Summary of Contents for Apco F3 Bi

- Page 1 2021/09/08 (rev. 1.0) offline www.apcoaviation.com 7 Chalamish St., Ind. Park Caesarea, 3088900 ISRAEL...

-

Page 2: Table Of Contents

www.apcoaviation.com CONTENTS: DISCLAIMER OF LIABILITY INTRODUCTION TECHNICAL DATA CONSTRUCTION, MATERIALS and ASSEMBLY FLEXON® Batten system: TRIMMING TRIKE / FRAME EMERGENCY PARACHUTE SPEED SYSTEM 10 RISERS 11 TRIMMERS 12 A-ASSIST SYSTEM 13 HIT VALVES (High-speed In-Take) 14 INSPECTION 15 BEFORE THE FIRST FLIGHT 16 FLYING 17 PACKING 18 MAINTENANCE &... -

Page 3: Disclaimer Of Liability

APCO Aviation Ltd. is engaged in the manufacture and sale of hang gliding, paragliding, motorized Para/hang gliding and emergency parachute equipment. This equipment should be used under proper conditions and after proper instruction from a qualified instructor. APCO Aviation Ltd. has no control over the use of this equipment and a person using this equipment assumes all risks of damage or injury. -

Page 4: Introduction

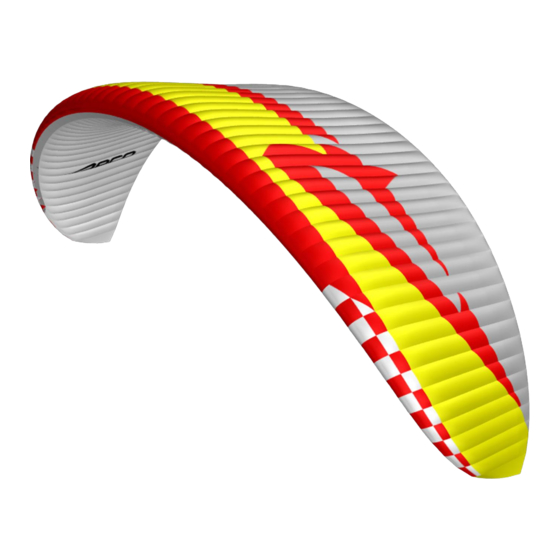

The canopy sail tension has been optimised so that the wing becomes a homogeneous unit, solid and reassuring in flight, and resulting in our cleanest wing yet! The riser / speed system / trim system was re-designed specifically for trike use, incorporating Apco’s ground breaking riser technologies, and has a greater usable range than any tandem wing we have built before. -

Page 5: Technical Data

www.apcoaviation.com 3 TECHNICAL DATA F3 / Size Code 22336 Cells Area [m 36.0 Area (projected) [m 30.46 Span (incl. Stabilizer) [m] 14.7 Span (projected) [m] 11.64 Aspect Ratio Aspect Ratio (projected) 4.45 Weight Range (all up) Para-Trike [kg] Up to 450 Canopy Weight [kg] Root Cord m 2.96... -

Page 6: Construction, Materials And Assembly

On either side the wing ends in a stabilizer or wing tip, which provides straight-line (Yaw) stability and produces some outward lift to keep the span-wise tension. The front part of the ribs utilise APCO's FLEXON batten system to keep the leading edge shaped at high speeds and in turbulent air. They also improve the performance and the launch characteristics of the glider. -

Page 7: Trike / Frame

Attaching the rescue parachute should be done in accordance with the recommendations of the trike manufacturer and reserve parachute manufacturer. When we fly the F3Bi, we use the the Apco Trike Pilot and Trike Passenger harnesses, combined with Mayday UL28 Parachute, packed in the matching reserve container. Always check the reserve handle and locking pins during every pre-flight... -

Page 8: Speed System

www.apcoaviation.com 9 SPEED SYSTEM Certain Trike manufacturers give the option to use a speed-system acting on the front of the risers to accelerate the wing, which may be used in conjunction with the trim system. We have designed the F3Bi risers with this in mind. ASSEMBLY &... -

Page 9: Trimmers

The Trim System of the F3Bi is very effective for accelerating the wing on long flights. The trim system differs from previous Apco gliders in that it releases the B riser, which gives a clean rotation... -

Page 10: Assist System

www.apcoaviation.com 12 A-ASSIST SYSTEM The A-Assist system may improve launch characteristics if needed, it may be especially useful with weaker trikes. The system works by decreasing the angle of attack while the wing is behind the trike, and gradually disengages as the wing rises overhead. This is done by attaching a line from the frame about 30cm in front of the riser attachment points, to the speed system on the risers. -

Page 11: Hit Valves (High-Speed In-Take)

A. It was checked with APCO that the specific trike can be flown with your new wing. In case the specific combination is not checked by APCO – your dealer must take the following necessary steps : B. Wing to be fully inspected by the dealer as in the paragraph above C. - Page 12 Porosity is measured with a calibrated Porosimeter. It should be measured in at least 5 different places on the upper surface. Below is an example of the sections we test at Apco. The upper surface, at 20-35% chord (from L/E) is most prone to becoming porous, and is...

- Page 13 www.apcoaviation.com LINE MAINTENANCE Superaramide lines are known to be sensitive to the influence of the elements. They must be carefully inspected periodically. In his/her own interest, the pilot must observe the following points to ensure maximum performance and safety from the glider. Avoid sharp bending and squeezing of lines.

-

Page 14: Before The First Flight

www.apcoaviation.com 15 BEFORE THE FIRST FLIGHT BRAKE SETTING Before the first flight the pilot / dealer has to inflate the glider in the flight configuration, on the intended trike frame, to check and if needed, adjust the brake line length as required. It is important that the brakes are not set too short. -

Page 15: Flying

(Chapter 16). Still there is additional information needed, concerning power output, proper matching of the wing/engine/propeller etc. APCO can try to give advice on some possible tested combinations, but if you contact your nearest APCO dealer or frame manufacturer they will always be ready to help. - Page 16 www.apcoaviation.com FIRST FLIGHTS In order to get familiar with your wing we recommend flying with trimmers at position first in stable non-turbulent weather. Once you feel confident with your wing, you can start experimenting with faster trim settings and speed system, taking all necessary precautions.

- Page 17 www.apcoaviation.com to counter the engine thrust, so that it can push you forward rather than towards the ground. The best option is not to use the brakes, allowing the paraglider to rise as it was laid out. If it starts to deviate from its course, pull the opposite riser and run under the centre of the wing while continuing in initial direction.

- Page 18 www.apcoaviation.com Besides, you should always be able to land safely in case of engine malfunction, so it’s better not to take unnecessary risk and always fly with a safe margin of speed and height Depending on the power unit geometry, it is possible that after take-off you will notice a propeller torque (known as P-factor), which may induce a turn, which increases with the amount of power, this can be countered with steering, and asymmetric trimmer settings.

- Page 19 www.apcoaviation.com TRIMMERS AND SPEED-SYSTEM SETTINGS You are free to experiment with all possible settings, as long as you are safe altitude and watch the weather. Fully opened trimmers increase the speed of the wing and overall penetration and reflex, but when trimmers are opened it is highly recommended to use secondary steering only (stabilo steering), using the main brake handles will increase the risk of a collapse.

- Page 20 www.apcoaviation.com The main advantage of this procedure is of course the possibility of going around with the wing again (repeating the approach) if anything goes wrong. Still, if you forget to switch off the ignition before the wing falls down, there is a considerable risk of damaging propeller, catching lines in it or even suffering injuries connected with falling on your running engine.

- Page 21 www.apcoaviation.com FLYING SPEED Indicated trim speed is dependent on the amount of brake the pilot is using, wing loading, altitude above sea level and the accuracy and make of speed probe. The speeds recorded in technical data were at optimum wing loading at sea level using a Flytec, 6030 thus there could be a slight variation in speed range numbers that a pilot may record.

- Page 22 www.apcoaviation.com To help re-inflation it is possible to pull some brake on the collapsed side and release immediately. In the event of a big deflation, i.e. 70%, it is important to apply brake on the inflated side of the wing, but care must be taken not to pull too much as you could stall the flying side.

- Page 23 www.apcoaviation.com Signs of parachutal stall • The pilot has very little or no forward airspeed and no wind in his face. • The glider will be fully open but the cells will be bulging in and not out on the bottom surface. •...

- Page 24 www.apcoaviation.com If you unexpectedly encounter strong turbulence, fly with trimmers open and no brakes applied to let the reflex stabilize the glider, use only secondary brake handles (tip steering) and land as soon as possible. STEERING NOT FUNCTIONING If the pilot cannot reach the brake or steering lines for any reason or if they are not functioning properly, (for example: If they break on a damaged point) the pilot can control the glider by pulling down on the rear risers, and depending on the harness / frame-type and configuration, also by using weight shift.

-

Page 25: Packing

www.apcoaviation.com WATER LANDING As you approach landing, open all the buckles of the harness except for one leg. Just before landing, release the remaining buckle. Let the wing pitch completely forward until it hits the water with the leading edge openings; the air inside will then be trapped, forming a big air mattress and giving the pilot more time to escape. -

Page 26: Butt Hole Ii (Auto Debris Release Valves)

22 THREE YEAR WARRANTY The following warranty is granted by APCO Aviation Ltd. with respect to all of its standard Serial Production Wings, manufactured from January 1, 1994, subject to full compliance by the purchaser/owner to its following terms, as hereby detailed:... - Page 27 This warranty is subject to the following limitations: a . The original purchaser has properly completed and returned the Warranty Registration Card to APCO Aviation Ltd. b . The wing owner duly records the wing’s flight time and use, in an official Log Book, signed by himself and/or an official instructor site supervisor, meet official etc.

-

Page 28: General Advice

www.apcoaviation.com 23 GENERAL ADVICE A qualified person or agent of the company should check the glider every year. The glider is carefully manufactured and checked by the factory. Never make changes to the wing or the lines. Changes can introduce dangerous flying characteristics and will not improve flying performance. -

Page 29: F3Bi - 36 - Sketches

www.apcoaviation.com 24 F3Bi - 36 - SKETCHES... - Page 30 www.apcoaviation.com...

- Page 31 APCO wishes you many hours of enjoyable flying - Take Air!

Need help?

Do you have a question about the F3 Bi and is the answer not in the manual?

Questions and answers