Table of Contents

Summary of Contents for Precision 51221076

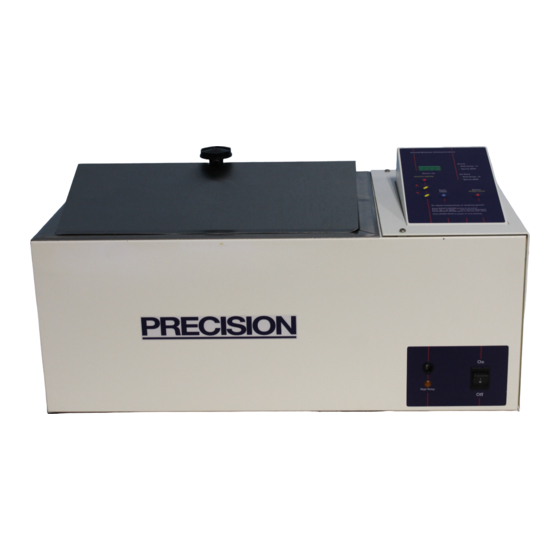

- Page 1 Installation/Service Manual Dubnoff & Shallow Form Shaking Water Baths Precision 170 Marcel Drive Winchester, VA Phone: 540-869-8623 Toll Free: 800-621-8820 FAX: 540-869-8626 Manual P/N 36100126 (34002554) Rev.B Dated 08NOV01...

- Page 2 AND THE PRODUCT IT DESCRIBES ARE SUBJECT TO CHANGE WITHOUT NOTICE. PRECISION MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THIS MANUAL. IN NO EVENT SHALL PRECISION BE LIABLE FOR ANY DAMAGES, DIRECT OR INCIDENTAL, ARISING OUT OF OR RELATED TO THE USE OF THIS MANUAL.

- Page 3 REVISION STATUS AMENDED PAGES INDEX DATE NOTES 6/99 Initial release NOV01 Add caution "acidic & caustic substance .."...

-

Page 4: Table Of Contents

Contents INTRODUCTION ........................1 UNPACKING AND DAMAGE ....................1 GENERAL INFORMATION.......................2 PERFORMANCE ........................2 INSTALLATION ........................3 WATER LEVEL REGULATOR ....................4 EXPLANATION OF CONTROLS ....................6 OPERATION ..........................7 MAINTENANCE ........................8 TROUBLESHOOTING ......................9 PARTS REPLACEMENT ......................14 TEMPERATURE CALIBRATION ...................17 REPLACEMENT PARTS LIST ....................18 ASSEMBLY & SCHEMATIC DWGS ..................20 WARRANTY ...........................29... -

Page 5: Introduction

Your satisfaction and safety are important to agent. Failure to adequately describe such exter- PRECISION and a complete understanding of nal evidence of loss or damage may result in the this unit is necessary to attain these objectives. -

Page 6: General Information

GENERAL INFORMATION steel and is designed for operation with distilled water or water solutions, such as water/ethylene The Precision Dubnoff Metabolic Shaking Incubator glycol. Do not use deionized water. If deionized Bath and the Precision Shallow-Form Shaking is the only water available, a mixture with a 50/50 Bath have been designed primarily for the incubation ratio of deionized and tap water should be used. -

Page 7: Installation

INSTALLATION Shaker Clip Installation - The spring retainers provided are designed to firmly hold flask clips in the shaking tray holes. WARNING It is important that these retainers be inserted INSTALLATION SHOULD BE COMPLETED BY into tray holes before inserting optional flask QUALIFIED PERSONNEL ONLY. -

Page 8: Water Level Regulator

Uncoil Tygon tubing & press onto 1/4" Hose WATER LEVEL REGULATOR Barb Fitting (located at the top of water level (OPTIONAL) regulator). INSTALLATION INSTRUCTIONS - Use the Hook-up other end of the tygon tubing to water following steps along with Fig. 1 & 2 shown on the supply &... - Page 9 WATER LEVEL REGULATOR ASSEMBLY FIGURE 1 SIDE VIEW OF BATH FIGURE 2 CUTAWAY FRONT VIEW OF BATH...

-

Page 10: Explanation Of Controls

EXPLANATION OF CONTROLS 3. Indicator Lamps - These lamps indicate Power Switch - The power switch is located on which of 4 parameters (Actual Temp, Actual the lower right hand side of the bath, it provides Speed, Setpoint Temp, and Setpoint Speed) power for the entire unit. -

Page 11: Operation

OPERATION b. Press UP or DOWN until desired speed is displayed. CAUTION c. Press ENTER again to set new speed. EXERCISE CARE WHEN USING ACIDIC OR d. Display will show actual speed for 10 CAUSTIC SOLUTIONS AS THEY WILL ATTACK THE GALVANIZED STEEL BATH BODY IF SPILLED seconds, then return to actual temperature. -

Page 12: Maintenance

OTHER ADEQUATE HAND PROTECTION. bath media, add a little formaldehyde or quaternary WEAR GOGGLES OR OTHER ADEQUATE EYE ammonium germicide available from Precision, PROTECTION. WORK ONLY IN AREAS WITH P/N 51200912. ADEQUATE VENTILATION. -

Page 13: Troubleshooting

TROUBLESHOOTING Turn ON the main power. voltmeter should reading WARNING approximately 14 volts DC ±2. SERVICE SHOULD BE PERFORMED ONLY BY A QUALIFIED TECHNICIAN. BEFORE REPLACING Connect the positive lead to TP3 ±5V. The ELECTRICAL MECHANICAL voltmeter should be reading +5 volts DC ±0.5. COMPONENTS, UNPLUG THE LINE CORD. - Page 14 GENERAL INFORMATION - The POWER SUPPLY TP1-COM test point. Measure the voltage at PCB ASSEMBLY #34372501 has the triac (solid U7-pin 2. It should be approximately 14 volts state AC voltage switch) on it which supplies the DC. Then measure the voltage at U7-Pin 6. power to the heater.

- Page 15 d. If the last two steps are not as stated, then ********* Problem B: Constant Heat ********** most likely the CPU board is bad and it will Bath is heating when it is not requesting heat. have to be replaced. If they are,continue on. a.

- Page 16 *** Problem C: Unstable Temperature *** c. Slide the push rod back and forth. The push rod should slide very easily in its housing. If Control or Display not, replace the push rod and the bearing Use gable cover provided to improve housing.

- Page 17 Check Optical transmitter. e. If this signal is NOT changing as mentioned a. Connect the negative lead of a DC voltmeter above when the START/STOP key is pressed, then most likely the problem is in the to TP1-COM on the CPU board. DISPLAY board and it will have to be replaced.

-

Page 18: Parts Replacement

Before removing any parts for replacement, verify PARTS REPLACEMENT part in question by following the instructions listed in the troubleshooting guide. WARNING BEFORE REPLACING ANY PART, BE SURE Refer to Parts Replacement Table below for BATH IS DISCONNECTED FROM POWER appropriate replacement procedures. - Page 19 PARTS REPLACEMENT (CONT'D) Replace Heater From inside control housing, remove 2 nuts and disconnect wires from heater leads. Remove two hex nuts from heater ends using a 13/16" socket and remove heater Reverse above procedure to install new heater. Replace "HI Limit" Remove four leads from thermostat terminals.

- Page 20 PARTS REPLACEMENT (CONT'D) Replace CPU or 6. The software must be configured to match the Bath model. Display/Keyboard Board To enter configuration mode, press the upper left pushbutton See note below ** while applying power. The upper left push-button is labeled "Select/Enter."...

-

Page 21: Temperature Calibration

TEMPERATURE CALIBRATION The display will now show CXX.X (XX.X is the The following provides a step-by-step procedure actual bath temperature) - this is Low for temperature calibration. Do not deviate from Temperature Calibration. the procedure or the calibration of your bath may be inaccurate. -

Page 22: Replacement Parts List

REPLACEMENT PARTS LIST Part Number Description 115V 230V PCB, Assy. Kit, Power Supply 51245021 PCB, Assembly, CPU 51245217 PCB, Assembly, Display 34373101 Voltage Connector 34376401 34376402 Wire Harness 34376501 RPM Optical Sensor Assembly 51245155 Temp. Probe Assembly 51245243 Bearing Assembly Kit 51245254 Push Rod 34541754... - Page 23 ACCESSORY PARTS LIST Catalog Item Number 51200855 Shaker Tray Assembly 34002524 Gable Cover (Dubnoff) 51200866 Gable Cover (Shallow Form) 51200844 Water Level Regulator Kit 34542220 Flow Meter Assembly 34542228 Flow Meter Bracket 34380301 Gassing Hood, Small 34380302 Gassing Hood, Large 34542213 0.5 ml Microcentrifuge Tube Rack 34542214...

-

Page 24: Assembly & Schematic Dwgs

ASSEMBLY & SCHEMATIC DWGS. - Page 25 220076.DWG...

- Page 26 SCREW RPM DETECTOR WASHER ASSY LOCKWASHER PLASTIC BEARING SCREW PUSH ROD BRACKET ECCENTRIC METAL DISC SCREW SET SCREW THERMOSTAT SCREW BRACKET SCREW 230V VERSIONS ONLY TRANSFORMER OPTICAL DISC SCREW POWER ON/OFF SWITCH END VIEW (WITH CONTROL COVER REMOVED AND WIRING EXCLUDED) F:\E3032\MANUAL\SHAKER.PRT...

- Page 27 O'RING BEARING ASSY BEARING CAP SPACER WIPER SEAL JAM NUT TO REMOVE BEARING ASSEMBLY: -HOLD BEARING CAP FIRMLY WITH WRENCH -REMOVE JAM NUT -SLIDE BEARING ASSEMBLY AND BEARING CAP OUT INTO PAN UPPER VIEW BEARING ASSEMBLY O'RING FLEX FITTING TEMP PROBE ASSY REMOVE THIS WAY TO REMOVE TEMPERATURE PROBE: -HOLD NUT ON INSIDE OF PAN...

- Page 28 (PROVIDED O'RING WITH HEATER) (PROVIDED HEATER WITH HEATER) HEATER LEAD TO REMOVE HEATER: (PART OF WIRE -REMOVE HEATER BRACKET(S) HARNESS) FROM INSIDE OF PAN -REMOVE HEATER LEADS FROM END OF HEATER -REMOVE LARGE NUT LOCATED IN AREA BETWEEN PAN AND BODY INSULATION WALL -LIFT HEATER OUT OF PAN...

- Page 29 CONTROL COVER TO TEMP OPTICAL PROBE SENSOR TO POWER SUPPLY DISPLAY PCB ASSY BOARD J102 LOCATED UNDERNEATH CPU PCB ASSY CPU PCB ASSSEMBLY CONFIGURATION...

- Page 30 F:\E3032\MANUAL\66722C.PRT...

- Page 31 F:\E3032\MANUAL\00378901.PRT...

- Page 32 F:\E3032\MANUAL\00378902.PRT...

-

Page 33: Warranty

(1) year from the date of delivery of the products. Sole obligation of PRECISION shall be to repair or replace at our option, FOB factory or locally, without charge, any part(s) that prove defective within the warranty period, provided the customer notifies PRECISION promptly and in writing of any such defect.

Need help?

Do you have a question about the 51221076 and is the answer not in the manual?

Questions and answers