Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ESS IPS Belt Cleaner

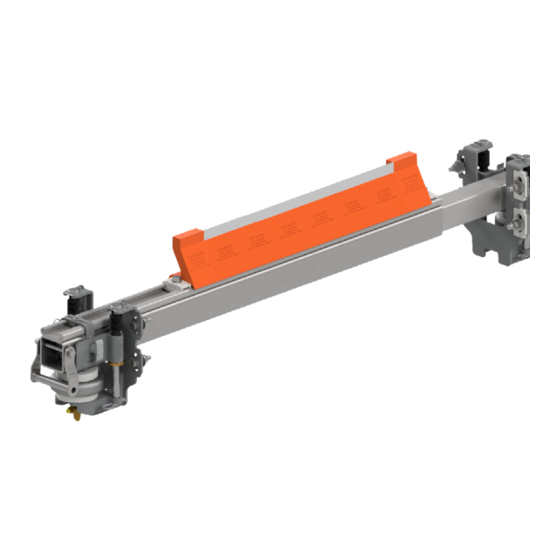

- Page 1 IPS Belt Cleaner Installation and Operation Manual IPS Belt Cleaner 19/11/2021...

- Page 2 Braeside VIC 3195 essvic@esseng.com.au VICTORIA Unit 1 / 20 Doyle Avenue (02) 4272 4422 PO Box 343 WOLLONGONG esswol@esseng.com.au Unanderra NSW 2526 TOLL FREE 1800 074 446 FROM ANYWHERE IN AUSTRALIA VSS TOLL FREE 1800 300 877 IPS Belt Cleaner 19/11/2021...

-

Page 3: Warranty Note

ESS WARRANTS the IPS Cleaner to be free of defects in both materials and workmanship for a period of 12 months from the date of despatch of the product from the ESS factory. The warranty given by ESS in this regard will extend only to replacing or repairing product shown to be defective. - Page 4 OPERATION OF THE AIR TENSIONER SECTION 7 RETROFITTING EXISTING CLEANERS SECTION 8 COMMISSIONING SECTION 9 ROUTINE MAINTENANCE AND SERVICE SECTION 10 TROUBLE SHOOTING SECTION 11 INSTALLATION DRAWINGS SECTION 12 EXPLODED PARTS DRAWINGS SECTION 13 FINAL CHECKLIST IPS Belt Cleaner 19/11/2021...

- Page 5 The IPS Belt Cleaner is designed to be quickly and easily serviced from outside of the conveyor enclosure. When correctly installed, there should be no reason to reach into the chute or enclosure to inspect, adjust or change blades on the cleaner.

-

Page 6: Section 2 - Introduction

SECTION 2 - INTRODUCTION The IPS Belt Cleaner is a conveyor belt secondary cleaner, and is usually used in conjunction with a head pulley primary cleaner such as the ESS XHD, DT or TM DOCTOR BLADE Primary Cleaners. The IPS is normally mounted such that the cleaning blades contact the belt as it leaves the head pulley or other accessible position on the return belt. - Page 7 The ESS IPS Cleaner can be supplied or retrofitted with a variety of cleaning blades. These include: ABR Tool Steel blades – General purpose blade, suitable for mechanically spliced belts. Tungsten Carbide Blades – For very abrasive materials and high speed belts. Also available in Clip Type for mechanically spliced belts.

-

Page 8: Section 3 - Preparation For Installation

Does the belt run true, or track off to one side? Is the Head Pulley out-of-round? Consult ESS if any UNUSUAL conditions are observed in the above. These conditions may result in recommendation of a different installation position or even a different cleaner. -

Page 9: Section 4 - Installation

Note: For installation below pressure rollers mark the vertical line 100 mm from the centreline of the roller. (See figure 2b). This line represents the centre line of the In-Line Cleaner and the cleaner mount brackets. Figure 2a – Installation on horizontal belts IPS Belt Cleaner 19/11/2021... - Page 10 To do this, simply remove the retaining pin in the operator side mount, and slide the blade cartridge from the mainframe. Then remove the retaining pin in the far side mount to remove the mainframe. IPS Belt Cleaner 19/11/2021...

- Page 11 Centre the blades to the belt by loosening and re-positioning the blade locks. Fit the blade cartridge retaining pin. Note: If the cartridge is too long and cannot be installed without hitting the opposite end structure, contact ESS for instruction. IPS Belt Cleaner 19/11/2021...

- Page 12 Connect the other side of the Tee fitting to the incoming regulated compressed air supply from the ESS Air Tensioner Control Box. Connect the plant air supply to the inlet side of the Control Box. Refer to the installation manual for the ESS Control Box for further set-up instructions.

- Page 13 IPS Belt Cleaner 19/11/2021...

- Page 14 Start the conveyor and observe the cleaning action of the blades. Ensure that the blades ride smoothly on the belt with no vibration. ESS offers stronger springs for wider belts or heavy duty applications. These springs are supplied with cleaners for belts 2600 or wider. The tensioner adjustment will differ when these springs are used.

- Page 15 Refer to the Routine Maintenance Section 8. Re-assembly is the reverse of the above procedure. Re-adjust the cleaner as described in Section 5.2. IPS Belt Cleaner 19/11/2021...

- Page 16 Compressed Air ESS Control Box Supply (Range of Models Available) Air Line Passes Air Line to Through Mainframe Cleaner Tee Connection on Connection to Operator side far Side Air Bag Figure 6 – Air Supply Connections IPS Belt Cleaner 19/11/2021...

- Page 17 4, step 8 of this manual, figure 6 above and the ESS Control Box manual. Turn on the air supply and open the lockable ball valve. Open the individual isolation valve for this cleaner in the ESS Control Box to pressurise the tensioner.

- Page 18 Re-assembly is the reverse of the above procedure. Once the blade cartridge has been re- fitted and secured, open the isolation valve in the Control Box to pressurise and automatically adjust the cleaner to the belt. Check that the air pressure is to specification and adjust if necessary. IPS Belt Cleaner 19/11/2021...

- Page 19 20-Ten style mainframes can be retrofitted to the New ESS Inline IPS Mount Brackets. The optional ESS IPS Retrofit Kit can be utilised to install the mounts to an existing 20-Ten mainframe. Utilizing this kit will allow the customer to have the newest IPS Brackets without the expense of purchasing a complete new cleaner.

-

Page 20: Section 8 - Commissioning

Ensure that all blades are contacting the belt evenly. Ensure that there is no marking of the belt surface from the cleaner blades. Refer to the Trouble Shooting section or contact ESS if any problems are observed. -

Page 21: Section 9 - Routine Maintenance And Service

Grasp the handle and pull the blade cartridge off the mainframe and away from the mount bracket. Completely remove the blade cartridge from the mainframe, and place it in a suitable position for maintenance work to be carried out. IPS Belt Cleaner 19/11/2021... - Page 22 Re-tension the cleaner as described in Section 5.2 or 6.2. Step 6. Remove locks or tags and restart belt. Observe cleaner action and blade effectiveness. Replace cover - if fitted. Clean up work area. IPS Belt Cleaner 19/11/2021...

- Page 23 Install an idler roller over the belt near the blade cleaner contact point PROBLEM - Mainframe bent. CAUSE SOLUTION Mainframe undersized Stiffened mainframe required. Contact ESS for assistance Excessive tension Relax blade tension to maximum tension recommended in installation instructions Material build-up...

-

Page 24: Section 11 - Installation Drawings

SECTION 11 - INSTALLATION DRAWINGS IPS Belt Cleaner 19/11/2021... - Page 25 IPS Belt Cleaner 19/11/2021...

-

Page 26: Section 12 - Exploded Parts Drawings

SECTION 12 – EXPLODED PARTS DRAWINGS IPS Belt Cleaner 19/11/2021... - Page 27 IPS Belt Cleaner 19/11/2021...

- Page 28 IPS Belt Cleaner 19/11/2021...

- Page 29 IPS Belt Cleaner 19/11/2021...

- Page 30 IPS Belt Cleaner 19/11/2021...

- Page 31 IPS Belt Cleaner 19/11/2021...

- Page 32 IPS Belt Cleaner 19/11/2021...

-

Page 33: Final Checklist

Site Equipment Number / Location: _____________________ Site Contact: ________________________ Completed By: _____________________________________ (Circle Yes or No Below) 1. Was equipment to ESS Specification? _______________________________ Yes/No Drawing Number Ref: _____________________________________Attached? Yes/No If No, WHY ______________________________________________________________________________ _______________________________________________________________________________________ Will this affect performance? Yes/No...

Need help?

Do you have a question about the IPS Belt Cleaner and is the answer not in the manual?

Questions and answers