Table of Contents

Advertisement

Quick Links

Smart Solutions. Powerful Products.

Operation Maintenance Manual • Handling Equipment • Rig Floor Equipment

Solid Body Elevator

Copyright © 2017 FORUM ENERGY TECHNOLOGIES, INC. All rights reserved.

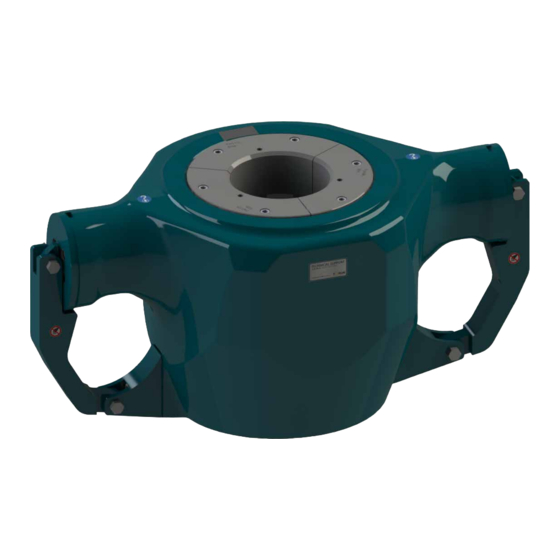

SBE-1250

Fig. 1:

Illustration Example VES-SBE-1250

Operating Instructions

Original Operating Instructions

Solid Body Elevator SBE-1250, VES-SBE-1250

P/N

Type

691250-Z-BC

SBE-1250

691250-Z-VES-1

VES-1-SBE-1250

691250-Z-VES-2

VES-2-SBE-1250

691250-Z-VES-3

VES-3-SBE-1250

Manual PN 691250-Z-BC-D

FORUM Handling Tools

Load Rating

Range

1250

5" - 12.

3 /4

1250

5" - 8.

5 /8

1250

8.

3 /4

" - 9.

5 /8

1250

9.

7 /8

" - 12.

3 /4

Revision: 04, 11-2015

"

"

"

"

Advertisement

Table of Contents

Summary of Contents for Forum SBE-1250

- Page 1 VES-2-SBE-1250 1250 3 /4 ” - 9. 5 /8 ” 691250-Z-VES-3 VES-3-SBE-1250 1250 7 /8 ” - 12. 3 /4 ” Manual PN 691250-Z-BC-D Revision: 04, 11-2015 FORUM Handling Tools Copyright © 2017 FORUM ENERGY TECHNOLOGIES, INC. All rights reserved.

- Page 2 The values specified in this manual represent the nominal value of a unit produced in series. The values in individual units may have slight differences. Only with written consent from FORUM Handling Tools may the contents of this instruction manual be passed on to third persons. Procedure descriptions and explanations are not to be passed on to third persons.Copying or multiplying for internal use is permitted.We are grateful for suggestions and critique regarding this...

-

Page 3: Table Of Contents

5.2.3 SAFETY ecUrIng creWS WIth ock WaSherS raWIng arts reak oWn and pare arts eneral afety reCaUtIons 5.3.1 veS-1-Sbe-1250, veS-2-Sbe-1250, veS-2-Sbe-1250 afety reCaUtIons 5.3.2 Sbe-1250 2.2.1 arnIng IgnS 5.3.3 UShIng SSembly 2.2.2 arnIng and afety IgnS on olId levator 5.3.4... - Page 4 Operation Maintenance Manual INSPECTION / MAINTENANCE UbrICatIon leanIng nspeCtIons 6.3.1 nSpectIon olloWIng rItIcal oadS 6.3.2 nSpectIon olloWIng emoval nspeCtIon ategorIes 6.4.1 nSpectIon ategory 6.4.2 nSpectIon ategory 6.4.3 nSpectIon ategory 6.4.4 nSpectIon ategory 6.4.5 nSpectIon IntervalS Und nSpectIon taSkS olId levator 6.4.6 nSpectIon hecklISt InImUm ImensIons...

-

Page 5: General

This operation manual (hereinafter called OMM) refers to the Solid Body Elevator (hereinafter called SBE-1250 and Improper use of the Solid Body Elevator releases VES-SBE-1250) from FORUM Handling Tools for use on oil FORUM Handling Tools from any liability for drilling platforms and rigs. -

Page 6: Potential Misuse

/or descriptions in this OMM. External effects or force majeure; FORUM Handling Tools is liable for all warranty obligations made within the scope of the contract for any faults or Lubricating the Solid Body Elevator with lubricants other omissions on our part, excluding further claims. -

Page 7: Obligations Of The Operating Company

Operation Maintenance Manual Obligations of the Operating Company Requirements for Operator Basic knowledge of safe handling and use of the Planning and Checking Safety Measures Solid Body Elevator includes knowledge of the general The obligation of the operating company to due diligence safety precautions. -

Page 8: User Groups

Authorizations (according to standards of safety engineering): Starting up SBE-1250. Service personnel Grounding SBE-1250. Marking of SBE-1250. Basic knowledge of installation and operation of the SBE-1250. Special Technical Knowledge The following work should be performed only by specially trained personnel: Work Performed Qualifications Personnel qualified or trained in industrial mechanics;... -

Page 9: Safety Symbols

Operation Maintenance Manual Safety Symbols Preliminary Safety Precautions The safety precautions in this OMM contain standardized Safety precautions are given in the preceding form at the depictions and symbols. Four hazard classes are beginning of complete sections or sections. They apply for distinguished depending on the probability of occurrence the entire section or the entire subsequent section. - Page 10 The illustrations are provided with WEAR PROTECTIVE HELMET! captions in telegraph style. WEAR EAR PROTECTION! Fig. 2: Illustration Example SBE-1250 INFO Additional information and relationships requiring special attention are distinguished in this manner. Solid Body Elevator PN 691250-Z-BC-D - Revision: 04...

-

Page 11: Conformity

Operation Maintenance Manual Conformity The SBE-1250 satisfies all requirements in applicable directives and standards. A sample of the EC Declaration of Conformity is given in the appendix. INFO This OMM is a part of the technical documentation for the Solid Body Elevator. -

Page 12: Online Technical Document Access

A digital version of the OMM as well as the operation instructions, safety- and update notes for other FORUM Handling Tools products can be reached via the blohmvoss-oiltools homepage. To join our Internet Technical Documentation service with the latest updates... -

Page 13: Information Via Extranet

A digital version of the OMM as well as the operation instructions, safety – and update notes for other FORUM Handling Tools products can be reached via the Extranet. To join our Internet Technical Documentation service with the latest updates on new technical... - Page 14 Operation Maintenance Manual [This] page [is] intentionally left blank. Solid Body Elevator PN 691250-Z-BC-D - Revision: 04 11-2015...

-

Page 15: Description

Operation Maintenance Manual DESCRIPTION 07-2018 PN 691250-Z-BC-D - Revision: 04 Solid Body Elevator... -

Page 16: General

3 /4 • Other size upon request. • SBE with fixed bore code. • VES-SBE bushing system for RRT with detachable couplings. • Manufactured according to API 8C PSL2. Main Assembly SBE-1250 and VES-SBE-1250 Fig. 5: SBE-1250 Fig. 6: VES-SBE-1250 Pos. -

Page 17: Main Dimensions

750 / 29.53 1282 / 50.47 900 / 35.43 691250-Z-VES-3 600 / 23.62 750 / 29.53 1282 / 50.47 900 / 35.43 Solid Body Elevator Bushing Type (VES-SBE-1250) Size Components Solid Body Elevator Size 5 /8 " 691253-1-531 7" 691253-1-530 VES-1-SBE-1250 8"... -

Page 18: Bore Codes

Operation Maintenance Manual Bore codes Weight Pipe Size O.D. [kg] [lbs] 691250-Z-223 5'' csg 1606 3541 691250-Z-224 ⁄ '' csg 1600 3527 691250-Z-225 ⁄ " csg 1597 3521 691250-Z-226 6" csg 1594 3514 691250-Z-227 ⁄ " csg 1591 3508 691250-Z-228 ⁄ " csg 1585 3494 691250-Z-229... -

Page 19: Operational Environment

8C and at least include the following information: General Markings according to API 8C • API Stamp (API monogram, spec, license). • Manufacturer’s specifications (FORUM logo). • Production Date (Month / Year). • Part number (marking P/N before the part number). - Page 20 Operation Maintenance Manual [This] page [is] intentionally left blank. Solid Body Elevator PN 691250-Z-BC-D - Revision: 04 07-2018...

-

Page 21: Safety

Operation Maintenance Manual SAFETY 07-2018 PN 691250-Z-BC-D - Revision: 04 Solid Body Elevator... -

Page 22: General Safety Precautions

Operation Maintenance Manual Safety Safety Precautions The safety precautions in this OMM are indicated using SAFETY IS EVERYONES RESPONSIBILITY BUT IT standardized depictions and symbols. Examples of the STARTS WITH YOU! symbols and terms used in this OMM are explained below. The Solid Body Elevator is designed and produced These are used in the form shown wherever possible with consideration of all required safety precautions. -

Page 23: Warning And Safety Signs On Solid Body Elevator

Danger of pinching/ SBE, where slings crushing hands! can be securely fastened. Thus, the safe transport of WARNING Sign Forum Handling Tools “Do Not Touch” equipment is ensured. PN 611524 07-2018 PN 691250-Z-BC-D - Revision: 04 Solid Body Elevator... -

Page 24: S Afety P Recautions For P Rotection Against

Operation Maintenance Manual Safety Precautions for Protection Danger of Pinching/Crushing WARNING against Remaining Hazards The Solid Body Elevator was designed and produced in Danger of pinching/crushing consideration of the safety precautions specified in hands! EC Directive 2006 / 42 / EC on Machinery. Moving parts pose a hazard during The Solid Body Elevator may be used only for: assembly, set-up and conversion work... -

Page 25: Uman E Rror

Operation Maintenance Manual Human Error Organizational Measures Ignorance of hazards, inattentiveness and limited reactions The operating company is responsible for ensuring that can lead to hazard situations while working with the all legally and officially prescribed approvals for operation Solid Body Elevator. of the Solid Body Elevator are present and in compliance with national laws and regulations. - Page 26 Operation Maintenance Manual [This] page [is] intentionally left blank. Solid Body Elevator PN 691250-Z-BC-D - Revision: 04 07-2018...

- Page 27 Operation Maintenance Manual TRANSPORT/ INSTALLATION 07-2018 PN 691250-Z-BC-D - Revision: 04 Solid Body Elevator...

-

Page 28: Transport / Setup

This provides sufficient protection against delivery. In the event of any discrepancies external influences. please contact the FORUM Handling Tools • Secure the Solid Body Elevator to prevent it from representative („X Contact worldwide“ on page Slipping or falling due to motion. - Page 29 • Make Sure all load hooks are fully installed in the lifting point » Thus, the safe transport of FORUM Handling Tools equipment is ensured. INFO Internal transport on site! • It is advised to use pallets for longer component transports.

-

Page 30: Ifting Arrangements

Operation Maintenance Manual Lifting arrangements 3.3.1 Solid Body Elevator Lifting arrangement Hoist the equipment safely Attach the Solid Body Elevator only at the attachment points provided for transport. Only use approbate lifting material with a load carrying capacity suitable to the weight of the elevator / spider. - Page 31 Operation Maintenance Manual Setup Preparation Remove the transport packaging and transport DANGER aids from the Solid Body Elevator and position the Solid Body Elevator on the rig, near the Suspended load! Elevator-Links. The falling load can cause severe, even Procedure lethal injuries. Place the Solid Body Elevator on a plane surface and »...

-

Page 32: Installation Checklist

Installation process. Check at least the above mentioned points on your Solid Body Elevator. For further questions or complete Installation Checklists (templates), please contact the Technical Support from FORUM Handling Tools. Solid Body Elevator PN 691250-Z-BC-D - Revision: 04 07-2018... - Page 33 Operation Maintenance Manual OPERATION 07-2018 PN 691250-Z-BC-D - Revision: 04 Solid Body Elevator...

-

Page 34: Operations

Operation Maintenance Manual OPERATIONS Operation WEAR PROTECTIVE GLOVES! Ensure that the SBE is operated only by personnel trained for this work and familiar with the risks involved in operating the equipment. WEAR SAFETY SHOES! Read these instructions carefully before operating the SBE. WARNING Danger of pinching/crushing WEAR PROTECTIVE HELMET! -

Page 35: Installations Procedure Sbe-1250

Operation Maintenance Manual Installations procedure SBE-1250 Installation Procedure 1. Pick up a RRT or pipe with an external upset. 2. Disassemble the RRT and lower it from the top through the SBE. Fig. 20: Step I 3. Place the load shoulder of the RRT on the top of the SBE, assemble the RRT. -

Page 36: Installations Procedure Ves-Sbe-1250

Operation Maintenance Manual Installations procedure VES-SBE-1250 Installation Procedure 1. Picking up a RRT or pipe with an external upset. 2. Transport the Bushing Assembly by using the ringbolts on the lifting assembly. 3. Unscrew the screws and washers from the lifting plate. - Page 37 Operation Maintenance Manual 6. Transport the bushing segment by using the ringbolt. Place the segment one by one in the Solid Body Elevator. Fig. 25: Step IV Fix and secure the Bushing Assembly when all segments are in place. Fig. 26: Step V 8.

-

Page 38: Installations Procedure Lifting Tool

Operation Maintenance Manual Installations procedure Lifting Tool Installation Procedure 1. Lift the SBE over the Lifting Tool. Fig. 28: Step I 2. Lower the SBE until the SBE is standing on the Lifting Tool frame. 3. SBE is now ready for transport. Fig. -

Page 39: Service

Operation Maintenance Manual SERVICE 07-2018 PN 691250-Z-BC-D - Revision: 04 Solid Body Elevator... -

Page 40: Repair By Customer

(Original Equipment Manufacturer) parts approved by maintenance and servicing of the SBE. Insist FORUM Handling Tools in conformance with the present on using original spare parts when carrying operating instructions. Use of parts not approved by out maintenance and repair work. -

Page 41: D Rawing , P Arts B Reak D Own And S Pare P Arts

The metric grade and make of the bolt can be seen on top of the bolt/nut. Fig. 31: Bolt head marking On FORUM Handling Tools Pipe Handling Equipment the metric grades 8.8, 10.9 and 12.9 are used and the tightening torques can be found in „Third Party Documents“. -

Page 42: Ves-1-Sbe-1250, Ves-2-Sbe-1250, Ves-2-Sbe-1250

Operation Maintenance Manual 5.3.1 VES-1-SBE-1250, VES-2-SBE-1250, VES-2-SBE-1250 Fig. 32: Drawing VES-SBE-1250 Parts list Pos. Qty. Description see table (page 32) Body 688080 Link Block 688082 Link Block Adapter 691252 Link Block Part 2 see table (page 32) Bushing Assembly 645620 Screw 613623-11... - Page 43 Operation Maintenance Manual 5.3.2 SBE-1250 Fig. 33: Drawing SBE-1250 Parts list 691250-Z-BC Qty. Description 691250-1-BF Body 688080 Link Block 688082 Link Block Adapter 691252 Link Block Part 2 645620 Screw 613623-11 Screw 675046 Screw 613556-41 752339 Cotter Pin 645697 Retaining Ring 792108...

-

Page 44: Ushing A Ssembly

Operation Maintenance Manual 5.3.3 Bushing Assembly Fig. 34: Drawing Bushing Assembly Parts list Pos. Qty. Description refer to Page 9 Bushing Assembly 691254 Lifting Assembly 792106 Washer 735324 Screw Solid Body Elevator PN 691250-Z-BC-D - Revision: 04 07-2018... -

Page 45: Ifting A Ssembly

Operation Maintenance Manual 5.3.4 Lifting Assembly Fig. 35: Drawing Lifting Assembly Parts list Pos. Qty. Description 691254-1 Lifting Plate 755402 Ring Screw 07-2018 PN 691250-Z-BC-D - Revision: 04 Solid Body Elevator... -

Page 46: Ifting T Ool

Operation Maintenance Manual 5.3.5 Lifting Tool Fig. 36: Drawing Lifting Tool Parts list Pos. Qty. Description 691260-1 Lifting Tool 613559 Ring Bolt 691260-2-BC Center Ring Borecode Size Center Ring P/N Borecode Size Center Ring P/N BC 223 5'' csg 691260-2-223 BC 241 '' csg 691260-2-241 3 /4... -

Page 47: Spare Parts

Operation Maintenance Manual Spare Parts 5.4.1 691250-RSP Spare Parts List for SBE-1250 (1 year operation) Pos. Qty. Description 645620 Screw 613623-11 Screw 613556-41 752339 Cotter Pin 645697 Retaining Ring 5.4.2 691250-VES-RSP Spare Parts List for VES-SBE-1250 (1 year operation) Pos. Qty. Description... - Page 48 Operation Maintenance Manual [This] page [is] intentionally left blank Solid Body Elevator PN 691250-Z-BC-D - Revision: 04 07-2018...

- Page 49 Operation Maintenance Manual INSPECTION / MAINTENANCE 11-2015 PN 691250-Z-BC-D - Revision: 002 Solid Body Elevator...

- Page 50 In the event of visible damage or excessive to avoid dangerous situations and reduce repair costs and wear contact the Forum B + V Oil Tools Service downtimes. Furthermore, the reliability and the service life Department or an authorized repair company.

- Page 51 SBE. Clean contamination from drilling from the representative. SBE regularly. The SBE should be cleaned thoroughly at the end of each shift at the latest. Forum B + V Oil Tools Lubrication area recommends cleaning the SBE with a high pressure steam Seat for Bushing Assembly (yellow coloured) cleaner.

- Page 52 In the event of cracks, excessive wear, etc. contact Perform an inspection IMMEDIATELY following any critical Forum B + V Oil Tools or an authorized service company. or unexpected loads. Critical loads could be: Loads resulting from shock when the drill pipe wedges.

- Page 53 Operation Maintenance Manual Inspection Categories 6.4.3 Inspection Category III The inspection of category III includes all inspections of 6.4.1 Inspection Category I inspection category II and additional tests. The SBE has to be observed during operation. Recognizing Scope/Prerequisites/Procedure: inadequate performance and apparent defects is the goal Verification of all wear limits.

- Page 54 Operation Maintenance Manual 6.4.6 Inspection Checklist INFO Ensure that maintenance work is The following check list serve as a copy accomplished only by sufficiently templates for inspections to be performed in qualified and trained personnel. compliance with API 8B. Performed inspections must always be documented and stored safely. Serial number: Inspection Category I Date / Place of Inspection:...

- Page 55 Operation Maintenance Manual Minimum Ear Dimensions Fig. 38: SBE front view Dimension "A" Type [mm/inch] SBE-1250 691250-Z-BC 212,5 / 8,37 VES-1-SBE-1250 691250-Z-VES-1 212,5 / 8,37 VES-2-SBE-1250 691250-Z-VES-2 212,5 / 8,37 VES-3-SBE-1250 691250-Z-VES-3 212,5 / 8,37 Critical Areas Fig. 39: Critical Areas 11-2015...

- Page 56 Operation Maintenance Manual [This] page [is] intentionally left blank. Solid Body Elevator PN 691250-Z-BC-D - Revision: 002 11-2015...

- Page 57 Operation Maintenance Manual STORAGE / DISPOSAL 07-2018 PN 691250-Z-BC-D - Revision: 04 Solid Body Elevator...

- Page 58 4. Lubricate the SBE as described in section “Lubrication”. Conserve all bare metal surfaces. FORUM Handling Tools recommends the use of a lubricant or Tectyl. » These surfaces should be checked periodically to be sure that no corrosion has occurred.

- Page 59 Ensure that all service and operating products as well as replacement parts are disposed of safely and ecologically. Please note specifically that FORUM Handling Tools is not obligated to take back used equipment. List of Service Products Used The Safety Data Sheets on the service products used are included in the appendix to OMM.

- Page 60 Operation Maintenance Manual [This] page [is] intentionally left blank Solid Body Elevator PN 691250-Z-BC-D - Revision: 04 07-2018...

- Page 61 Operation Maintenance Manual APPENDIX 07-2018 PN 691250-Z-BC-D - Revision: 04 Solid Body Elevator...

- Page 62 Operation Maintenance Manual Appendix eC d ample of eClaratIon hIrd arty oCUments afety heet omponentS Solid Body Elevator PN 691250-Z-BC-D - Revision: 04 07-2018...

- Page 63 Operation Maintenance Manual Sample of EC Declaration Fig. 43: EC Certificate of Conformity Sample 07-2018 PN 691250-Z-BC-D - Revision: 04 Solid Body Elevator...

- Page 64 Operation Maintenance Manual Third Party Documents Safety Data-Sheet Material Name Link to file [Aerosol] Krylon Paint Aerosols [Aerosol] Rust O Leum Paint Aerosols [Hydraulic Fluid] Aral Vitam GF 32 [Hydraulic Fluid] Citgo AW 68 [Hydraulic Fluid] Conoco Megaflow AW 32 68 [Hydraulic Fluid] Shell Tellus S2 M 32 [Hydraulic Fluid] Shell Tellus S2 M 68 [Hydraulic Fluid] Shell Tellus S2 V 15...

- Page 65 Operation Maintenance Manual Material Name Link to file [Paint] Paint Marking Ink [Paint] Ruthless Paint and Varnish Remover [Paint] Startex Paint Thinner [Paint] Uni Paint Markers [Safety adhesive] Loctite 242 Threadlocker [Safety adhesive] Loctite 262 (High Strength) [Safety adhesive] Loctite 515 Gasket Eliminator [Safety adhesive] Loctite Clover Compound [Safety adhesive] Loctite Silver Grade Anti Seize Components...

- Page 66 Broussard, LA 70518 USA Hermann-Blohm-Strasse 2 1023 Forum Drive fon: +49.40.37022 6855 fon: +1.337.373 1800 fax: +49.40.37022 6 896 fax: +1.337.373 4466 Forum Energy Technologies 920 Memorial City Way, Suite 1000, Houston, TX 77024 © Copyright 2017. All rights reserved...

Need help?

Do you have a question about the SBE-1250 and is the answer not in the manual?

Questions and answers