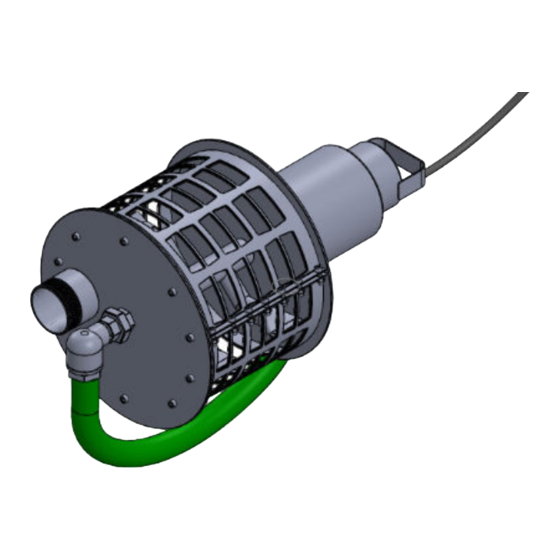

Summary of Contents for ROTORFLUSH RF300AR-E

- Page 1 RF300AR-E INSTRUCTIONS Rotorflush Filters Ltd, Langmoor Manor, Charmouth, Dorset, DT6 6BU, UK Tel 0044 (0) 1297 560229 Fax 0044 (00 1297 560110 Email: mail@rotorflush.com Company registration: 07472511 VAT No.: 675804603 www.rotorflush.com P a g e...

-

Page 2: Installation And Servicing Instructions

Improper use may cause serious injury to people or damage to property FAILURE TO OBSERVE THESE WARNINGS AND/OR ANY TAMPERING WITH THE FILTER EXEMPTS ROTORFLUSH FILTERS FROM ALL RESPONSIBILITY IN THE EVENT OF PERSONAL INJURY OR DAMAGE TO EQUIPMENT OR PROPERTY AND/OR TO THE FILTER Read this manual carefully and check to ensure that the Filter has been properly installed and connected in accordance with relevant safety standards before starting the Filter. - Page 3 Significant Protection and Precautions (as per EEC 98/37 p. 1.1.2 and 1.7.2; EN 292-2 p.5). Rotorflush filters are designed so that all moving parts are shrouded by protective casings. Rotorflush Filters declines all responsibility in the event of injury or damage caused as a result of tampering with these devices.

- Page 4 4. Flow rates and pressures The maximum usable flow through the filter, (with standard 300 micron screen), 560 litres per minute, depending on the total suspended solids contained in the fluid and the type of solids, (fatty/ sticky solids will reduce performance) 5.

- Page 5 Overload Protection The Rotorflush Filters single phase 110V and 220-240V have a built in thermal overload with automatic reset. However a correctly rated fuse or overload protection must be installed in the supply to the pump in addition to the pump’s thermal protection The Three Phase versions of Rotorflush Filters can be protected by using a magneto-thermic motor protector or a contactor with thermal relay.

- Page 6 P a g e RF300ARe Instructions v21...

-

Page 7: Troubleshooting

4. Check Filter Mesh for 4. Impeller Blocked damage. If damaged contact Rotorflush 5. Contact Rotorflush 5. Motor or capacitor damaged 1. Filter Blocked 1. Clean Filter. Reduce suspended solids Motor runs but no water in water. - Page 8 The 300 micron nylon screens every 5000 hours. For large mesh size duration will depend on mesh size and the environment the strainer is in but every 5000 hours is an average guideline. New mesh screens are available from Rotorflush Filters Ltd Servicing the cleaning Rotor Over a period of time, there may be a decline in the cleaning performance of the filter and blockage may occur.

- Page 9 P a g e RF300ARe Instructions v21...

- Page 10 2. Remove the Clamp and damaged mesh. (as shown above) Clean the inner filter Cage and Clamp surfaces to aid fitment of new mesh. 3. Place the Stainless filter mesh (available from Rotorflush Filters) around the filter cage. Ensuring that the joint is in line with a cage upright as shown below.

- Page 11 Either way this will eventually lead to a pump failure. If there is a miss-alignment please go back to step 1. *If in doubt or you encounter difficulties please feel free to contact Rotorflush Filters Ltd. 11 | P a g e...

- Page 12 NOTES. 12 | P a g e RF300ARe Instructions v21...

Need help?

Do you have a question about the RF300AR-E and is the answer not in the manual?

Questions and answers