Table of Contents

Advertisement

Quick Links

Automating Tomorrow

™

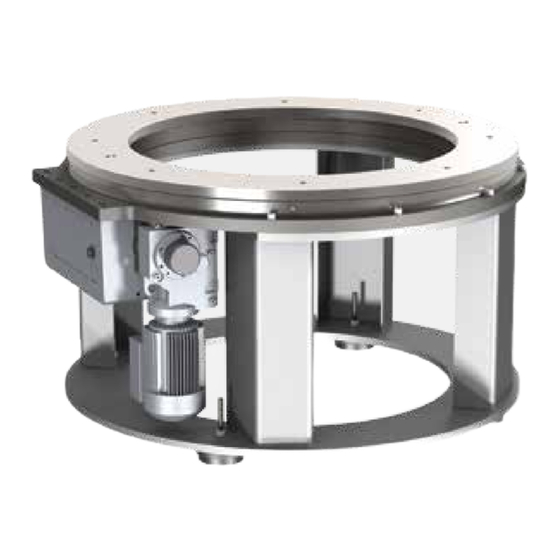

RNG Series

Service Manual

WARNING: This is a controlled document. It is your responsibility to deliver this information to the end user of the

DESTACO CAMCO product. Failure to deliver this could result in your liability for injury to the user or damage to the

machine. For copies of this manual, call your Customer Service Representative at 1-800-645-5207.

destaco.com

Advertisement

Table of Contents

Summary of Contents for Dover DESTACO CAMCO RNG Series

- Page 1 Automating Tomorrow ™ RNG Series Service Manual WARNING: This is a controlled document. It is your responsibility to deliver this information to the end user of the DESTACO CAMCO product. Failure to deliver this could result in your liability for injury to the user or damage to the machine.

- Page 2 RNG Series Service Manual...

-

Page 3: Table Of Contents

RNG Series Service Manual Table of Contents Introduction .......................... 4 Warnings and Cautions ...........................4 Spare Parts Kit ..............................4 Before Starting ..............................4 Required Tools..............................5 IMPORTANT ..............................5 Torque Requirements for Tightening Screws ....................5 Inspection ..........................6 Prepare for Inspection .............................6 Inspection .................................6 Oil Seal Replacement ...................... -

Page 4: Introduction

RNG Series Service Manual Introduction This service manual pertains to the disassembly and assembly of the CAMCO Ring Index Drive models 750RNG, 1100RNG and 1550RNG. This manual is to be used in conjunction with the General Service Manual, which describes the lubrication and general maintenance of CAMCO Index Drives. -

Page 5: Required Tools

RNG Series Service Manual Required Tools Repair of any CAMCO Ring Index Drive requires the following tools: 1. Spanner Wrench #10 2. Socket for M8 FHCS NOTE During some portions of repair, the motor drive package can be used to rotate the input shaft and follower wheel. -

Page 6: Inspection

RNG Series Service Manual Inspection Prepare for Inspection NOTE: Generally, cam followers are replaced as added insurance against later failure. 1. Remove only those structural members When in doubt, replace the cam followers. and fixtures required to gain access to the index drive and to allow for completing the 3. -

Page 7: Oil Seal Replacement

RNG Series Service Manual Oil Seal Replacement DE-STA-CO recommends replacing the Input 2. Check the input shaft for surface nicks, oil seals (Item #11) anytime the input is burrs or a groove from the sealing lip. disassembled regardless of whether they are Look for spiral machine marks that can damaged or not. - Page 8 RNG Series Service Manual larger than the bore size. The bore positions the seal correctly on the should be .005” (.127 mm) larger than shaft. the shaft size, and the face of the tool 9. When an installation tool cannot be should be relieved so that pressure is manufactured, install the seal by tapping applied only near the outside...

-

Page 9: Cam Follower Replacement

RNG Series Service Manual Cam Follower Replacement Cam Follower Removal 4. Remove , the cam follower screw (Item #20) and the heavy washer (Item #16). Instructions for replacing cam followers CAMCO used Red Perma-Lok‚ to secure assume the cam and follower wheel will not these screws If you encounter difficulty be removed. -

Page 10: Cam Follower Installation

RNG Series Service Manual Cam Follower Installation Insert a screw into the bottom of the follower and slide the follower into the The instructions for replacing cam followers tool. While holding the tool against assume the follower wheel and cam were not the face of the wheel, tap the screw removed. -

Page 11: Cam And/Or Input Shaft Replacement

RNG Series Service Manual Cam and/or Input Shaft Replacement Input Shaft Removal Lok‚ to secure the locknuts. If you encounter difficulty, apply heat to the Instructions for removing the cam and input locknut and remove while still warm. shaft assume the follower wheel will not be removed. -

Page 12: Cam Installation

RNG Series Service Manual color and number of shims used 8.2. Record these values with the determines bearing preload. previously recorded values for input shim. 5.3. Remove the input bearing cone (Item #13) on the side of the input shaft Cam Installation with the shortest extension. - Page 13 RNG Series Service Manual 2.2. Use this measurement to adjust the 6. Install a locknut (Item #22) and amount of input shim (Item # 3) used lockwasher (Item #23) on the opposite when installing the new bearings. side of the cam. Inspect and reuse existing locknuts and lockwashers if they 3.

-

Page 14: Setting Cam

RNG Series Service Manual 9.1. Use duplicate shims to those Setting Cam previously removed, but adjust the 1. With a depth micrometer, measure from shims for the measured height of the the face of the dwell rib on one side of the bearings. - Page 15 RNG Series Service Manual 7.3. Use a Spanner Wrench that has been CAUTION locked (jammed) against the side of Do not grind tips excessively. the housing to hold the locknut while CAUTION turning the input shaft. Or you can Tip relief must be evident. If tips are not use a second wrench to lock the properly relieved, the cam followers will hit the locknut while the first wrench is...

-

Page 16: Follower Wheel/Output Bearing Replacement

RNG Series Service Manual Follower Wheel/Output Bearing Replacement Follower Wheel/Output Bearing 1.1. Use a boom crane or hoist to lower the follower wheel onto the base. Removal Align dowel holes in follower 1. Use the motor drive package to position wheel/output bearing (Item #14) with the input shaft keyway such that the cam dowel holes in base plate (Item #8). -

Page 17: Final Assembly

RNG Series Service Manual Final Assembly 1. If removed, reinstall the housing access 5. Re-install the drive package (Item #19) cover (Item #5). according to drive package manual. 1.1. Apply a thin bead of "General Electric Silicone Rubber RTV-6" or equivalent to the housing area where the cover seats. -

Page 18: How To Order Parts

RNG Series Service Manual How to Order Parts Please refer to the parts lists shown in this Service Manual. These parts lists are for standard Index Drives. If you feel your drive is nonstandard or you are in doubt, you should contact DE-STA-CO CAMCO Products Customer Service at (847) 459-5200 and request a Bill of Materials for your specific unit based on its serial number. -

Page 19: 750Rng Parts Drawing

RNG Series Service Manual 750RNG Parts Drawing... -

Page 20: 750Rng Parts List

RNG Series Service Manual 750RNG Parts List Item Number Part Number Description 1 ....... Consult Factory ......CAM 2 ....... Consult Factory ......DIAL RING 3 ....... E7A84828018800 ...... SHIM .002 THK INPUT 1100RNG ......... E7A84828028800 ...... SHIM .005 THK INPUT 1100RNG ......... -

Page 21: 1100Rng & 1550Rng Parts Drawing

RNG Series Service Manual 1100RNG & 1550RNG Parts Drawing... -

Page 22: 1100Rng Parts List

RNG Series Service Manual 1100RNG Parts List Item Number Part Number Description 1 ....... Consult Factory ......CAM 2 ....... E7G84543000000 ...... DIAL RING – STEEL (STANDARD) E7G85086000000 ...... DIAL RING – ALUMINUM (SPECIAL) 3 ....... E7A84828XX0000 ...... SHIM, INPUT 4 ....... -

Page 23: 1550Rng Parts List

RNG Series Service Manual 1550RNG Parts List Item Number Part Number Description 1 ....... Consult Factory ......CAM 2 ....... E8G85069000000 ...... DIAL RING – STEEL (STANDARD) E8G85087000000 ...... DIAL RING – ALUMINUM (SPECIAL) 3 ....... E7A84828XX0000 ...... SHIM, INPUT 4 ....... -

Page 24: Felt Seal Installation

RNG Series Service Manual Felt Seal Installation... - Page 25 RNG Series Service Manual...

- Page 26 Netherlands Auburn Hills, MI USA Red Wing, MN USA France Mt. Juliet, TN USA Germany Wheeling, IL USA China Spain India Thailand Global Locations NORTH AMERICA ASIA Corporate Headquarters Bangkok, Thailand Auburn Hills, Michigan Tel: +66-2-326-0812 Toll Free: 1.888.DESTACO Customer Service: info@destaco.com Marketing: marketing@destaco.com Shanghai, China Global Technology Center...

Need help?

Do you have a question about the DESTACO CAMCO RNG Series and is the answer not in the manual?

Questions and answers