Table of Contents

Troubleshooting

Summary of Contents for Lissmac SBM-XL 1000 G2S2-60

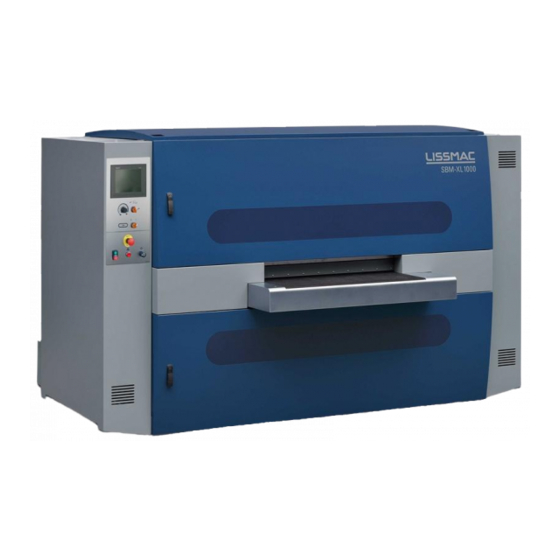

- Page 1 METAL PROCESSING OPERATING MANUAL GRINDING MACHINE SBM-XL 1000 G2S2-60 SBM-XL 1500 G2S2-60 LISSMAC Maschinenbau GmbH Lanzstraße 4 D-88410 Bad Wurzach Telefon +49 (0) 7564 / 307 - 0 Telefax +49 (0) 7564 / 307 - 500 lissmac@lissmac.com www.lissmac.com...

-

Page 3: Imprint

Imprint Imprint Operating manual for Grinding machine SBM-XL 1000 G2S2-60 SBM-XL 1500 G2S2-60 Status 01-2019 Translation of the original operating manual Manufacturer: LISSMAC Maschinenbau GmbH Lanzstraße 4 D-88410 Bad Wurzach Phone +49 (0) 7564 / 307 - 0 Fax + 49 (0) 7564 / 307 - 500 E-mail: lissmac@lissmac.com... -

Page 4: Table Of Contents

Table of contents Table of Contents Imprint ......................3 Table of Contents ..................4 About this manual .................. 6 Target group ..................6 Additional documents ............... 6 Presentation of warnings ..............7 ... - Page 5 Table of contents Turning on the machine ..............33 Setting sheet thickness ..............34 Setting feed ..................35 Grinding workpieces............... 36 Grinding units ................. 38 5.8.1 Workpieces remaining in the machine ....... 39 ...

-

Page 6: About This Manual

About this manual 1 About this manual Target group This operating manual contains important information on how to operate the machine safely, properly and economically. The operating manual is directed at the machine operator and the operating and maintenance personnel. Each person responsible for operating and maintenance work on the machine must have read and understood this operating manual. -

Page 7: Presentation Of Warnings

About this manual Presentation of warnings In this operating manual warnings are presented according to the following examples: SIGNAL WORD! Type and source of danger Consequences of non-compliance Actions to avert the danger. The signal word under the danger symbol indicates the degree of danger: This signal word signifies an extremely dangerous situation. -

Page 8: Safety

Safety 2 Safety Safety instructions The SBM-XL G2S2-60 Grinding machine is constructed with the latest technology and to recognised safety system regulations. However, during its use, danger for persons and property damage can occur. The machine is to be used only for intended use in technically faultless condition and in observance of safety instructions. -

Page 9: Personnel Selection And Qualifications

Safety Personnel selection and qualifications Only responsible and authorised personnel of legal minimum age may work on the machine. Personnel who are being trained or orientated on the machine may only work on the machine under continuous supervision of an experienced person. -

Page 10: Maintenance, Service And Troubleshooting

Safety Maintenance, Service and Troubleshooting Have special work performed only by technicians authorised for it. Perform adjustment, maintenance and service work according to instructions in the operating manual. Keep the specified intervals for service work. Inform operating personnel before beginning special and maintenance work. -

Page 11: Safety Instructions For Special Types Of Dangers

Safety Safety instructions for special types of dangers 2.7.1 Electric power In case of problems with the electrical power supply, turn the machine off immediately. When changing fuses only use original fuses with specified amperage. Only electricians or trained personnel under the guidance and monitoring of an electrician perform work on electric equipment of the machine in accordance with electrical regulations. -

Page 12: Explanation Of Warning Symbols On The Machine

Safety Explanation of warning symbols on the machine The following symbols are located on the machine (see page 16 to 18) and warn of dangers coming from the machine: Symbol Symbol Meaning This symbol on the machine indicates that dust and splinter may be ejected from the machine during grinding. - Page 13 Safety Symbol Symbol Meaning Information about belt arrangement, bottom. Warning!! Disconnect power before working within Information about forklift transport. Symbol, Hand wheel for moving bottom S-unit Symbol, Hand wheel for adjusting sheet thickness. Symbol, Hand wheel for moving top S-unit This symbol on the hydraulic tank indicates the hydraulic oil level.

- Page 14 Safety Symbol Symbol Meaning Information about the switch position and functions of the gear box. Lifting point for crane hooks The symbol indicates the minimum length of the workpiece to be machined. Symbol Grease gun, here lubrication nipple (see 7.3) Symbol, Direction of rotation arrow Information about the switch position of the main switch.

-

Page 15: Symbols On The Machine Front Side

Safety Symbols on the machine front side The next few pages will illustrate the positions where symbols/warning labels are applied to the machine. The symbols/warning labels for each position number are shown on page 12/13/14. Abb. 1: Symbols on the machine front side Symbol "Wear safety glasses"... -

Page 16: Symbols In The Machine

Safety 2.10 Symbols in the machine Abb. 3: Symbols in the machine Symbol, Dangerous electrical voltage Hydraulic pressure Belt arrangement, top Belt arrangement, bottom Hydraulic oil level label Abb. 4: Symbols in the machine Symbol, Turning V-belt pulleys Symbol, Hand wheel for moving bottom S-unit Symbol, Hand wheel for adjusting sheet thickness. -

Page 17: Symbols On The Back Of The Machine

Safety 2.11 Symbols on the back of the machine Abb. 5: Symbols on the back of the machine Warning!! disconnect power before working within Symbol, Observe operating manual EMERGENCY STOP label Information about forklift transport Information about the switch position of the main switch Grinding machine SBM-XL 1000/1500 G2S2-60... - Page 18 Safety Notes: Grinding machine SBM-XL 1000/1500 G2S2-60...

-

Page 19: Product Description

Product description 3 Product description Appropriate usage The Grinding machine SBM-XL 1000+1500 G2S2-60 is intended exclusively for double sided deburring and rounding edges of steel and stainless steel sheets and following the information in this operating manual. Non-intended use particularly includes grinding and deburring of other materials and alloys. -

Page 20: Structure

Product description Structure Abb. 6: Components of the machine, input side (front) Attachment points for transporting the machine Touch screen Operating elements and »EMERGENCY STOP« button for immediately shutting off the machine in an emergency Upper door on the input side Conveyor belt for input of workpieces Adjustable machine feet Lower door on the input side... - Page 21 Product description Abb. 7: Components of the machine, output side (back) Upper door on the output side Connection for exhaust system Conveyor belt for output of workpieces Lower door on the output side >EMERGENCY OFF< button for turning on/off the mains supply for the entire machine Main switch for turning on/off the mains supply for the entire machine...

-

Page 22: Control Elements

Product description Control elements Abb. 8: Operating elements on touch screen Touch screen »Start system« button for turning on the machine »Control voltage Off / On« key switch for turning the mains supply for the drives and for the displays on/off »Stop system«... -

Page 23: Function

Product description Function Grinding units for grinding surfaces (SBM-G) and for rounding the edges (SBM-S) are combined in the SBM-XL G2S2 Grinding machine. Grinding units are each installed in pairs up and down. In this way the workpieces can be processed on both sides in one work step. The workpieces are guided into the machine up and down by feed rollers and transported between the grinding units. -

Page 24: Safety Equipment

Product description Position of grinding The positions of the upper and lower grinding units and the upper feed units and feed rollers can be set relative to the conveyor level. In this way, for example, rollers workpieces with differing sheet thicknesses can be processed or the grinding results are optimised. -

Page 25: Technical Data

Product description Technical data The following information refers to the SBM-XL 1000 G2S2-60 or SBM-XL 1500 G2S2-60 Grinding machines. SBM-XL 1000 G2S2-60 SBM-XL 1500 G2S2-60 Length approx. 3100 mm / 122 inch 3600 mm / 142 inch Dimensions and Width (incl. conveyor belt) - Page 26 Product description SBM-XL 1000 G2S2-60 SBM-XL 1500 G2S2-60 Feed Number of feed motors Tape front / back Drive power per feed motor 0,3 kW 0,3 kW Power consumption per feed 0,93 A 0,93 A motor Feed motor speed 1410 rpm...

-

Page 27: Preparation For Use

Preparation for use 4 Preparation for use Transporting the machine WARNING Heavy loads Injury from falling parts Only use lifting gear and loading equipment with sufficient lifting capacity. Only secure the machine on the four attachment points provided 1. ... -

Page 28: Installation And Assembly

Preparation for use Installation and assembly The machine must only be installed in an indoor space, which meets the following conditions: Fortified level floor with sufficient load carrying capability Temperature range: +10° to +40 °C Humidity: 5 – 95 % (not condensing) 4.3.1 Installing machine ... -

Page 29: Connecting The Exhaust

Preparation for use 4.3.3 Connecting the exhaust The machine is only to be operated with a functioning exhaust system. Exhaust system requirements are given in the technical data. Install the exhaust system near the machine. Connect the exhaust system electrically and secure against accidental starting. -

Page 30: Operation

Operation 5 Operation User interface Central functions and machine information is called up, displayed and can be changed using the touch screen. The menus are selected by touching the fields on the surface of the touch screen. Structure of the interface Abb. -

Page 31: Operation Using The Touch Screen

Operation Operation using the touch screen The following list describes and gives an overview of the menus available from there, their information and input options. Functions are only available with the proper user log in. Menu Functions and displays Main menu Setting the sheet thickness, Manual repositioning of the feed frame »Sheet thickness«... - Page 32 Wear position of the SBM-G and SBM-S assemblies. Setter: All actions of level 0 are included, Running in SBM-G abrasive Only accessible by LISSMAC Service Status display in Info area (Pos. 1) Machine door not closed All machine doors are closed...

-

Page 33: Turning On The Machine

Operation 5.4 Turning on the machine Before turning on the machine, the following conditions must be checked: Running direction of the grinding belts and abrasive belts correspond to the manufacturer's specifications. Function readiness of the connected exhaust system is ensured. ... -

Page 34: Setting Sheet Thickness

Operation Setting sheet thickness Before processing the workpieces, the sheet thickness of the workpieces must be measured and adjusted on the machine. The value for the sheet thickness is set commonly for the SBM-G and SBM- S grinding units. This means the upper feed rollers are moved with the upper grinding units upward or downward. -

Page 35: Setting Feed

Operation Setting feed Feed speed The grinding results of the SBM-S grinding units are dependent upon the feed speed, among other things. The following setting values can be used as a guideline for the feed speed: Normal setting: approx. 1 m/min ... -

Page 36: Grinding Workpieces

Operation Grinding workpieces WARNING Fine dust and flying sparks Ignition of grinding dust by flying sparks, dust explosion Only operate machine with exhaust system turned on. Do not process workpieces made of aluminium or aluminium alloys. Empty dust collection containers and exhaust system regularly and clean exhaust ducts. - Page 37 Operation Pictogram on the machine Place workpieces onto the conveyor belt as shown. To improve the grinding results, e.g. the position of the upper grinding unit can be changed and/or the grinding speed can be adjusted (see page 41 or page 35).

-

Page 38: Grinding Units

Operation Grinding units Option fields Tool change: Units move to their end position Sheet thickness moves to 5 mm position The units can only be opened in the end position Move machine free: Units move to end position and sheet thickness remains unchanged. -

Page 39: Workpieces Remaining In The Machine

Operation 5.8.1 Workpieces remaining in the machine NOTE Workpieces remaining in the machine Damage to the machine Make sure that no workpieces are between the feed rollers or in the exhaust duct. Press the »Stop system« button 19. To switch off the machine. ... -

Page 40: Turning The Sbm-G Grinding Unit On/Off

Operation 5.8.2 Turning the SBM-G grinding unit on/off Option fields Motor start Release for motor start Press the »Stop system« button 19. Turning off the To turn off the SBM-G unit: grinding unit. Select »Info« on the touch screen menu. ... -

Page 41: Turning The Sbm-S Grinding Unit On/Off

Operation 5.8.3 Turning the SBM-S grinding unit on/off To turn the SBM-S grinding unit on or off, proceed as in chapter 5.8.12. Changing the position of the upper and lower grinding units To optimise the grinding results during operation, the position of the upper and lower SBM-G and SBM-S grinding units relative to the position of the upper feed rollers can be changed. -

Page 42: Changing The Position Of The Sbm-G Grinding Unit

Operation 5.9.1 Changing the position of the SBM-G grinding unit Press the »Stop system« button 19. To change the position of the SBM-G grinding units, select the »SBM- G« menu. Move the grinding units upwards or downwards with the arrow keys for »SBM-G upper«... -

Page 43: Turning Off The Machine

Operation 5.10 Turning off the machine The machine can be turned off immediately in an emergency by pressing either of the two »EMERGENCY STOP« buttons 12 or 23. After activating button 12 or 23 and acknowledging with button 20, the machine can be started with the »Start system«... -

Page 44: Maintenance And Cleaning

Maintenance and Cleaning 6 Maintenance and Cleaning Changing the abrasive The upper and lower grinding units can be moved completely apart. Then the grinding belts of the SBM-G grinding units or the abrasive belts of the SBM-S grinding units can be changed more easily (tool change). Abb. -

Page 45: Changing The Grinding Belts Of The Sbm-G Grinding Units

Maintenance and Cleaning 6.1.1 Changing the grinding belts of the SBM-G grinding units Worn or damaged grinding belts must be replaced immediately. The following facts suggest worn grinding belts: Message »Grinding belt malfunction« Increased power consumption of the grinding motors ... - Page 46 Maintenance and Cleaning CAUTION Opened doors and swung out front grinding units Cutting off fingers and other body parts! Make sure that the feed is turned off. Only entrust the work to authorised personnel. Only start the machine with extreme caution. ...

- Page 47 Maintenance and Cleaning Level 4 user log in Checking running of the belt Select »Service« in the main menu. Select the motor whose belt should be run in while paying attention to the instructions on the touch screen. ...

-

Page 48: Changing The Abrasive Belts Of The Sbm-S Grinding Units

Maintenance and Cleaning 6.1.2 Changing the abrasive belts of the SBM-S grinding units Worn or damaged abrasive belts must be replaced immediately. For the SBM-S grinding units the abrasive belts can be changed individually NOTE Workpieces remaining in the machine Damage to the machine ... - Page 49 Maintenance and Cleaning Place new abrasive belts on the back guide plates and pay attention to Putting on new abrasive belts the correct running direction. To tighten the abrasive belts of the grinding units 29, 30, 32, and 33, screw on the tensioning screw up to the mark and secure with the counter nut.

-

Page 50: Cleaning

Maintenance and Cleaning Cleaning The machine must be cleaned after every shift (at least once per day) and dust removed. CAUTION Dust Long-term damage to health from inhalation Wear dust protection mask when cleaning the machine Turn on the exhaust system before cleaning. ... -

Page 51: Changing The Filter Pad On The Control Cabinet

Maintenance and Cleaning Changing the filter pad on the control cabinet NOTE Dirty filter pads Overheating and damage to the controls Clean or replace filter pads once per week. Remove both covers on the control cabinet on the the input side and the output side. -

Page 52: Service

Service 7 Service Service intervals The following service work should be performed regularly in the specified intervals. The intervals are shortened corresponding to multiple-shift operation. Service work Interval Clean interior of the machine and dust daily/once per shift collection container every 8 hrs Clean/replace filter pads on the control cabinet weekly... -

Page 53: Service Work

Service Service work 7.2.1 Tightening/replacingV-belts The force of the grinding motors is transferred via the V-belts to the driver rollers of the grinding units. V-belts are correctly tightened, if they can be pushed down by hand with average applied force by one V-belt width. Damaged V-belts must be replaced immediately. -

Page 54: Adjusting The Height Of The Front Sbm-G Grinding Units

Service 7.2.4 Adjusting the height of the front SBM-G grinding units The height of the front SBM-G grinding units 25 and 27 can be adjusted individually using set screws. For this the grinding material removal can divided evenly on the front and back grinding units. Both set screws must each be uniformly adjusted. - Page 55 Service Notes: Grinding machine SBM-XL 1000/1500 G2S2-60...

-

Page 56: Troubleshooting

Troubleshooting 8 Troubleshooting Messages The various operating states of the machine are displayed by messages on the touch screen. Some messages inform about malfunctions on the machine. These are displayed as text displays in the »Error messages« menu. Miscellaneous Error Description Cause Solution... - Page 57 Troubleshooting Sheet thickness Error Description Cause Solution Status Move from the end position 0201 Max. end position sheet End position of sheet thickness thickness reached Move from the end position 0202 Min. end position sheet End position of sheet thickness thickness reached ...

- Page 58 Troubleshooting Rear assembly Check motor protection 0550 Motor overloaded Motor protection G3 Check motor protection 0551 Motor overloaded Speed G3 LOWER G-unit Miscellaneous Error Description Cause Solution Status Move from the end position 0601 End position G reached Max.

- Page 59 Troubleshooting UPPER S-unit Miscellaneous Error Description Cause Solution Status Move from the end position 0801 End position S reached Max. end position S upper Move from the end position 0802 End position S reached Min. end position S upper ...

- Page 60 Troubleshooting LOWER S-unit Miscellaneous Error Description Cause Solution Status Move from the end position 1001 End position S reached Max. end position S lower Move from the end position 1002 End position S reached Min. end position S lower ...

-

Page 61: Customer Service

Troubleshooting Customer service If malfunctions occur which cannot be remedied by the customer themselves, contact the following customer service address: LISSMAC Maschinenbau GmbH Lanzstraße 4 D-88410 Bad Wurzach Phone +49 (0) 7564 / 307 - 0 Fax + 49 (0) 7564 / 307 - 500 E-mail: lissmac@lissmac.com... -

Page 62: Wear Parts And Consumables

Wear parts and consumables 9 Wear parts and consumables SBM-XL 1000 G1S2-60 Grinding machine Order number Wear part 208081 Feed roller 611100 Corrugated roller Ø 12 mm 208096 KU cylinder bushing 208169 Conveyor belt 1000 x 2000 mm 611026 Sheet - Front exhaust 611027 Sheet - Rear exhaust 611028... -

Page 63: Sbm-S Grinding Units

Wear parts and consumables Order number Wear part 611062 V-belt pulley bearing 611063 V-belt pulley tensioning unit 207404 Ball bearing for V-belt pulley tensioning unit 206627 Counter pressure ball bearing SBM-S grinding units Order number Wear part 206033 V-belts (set of 2) 681235 storage 611062... -

Page 64: Transport Belts

Wear parts and consumables Transport belts Control – transport belts Control of infinitely variable speed designed for operation of maximum 3 transport belts (straight). Control is already integrated in the curve transport belts. Technical data Transport belt 1m Transport belt 2 Transport belt 3 m Useful width: 1,000mm/1,500mm... -

Page 65: Taking Out Of Operation And Disposal

Taking out of operation and disposal 10 Taking out of operation and disposal If the machine should be dismantled after the end of its service life, it must be properly disassembled and the individual parts delivered to recycling and disposal. The following parts of the machine contain environmentally hazardous substances: ... -

Page 66: Warranty Conditions

Warranty conditions 11 Warranty conditions The warranty for this machine is 12 months. For the following listed wear parts the warranty only applies if the wear is not caused by operation. Feed and drive elements, such as toothed racks, gears, pinions, spindles, spindle nuts, spindle bearing, cables, chains, chain wheels, belts ... - Page 67 Warranty conditions Grinding machine SBM-XL 1000/1500 G2S2-60...

Need help?

Do you have a question about the SBM-XL 1000 G2S2-60 and is the answer not in the manual?

Questions and answers

How to rise the abrasive belts to replace bottom rollers