Table of Contents

Advertisement

Quick Links

O P E RA TI NG MA NUAL

Gyratory Compactor

MA NUA L CO DE

B041

DO NOT TRY TO OPERATE THIS APPLIANCE BEFORE READING

AND LEARNING THIS MANUAL IN ALL ITS PARTS

USERS: MACHINE MANUFACTURERS / DRAUGHTSMEN / OPERATORS MAINTENANCE / WORKERS

REV.

DESCRIZIONE

REDATTO/GESTITO

APPROVATO

COD. IDENT.

PAGINE

DATA EMIS.

06

Manuale Istruzioni

GN

UTEC

B041.M01.EN

07/2014

48

Advertisement

Table of Contents

Summary of Contents for Matest B041

- Page 1 O P E RA TI NG MA NUAL Gyratory Compactor MA NUA L CO DE B041 DO NOT TRY TO OPERATE THIS APPLIANCE BEFORE READING AND LEARNING THIS MANUAL IN ALL ITS PARTS USERS: MACHINE MANUFACTURERS / DRAUGHTSMEN / OPERATORS MAINTENANCE / WORKERS REV.

- Page 2 Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 2/47 07/2014 GENERAL INDEX Chapter 1 GENERAL INFORMATION Warnings Machine Identification Data EC Stamp WARNING and DANGER indications - SIGNS 1.10 Usage Aim of the Instructions Manual 1.11...

-

Page 3: General Information

Approvato Cod.Ident. Pagine Data Em. 3/47 Manuale Istruzioni UTEC B041.M01.EN 07/2014 Chapter 1 GENERAL INFORMATION 1.01 WARNINGS The manufacturer does not accept any responsibility for direct or indirect damage to people, things or animals and use of the appliance in different conditions from those foreseen. - Page 4 Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 4/47 07/2014 1.06 MODIFICATIONS AND ENCLOSURES OF THE INSTRUCTIONS MANUAL Il This manual reflects the state at the time of the launch of the machine on its market. If any modifications, improvements or adjustments have been made since machine supply the Manufacturer does not have to intervene on the marketed machine and will not consider the machine or the manual deficient or inadequate.

-

Page 5: Transportation And Movement

Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 5/47 07/2014 1.12 STORAGE The appliance must be stored and conserved in the original packaging and in a closed WARNING environment, protected from atmospheric agents with a minimum temperature of -15C° , and a maximum of +60C°... -

Page 6: Rear Panel

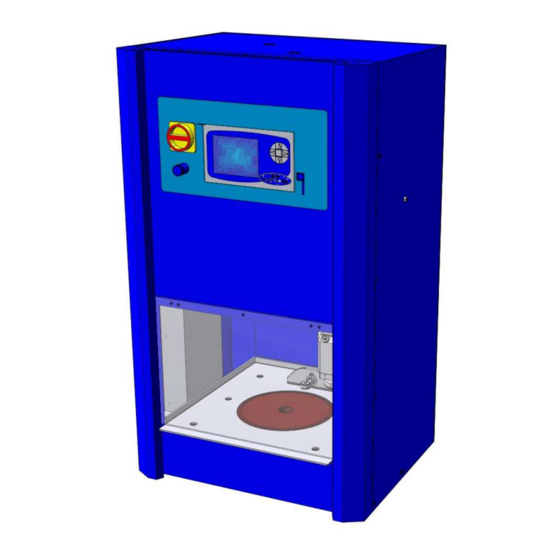

Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. 6/47 Manuale Istruzioni UTEC B041.M01.EN 07/2014 Chapter 2 TECHNICAL CHARACTERISTICS 2.01 GENERAL MACHINE DESCRIPTION This Gyratory Compactor, is used to simulate and reproduce the real compaction conditions under actual road paving operations, hence determining the compaction properties of the asphalt. - Page 7 Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 7/47 07/2014 LAYOUT : Gyratory Compactor + Integrated worktop + Extruder MOLD (accessory required for the execution of the test) MOLD BODY RING OF ARREST BOTTOM There are different types. See for commercial catalogs Fig.

-

Page 8: Main Features

Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 8/47 07/2014 HARDWARE: MAIN FEATURES: • Gyratory angle: adjustable from 0 to 2,4° The main hardware features of the machine’s mother • Gyration rate: adjustable from 5 to 60 work cycles/min board are described as follows. -

Page 9: Protection Devices

Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. 9/47 Manuale Istruzioni UTEC B041.M01.EN 07/2014 Continuous use of the appliance and machines predictably present in the DANGER installation environment could cause a heightened daily personal exposure to noise. Chapter 3 GENERAL SAFETY STANDARDS 3.01... -

Page 10: Installation Instructions

Cod.Ident. Pagine Data Em. 10/47 Manuale Istruzioni UTEC B041.M01.EN 07/2014 closing of the protection door. 3.04 ACTIVE SAFETY DEVICES Active safety devices are the devices or solutions which eliminate or reduce the risks to the operator and require active and conscious intervention by the operator for the preventive action to be carried out. - Page 11 Approvato Cod.Ident. Pagine Data Em. 11/47 Manuale Istruzioni UTEC B041.M01.EN 07/2014 4.05 PNEUMATIC CONNECTION Air Compressor (Optional) Connect the Compactor to compressed air system; the pipe must be connected to the AIR INLET FITTING located at the back of the compactor (pipe outer diameter 10 mm).

- Page 12 Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. 12/47 Manuale Istruzioni UTEC B041.M01.EN 07/2014 5.02 COMMANDS AND SIGNALS The man-machine interface pass EMERGENCY through the LCD TFT QVGA STOP BUTTON (320x240 pixel) touch-screen MAIN SWITCH supported by a keyboard with 5 DISPLAY crosswise keys.All the machine...

- Page 13 Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 13/47 07/2014 MACHINE INTERACTION BUTTONS: All controls on the screens are shown as buttons and can be classified as follows: Conceived for the execution of a machine function; this button 1.

-

Page 14: Text Scroll

Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 14/47 07/2014 It is visualized when a “parameter” button with an alphanumeric text on a grey background has been activated. TEXT SCROLL The below example shows the graphic scroll for the month selection (screen of data and time setting). - Page 15 Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 15/47 07/2014 numeric/alphan umeric value Touch or push the confirmation key to confirm the new value; wait for with the virtual the closure of the virtual keyboard and for the update of the relevant “parameter” button.

-

Page 16: Machine Setup

The first time these operations must be performed by qualified personnel in the presence of the operator in charge. (Standard EN 292-2 art. 5.5 1d) 6.01 REGULATIONS The Matest Gyratory Compactor is calibrated at the factory to perform a set ATTENTION gyration angle (lock position “1B”) and null angle (lock position “1A”). The gyration angle can be changed within a working range acceptable for the machine, adjusting the two dowels and nuts (“2”... - Page 17 Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 17/47 07/2014 It is NECESSARY to perform the following Calibration Checks, respecting the provided deadlines, in order to comply with the instructions of the International ATTENTION Standards in force related to the test (EN 12697-10, EN 12697-31 / ASTM D6925 / AASHTO T312), and to control the possible settlements and run in wear conditions of the machine and its parts: LILT TIME →...

- Page 18 Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 18/47 07/2014 Type 2 If your PISTON has 3 teeth and 3 screws (see photo), fit the piston with the rod, when in lowered position. Then enter the 3 teeth. Once lined,...

-

Page 19: Cleaning And Lubricating

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 19/47 07/2014 2. CLEANING AND LUBRICATING ATTENTION accurate cleaning mould andall parts inside the machine TEST CHAMBER is very important good test execution. Failure to properly clean and... - Page 20 Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 20/47 07/2014 3. SPECIMEN POSITIONING • Insert the lower plate (puck) into the mould (use the extruder to make this operation easier). • Pour the asphalt mixture into the mould.

-

Page 21: Control Panel Menu

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. 21/47 Manuale Istruzioni UTEC B041.M01.EN 07/2014 7.04 REGULATION MAIN MENU The main menu allows the selection of the machine main functions. It has been Thefollowing list includes the icons that represent organized in such a way to visualize a variable number of items depending on the regular functions and does International Standards installed on the machine. -

Page 22: Date And Time

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 22/47 07/2014 DATE AND TIME Parameter Values 1-31 for the following months: January, March, May, July, August, October, Dicember; 1-30 for April, June, September, November; 1-29 for February in case of al leap year;... - Page 23 Approvato Cod.Ident. Pagine Data Em. 23/47 Manuale Istruzioni UTEC B041.M01.EN 07/2014 TOUCH-SCREEN CALIBRATRION The touch-screen calibration screen will be as shown hereinafter: WARNING IMPORTANT: Once the calibration procedure has been activated, it cannot be interrupted and have to be concluded.

-

Page 24: Software Maintenance

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. 24/47 Manuale Istruzioni UTEC B041.M01.EN 07/2014 SOFTWARE MAINTENANCE Device name (“TMNET- Commands xxxxxxxx). Exit to Windows CPU name Execution of the selected Operating system version operation Close the screen Operation Storage device... -

Page 25: System Configuration Menu

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 25/47 07/2014 SYSTEM CONFIGURATION MENU It allows the selection of the “specific” configuration functions of the appliance. The main menu items are as follows: input analog channels output... - Page 26 Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 26/47 07/2014 Parameter Values Type Indicates the type of information read by the analog channel. “Displacement” is selected by default in the gyration angle channel (*) and specimen height channel; “Load” is selected by default in the applied load channel.

- Page 27 Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 27/47 07/2014 When the manual activation To calibrate the analog channels proceed as follows: is started, the machine: • enters immediately the Add the desired number of steps to the calibration table by means of this button.

- Page 28 Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 28/47 07/2014 4. Stop the manual activation by pressing the button key-pad. It is also possible to check the correct calibration of the analog channel using the button Readout zeroing...

- Page 29 Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 29/47 07/2014 1. Increase/decrease the load applied to the standard cell by pressing the buttons when using the key-pad) 2. Stop the manual activation by pressing the button or the button when using the key-pad.

- Page 30 Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 30/47 07/2014 To calibrate the analog channels proceed as follows: 1. Add the desired number of steps to the calibration 3. Set manually the points table by means of the...

-

Page 31: Machine Configuration

Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 31/47 07/2014 When the manual activation The manual activation function must be activated ATTENTION is activated, the machine only by professional and experienced staff, as this will move the piston down... - Page 32 Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 32/47 07/2014 :Initialization :Rotation with load application :Piston rise :Manual activation :Ready (initialization phase is over) :Piston fall :Pause :Rotating phase to find the zero position ALARMS Comandi...

- Page 33 Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. 33/47 Manuale Istruzioni UTEC B041.M01.EN 07/2014 Commands next former print page page to close the screen of the test results printing and storage. 7.05 Switching the appliance on GYRATORY COMPACTION The gyratory compaction can be performed only purchasing the ATTENTION appropriate licence.

- Page 34 Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 34/47 07/2014 analog channel. • Press the button to access the screen on. • Place the mold on the scale Press the button to tare. Pour the material into the mold and wait for the reading to stabilize.

- Page 35 Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 35/47 07/2014 Results Test results screen will be displayed automatically at the end of the compaction phase (numeric visualization). 22. Touch the button alternate numeric visualization with the graphic one, and vice versa.

- Page 36 Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 36/47 07/2014 Example file stored [GRAPH] [DATA] Gyrations Angle [°] Load [kN] Height [mm] Density Test: [Description] [kg/m³] Test type: Giratory compactor test 1.139 10.635 117.130 2415.629 Test date: 1/16/2013 1.134...

- Page 37 Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 37/47 07/2014 7.06 NORMAL STOP The test can be stopped by pressing the buttons. For an emergency stop of the machine, it is necessary to press the emergency button located on the top cover of the digital control unit.

-

Page 38: Maintenance

Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. 38/47 Manuale Istruzioni UTEC B041.M01.EN 07/2014 Chapter 8 MAINTENANCE 8.01 PERIODICAL CHECKS All the operations of maintenance, checking and control must be carried out by personnel professionally qualified and knowledgeable about machine and mechanisms. -

Page 39: Spare Parts

Approvato Cod.Ident. Pagine Data Em. 39/47 Manuale Istruzioni UTEC B041.M01.EN 07/2014 8.03 EXTRAORDINARY MAINTENANCE For extraordinary maintenance operations refer directly to the Manufacturer. 8.04 AUTHORISED MAINTENANCE CENTRES For information on the nearest authorised help centre it is essential to contact the manufacturer. - Page 40 Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. 40/47 Manuale Istruzioni UTEC B041.M01.EN 07/2014 and treatment services for deplete devices that will come back through these recycling sites, according to the local statement PNEUMATIC SYSTEM DIAGRAMS ENCLOSURE Gyratory Compactor Extruder (optional) (optional)

-

Page 41: Wiring Diagrams

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. 41/47 Manuale Istruzioni UTEC B041.M01.EN 07/2014 WIRING DIAGRAMS ENCLOSURE... - Page 42 Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 42/47 07/2014...

- Page 43 Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 43/47 07/2014...

- Page 44 Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. 44/47 Manuale Istruzioni UTEC B041.M01.EN 07/2014 ACCESSORY ENCLOSURE Assembling Integrated worktop /Mechanical automatic specimen extruder...

- Page 45 Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 45/47 07/2014 Assembling Integrated worktop / Machine...

- Page 46 Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em. Manuale Istruzioni UTEC B041.M01.EN 46/47 07/2014...

- Page 47 Check that the lower collar of the mould is well contained between the three contrast pins of the specimen extruder. Do not touch the mould and any part of the DANGER extruder during the extruding phase, to avoid fingers crushing. Vertical force testing device (B041-30) Digital vertical force testing device (B041-31)

Need help?

Do you have a question about the B041 and is the answer not in the manual?

Questions and answers