Subscribe to Our Youtube Channel

Summary of Contents for ITW Dynatec Dyna BFS

- Page 1 Adhesive Application Solutions | ISO 9001 certified Dyna BFS Spray Applicator PN 75.04401.842 Technical Documentation, Rev.9.16 ITW Dynatec An Illinois Tool Works Company www.itwdynatec.com...

-

Page 2: Information About This Manual

Please be sure to include the serial number of your application system each time you order replacement parts and/or supplies. This will enable us to send you the correct items that you need. ITW Dynatec Service Parts and Technical Service: AMERICAS EUROPE, MIDDLE ASIA PACIFIC EAST &... -

Page 3: Table Of Contents

Setting-up operation ........................ 14 2.2 Technical Data ....................15 Dimensions Dyna BFS Spray Applicator ................16 2.3 Description of Dyna BFS Spray Applicator ........... 17 Component classification ......................18 Chapter 3 Installation ............. 19 3.1 Conditions for set-up and mounting .............. 19 3.2 Installation .................... - Page 4 Chapter 7 Drawings & Bills of Materials ......43 Dyna BFS Spray Applicator, PN 75.04401.842 ..............43 ModPlus Spray Module for Dyna BFS complete, PN 75.00000.740 ........46 Optional Spray Nozzle and according Cap Nut ..............46 Chapter 8 Options & Accessories ........47 Hose connections ........................

-

Page 5: Chapter 1 Safety Instructions

2. Do not remove or deface any of the warning labels, signs and caution statements on the equipment. 3. Replace any warning labels, signs and caution statements which have been removed or defaced. Replacements are available from ITW Dynatec. Dyna BFS Applicator, Rev.9.16 Page 5... -

Page 6: Safety Symbols In This Manual

9. Use the unit only as it is intended to. 10. Never let the unit run unattended. 11. Operate the unit only in a faultless and fully functional condition. Check and make sure that all safety devices work in proper form! Page 6 Dyna BFS Applicator, Rev.9.16... -

Page 7: Explosion/ Fire Hazard

1. PUR adhesives emit fumes (MDI and TDI) that can be dangerous to anyone exposed to them. These fumes cannot be detected by the sense of smell. ITW Dynatec strongly recommends that a power‐vented exhaust hood or system be installed over any PUR system. -

Page 8: Electrical

1. Severe burns can occur if unprotected skin comes in contact with molten adhesive or hot application system parts. 2. Face shields (preferred) or safety glasses (for minimum protection), heat-resistant protective gloves and long-sleeved clothing must be worn whenever working with or around adhesive application systems. Page 8 Dyna BFS Applicator, Rev.9.16... -

Page 9: High Pressure

For this reason, always wear eye protection and protective clothing. 4. Either of the two High Pressure symbols shown may be used on ITW Dynatec equipment. 5. Keep the given operating pressure. -

Page 10: Servicing, Maintenance

3. Use only lifting devices that are suitable for the weight and the dimensions of the equipment (see drawing of the equipment). 4. The unit has to be transported upright and horizontally! 5. The unit has to cool down to room temperature before packaged and transported. Page 10 Dyna BFS Applicator, Rev.9.16... -

Page 11: Treatment For Burns From Hot Melt Adhesives

Appropriate extinguishing agents: Foam extinguisher, Dry powder, Spray, Carbon dioxide (CO2), Dry sand. For safety reasons not appropriate extinguishing agents: None. Firefighting - burning electrical equipment: Appropriate extinguishing agents: Carbon dioxide (CO2), Dry powder. Dyna BFS Applicator, Rev.9.16 Page 11... -

Page 12: Keep Attention To Environmental Protection Standards

3. These matters have to be caught, kept, transported and disposed in appropriate reservoirs! 4. Dispose these matters according to the international, national and regional regulations. Page 12 Dyna BFS Applicator, Rev.9.16... -

Page 13: Chapter 2 Description And Technical Specs

If the unit is not used in accordance with this regulation, a safe operation cannot be guaranteed. The operator - and not ITW Dynatec - is liable for all personal injury or property damages resulting from unintended use! Intended use includes, that you •... -

Page 14: Technical Changes

Any kind of technical changes having impact to the security or the operational liability of the system should only be done by written agreement of ITW Dynatec. Suchlike changes made without given a corresponding written agreement will lead to immediate exclusion of liability granted by ITW Dynatec for all direct and indirect subsequent damages. -

Page 15: Technical Data

Heater cartridge Supply block Heater cartridge Air Heater Electrical: Power supply 240V Power consumption, system maximum 360W Temperature sensor 1x, PT 100 Performance: Operating temperature until max. 200°C (392°F) Operating pressure 6 bar (87 psi) Dyna BFS Applicator, Rev.9.16 Page 15... -

Page 16: Dimensions Dyna Bfs Spray Applicator

Description and Technical Specs Dimensions Dyna BFS Spray Applicator Retainer for threaded rod attachment Retainer for attachment diameter 10-14 mm Dimensions in mm. Dyna BFS Spray Applicators are available in following standard configurations (other configurations on request): Page 16 Dyna BFS Applicator, Rev.9.16... -

Page 17: Description Of Dyna Bfs Spray Applicator

The Dyna BFS Spray Applicator is intended for the application of hot-melt adhesives. The adhesive is swirled using air so !hat a spiral coating is attained. Dyna BFS Spray Applicator is available in two widths, with one, two or four application modules. Refer to illustrations on previous page. -

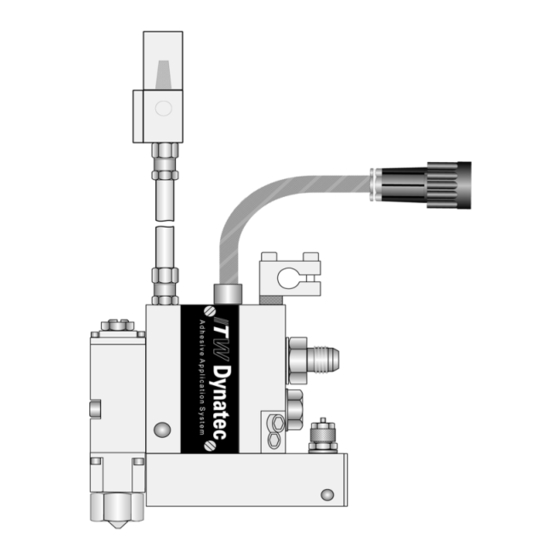

Page 18: Component Classification

Description and Technical Specs Component classification Connector plug to material hose Solenoid valve Retainer Application module Material hose Mod-Plus connection Filter screw plug Spray air connection Cap nut Screw plug of the Nozzle drain hole Page 18 Dyna BFS Applicator, Rev.9.16... -

Page 19: Chapter 3 Installation

ADVICES • Check all screw connections at the unit and retighten if necessary. • Lay the cables and heated hoses so that no risk or least possible risk of stumbling occurs. Dyna BFS Applicator, Rev.9.16 Page 19... -

Page 20: Installation

3. Fasten the hose to the Applicator’s material connection using a wrench. Material hose 4. Connect air hose for spray air at the air heater. connection Spray air connection Page 20 Dyna BFS Applicator, Rev.9.16... - Page 21 7. Screw the air connection into the valve using a G1/8 thread screw. (Use Cu-sealing washers Connection Fastening only). cable entrance screw G 1/8 connection thread 8. Connect the Applicator’s connector plug to the material hose. Dyna BFS Applicator, Rev.9.16 Page 21...

-

Page 22: Installation Variants

4/2 way solenoid valve Material hose Spray air adjustment Separately switched spray air 3/2 way solenoid valve 4/2 way solenoid valve Material hose Adjustable and commonly switched spray air 4/2 way solenoid valve Throttle valve Material hose Page 22 Dyna BFS Applicator, Rev.9.16... -

Page 23: Quality Of Compressed Air

Classification of Quality Classes According to ISO 8573-1: Class 1. Particulate Material 2. Water Content 3. Oil Content max. oil max. particle size max. particle density max. pressure dew point concentration (μm) (mg/m3) (°C) (mg/m3) 0,01 not defined Dyna BFS Applicator, Rev.9.16 Page 23... - Page 24 ITW Dynatec Chapter 3 Installation This page intentionally left blank. Page 24 Dyna BFS Applicator, Rev.9.16...

-

Page 25: Chapter 4 Start-Up, Shutdown

Let yourself and the people working with or working on the unit be introduced to the unit on this occasion. ITW Dynatec takes no responsibility for damages or faults caused by any untrained personnel. - Page 26 • all motors are switched on. Risk of stumbling on cables and heated hoses! Keep your hands away from running parts of the unit (pumps, motors, rolls or others). Page 26 Dyna BFS Applicator, Rev.9.16...

-

Page 27: Start-Up

Adhesive and air will come out of the nozzle. The purging procedure is completed, only when adhesive Manual comes out of the Applicator without any air and bubbles. trigger After purging, the Applicator is ready for operation. Dyna BFS Applicator, Rev.9.16 Page 27... -

Page 28: Shutdown

2. Release adhesive remains from hose and Applicator, which is to be disassembled. 3. Release remaining pressure from the unit. 4. Disconnect power supply lines. 5. Dismount hose from Adhesive Supply Unit and Applicator. 6. Disassemble components into mechanical and electrical assemblies. 7. Dispose of components. Page 28 Dyna BFS Applicator, Rev.9.16... -

Page 29: Chapter 5 Maintenance And Repair Notes

Maintenance and Repair Notes 5.1 Security advices for maintenance and repair Heed all security advices given in Chapter 1. Use only original parts from ITW Dynatec, otherwise ITW Dynatec’s warranty is void! Maintenance and repair work is only permitted for skilled personnel! -

Page 30: Cleaning The Applicator

Before each start of production, purge the Applicator, i.e. let the adhesive flow out until the adhesive is clean and bubble free. Thereafter switch off the adhesive and clean the nozzle from adhesive. Continue production. Page 30 Dyna BFS Applicator, Rev.9.16... -

Page 31: Purging The Filter Element

After finishing the maintenance or repair works: Remove all materials and tools used during the repair or maintenance from the workspace of the unit. Continue production. Stop screw Screw plug Dyna BFS Applicator, Rev.9.16 Page 31... -

Page 32: Replacing The Filter Element

Before each start of production, purge the Applicator, i.e. let the adhesive flow out until the adhesive is clean and bubble free. Thereafter switch off the adhesive and clean the nozzle from adhesive. Continue production. Page 32 Dyna BFS Applicator, Rev.9.16... -

Page 33: Demounting And Cleaning The Nozzle

Before each start of production, purge the Applicator, i.e. let the adhesive flow out until the adhesive is clean and bubble free. Thereafter switch off the adhesive and clean the nozzle from adhesive. Continue production. Dyna BFS Applicator, Rev.9.16 Page 33... -

Page 34: Replacing The Application Module

Before each start of production, purge the Applicator, i.e. let the adhesive flow out until the adhesive is clean and bubble free. Thereafter switch off the adhesive and clean the nozzle from adhesive. Continue production. Page 34 Dyna BFS Applicator, Rev.9.16... -

Page 35: Checking And Replacing The Heater Cartridges And Temperature Sensor

Applicator. In practice, resistance values of 110 - 180 ohms will be measured. Connector plug Impulse only electric head Impulse only electric head Pt 100 Pt 100 Heating Heating Protective conductor See the next sections to replace a heater cartridge or a temperature sensor. Dyna BFS Applicator, Rev.9.16 Page 35... -

Page 36: Resistance Tables, Temperature Sensors

Maintenance and Repair Notes Resistance Tables, Temperature sensors Temperature sensor PT 100 Ohms Temperature sensor Ni 120 Ohms Control option: DCL Control option: NOR Temperature Resistance Temperature Resistance in Ohms in Ohms °F °C °F °C Page 36 Dyna BFS Applicator, Rev.9.16... -

Page 37: Replacing The Heater Cartridge In Supply Block

Before each start of production, purge the Applicator, i.e. let the adhesive flow out until the adhesive is clean and bubble free. Thereafter switch off the adhesive and clean the nozzle from adhesive. Continue production. Dyna BFS Applicator, Rev.9.16 Page 37... -

Page 38: Replacing The Heater Cartridge In Air Heater

Before each start of production, purge the Applicator, i.e. let the adhesive flow out until the adhesive is clean and bubble free. Thereafter switch off the adhesive and clean the nozzle from adhesive. Continue production. Page 38 Dyna BFS Applicator, Rev.9.16... -

Page 39: Replacing The Temperature Sensor

Before each start of production, purge the Applicator, i.e. let the adhesive flow out until the adhesive is clean and bubble free. Thereafter switch off the adhesive and clean the nozzle from adhesive. Continue production. Dyna BFS Applicator, Rev.9.16 Page 39... -

Page 40: Maintenance Plan

5.8 Maintenance plan CAUTION • Heed all security advices given in Chapter 5.1. • Use only original parts from ITW Dynatec, otherwise ITW Dynatec’s warranty is void! • Heed the current safety data sheets when handling the hazardous substances (cleaner, etc.). -

Page 41: Chapter 6 Troubleshooting

Applicator is too hot 1. Temperature setpoint is 1. Check temperature settings too high. and reset if necessary. 2. Temperature sensor 2. Check temperature settings defective. and replace if necessary. 3. Controller defective. 3. Replace controller. Dyna BFS Applicator, Rev.9.16 Page 41... - Page 42 1. Increase temperature. Adhesive amount too high. 1. Nozzle orifice too large. 1. Change nozzle. 2. Temperature too high. 2. Reset temperature. 3. Adhesive pressure too 3. Decrease adhesive pressure high. at the Adhesive Supply Unit. Page 42 Dyna BFS Applicator, Rev.9.16...

-

Page 43: Chapter 7 Drawings & Bills Of Materials

Heater cartridge Ø6,5 x 50 mm, 160W, 220V for air heater 75.00000.116 Cover 00.50308.963 Counter sunk slotted screw M 3 x 8 75.00000.740 ModPlus Spray module for Dyna BFS complete 75.00000.127 Sealing 103733 Cover plate 104128D Heater cartridge Ø12,5x34mm, 200W, 240V 75.00000.002... - Page 44 ITW Dynatec Chapter 7 Drawings & Bills of Materials Throttle 15 17a 11,12,13 Drawing: Dyna BFS Spray Applicator, PN 75.04401.842 Page 44 Dyna BFS Applicator, Rev.9.16...

- Page 45 Chapter 7 ITW Dynatec Drawings & Bills of Materials Dyna BFS Applicator, Rev.9.16 Page 45...

-

Page 46: Modplus Spray Module For Dyna Bfs Complete, Pn 75.00000.740

ITW Dynatec Chapter 7 Drawings & Bills of Materials ModPlus Spray Module for Dyna BFS complete, PN 75.00000.740 Pos. Part Number Description Qty. 06.00447.008 O-ring, -008 Viton 71.00790.104 Cap nut for BFS Module 95.31025.102 Spray nozzle d=0,25 mm, version high-alloyed steel 95.31030.102... -

Page 47: Chapter 8 Options & Accessories

BFS Throttel valve 07.81000.005 Throttle valve GR 1/8 08.00806.103 PTFE Air hose 3/2 way solenoid valve 4/2 way solenoid valve 07.93024.717 3/2 way solenoid valve 24 VDC, 12,7 W Accessories without throttle valve Dyna BFS Applicator, Rev.9.16 Page 47... - Page 48 ITW Dynatec Chapter 8 Options & Accessories This page intentionally left blank. Page 48 Dyna BFS Applicator, Rev.9.16...

-

Page 49: Chapter 9 Recommended Spare Parts

Heater cartridge Ø6,5 x 50 mm, 160W, 220V for air heater 75.00000.740 ModPlus Spray module for Dyna BFS complete 104128D Heater cartridge Ø12,5x34mm, 200W, 240V ModPlus Spray Module for Dyna BFS complete, PN 75.00000.740 Pos. Part Number Description Qty. 06.00447.008 O-ring, -008 Viton 71.00790.104... - Page 50 ITW Dynatec Chapter 9 Recommended Spare Parts This page intentionally left blank. Page 50 Dyna BFS Applicator, Rev.9.16...

-

Page 51: Chapter 9 Schematics

Heating, Head Temperature sensor Ni 120, Head Heating , Head Protective conductor Connections showed from front Euchner plug Connecting plug Heating ���� Heating Temperature sensor Pt100 Temperature sensor Pt100 Protective conductor Connections showed from front Dyna BFS Applicator, Rev.9.16 Page 51... - Page 52 ITW Dynatec Chapter 9 Schematics This page intentionally left blank. Page 52 Dyna BFS Applicator, Rev.9.16...

- Page 53 Chapter 9 ITW Dynatec Schematics This page intentionally left blank. Dyna BFS Applicator, Rev.9.16 Page 53...

- Page 54 ITW Dynatec Chapter 9 Schematics ITW Dynatec Service Parts and Technical Service: AMERICAS EUROPE, MIDDLE ASIA PACIFIC EAST & AFRICA ITW Dynatec ITW Dynatec ITW Dynatec ITW Dynatec 31 Volunteer Drive Industriestrasse 28 Unit2, B1 Building Tsukimura Building 5th Floor...

Need help?

Do you have a question about the Dyna BFS and is the answer not in the manual?

Questions and answers