Summary of Contents for Source VERSA-SLAB

- Page 1 SOURCE VERSA GATE VALVES VERSA-SLAB GATE VALVES API 6A LICENSE API 6D LICENSE LICENSE NO. 6A-0541 LICENSE NO. 6D-0477 Issued 210723...

- Page 2 Versa Slab-LS Gate Valve Brochure Versa Slab-HS Gate Valve Brochure TECHNICAL INFORMATION Valve Reference Dimensions and Weights Recommended Flange Bolt Lengths and Ring Gasket Gate Valve Trim Chart OPERATING AND SERVICE MANUAL Versa-Slab-LS Gate Valve Versa-Slab-HS Gate Valve Versa-Slab High Pressure Gate Valve...

- Page 3 Drilling & Production API 6A Gate Valve VERSA-SLAB -LS GATE VALVE API 6A LICENSE LICENSE NO. 6A-0541 SV-02 R00...

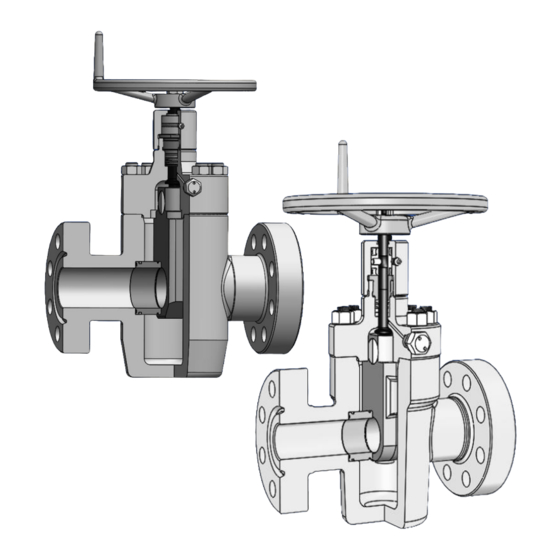

- Page 4 Advantages of the SOURCE Design The VERSA GATE VALVE series offer an economical field proven oilfield valve for the oil & gas industry. A choice of versa-slab and versa-wedge gates is available which are purpose designed to maximize usage of common parts such as the universal valve body and bonnet assembly to afford an overall cost effective valve .

- Page 5 Metal to Metal Seal Seat to Body Seat Metal to Metal Seal Floating Gate and Seat Design Body Source Manufacturing (Shanghai) Co., Ltd 988 Xiang Jing Road, Songjiang District Shanghai 201613, P.R.China Tel: 86 21 57775088 Fax: 86 21 57775068 Email: sales@source-mfg.com...

- Page 6 DRILLING & PRODUCTION API 6A GATE VALVE VERSA-SLAB -HS GATE VALVE API 6A LICENSE LICENSE NO. 6A-0541 SV-01 R00...

- Page 7 GATE VALVE The VERSA GATE VALVE series offer an economical field proven oilfield valve for the oil & gas industry. A choice of versa-slab and versa-wedge gates is available which are purpose designed to maximize usage of common parts such as the universal valve body and bonnet assembly to afford an overall cost effective valve .

- Page 8 Metal to Metal Seal Seat to Body Metal to Metal Seat Seal Floating Gate and Seat Design Body Source Manufacturing (Shanghai) Co., Ltd 988 Xiang Jing Road, Songjiang District Shanghai 201613, P.R.China Tel: 86 21 57775088 Fax: 86 21 57775068 Email: sales@source-mfg.com...

- Page 9 Seat to Body Seat Seat Seal Metal to Metal Seal Floating Gate and Seat Design Body Source Manufacturing (Shanghai) Co., Ltd 988 Xiang Jing Road, Songjiang District Shanghai 201613, P.R.China Tel: 86 21 57775088 Fax: 86 21 57775068 Email: sales@source-mfg.com...

- Page 10 SOURCE VERSA VALVES SLAB GATE VALVE REFERENCE DIMENSIONS AND WEIGHTS Valve Bore Flange Face to Face Bore Centerline to Bottom of Valve Bore Centerline to Handwheel Top Handwheel Diameter Number of Turns to Open/Close WT Estimated Weight Working Nominal Pressure...

- Page 11 SOURCE VERSA VALVES RECOMMENDED FLANGE BOLT LENGTHS & RING GASKET TYPE Recommended Bolt Lengths Stud Nominal Working Ring Gasket Bolt Size and Length Size Pressure (psi) Thread +0.125/−0 2000 5/8-11 UNC 2 1/16 3000-5000 7/8-9 UNC 10000 3/4-10 UNC BX-152...

- Page 12 X. 6.CRA material is not available for temp. Y service. NOTE 7.Source reserves the right to use material class ZZ when customers request Minimum temperature is the lowest ambient temperature to which the equipment can be materials of construction that do not comply with current NACE MR0175/ISO subjected.

- Page 13 Operating & Service Manual OPS-804 Rev.01 VERSA-SLAB -LS GATE VALVE Operating & Service Manual Source Manufacturing (Shanghai) Co., Ltd 988 Xiang Jing Road, Songjiang District Shanghai 201613, P.R.China Tel: 86 21 57775088 Fax: 86 21 57775068 Email: sales@source-mfg.com...

- Page 14 This document contains Source proprietary and confidential information that is legally privileged and is intended only for the person or entity to which it is addressed and any unauthorised use is strictly prohibited.

-

Page 15: Table Of Contents

Table Of Content Section 1 Warnings ..............................1 Section 2 General Operation ..........................2 2.1 General Description ........................... 2 2.2 Operation Specification ........................2 Section 3 Assembly Procedure ........................... 3 3.1 Installing Seat Assembly to Valve Body ..................3 3.2 Installing Bonnet Assembly ......................4 3.3 Install Gate to Bonnet Assembly .................... -

Page 16: Section 1 Warnings

Section 1 Warnings The VERSA-SLAB –LS Gate Valve is a bi-direction non-rising stem manual operated valve incorporating a floating gate and seats design. The gate is connected to the stem through a barrel lift nut in the gate. This arrangement permits the gate to float freely and enhance a pressure assisted seal when acted on by the differential pressure across the gate. -

Page 17: Section 2 General Operation

2.1 General Description –LS Gate Valve means closing member (shutter) movable in the vertical direction of the The VERSA-SLAB channel axis of the valve, the pipe is mainly used as cutting medium effect, i.e., fully open or fully closed use. -

Page 18: Section 3 Assembly Procedure

Section 3 Assembly Procedure 3.1 Installing Seat Assembly to Valve Body Thoroughly clean the internal of valve body. Lightly grease seat and install lip seal on the side of groove towards wave spring end of seat. Coat the seat pockets in the valve body with grease. Carefully press seat assembly evenly into the seat pockets, wave spring facing inside of pocket. -

Page 19: Installing Bonnet Assembly

3.2 Installing Bonnet Assembly CAUTION: The stem bearing assembly must be firmly lock down by the bonnet cap against the packing gland to operate properly. Any slack or clearance in the bearing spacer, bearings due to improper assembly would affect the operating torque as the needle bearings would no longer working effectively. Lightly grease stem and install to bonnet from the bottom. -

Page 20: Installing Bonnet/Gate Assembly To Valve Body

Lightly grease the 2 sealing faces of the gate. 3.4 Installing Bonnet/Gate Assembly to Valve Body Carefully lift bonnet/gate assembly over the valve body and stab the gate in the space between the seats. A seat spreader aid may sometimes be necessary to spread the seats to make it easier for installing the gate. -

Page 21: Lubrication

Orient the bonnet to locate the injection fitting at 90º to the direction of flow for easy access during field lubrication. Make up four nuts in alternate position around the bonnet and operate the valve close and open to verify it is working smoothly. - Page 22 Operating & Service Manual OPS-804 Rev.01...

-

Page 23: Section 4 Regular Field Maintenance

Section 4 Regular Field Maintenance 4.1 Stem Bearing Assembly Lubrication Regular lubrication of the stem bearing assembly is essential to maintain a trouble free and smooth operation of a valve. A good grade of automotive grease is generally used and is injected through the grease zerk located on the bonnet cap with a hand held lubricate. -

Page 24: Field Replacement Of Parts

Replacement of Stem Packing –LS Gate Valve is designed with the stem back seat feature to allow replacement of The VERSA-SLAB stem packing while the valve is in service. The stem back seat can be performed with the valve either in the open or closed position. - Page 25 Back Seat Stem – Valve in Open Position Open valve fully and rotate hand-wheel counterclockwise about 2 turns to allow sufficient clearance for the stem/gate assembly to move up against the bonnet back seat profile when the bonnet cap is back off.

- Page 26 Install new stem packing careful to install them with the expander spring side facing down into the bon- net box. A little oil would help to squeeze the packing down. Replace packing gland. (See Assembly Procedure for more information on assembly) CAUTION: If the replacement of stem packing is perform under line pressure and stem back seat, the task should be carried out in the most efficient and swift manner to minimize exposure time.

-

Page 27: Section 5 Recommended Spare Parts

Section 5 Recommended Spare Parts Two forms of Versa-Slab Gate Valve Repair Kits are available to cater for regular and major refurbishing of used valves. A mini-repair kit is for regular for replacement of all elastomeric parts. An all-renew repair kit is for a complete rebuilt of a valve when it is deemed economical to do so. The all-renew repair kit consists of all the parts in a valve except valve body &... - Page 28 Rev. Date Record of Changes 2014/12/25 Initial Release 2016/05/10 Correct typo error & Re-edit Operating & Service Manual OPS-804 Rev.01...

- Page 29 Operating & Service Manual OPS-801 Rev.06 VERSA-SLAB -HS GATE VALVE Operating & Service Manual Source Manufacturing (Shanghai) Co., Ltd 988 Xiang Jing Road, Songjiang District Shanghai 201613, P.R.China Tel: 86 21 57775088 Fax: 86 21 57775068 Email: sales@source-mfg.com...

- Page 30 This document contains Source proprietary and confidential information that is legally privileged and is intended only for the person or entity to which it is addressed and any unauthorised use is strictly prohibited.

- Page 31 Table Of Content Section 1 Warnings ..............................1 Section 2 General Operation ..........................2 2.1 General Description ........................... 2 2.2 Operation Specification ........................2 Section 3 Assembly Procedure ........................... 3 3.1 Installing Seat Assembly to Valve Body ..................3 3.2 Installing Bonnet Assembly ......................4 3.3 Install Gate to Bonnet Assembly ....................

-

Page 32: Section 1 Warnings

Section 1 Warnings The VERSA-SLAB Gate Valve is a bi-direction non-rising stem manual operated valve incorporating a floating gate and seats design. The gate is connected to the stem through a barrel lift nut in the gate. This arrangement permits the gate to float freely and enhance a pressure assisted seal when acted on by the differential pressure across the gate. -

Page 33: Section 2 General Operation

Section 2 General Operation 2.1 General Description The VERSA-SLAB Gate Valve means closing member (shutter) movable in the vertical direction of the channel axis of the valve, the pipe is mainly used as cutting medium effect, i.e., fully open or fully closed use. -

Page 34: Section 3 Assembly Procedure

Section 3 Assembly Procedure 3.1 Installing Seat Assembly to Valve Body Thoroughly clean the internal of valve body. Lightly grease seat and install lip seal on the side of groove towards wave spring end of seat. Coat the seat pockets in the valve body with grease. Carefully press seat assembly evenly into the seat pockets, wave spring facing inside of pocket. -

Page 35: Installing Bonnet Assembly

3.2 Installing Bonnet Assembly CAUTION: The stem bearing assembly must be firmly lock down by the bonnet cap against the packing gland to operate properly. Any slack or clearance in the bearing spacer, bearings due to improper assembly would affect the operating torque as the needle bearings would no longer working effectively. Lightly grease stem and install to bonnet from the bottom. -

Page 36: Installing Bonnet/Gate Assembly To Valve Body

3.4 Installing Bonnet/Gate Assembly to Valve Body Carefully lift bonnet/gate assembly over the valve body and stab the gate in the space between the seats. A seat spreader aid may sometimes be necessary to spread the seats to make it easier for installing the gate. -

Page 37: Lubrication

Orient the bonnet to locate the injection fitting at 90º to the direction of flow for easy access during field lubrication. Make up four nuts in alternate position around the bonnet and operate the valve close and open to verify it is working smoothly. - Page 38 Assembly Drawing: Operating & Service Manual OPS-801 Rev.06...

-

Page 39: Section 4 Regular Field Maintenance

Section 4 Regular Field Maintenance 4.1 Stem Bearing Assembly Lubrication Regular lubrication of the stem bearing assembly is essential to maintain a trouble free and smooth operation of a valve. A good grade of automotive grease is generally used and is injected through the grease zert located on the bonnet cap with a hand held lubricate. -

Page 40: Field Replacement Of Parts

4.3 Field Replacement of Parts Replacement of Stem Packing The VERSA-SLAB Gate Valve is designed with the stem back seat feature to allow replacement of stem packing while the valve is in service. The stem back seat can be performed with the valve either in the open or closed position. - Page 41 Back Off Bonnet Cap 3 Turns Stem Back Seat to Bonnet Valve Full Open Back Off 2-3 Turns Diagram V a Diagram V b Back Seat Stem – Valve in Open Position Open valve fully and rotate hand-wheel counterclockwise about 2 turns to allow sufficient clearance for the stem/gate assembly to move up against the bonnet back seat profile when the bonnet cap is back off.

- Page 42 Install new stem packing careful to install them with the expander spring side facing down into the bonnet box. A little oil would help to squeeze the packing down. Replace packing gland. (See Assembly Procedure for more information on assembly) CAUTION: If the replacement of stem packing is perform under line pressure and stem back seat, the task should be carried out in the most efficient and swift manner to minimize exposure time.

-

Page 43: Section 5 Recommended Spare Parts

Section 5 Recommended Spare Parts Two forms of Versa-Slab Gate Valve Repair Kits are available to cater for regular and major refurbishing of used valves. A mini-repair kit is for regular for replacement of all elastomeric parts. An all-renew repair kit is for a complete rebuilt of a valve when it is deemed economical to do so. The renew repair kit consists of all the parts in a valve except valve body &... - Page 44 Rev. Date Record of Changes 2009/03/31 Update valve model from Versa-LS to Versa-HS 2015/05/10 Correct typo error & Re-edit 2016/06/06 Update valve size range, add recommended grease type Operating & Service Manual OPS-801 Rev.06...

- Page 45 Operating & Service Manual OPS-814 Rev.00 VERSA-SLAB GATE VALVE High Pressure(10000Psi) Operating & Service Manual Source Manufacturing (Shanghai) Co., Ltd 988 Xiang Jing Road, Songjiang District Shanghai 201611, P.R. China Tel: 86 21 57775088 Fax: 86 21 57775068 Email: sales@source-mfg.com...

- Page 46 This document contains Source proprietary and confidential information that is legally privileged and is intended only for the person or entity to which it is addressed and any unauthorised use is strictly prohibited.

- Page 47 Table of Content SECTION 1 WARNINGS ............................1 SECTION 2 GENERAL OPERATION........................2 ............................. 2 ENERAL ESCRIPTION ..........................2 PERATION PECIFICATION SECTION 3 ASSEMBLY PROCEDURE ....................... 3 ....................3 NSTALLING SSEMBLY TO ALVE ......................4 NSTALL ATE TO ONNET SSEMBLY .................

-

Page 48: Section 1 Warnings

Section 1 Warnings The VERSA-SLAB Gate Valve is a bi-direction non-rising stem manual operated valve incorporating a floating gate and seats design. The gate is connected to the stem through a barrel lift nut in the gate. This arrangement permits the gate to float freely and enhance a pressure assisted seal when acted on by the differential pressure across the gate. -

Page 49: Section 2 General Operation

Section 2 General Operation 2.1 General Description The VERSA-SLAB Gate Valve means closing member movable in the vertical direction of the channel axis of the valve, the pipe is mainly used as cutting medium effect, i.e., fully open or fully closed use. The gate valve is generally not used to throttle flow. -

Page 50: Section 3 Assembly Procedure

Section 3 Assembly Procedure 3.1 Installing Seat Assembly to Valve Body Thoroughly clean the internal of valve body. Lightly grease seat and install seat seal assembly to seat per correct direction as shown in Diagram 1 Coat the seat pockets in the valve body with grease. Carefully fit seat assembly evenly into the seat pocket. -

Page 51: Install Gate To Bonnet Assembly

Install packing gland over stem and make up to bonnet. The packing gland should be sitting butt tight on top of bonnet per Diagram 2 (b). Install bearing assembly and split shoulders (with elastic O-ring) over stem. Rotate stem until stem/bearing assembly sits firmly on top of packing gland per Diagram 2 (c). -

Page 52: Installing Bonnet/Gate Assembly To Valve Body

Insert Lift Nut to Gate Gate Install Gate to Bonnet Assembly Diagram 3 (a) Diagram 3 (b) 3.3 Installing Bonnet/Gate Assembly to Valve Body Carefully lift bonnet/gate assembly over the valve body and stab the gate in the space between the seats per Diagram 4 (a) &... -

Page 53: Lubrication

(Reference API 6A Recommended Bolting Torque). Torque Bonnet Cap Tight (200-300ft/lbs) Install Socket Set Screw Shown Out of Phase 90° Diagram 4 (c) 3.4 Lubrication Fill the valve cavity with lubricant through the injection fitting per Table 1. After removing the grease gun, use a stinger to open the ball-check in the injection fitting to allow excessive grease to bleed off. - Page 54 Operating & Service Manual OPS-814 Rev.00...

-

Page 55: Stem Bearing Assembly Lubrication

Section 4 Regular Field Maintenance 4.1 Stem Bearing Assembly Lubrication Regular lubrication of the stem bearing assembly is essential to maintain a trouble free and smooth operation of a valve. A good grade of automotive grease is generally used and is injected through the grease zerk located on the bonnet cap with a hand held lubricate. -

Page 56: Field Replacement Of Parts

4.3 Field Replacement of Parts Replacement of Stem Packing The VERSA-SLAB Gate Valve is designed with the stem back seat feature to allow replacement of stem packing while the valve is in service. The stem back seat can be performed with the valve either in the open or closed position. - Page 57 Back Off Bonnet Cap 3 Turns Shown Out of Phase 90? Stem Back Seat to Bonnet Use Stinger to Open Ball-Check Valve Full Open, Back Off 2-3 Turns Back Seat Stem – Valve in Open Position Open valve fully and rotate hand-wheel clockwise about 2-3 turns to allow sufficient clearance for the stem/gate assembly to move up against the bonnet back seat profile per Diagram 5 (a).

- Page 58 If the replacement of stem packing is perform under line pressure and stem back seat, the task should be carried out in the most efficient and swift manner to minimize exposure time. Remove stinger cap and reinstall protective cap to bonnet injection fitting. Install bearing assembly and bonnet cap and set screw.

-

Page 59: Section 5 Recommended Spare Parts

Section 5 Recommended Spare Parts An all-renew repair kit is for a complete rebuilt of a valve when it is deemed economical to do so. The all-renew repair kit consists of all the parts in a valve except valve body & bonnet, studs & nuts and hand-wheel. Operating &... -

Page 60: Section 6 Annex

Section 6 Annex Recommended torques extracted from API 6A Rev. Date Record of Changes 2018/02/02 Initial release Operating & Service Manual OPS-814 Rev.00...

Need help?

Do you have a question about the VERSA-SLAB and is the answer not in the manual?

Questions and answers