Advertisement

Quick Links

Advertisement

Summary of Contents for EDG C1

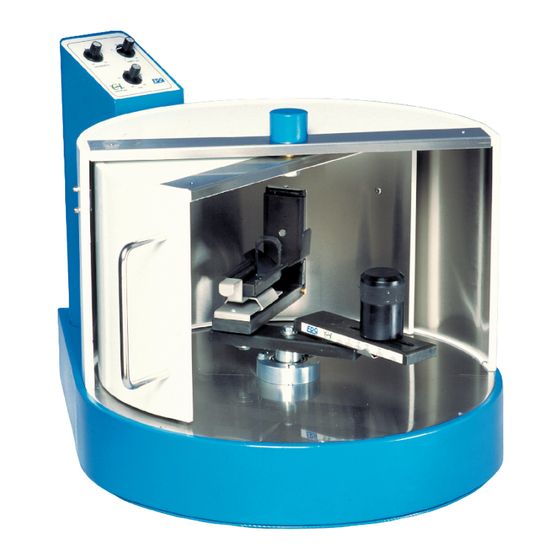

- Page 1 Centrifuge C1...

- Page 2 INSTRUCTION MANUAL EDG EQUIPAMENTOS thanks for your preference. We describe the procedures for the proper installation, operation and utilization of the available resources in your EDG - CI CENTRIFUGE. PRESENTATION The technological advances have provided new materials and revolutionary techniques to the professionals of the prosthesis area, however, the old spring centrifuge continues the same of 100 years ago.

- Page 3 The metal must be injected in the ring the fastest and softest as possible, avoiding chocks and turbulence. In the EDG – C1 Centrifuge this is reached by the set of the articulated arm and the electronical start sensor. Together they smooth the initial movement, allowing that the liquid metal flow fill in the ring cavity without any turbulence, which is a cause of coating erosion.

- Page 4 Casting pressure FIG. 1...

- Page 5 The security is no doubt the most critical item related to casting with spring centrifuge. In the EDG – C1 Centrifuge all the care to keep the security to the user was taken. 1 – The centrifuge only starts after closing the protection.

- Page 6 Operation EDG - C 1 Centrifuge leaves the factory ready to operate with American- type melting pots. If the user prefers the German- type ones, unscrew the screws that fix the melting pot’s rack (1) to its support (12) and substitute it for a German- type rack, which comes with the machine.

- Page 7 adjust in the panel the acceleration key (6) using the criteria established in the table -2 Table -2 ACCELERATION METAL WEIGHT (GR) 0....25 26....45 46...... centrifuging time (7) is the time in which the casting metal must be under pressure until its total solidification.

- Page 8 Counterweight setting (8): the exclusive arm design (2) of the EDG - C1 CENTRIFUGE compensates small balance errors, letting this operation easy and simple to be executed. 4 rings come with the centrifuge having the following sizes: 1x, 3x, 6x, 9x. In the equipment arm there are marks (14) that indicate the counterweight position for each one of the rings above.

- Page 9 The inferior lid of the equipment base can only be opened by authorized people. Problems & solutions The EDG Equipamentos will always be ready to attend you in case your centrifuge needs settings or repair. However, even if the equipment is under warranty, before asking for technical assistance check if the problem doesn’t have a simple solution.

- Page 10 Problem If the lamp lights but the equipment works very slowly or in an irregular way. Causes & solutions Your electrical network tension is below the minimum allowed tension or the equipment is selected in 110 volts and the commuter switch is in the 220 volts position. Check the network tension and the commuting switch.

- Page 11 Problem If the ring tends to get out of the position and the metal is injected out of it Causes & solution The ring is not fitted properly in the melting pot. The melting pot extremity that is adapted to the ring is broken or defective. Technical assistance São Carlos SP - Tel.

- Page 12 Industry: Rua Eduardo Gobato, nº 300 Bairro CEAT CEP: 13.573-440 Caixa Postal - 2096 São Carlos SP Brazil Phone / Fax: 55 (16) 3377-9600 Sales: Phone: 55 (11) 5051 - 5043 edg@edg.com.br www.edg.com.br...

Need help?

Do you have a question about the C1 and is the answer not in the manual?

Questions and answers