Advertisement

DIGITAL TEMPERATURE

ADJUSTMENT SYSTEMS

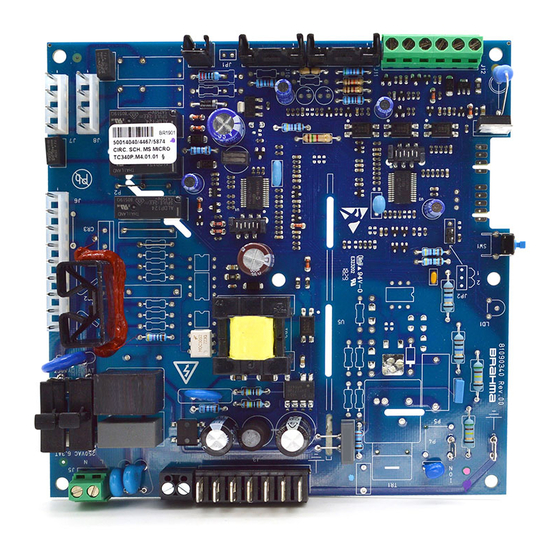

Type TC340

DIGITAL IGNITION AND FLAME CONTROL

SYSTEMS FOR HOT AIR GENERATORS (TYPE

TC340A – TC340P) AND FOR MODULATING

PREMIX BURNERS (TYPE TC340P1)

14698_r00

DESCRIPTION

These systems are specifically designed for safety cycle control

and temperature adjustment in hot air generators equipped with

automatic-ignition fan-assisted gas burners and in modulating

premix burners.

GENERAL FEATURES

The systems are provided with the following important features:

− compliance with EN 298:2003-09 (European standard for

automatic gas burner control and flame monitoring systems);

− CE approval according to Gas Appliance Directive 90/396/EEC

and following amendments (Directive 93/68/EEC);

− suitable for both phase-phase and phase-neutral power supply

systems;

− non-polarized flame signal amplifier (the power supply polarity

may not be respected even in case of a phase-phase power

supply network);

− control of the hot air convector blower (FAN) by means of a

phase-cut driver;

− control of the burner motor by means of a phase-cut driver (for

fan-assisted gas burner appliances) or through a PWM signal

(for premix gas burner appliances equipped with brushless fan

with integrated management electronics);

− two independent safety contacts for driving the EV1 main

solenoid gas valve;

− inbuilt capacitive-discharge ignition transformer (version for fan-

assisted appliances);

− output for the control of an auxiliary electronic ignition

transformer;

− prearranged for the control of the EV2 second valve stage by

means of two independent contacts taking the power supply

from the EV1 first valve stage (version for fan-assisted

appliances);

− burner power modulation by means of a current modulator

(version for fan-assisted appliances) or through a PWM signal

(version for premix appliances);

− possible interfacing with a BRAHMA digital chronothermostat

type ENCRONO GA1 through OpenTherm™ communication

protocol, or with a power-free contact room thermostat;

− possible

interfacing

"cascade"

applications

protocol);

− summer ventilation function (only in connection with BRAHMA

chronothermostat type ENCRONO GA1);

− control of a BRAHMA double NTC temperature probe type

ST16 with outlet air temperature adjustment and safety

functions;

− control of a BRAHMA double NTC temperature probe type

ST08 with outlet air temperature adjustment functions;

− possible control of a safety thermostat;

− prearranged to control a BRAHMA NTC temperature probe

type ST07 with room or outside temperature adjustment

functions;

− possible connection to a fire damper contact (optional);

− possible application in modulating premix burners equipped

with three-point adjuster or adjustment thermostat;

− possible application in appliances provided with 0÷10V

analogue signal adjustment (e.g. PLC);

− on-board manual reset push-button;

− operation status and failure signalling by a two-colour LED;

with additional

TC340 devices for

(OpenTherm™

communication

1/18

Advertisement

Table of Contents

Summary of Contents for BRAHMA TC340

- Page 1 − summer ventilation function (only in connection with BRAHMA chronothermostat type ENCRONO GA1); − control of a BRAHMA double NTC temperature probe type ST16 with outlet air temperature adjustment and safety functions; − control of a BRAHMA double NTC temperature probe type ST08 with outlet air temperature adjustment functions;...

-

Page 2: Technical Data

BRAHMA serial interface type 810 and management software. NOTES This parameter will be described in detail in the “Heating mode (FAN function)” section. It can be modified through BRAHMA serial interface type 810 and management software. If the air pressure switch remains in “no-air-flow” position (fan-assisted versions) or if the burner motor revolutions per minute are insufficient in case a brushless fan is used (premix versions). -

Page 3: Installation Directions

System temperature probes Fire damper (STF) The BRAHMA system type TC340 is provided with several inputs This input (option S) enables to check the status of the fire damper to control different temperature probes used for both temperature contact: in case this contact is open (anomaly condition), the adjustment and safety related functions. - Page 4 - through a BRAHMA chronothermostat type ENCRONO GA1; discharge electrodes. - through a power-free contact with room thermostat function; - through an additional BRAHMA device type TC340 in case of CHECKING AT START-UP cascade systems. Check the control system before the first start-up, after any The control unit starts the ignition cycle by checking the air overhaul and after a long period of non-operation.

- Page 5 Fig. 5 – Types of temperature adjustment Fig. 5 shows the three types of temperature adjustment available in the system. In case an outside temperature probe is used, the TC340 device calculates the percentage of modulation power through the following formula:...

- Page 6 ! ! ! ! IMPORTANT NOTE The summer ventilation function can be activated only if a BRAHMA chronothermostat type ENCRONO GA1 is used. For further details please refer to the data sheets of this device. If this remote adjuster is not available, summer ventilation will have to be managed externally by supplying the FAN hot air blower as described hereunder.

- Page 7 ! ! ! ! IMPORTANT NOTE This parameter can be modified through BRAHMA serial interface type 810 and management software. Once the heat exchanger has been suitably cooled (temperature Outside temperature probe function measured by the SR heating circuit probe lower than the T...

-

Page 8: Resetting The Control Unit

If the control unit goes to non-volatile lockout, to reset the system accomplished. press the reset push-button (mounted on board or on the BRAHMA To better understand this function, please refer to figure 9, chronothermostat type ENCRONO GA1) till the lockout signal representing an example with a control unit having a pre-purge switches off. - Page 9 PART REFERENCES Type TC340 (1) . (2)(3) . (4) . (5) option (6) (7) (8) (9) (10) (11) (12) (13) (14) (15) (16) (17) (18) (19) (20) (21) (22) (23) (24) (25) (26) Type description Type of application device for fan-assisted hot air generators...

- Page 10 No letter: gas valve with 220-240V power supply. Standard mode use of BRAHMA gas valve type VCM01* S [0/P] [0/P] 24VDC (valve with pressure sensor) use of BRAHMA gas valve type VCM01* [0/P] [0/P] 24VDC (valve without pressure sensor) EV2 gas valve (in case of standard EV1 only)

-

Page 11: Wiring Diagrams

WIRING DIAGRAMS The following wiring diagrams refer to the most complete device versions. WIRING DIAGRAM FOR BRAHMA DEVICES type TC340 A .**.**.** RESET 4 3 2 1 4 3 2 1 ACC2 MARRONE NERO FAN2 ACC1 Key to symbols Chronothermostat type ENCRONO GA1... - Page 12 WIRING DIAGRAM FOR BRAHMA DEVICES type TC340 P .**.**.** RESET 4 3 2 1 4 3 2 1 +24V MARRONE NERO ACC1 FAN2 Key to symbols Chronothermostat type ENCRONO GA1 Fire damper Burner motor Room temperature probe (optional) Hot air blower...

- Page 13 WIRING DIAGRAM FOR BRAHMA DEVICES type TC340 A .**.**.** opt. C1 / C2 RESET 4 3 2 1 4 3 2 1 ACC2 SP (Nota 1) MARRONE NERO FAN2 ACC1 Key to symbols Chronothermostat type ENCRONO GA1 Room temperature probe (optional)

- Page 14 WIRING DIAGRAM FOR BRAHMA DEVICES type TC340 P1 .**.**.** opt. G NT NS RESET 4 3 2 1 ACC2 M (Nota 2) +24V IN(+) IN(-) ACC1 Key to symbols Heat demand room thermostat Three-point adjuster Adjustment thermostat / BOOST function...

- Page 15 WIRING DIAGRAM FOR THE CASCADE CONNECTION OF SEVERAL DEVICES THROUGH OpenTherm™ MASTER Nota 1 SLAVE 1 SLAVE 2 SLAVE “n” NOTES The cascade connection is possible also by a contact chronothermostat. This configuration is not used in TC340P1 versions. 14698_r00 15/18...

-

Page 16: Types Of Connection

TYPES OF CONNECTION All connections available in the system are listed below. Reference Description Type of connector Functional earth (flame monitoring) Female fast-on 6.3 mm Flame detection electrode Female fast-on 4.8 mm ACC2 Ignition electrode Female fast-on 2.8 mm Load safety earth connection Female fast-on 6.3 mm (7 pins) Earth connection input 2-pin screw terminal board for cables Ø... - Page 17 OPERATING CYCLE DIAGRAMS TC340(A-P) – Standard operating cycle using BRAHMA chronothermostat type ENCRONO GA1 TC340(A-P) – Standard operating cycle using a contact room thermostat NOTES − the EV2 second valve stage, if available, depending on option no. 23 may be activated in a different moment in comparison to what appears in the diagrams (in these specific cases, option X);...

- Page 18 OPERATING CYCLE DIAGRAMS TC340P1 – Standard operating cycle ATTENTION: Company BRAHMA S.p.A. takes no responsibility for any damage resulting from Customer's tampering with the device. NOTES ABOUT PRODUCT DISPOSAL The device contains electronic components and cannot therefore be disposed of as normal household waste. For the disposal procedure, please refer to the local rules in force for special waste.

Need help?

Do you have a question about the TC340 and is the answer not in the manual?

Questions and answers