Summary of Contents for Deger DEGERtracker D60H

- Page 1 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H DEGERtracker D80 DEGERtracker D100...

- Page 2 / publisher. We reserve the right for technical changes. Version: 2017-03-24 Original version in German 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 2...

-

Page 3: Table Of Contents

Concrete foundation ........................16 5.1.4 Creating concrete foundation....................... 17 Assembly of the DEGERtracker ....................... 18 Assembling the base frame ......................19 Assembling the aluminum profiles ....................21 Further preparation .......................... 22 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 3... - Page 4 Declaration of Conformity ........................ 40 14.2 TÜV Certificate ..........................41 Taking the DEGERtracker out of service ..................... 42 15.1 Disassembly............................. 42 15.2 Waste disposal ..........................43 Publisher Information ........................... 44 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 4...

-

Page 5: Abbreviations

EC-6, CCB, MLD sensors, wind monitor, snow sensor OSHA Occupational Safety and Health Administration Power Box (part of control) Personal Protective Equipment Spanner Width (wrench size) Uninterruptible Power Supply 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 5... -

Page 6: General

The snow sensor shall not release from the clearance obligation of the module surface from snow. For the DEGERtracker D60H the max. permissible load is 35 kg/m² (this corresponds with approx. 8 cm wet snow and approx. 15 cm powder snow). -

Page 7: Symbols Used

______________________________________________________________________________________ CAUTION! Low risk endangerment, failure to comply can lead to medium physical injuries. ______________________________________________________________________________________ ATTENTION! Danger of material damage, when failing to comply with this note. ______________________________________________________________________________________ 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 7... -

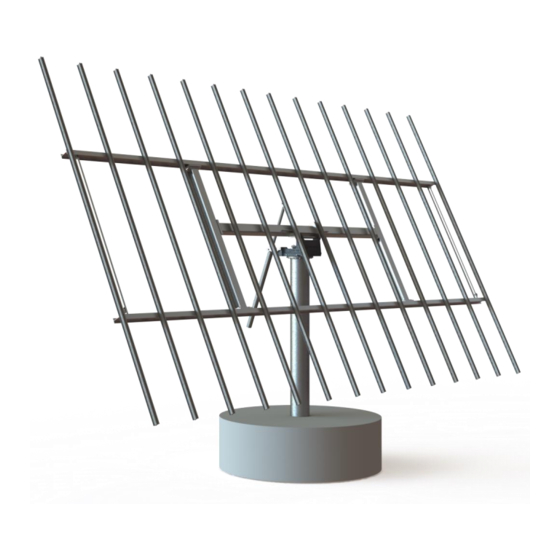

Page 8: Product Description

- When working at heights in excess of 1 m, anti-fall measures and PPE to protect against falling. - Any and all safety equipment and standards to be in compliance with Federal, state, and local codes and OSHA standards 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 8... -

Page 9: Safety Notes

DEGERenergie cannot be held responsible for systems that are not constructed in accordance with the module configuration layout provided by DEGER together with the order confirmation! The total module surface is determined in a location related manner with the DEGER planning tool and must under no circumstances be exceeded. -

Page 10: Scope Of Delivery

Scope of delivery 2.4.1 Scope of delivery of the DEGERtracker 8,9,10 22,23,24 11,12,13 1,2,3 22,23,24 15,16,17 18,19,20 12,14 19,20 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 10... - Page 11 * The article number, the exact quantity and dimensions depend on the size and type of module configuration. ** Depends on the size of system (D60H, D80, D100) Article number, exact quantity and dimensions can be found in the delivery note. 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 11...

-

Page 12: Accompanying Documentation

- Screwdriver for slotted-head bolts 0.8x4x100 - Screwdriver for Phillips head bolts PH1 - Appropriate square timbers or metal structure which can hold a load of 2 tonnes as support 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 12... -

Page 13: Machines To Be Provided By The Customer

0.5 to 1.35 kN/m² depending on terrain topography, mast length, module configuration and wind zone. 2.6.2 Permitted tolerances The horizontal SAFE position (table position) can have a tolerance of ±5°. 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 13... -

Page 14: Unloading And Intermediate Storage

Use a flat surface for intermediate storage. In the case of very soft soil it is highly recommended to place timber beams under the steel parts. Strictly comply with the climatic conditions listed in the chapter "Technical data". 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 14... -

Page 15: Abridged Assembly Instructions For The Degertracker

Mount the rotating head to the mast ______________________________________________________________________________________ Assemble the elevation drive (EMO) Exemplary picture DEGERtracker D100 ______________________________________________________________________________________ Mount the solar modules on the aluminum profiles Exemplary picture DEGERtracker D100 ______________________________________________________________________________________ Assemble the MLD-control 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 15... -

Page 16: Preparations For The Degertracker Assembly

5.1.2 Mast with wall flange The mast with wall flange has been designed for mounting the DEGERtracker D60H to walls which are suitable for this purpose. The confirmation of a structural calculation must be available before assembly work is started. -

Page 17: Creating Concrete Foundation

C25/30 (flow able) and compact the concrete. ATTENTION! Fill up mast base up to the top edge of the foundation. 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 17... -

Page 18: Assembly Of The Degertracker

When assembling the DEGERtracker, sharp edged parts can cause serious hand injuries. Wear safety gloves. DANGER Danger of injury due to improperly performed assembly work! Improperly executed assembly work can lead to severe injuries. 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 18... -

Page 19: Assembling The Base Frame

M16 each to the flange of the central tube. Due to the asymmetric arrangement of holes, the cross-bars cannot be incorrectly mounted to the central tube. Tightening torque: 300 Nm 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 19... - Page 20 Do not tighten too much, since this may distort the frame! The red marked nut is a lock nut. 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 20...

-

Page 21: Assembling The Aluminum Profiles

The solar modules must not be arranged in any other way, than described in the module configuration layout from DEGER. The total module surface is determined with the DEGER planning tool, specifically for the location. Defects caused by failing to comply with the module configuration layout are not covered under warranty. -

Page 22: Further Preparation

2. Apply the sticker "Access for unauthorized persons prohibited!" so that is well visible on the mast at mid- height. 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 22... -

Page 23: Mounting To The Mast

4. Fasten the rotating head by turning 18 bolts M16x75 with one washer each into the mast flange from underneath. 5. Tighten the bolts crosswise to avoid warping of the gearbox! Tightening torque: 200 Nm 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 23... -

Page 24: Assembling The Elevation Drive (Emo)

Then, tighten the bolt again. Locking plate 2. Fasten the EC-6 with two bolts M8x12 and washer M8 to the side of the rotating head. Tightening torque: 19 Nm 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 24... -

Page 25: Assembly Of Modules

Specific fastening materials, which may possibly be prescribed by the module manufacturer, and the necessary information are not part of the scope of delivery from DEGER. The permissible fastening of the modules must be clarified with the module manufacturer beforehand. -

Page 26: Clamping Between Modules

The permissible fastening and the area of fastening of the modules must be comply with the module manufacturer specification. Permitted maximum value for this bolt is 20Nm. DEGERenergie doesn’t assume any responsibility for this value. 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 26... -

Page 27: Preparation To Connect The Mld-Control To The Electrical Installation Of The Customer

The position of the bores in the mast flange has no influence. 2. Fasten the boomerang with the two bolts M5x18. Tightening torque: 6.5 Nm Northern Hemisphere Southern Hemisphere 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 27... -

Page 28: Grounding The System

3. Open the cover on the EC-6 and lay it safely to the side. Connect the cable of the EMO to terminal 1 (strand 2 or blue) and 2 (strand 1 or brown), as described in the assembly instructions “MLD Control EC-6 with CCB”. 4. Close the cover of the EC-6. 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 28... -

Page 29: Overview Of Cable Routing Through The Gearbox Cover Plate

3. Loosely fasten all cables with a cable strap at both bores. 4. Fasten the front gearbox cover again with the two bolts M8x12 and one washer each. Tightening torque: 24 Nm 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 29... -

Page 30: Assembly Of Mld-Sensors

Fasten the mounting bracket of the MLD-sensor to the module frame or the aluminum section with bolt M6x16. 3. Align the MLD-sensor under an angle of 90° to the module MLD-sensor EL edge, as shown. 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 30... -

Page 31: Install Mld Control System

EC-6 with MLD sensors Pin 1, 2, 3, 4 CCB with joystick Optional: sunlight sensor Pin + - 20 Cable: br, bl, bk Wind monitor standard and advanced Optional: Snow Sensor 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 31... -

Page 32: Overview

Overview The illustration shows a view of the rear. 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 32... -

Page 33: Commissioning

2. Alternatively, you may also supply the drives for EL and AZ from a 12 to 26 V battery pack. Change the sense of rotation in the EC-6 as per wiring diagram 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 33... -

Page 34: Declaration Of Obligation On Liability For Material Defects

The German version of this declaration is legally binding. Industriestrasse 70 Translations into other languages serve only for a better comprehension. D - 72160 Horb a.N. www.DEGER.biz ___________________________________ (Hünkar Korkmaz, CEO) 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 34... -

Page 35: Optional Accessories

M8x20 and at the bottom to the plate using hexagon bolt M8x30, nut M8 and washer. Tightening torque: 25 Nm The required tapped bores are already available in the rotating head. 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 35... -

Page 36: Cleaning And Maintenance

After two years, then every five years: Lubricate the gearbox through the internal and external grease nipples. From the factory the system is filled with the DEGER grease. This lubricant cannot be mixed with other lubricants! Elevation drive and central bolt on rotating head must not be greased! ... -

Page 37: Spare Parts

T: +30 210 876 4811 Portugal service.pt@DEGERiberica.com T: +351 934 845 929 Spain service@DEGERiberica.com T: +34 93 480 84 66 Canada service.ca@DEGERenergie.com T: +1 519 925 5427 service.us@DEGERenergie.com 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 37... -

Page 38: Troubleshooting

If it is absolutely essential to conduct a test with a live power supply, then injury to persons or property must be prevented by taking the appropriate steps to rule out such an event occurring. 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 38... -

Page 39: Fault Message

Installer Operator for returning parts: DEGERenergie GmbH & Co. KG Company / Name Service Industriestr. 70 D-72160 Horb a.N. Germany Address Post code/Place Contact > Phone number, e-mail address 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 39... -

Page 40: Appendix

This declaration of conformity will lose its validity, if the product is modified, supplemented or changed in any other way without our explicit consent and/or components not belonging to the range of accessories offered by DEGER, are used and also in case of improper assembly and installation or unintended use. -

Page 41: Tüv Certificate

14.2 TÜV Certificate 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 41... -

Page 42: Taking The Degertracker Out Of Service

Wear hard hat, safety shoes and safety gloves. Disassembly of the DEGERtracker must be carried out in reverse order to the description in the chapter "Assembly". Strict compliance with the listed safety regulations is mandatory. 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 42... -

Page 43: Waste Disposal

Corresponding information is contained in the transport regulations for the product. Should the transport regulations no longer be available, you can request these from DEGERenergie. They are also available for downloading from the website www.DEGER.biz in the dealer section. -

Page 44: Publisher Information

+49 (0) 7451-53914-0 Fax: +49 (0) 7451-53914-10 www.DEGER.biz info@DEGERenergie.com CEO: Hünkar Korkmaz Registered Head Office: Horb a.N. Registrar of Companies: Stuttgart county court HRB 730079 Vat No.: DE 295812054 24.03.2017 ASSEMBLY AND OPERATING MANUAL DEGERtracker D60H, D80, D100 Page 44...

Need help?

Do you have a question about the DEGERtracker D60H and is the answer not in the manual?

Questions and answers