Table of Contents

Advertisement

®

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with these instructions will result in voiding of the product warranty and may

result in personal injury and/or property damage.

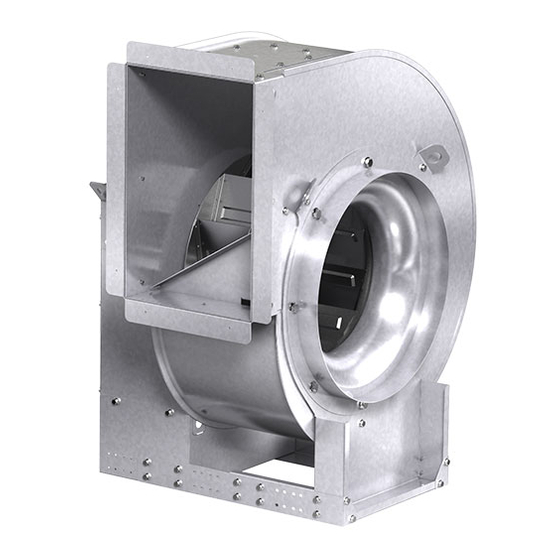

USFD-100

USF-200

General Safety Information

Only qualified personnel should install this fan.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards.

Other considerations may be required if seismic

activity is present. If more information is needed,

contact a licensed professional engineer before

moving forward.

1. Follow all local electrical and safety codes, as

well as the National Electrical Code (NEC) and the

National Fire Protection Agency (NFPA), where

applicable. Follow the Canadian Electric Code

(CEC) in Canada.

2. The rotation of the wheel is critical. It must be free

to rotate without striking or rubbing any stationary

objects.

3. Motor must be securely and adequately grounded.

4. Do not spin fan wheel faster than max cataloged

fan RPM. Adjustments to fan speed significantly

effects motor load. If the fan RPM is changed, the

motor current should be checked to make sure it is

not exceeding the motor nameplate amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with the

equipment.

7. Never open access doors to a duct while the fan is

running.

®

USF-300

Always disconnect, lock and tag power source

before installing or servicing. Failure to disconnect

power source can result in fire, shock or serious

injury.

When servicing the fan, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

Precaution should be taken in explosive

atmospheres.

Pour écarter les risques d'incendie, de choc

électrique ou de blessure grave, veiller à toujours

débrancher, verrouiller et étiqueter la source de

courant avant l'installation ou l'entretien.

Lors de toute intervention sur la soufflante, le moteur

peut être suffisamment chaud pour provoquer

une douleur voire une blessure. Laisser le moteur

refroidir avant toute maintenance.

Faire preuve de précaution dans les atmosphères

explosives.

Model USFD-100, USF-200, 300 and 400

Utility and Centrifugal Fans

USF-400

DANGER

CAUTION

CAUTION

DANGER

ATTENTION

ATTENTION

Utility and Centrifugal Fans

Document 479870

Model CSW

CSW

1

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Greenheck USFD-100

-

Page 1: General Safety Information

Document 479870 Model USFD-100, USF-200, 300 and 400 Model CSW ® Utility and Centrifugal Fans Installation, Operation and Maintenance Manual Please read and save these instructions for future reference. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. -

Page 2: Receiving

INDOOR - Receiving The ideal environment for the storage of fans and accessories is indoors, above grade, in a Upon receiving the product, check to ensure all low humidity atmosphere which is sealed to prevent items are accounted for by referencing the delivery the entry of blowing dust, rain or snow. -

Page 3: Table Of Contents

Machined parts coated with rust preventive should be Table of Contents restored to good condition promptly if signs of rust General Safety Information ....1 occur. -

Page 4: General Information

Service disconnects shall be locked-out when maintenance is being performed. NOTE The USFD-100 model has an integrated electrical disconnect. Moving Parts All moving parts must have guards to protect personnel. Refer to local codes for requirements as to the number, type and design. -

Page 5: Fans - Rigging And Lifting

Sizes 7 thru 24 4. Fan to be kept level during lifting and installation. USFD-100, USF-200 and USF-300 Arrangement 10 5. Spreader bars must span the unit to prevent Without Isolation Base damage to the unit by the lifting cables. - Page 6 Sizes 7 thru 30 USF-400 and CSW Class 0, I, II, Arrangement 10 CSW Arrangement 1 Without Isolation Base W or Z Motor Position Isolation Base CSW Arrangement 4 CSW Arrangement 1 Without Isolation Base X/Y Motor Position Isolation Base Utility and Centrifugal Fans ®...

- Page 7 Sizes 7 thru 30 Sizes 33 thru 73 CSW Arrangement 1 USF-400 and CSW Arrangement 10 No Motor Without Isolation Base Without Isolation Base CSW Arrangement 4 Without Isolation Base Utility and Centrifugal Fans ®...

- Page 8 Sizes 33 thru 73 CSW Arrangement 1 CSW Arrangement 1 X/Y Motor Position W or Z Motor Position Isolation Base Isolation Base CSW Arrangement 1 No Motor Without Isolation Base CSW Arrangement 8 Isolation Base NOTE Lift unit from fan lifting points, not from isolation base. Utility and Centrifugal Fans ®...

- Page 9 Sizes 33 thru 73 CSW Arrangement 3 CSW Arrangement 3 No Motor, No Drives X/Y Motor Position Without Isolation Base CSW Arrangement 3 CSW Arrangement 9 W or Z Motor Position Isolation Base Isolation Base Utility and Centrifugal Fans ®...

-

Page 10: Installation

POOR GOOD need to be made for the fan to drain properly. The USFD-100, USF-200, and USF-300, all sizes, have field rotatable housings. For the USF-400 and CSW, rotatable housings are standard on sizes 30 and less, arrangements 1, 9 and 10, and Class 0, I and II. -

Page 11: Ducted Outlet Installations

Fans used for grease exhaust need to be equipped with a separate grease collector. Drain Options 3/4 to one wheel USFD-100 Drain only* diameter None USF-200 Drain only* With plug... -

Page 12: Bases (Foundation And Isolation)

Bases (Foundation and Isolation) Installation of UL/cUL 762 Listed Fans for Restaurant Exhaust Critical to every fan installation is a strong, level foundation. A reinforced poured concrete pad with The UL/cUL 762 listing for restaurant exhaust is a steel base or inertia base provides an excellent available on the USF-300 and 400 and CSW. -

Page 13: V-Belt Drives V-Belt Drive Installation

V-Belt Drives Field Coating Touch-Up Procedure for Scratched Areas V-Belt Drive Installation Standard coating and color is RAL 7023 Concrete 1. Remove the protective coating from the end of the Grey. The procedure outlines the correct method for fan shaft using mineral spirits or another similar repairing minor scratches in the coating. -

Page 14: Radial Gap, Overlap And Wheel Alignment

Wheels as viewed from the drive side: Radial Gap and Overlap Dimensions Overlap Overlap Tolerance USFD-100 Airflow Airflow inches (mm) (145) ⁄ ⁄ ⁄ (148) ⁄... -

Page 15: Unit Start-Up

Unit Start-Up Additional Steps for Initial Start-Up WARNING 1. Check for proper wheel Disconnect and secure to the OFF position all rotation by momentarily electrical power to the fan prior to inspection energizing the fan. or servicing. Failure to comply with this safety Access to view the precaution could result in serious injury or death. -

Page 16: Vibration

Vibration Routine Maintenance and Operation On start-up and during operation, the unit should operate smoothly with minimal vibration. It is possible WARNING that a higher degree of vibration may be experienced. Excessive vibration if left unchecked, can cause a Before taking any corrective action, make certain multitude of problems, including structural and/or unit is not capable of operation during repairs. -

Page 17: Belt Drive Maintenance

Measuring Belt Tension, found online at www. The lubrication interval may be modified based on the greenheck.com in the library section. condition of the purged grease. If bearing is not visible to observe purged grease, lubricate with number of shots Check belt tension two times during the indicated in chart for bore size. -

Page 18: Variable Frequency Drive Operation

Failure to remove resonant frequencies from the operating range will decrease the operating life of the fan and void the warranty. Model USFD - Variable Speed Drives The USFD-100 comes equipped with a factory integrated speed controller. Single-phase models will ® use a Vari-Green Motor and Potentiometer dial to adjust motor rpm. -

Page 19: Bearing Replacement

Bearing Replacement For Arrangements 1, 3, 8, 9 or 10 Bearing Installation The intent of this procedure is to allow a field service 1. Before installing, read bearing manufacturers’ technician to replace bearings with the fan remaining procedures. Before putting the new bearings on in place in its intended application. -

Page 20: Parts List

Refer to UL Listing Mark for the fans antidéflagrant. Pour connaître les emplois autorisés approved usage. de l’appareil, voir son marquage de conformité UL. • USFD-100 Scroll Housing Motor Motor Cover Wheel... - Page 21 • USF-200 • USF-300 Shaft Pulley (driven) Belt(s) Motor Pulley (driver) Drive Side Bearing Weatherhood Opposite Drive Side Bearing Components Fan Shaft Heat Slinger* (USF-300) Rub Ring* (USF-300) Shaft Seal* (USF-300) Drive Frame Assembly Motor Scroll Housing Outlet Flange* Wheel Inlet Cone Inlet Flange* Outlet Guard*...

- Page 22 • USF-400 • CSW Shaft Pulley Belt(s) (driven) Motor Cover Drive Side Bearing Opposite Drive Side Bearing Fan Shaft Heat Slinger* Rub Ring* Shaft Seal* Motor Pulley (driver) Drive Frame Assembly Adjustable Motor Plate Motor Scroll Housing Punched Outlet Flange* Companion Outlet Flange* Wheel Inlet Cone...

-

Page 23: Troubleshooting

Troubleshooting WARNING AVERTISSEMENT Before taking any corrective action, make certain Avant d’entreprendre toute action corrective, unit is not capable of operation during repairs. s’assurer que l’appareil ne pourra pas fonctionner durant les réparations. Problem Cause Corrective Action Adjust wheel and/or inlet cone. Wheel Rubbing Inlet Tighten wheel hub or bearing collars on shaft. -

Page 24: Maintenance Log

________________________________________________ ________________________________________________ Our Commitment As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications without notice. Specific Greenheck product warranties are located on greenheck.com within the product area tabs and in the Library under Warranties.

Need help?

Do you have a question about the USFD-100 and is the answer not in the manual?

Questions and answers