Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for LDetek MD3

- Page 3 MultiDetek 3 Trace impurities analyzer USER’S MANUAL V1.2 Printed in Canada Copyright 2022...

-

Page 4: Table Of Contents

Table of Contents Table of Contents ........................4 Table of Figures ........................5 1. Forewarning ........................1 2. Warranty, maintenance, and service policies ............... 2 3. Declaration of conformity ....................5 4. Specifications ........................7 5. Specifications ........................8 5.1. Detector cautions ......................8 5.2. -

Page 5: Table Of Figures

Table of Figures Figure 1: Boot up screen ......................10 Figure 2: Boot up alerts ......................10 Figure 3: Oven setpoint ......................11 Figure 4: Flow setpoint ......................12 Figure 5: Operating Parameters ..................... 13 Figure 6: Typical Installation ....................16 Figure 7: Same source actuation .................... - Page 6 Figure 50: Modbus information window ................63 Figure 51:Regeneration window .................... 64 Figure 52: About menu ......................65 Figure 53: Firmware Update ....................65...

-

Page 7: Forewarning

If any error is suspected by the reader, please contact LDetek. LDetek reserves the right to make any changes to subsequent editions of this document without prior notice to holders of this edition. -

Page 8: Warranty, Maintenance, And Service Policies

EXPRESS AND IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THIS WARRANTY IS THE ONLY WARRANTY MADE BY LDETEK INC. WITH RESPECT TO THE GOODS DELIVERED HEREUNDER, AND NO EMPLOYEE, REPRESENTATIVE OR OTHER PERSON OR ENTITY IS AUTHORIZED TO... - Page 9 MULTIDETEK3 User’s manual MANUFACTURED BY SELLER GIVING RISE TO THE CAUSE OF ACTION. BUYER AGREES THAT IN NO EVENT SHALL SELLER'S LIABILITY EXTEND TO INCLUDE INCIDENTAL OR CONSEQUENTIAL DAMAGES. CONSEQUENTIAL DAMAGES SHALL INCLUDE BUT ARE NOT LIMITED TO, LOSS OF ANTICIPATED PROFITS, LOSS OF USE, LOSS OF REVENUE, COST OF CAPITAL AND DAMAGE OR LOSS OF OTHER PROPERTY OR EQUIPMENT.

-

Page 10: Table Of Contents

Write RMA number on the outside of the box. Use an LDetek approved carrier. Also, the delivery must be sent to LDetek facilities. LDetek will not accept airport to airport delivery. LDetek will not cover the transportation fees. -

Page 11: Declaration Of Conformity

3. Declaration of conformity E U Declaration of Conformity 1. Product model: M ulti D etek 3 Compact gas chromatpgraph 2. Name and address of the manufacturer: LDetek Inc. Monfette E. Thetford Mines, QC G6G 7K6 (418) 755 - 1319 Email: info@ldetek.com... - Page 12 MULTIDETEK3 User’s manual...

-

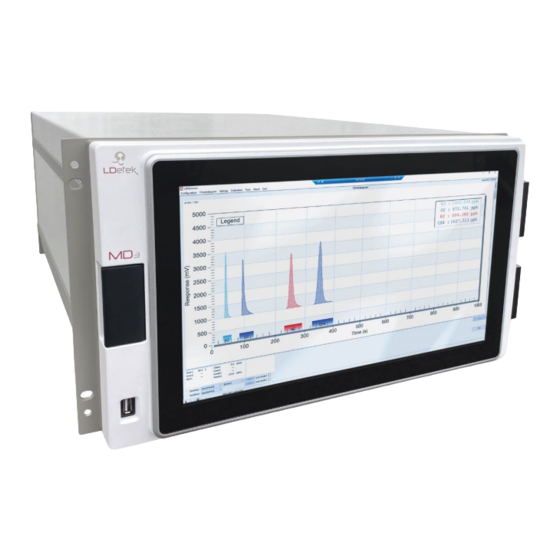

Page 13: Specifications

MULTIDETEK3 User’s manual 4. Specifications • PED / TCD / FID Gas Chromatography Detector: • Quartz Crystal Microbalance / Ceramic Metal-Oxide / Online Detectors: Electrochemical / Zirconia • Temperature controlled process GC Standard features: • 15,6’’ wide touchscreen with 1366 x 768 HD resolution (IP65) •... -

Page 14: Specifications

MULTIDETEK3 User’s manual 5. Specifications 5.1. Detector cautions The MultiDetek3 uses multiple detection techniques known from the industry for many years. It can be PED, FID, TCD and other types on request. The principle of the PED is based on spectroscopic emission. The detector is a pure quartz cell put in an electromagnetic field created by a specific high-intensity generator. -

Page 15: Start-Up

MULTIDETEK3 User’s manual 5.3. Start-up All LDetek products are properly packed in a cardboard box and all instruments come with an associate document name “Operating parameter”. Refer to the steps below to ensure the proper start-up for this unit. 1. Unpack the instrument carefully from the box and inspect it to be sure it is in good condition and hasn’t been damaged during shipping. -

Page 16: Figure 1: Boot Up Screen

MULTIDETEK3 User’s manual Figure 1: Boot up screen 9. Every active alert except “Sample Low Flow” must be resolved before going further. Double-click on the red alert bar and check the alerts. See Alerts menu for reference below. Figure 2: Boot up alerts... -

Page 17: Figure 3: Oven Setpoint

Settings>>Oven select the right oven and look at the first value of the timetable (beside “at start”). If after few minutes, the oven temperature deviation is still active and no temperature change occurred, then it is required to contact LDetek support for further instructions. -

Page 18: Figure 4: Flow Setpoint

The detector will turn on automatically once the carrier gas set points and a basic purge of the system are achieved. If after confirming the above you still have an active ‘Detector # OFF’’ alerts displayed, then it is required to contact LDetek support for further instructions. -

Page 19: Figure 5: Operating Parameters

Due to the vibrations during shipping, sometimes the system properties are modified and could result changing in the elution time of peaks. In this case, LDetek experts will be able to guide you in the modification of the system parameters with the file provided. -

Page 20: Shut-Off

MULTIDETEK3 User’s manual When all peaks appear at the right timing using the span gas, the span calibration o f the system can be done. Refer to section 7.4 of this manual for calibration menu details. After running the span calibration, the system can be switched on process gas and is ready for normal operation. -

Page 21: Typical Installation

MULTIDETEK3 User’s manual outlet connection of the purifier with a female cap. 13. Remove the tube connected at the inlet connection of LDP1000 and quickly cap the inlet connection of the purifier with a female cap. 14. Shutdown the carrier gas source on the cylinder or tank. 5.5. -

Page 22: Figure 6: Typical Installation

MULTIDETEK3 User’s manual Figure 6: Typical Installation... - Page 23 MULTIDETEK3 User’s manual 5.5.2. Valves actuation Separating the actuation from the reference carrier gas allows our gas chromatograph MultiDetek3 to achieve better results and more stability. The reason for it is mainly caused by the pressure changes when valves actuate during a cycle that will impact the equilibrium of the carrier gas reference.

-

Page 24: Figure 7: Same Source Actuation

MULTIDETEK3 User’s manual Figure 7: Same source actuation... -

Page 25: Figure 8: 2 Sources Actuation

MULTIDETEK3 User’s manual Figure 8: 2 sources actuation... - Page 26 MULTIDETEK3 User’s manual 5.5.3. O2 doping Figure 6 shows a typical installation that requires O2 doping. This feature is used to keep our system saturated with Oxygen. In chromatography, it is well known that oxygen is adsorbed by the Molecular Sieve and also by the porous polymer type columns used for separating and measuring trace oxygen.

-

Page 27: Figure 9: O2 Doping

Figure 9: O2 doping... -

Page 28: Hardware Description

6. Hardware description The MultiDetek3 has major components included in its chassis. This section will describe each component that can be replaced for maintenance or upgrade. 6.1. Detectors The PED detector module is a 155 mm (6.1”) x 82 mm (3.22”) x 63 mm (2.48”) box that contains all components needed to proceed to accurate measurement. -

Page 29: Motherboard

6.2. Motherboard This I/O board controls all components inside the analyzer (flow, detectors acquisition, temperatures, etc.). When replacing this motherboard be sure to avoid any electrostatic contact. The Board conception is modular, so it facilitates the replacement of parts on site. The flow sensor for carrier and sample can easily be replaced on site. -

Page 30: Sample Gas Proportional Valve, Mini Pump, Or Septum Injector

For some applications with condensable gases, the valves can be mounted in a heated box contained by the MultiDetek3 chassis. That heated box can also be purged with inert gas when hazardous or toxic gases are present. Please contact LDetek for more information. -

Page 31: Carrier Gas Electronic Pressure Regulator (Ldepc)

Carrier gas electronic pressure regulator (LDepc) The carrier gas flow control in the MultiDetek3 is managed by a high purity LDetek electronic pressure controller (EPC). The carrier flow control can be mounted inline or in bypass mode depending on the application. -

Page 32: Large 15.6'' Touch Screen Lcd & Ldchroma

6.7. Large 15.6’’ touch screen LCD & LDChroma+ The MultiDetek3 offers an easy and complete interface working on Windows 10 IoT. With its clear 15.6’’touch screen LCD, it allows the operator to easily navigates through different menus. Moreover, the system includes an Ethernet port for remote control. - Page 33 Handling highly flammable gas like silane or any other hazardous or explosive gases requires a high level of safety, and it is what LDetek offers with its built-in sample purging and monitoring system inside the MultiDetek3 compact GC. This system consists of 4...

-

Page 34: Bolt On Compact Purifier

6.9. Bolt on compact purifier A compact purifier can be bolt on the MultiDetek3 back panel. It offers the same performances than standard large gas purifier in a compact design. The maintenance is easy since the compact unit is mounted on the back panel of the MultiDetek3, and it is easy to have access from the back side. -

Page 35: Ldchroma

7. LDChroma+ The MultiDetek3 has a dual-core microcontroller (one core is a DSP for digital signal processing) that communicate with an 8-inch panel PC (touch screen). It offers an easy and complete interface named LDChroma++ working on Windows 10. You can use the USB connector on the front panel to connect a keyboard. -

Page 36: Figure 17: Method Manager

7.1.2. Method Manager The Method Manager menu allow you to manage all the methods you have on your GC. Figure 17: Method Manager Open: Allows you to open the selected method. Delete: Allows you to delete the selected method. Copy: Allows you to copy the selected method. Rename: Allows you to rename the selected method. -

Page 37: Figure 18: Calib Manager

7.1.3. Calib Manager The Calib Manager menu allow you to manage all the calibrations you have on your GC. Figure 18: Calib Manager Delete: Allows you to delete the selected calibration. Copy: Allows you to copy the selected calibration. Rename: Allows you to rename the selected calibration. 7.1.4. -

Page 38: Figure 19: Network

Figure 19: Network 7.1.6. User and Admin Mode User Mode: While in this mode, the user has limited access to settings Admin Mode: While in this mode, the user has access to all the settings. The factory password to access this mode “12345”. It can be change in the setting menu (see section 7.3.1.8). -

Page 39: Chromatogram Tab

7.2. Chromatogram tab 7.2.1. Chromatogram The Chromatogram menu is where you run the analysis. It is where you can see the chromatogram, the results, the alerts, the oven temperature, the sample flow, and the carrier flow. You can also configure the sampling for analysis running. Figure 21: Chromatogram menu... - Page 40 1- On the chromatogram, the X-axis shows the time in second and Y-axis shows the voltage in mV. 2- To see the voltage of each sensor you must over the mouse on “Legend” in the top left corner of the chart. By moving the mouse arrow in the chart, you will see the mV in the legend for each sensor.

-

Page 41: Figure 22: Left Bottom Bar

The next icon is a floppy drive. If it is coloured, it tells the user that some changes were made but they are not saved to the disk yet. The next icon is for LDReport. If it is colored in red, it tells the user that LDChroma+ is correctly connected to LDReport. -

Page 42: Figure 23: Middle Bottom Bar

7.2.2.2. Middle bottom bar The middle part of the bottom bar shows the “device status”. When the communication between the panel PC and the motherboard is establish, it is displayed “MD3-XXXX connected” If there is no communication between the pane PC and the motherboard, it is displayed MD3-XXXX not connected. -

Page 43: Figure 25: Historic Menu

Compare…: To compare many historic data. Reprocess data: To reprocess historic data. Set Description…: To edit historic description. Rework Raw Data…: To resend historic data to MD3 for reworking. Tools…: To add offset or gain on historic sensor data. -

Page 44: Figure 26: Historic List Window

Figure 26: Historic list window Last Historics: To display last historics. Today: To display historics for the day. Next Day: To display historics for the next day. Previous Day: To display historics for the previous day. Request…: To make historics list request from LDReport. Refresh: To refresh historics list. -

Page 45: Figure 27: Peak Results

If you double-click on a result, a new window will show up with more information such as concentration, area, retention time, height, and noise. Figure 27: Peak Results If you double-click on a peak, you will see the settings used for the peak detection algorithm. -

Page 46: Settings Menu

Setting In this menu, there are all the parameters of the MultiDetek3. These parameters should not be changed without contacting LDetek support. The available settings may vary depending on the software version. To update the software, please contact LDetek support to ensure the versions are compatible with your system. -

Page 47: Figure 29: Settings Menu

7.3.1.1. Methods Figure 29: Settings menu Analysis Time: The cycle time of the method Stream Change Time: It is the time where it is possible to change the current stream without affecting this analysis. This parameter is used only when running a sequence and if the next analysis in the sequence has a different stream. - Page 48 (D) Time axis max: The maximum value of time axis (E) Peak at span: The value of peak span (F) Peak base: The value of peak base. (G) Peak box height: The value of peak box height. (H) Peak box base: The value of peak box base.

-

Page 49: Figure 30: Peak Setting Menu

7.3.1.2. Peak Figure 30: Peak setting menu Setup: The peak detection algorithm can be changed by double-clicking on setup Start: The start time of the current peak End: The stop time of the current peak LDL: The lowest detectable limit (LDL). Any result with a concentration lower than this value will be considered as LDL. - Page 50 The parameters bellow “LDL” may vary depending on the peak detection algorithm used. The detections algorithms are described below. There are 7 types of detection for a peak. Biggest Peak: In the peak window, the algorithm will detect every rise and every drop.

-

Page 51: Figure 31: Flow Setting Menu

7.3.1.3. Flow Figure 31: Flow setting menu Setup: By double-clicking on it you can change: • The name of the flow • The type of flow o Sample o Carrier • The flow control type o Automatic (closed-loop control) o Manual (just for reading, no output) o LDepc (extern control) •... - Page 52 The percentage of deviation allowed before the flow deviation Pct Alert: alert Low Limit: The lowest value to be considered as a normal condition. If we have reading lower than that, the system will stop trying to control it. Because there is probably something wrong, a broken sensor for instance.

-

Page 53: Figure 32: Oven Setting Menu

7.3.1.4. Oven Figure 32: Oven setting menu Setup: By double-clicking on it you can change: • The name of the oven • T° sensor you want to use for this oven • The type of oven o On/Off (isothermal oven) o On/Off+fan (programmed ramping oven) o Proportional (HCD) •... - Page 54 we have reading lower than that, the system will stop trying to control it. Because there is probably something wrong, a broken sensor for instance. Hi Limit: The highest value to be considered as a normal condition. If we have reading higher than that, the system will stop trying to control it.

-

Page 55: Figure 33: Detector Setting Menu

7.3.1.5. Detector Figure 33: Detector setting menu Setup: By double-clicking on it you can change: • The name of the detector • The type o Plasma o TCD • Input / Output needed for the control and monitoring Power Output: The value in % for the power delivered to the detector Power Relay: Selection of a relay to cut power to detector. -

Page 56: Figure 34: Sensor Setting Menu

7.3.1.6. Sensor Figure 34: Sensor setting menu Setup: By double-clicking on it you can change: • The name of the sensor • The color on the chart • The type of filter o Average o Median o FIR o Curve Fitting Base Offset: If you enter 0, this parameter has no effect. -

Page 57: Figure 35: Valve Setting Menu

7.3.1.7. Valve Figure 35: Valve setting menu Setup: By double-clicking on it you can change: • The name of the valve • The digital output associated with it Type: Configuration of the valve (Injection, Heartcut, Backflush, etc.) Sampling Loop: It shows the sampling loop volume if it is a valve that contains sample loop. -

Page 58: Figure 36: Machine Setting Menu

To activate automatic printing after each analysis printing: Default Printer: To select a default printer TagName: Alias of MD3 Password: To manage password for the admin mode Recording: To manage the folder or drive where the analysis results are recorded... -

Page 59: Figure 37: 4-20Ma Settings Menu

7.3.1.9. 4-20mA Figure 37: 4-20mA settings menu Setup: By double-clicking on it you can change: • The name of the 4-20mA • The analog output associated with it Measure The current measured during the calibration should be d 4mA: put there. By double clicking on the field, the output will be set to 4mA. -

Page 60: Figure 38: Stream Settings Menu

7.3.1.10. Stream Figure 38: Stream settings menu Setup: By double-clicking on it you can change: • The name of the stream • The digital output associated with it Use for Calib.: This is used to determine the stream used for calibration of the analyser Display order: This determines the order this stream will have in the menu. -

Page 61: Figure 39: Sequence Setting Menu

7.3.1.11. Sequence Figure 39: Sequence setting menu Setup: By double-clicking on it you can change the name of the Sequence Disable Stream at If it is enabled, at the end of the sequence, no stream will be selected Add: To add an analysis to the current sequence Modify: To modify an analysis in the current sequence Delete:... -

Page 62: Figure 40: Column Setting Menu

7.3.1.12. Column Figure 40: Column setting menu Setup: By double-clicking on it you can change the name of the column • • the oven that contains this column • the valve(s) and state of it(them) when column regeneration is in process Description: Additional description on the column Temperature:... -

Page 63: Figure 41: Modbus Setting Menu

7.3.1.13. Modbus Figure 41: Modbus setting menu Slave ID: The SlaveID is a unique number for each Slave in your Modbus network. The SlaveID can be any number between 1 and 254. If a Slave receives a communication with a wrong SlaveID, it will be ignored High byte Options to adapt the communication to different DCS default language /High word... -

Page 64: Figure 42: Qma Setting Menu

7.3.1.14. QMA Figure 42: QMA setting menu Enable: Enable or disable the QMA Peak: Assign the QMA to peak. Valve: Assign a valve to the QMA. The selected valve will control the sensor. Oven: Assign an oven to the QMA. The selected oven will control the sensor temperature. -

Page 65: Figure 43: Calibration Menu

In this menu, there are level of use of various elements of the GC. These parameters should not be changed without contacting LDetek support. The available settings may vary depending on the software version. To update the software, please contact LDetek support to ensure the versions are compatible with your system. -

Page 66: Calibration Menu

7.4. Calibration Menu Figure 44: Calibration menu Peak: The name of the impurities _Area: The area of calibration Unit: The concentration calibration Apply: To save all the change that were made Calibration It displays the historic of the previous calibration. It is possible to load Historic: a previous one if needed. -

Page 67: Diagnostics Menu

7.5. Diagnostics Menu 7.5.1. Analog input This menu displays all analog inputs in the MultiDetek3 with their actual value in counts and converted into units. The progress bar in the corner shows the refreshing rate Figure 45: Analog input window 7.5.2. -

Page 68: Figure 47: Digital Output Window

7.5.3. Digital output This menu displays all digital output in the MultiDetek3 with their actual value. If the square is grey, the state of the output is unknown (probably a communication problem), if the square is dark green, the output is OFF, if the square is light green, the output is ON. You can force any output at OFF or ON. -

Page 69: Figure 49: Modbus Register Window

7.5.5. Modbus/Register This menu displays the actual values of every Modbus registers Figure 49: Modbus register window 7.5.6. Modbus/Connection This menu displays which IP is connected the MD2 and if there is some activity (send and receive data) Figure 50: Modbus information window 7.5.7. -

Page 70: Regeneration

7.6. Regeneration This menu is used to start a regeneration. The settings are pre-configured in the setting menu. Figure 51:Regeneration window... -

Page 71: About Menu

Figure 52: About menu 7.8. Firmware Update This menu is used to update the firmware of the MultiDetek3. A firmware update should not be done without contacting LDetek support Figure 53: Firmware Update... -

Page 72: Backpanel Terminal Identification

8. Backpanel terminal identification... - Page 73 4-20mA1+ to 4-20mA10+: Analog output positive terminals for peak #1 to peak #10 (use 500ohm resistor between + and – terminals for 0-10VDC resolution on data recorder) 4- 20mA1- to 4-20mA 10-: Analog output negative terminals for peak #1 to peak #10 (Use 500ohm resistor between + and –...

-

Page 74: Drawings & Schematics

9. Drawings & Schematics... - Page 80 TCD detector PED detector Easy front access door Panel PC Accessible isothermal ovens (6x)

-

Page 82: Spare Part List

Referring to the spare part list: the manufacturer item numbers, the descriptions, the replacement frequencies as well as the associated procedure numbers are identified. 10.1. Spare part list Contact LDetek service department (support@ldetek.com) with the serial number of your instrument for the spare part list referring to your instrument. - Page 83 9 The green LED turns on when the oven is heating. Check if the LED is ON or OFF or blinking. If the setpoint is 50Celsius and the reading value is 10Celsius, then the LED should be ON all the time 5. Contact LDetek support (support@ldetek.com) with the results obtained in the previous steps 1.

- Page 84 1. Make sure there is no active alarm. If there are alarms, they must be resolved 2. Make sure the calibration has been done properly 3. Provide the followings information to a LDetek support (support@ldetek.com) Unstable reading...

- Page 88 Where innovation leads to success...

Need help?

Do you have a question about the MD3 and is the answer not in the manual?

Questions and answers