generator at all times.

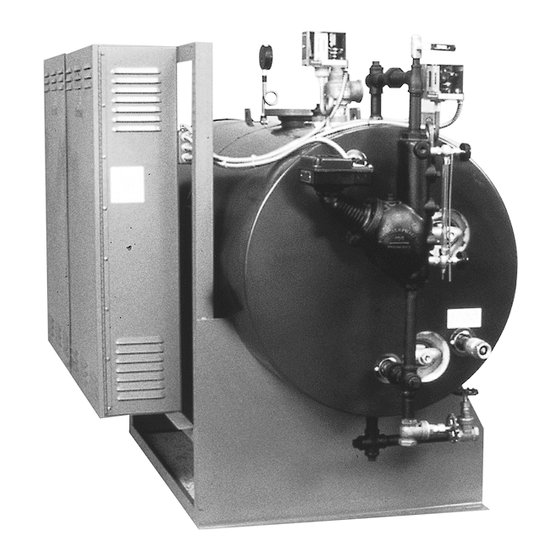

CHS-360 Steam Boiler

CAUTION: To avoid electrical shock hazard, boilers

must be suitably grounded to earth.

NOTE: Chromalox boilers are pre-tested before shipment; no internal

piping or wiring is necessary. WARNING: Substitution of compo-

nents or modification of wiring without prior consent of Chromalox,

Inc. voids warranty.

1. Locate unit on level floor or platform. NOTE: A minimum dis-

tance of 60 inches from wall, other equipment, etc. must be

allowed for removal of the elements.

2. Complete all piping to boiler. Connect water line to tagged fitting

on the motor and pump assembly, if used, or to tagged fitting on

water control feeder.

© 2010 Chromalox, Inc.

Installation, Operation

and

Horizontal Electric Steam Boiler

Model Number CHS 0 – 150 PSI

Specifications — 480 Volt Boilers*

Model

B.H.P.

Fuse Delta

Number

Rating kW Contactors Size

CHS-150*

15.3

150

5

50A 60A

CHS-180*

18.4

180

6

50A 60A

CHS-210*

21.4

210

7

50A 60A

CHS-240*

24.5

240

8

50A 60A

CHS-270*

27.6

270

9

50A 60A

CHS-300*

30.6

300

10 50A 60A

CHS-360

36.7

360

12 50A 60A

CHS-420

42.9

420

14 50A 60A

CHS-495

50.5

495

11 60A 100A

CHS-540

55.1

540

12 60A 100A

CHS-630

64.3

630

14 60A 100A

CHS-720

73.5

720

16 60A 100A

CHS-810

82.7

810

18 60A 100A

CHS-945

96.4

945

21 60A 100A

CHS-1080 110.0 1080 24 60A 100A

CHS-1215 124.0 1215 27 60A 100A

CHS-1350 138.0 1350 30 60A 100A

CHS-1485 152.0 1485

3

60A 100A

CHS-1620 165.0 1620 36 60A 100A

*150 kW Thru 300 kW Boilers available in 280V and 240V. Check Factory

INSTALLATION

3. When any type of feed other than a pump feed is used – the exist-

ing water supply must be 10 pounds greater than the boiler operat-

ing pressure to assure water supply maintains proper water level in

boiler. Otherwise, lack of water can cause heater failure. Keep feed

water line valves open at all times.

4. All water feed systems are connected to supplied water inlet check

valve.

5. Connect steam line (with Globe valve) to boiler steam outlet. Valve

should be placed as close as possible to boiler outlet.

6. To insure maximum efficiency of supplied kw, all piping from out-

let should be insulated.

7. Drain and relief valve piping should be in accordance with state

and local codes.

4

(Supersedes PQ404-5)

161-048642-001

OCTOBER, 1983

Power CC

Size of

Nominal

90˚C

Amps

Size

Wire

per

Elements

kW

(Amps)

(M.C.M) Circuit

(kW)

2

30

1

300

4/0

181

1

30

1

300

250

217

3

3

30

1

600

600

253

1

30

1

600

400

290

4

4

30

1

600

600

326

1

30

1

600

600

362

5

2

30

2

300

250

217

3

4

30

2

600

350

254

1

3

45

2

600

500

297

1

45

2

600

600

324

4

4

45

2

600

700

378

1

5

45

3

600

400

324

1

45

3

600

600

324

6

45

3

600

700

378

7

45

4

600

500

324

8

45

4

600

700

378

9

45

5

600

600

324

10

45

5

600

700

378

11

45

6

600

600

324

12

CHS

PQ404-6

Output

Standard Lbs. per

Control

Hr. at

System

212˚F

60

452

30

30

543

60

633

30

60

723

60

814

30

60

904

90

1085

60

90

1266

60

135

1492

90

135

1628

135

1889

90

135

2170

45

135

2441

135

2848

135

3255

135

3662

135

4069

135

4476

135

4883

Advertisement

Summary of Contents for Chromalox PQ404-6

- Page 1 NOTE: Chromalox boilers are pre-tested before shipment; no internal piping or wiring is necessary. WARNING: Substitution of compo- nents or modification of wiring without prior consent of Chromalox, Inc. voids warranty. 1. Locate unit on level floor or platform. NOTE: A minimum dis- tance of 60 inches from wall, other equipment, etc.

- Page 2 76” 58” CHS-945 thru CHS-1080 76” 68” CHS-1215 thru CHS-1620 86” 76” *4” and 6” are flanged. Typical Plumbing Installation of a Steam Boiler with Condensate Return System Insulated Steam Lines (Pitch Down 5˚) Globe Safety Valve Valve Vacuum Check...

- Page 3 THEIR OWN CONDENSATE OR PUMP SYSTEMS. 1. Check the voltage of the motor before making the wiring connec- tion. Some Chromalox boilers are supplied with dual voltage sys- tems. The motor should always match the voltage of the control circuit.

- Page 4 Power Circuit Terminal Block Power Curcuit Relay Step Sequencer Typical 3 Phase Heater Group Figure 9 – Power Circuit Detail WIRING (cont’d.) Figure 8 – Typical Wiring Diagram To Other Heater Groups Control Voltage Other Heater Groups Low Water Probe Figure 10 –...

-

Page 5: Pre-Operation Check

PRE-OPERATION CHECK B. ADJUSTING OPERATING PRESSURE CONTROLS 1. Chromalox boilers are supplied with operating and high limit pres- sure controls. One is used for controlling the operating pressure of the boiler while the other is used as a high limit control. To deter- mine the difference in the controls, the high limit has a manual reset lever on top of the case. -

Page 6: Operation

Both the valve and the boiler are controlled by an electric control unit which indicates with pilot lights when the drain valve is in the opened or closed position and when the boiler is ON or OFF. In addition to the automatic control function, the unit has a push button which momen- tarily de-energizes the boiler and opens the drain valve regardless of the time of day. - Page 7 “boiler normal” if the boiler is to be shut down each night. Set it to “24-hour duty” if the boiler is to remain on continuously 24 hours per day (except during blowdown).

- Page 8 SCR and, in turn, energize the control relay. As the water level in the boiler drops below the level of the probe. the AC circuit is broken and the control relay is de-energized. The con- trol will not energize until sufficient water is present in the boiler.

- Page 9 1. With boiler off, remove wiring from pressure control on sequencer low voltage terminal board. 2. Turn on boiler to supply the voltage to sequencer. Short terminal R and B for counter-clockwise rotation and terminal R and W for clockwise rotation.

-

Page 10: Maintenance

Solid State Progressive Sequencer (See Figure 22) The solid state progressive sequencer provides accurate electronic control of multi-stage loads of the type used in Chromalox steam boil- ers. It features progressive sequencing (first on-first off) which equal- izes the operating time of each load. This control gives visual indica- tion of each energized stage by means of integral solid state light emit- ting diodes. - Page 11 11. As boiler automatically refills, observe the new flange assembly for possible leaks. If water is noticed, the bolts must be retightened. Before doing this, turn the boiler off at the main fuse safety switch. 12. As boiler is heated to working pressure, check flange assembly again for leaks.

-

Page 12: Limited Warranty

Safety Valve – 15#, 1 ........Please refer to the Chromalox limited warranty applicable to this product at http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Need help?

Do you have a question about the PQ404-6 and is the answer not in the manual?

Questions and answers