Summary of Contents for Source VERSA-WEDGE

- Page 1 SOURCE VERSA GATE VALVES VERSA-WEDGE GATE VALVES API 6A LICENSE API 6D LICENSE LICENSE NO. 6A-0541 LICENSE NO. 6D-0477 Issued 210723...

- Page 2 SOURCE VERSA VALVES Table of Content VERSA VALVE FEATURES Expanding Gate Valve(Non-Rising Stem) Brochure Expanding Gate Valve(Rising Stem) Brochure TECHNICAL INFORMATION Valve Reference Dimensions and Weights Recommended Flange Bolt Lengths and Ring Gasket Gate Valve Trim Chart OPERATING AND SERVICE MANUAL...

- Page 3 DRILLING & PRODUCTION GEOTHERMAL WELLHEAD VALVE VERSA-WEDGE GATE VALVE API 6D LICENSE LICENSE NO. 6D-0477 SV-04 R00...

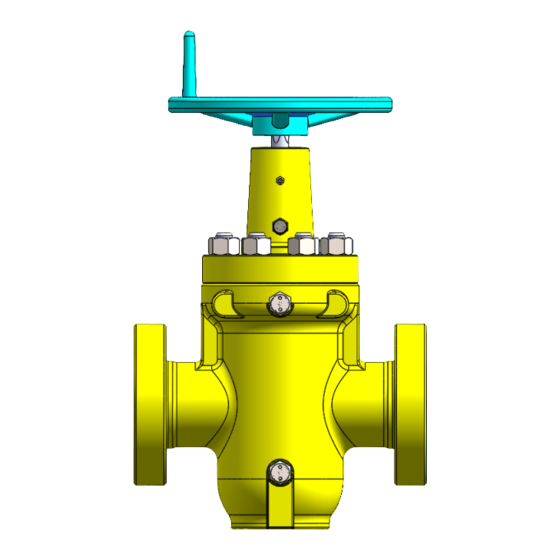

- Page 4 PRODUCTS INTRODUCTION The GEOTHERMAL EXPANDING GATE VALVE is an unidirectional manual operated valve with non-rising or rising stem and parallel expanding gate and segment design. The parallel expanding gate design provides a tight mechanical seal which is normally unaffected by pressure fluctuations or variations.

- Page 5 PRODUCT VIEW AND FUNCTION THREE OPERATION STATUS: Spring Segment Gate Stroking Position: Fully Opened: Fully Closed: When stroking to open or The segment going down is The segment is stopped by closed position, the gate stopped by contact with the contacting with the bonnet and segment is held by bottom body.

- Page 6 Metal to Metal Gate Seal Seat to Gate Assembly Seat Shrink Fit Seat to Body Gate Guide Body Source Manufacturing (Shanghai) Co., Ltd 988 Xiang Jing Road, Songjiang District Shanghai 201613, P.R.China Tel: 86 21 57775088 Fax: 86 21 57775068 Email: sales@source-mfg.com...

- Page 7 DRILLING & PRODUCTION GEOTHERMAL WELLHEAD VALVE VERSA-WEDGE GATE VALVE API 6D LICENSE LICENSE NO. 6D-0477 SV-05 R00...

- Page 8 PRODUCTS INTRODUCTION The GEOTHERMAL EXPANDING GATE VALVE is an unidirectional manual operated valve with non-rising or rising stem and parallel expanding gate and segment design. The parallel expanding gate design provides a tight mechanical seal which is normally unaffected by pressure fluctuations or variations.

- Page 9 PRODUCT VIEW AND FUNCTION THREE OPERATION STATUS: Spring Segment Gate Stroking Position: Fully Closed: Fully Opened: When stroking to open or The segment going down is The segment is stopped by closed position, the gate stopped by contact with the contacting with the bonnet and segment is held by bottom body.

- Page 10 Metal to Metal Assembly Seal Seat to Gate Seat Shrink Fit Seat to Body Gate Guide Body Source Manufacturing (Shanghai) Co., Ltd 988 Xiang Jing Road, Songjiang District Shanghai 201613, P.R.China Tel: 86 21 57775088 Fax: 86 21 57775068 Email: sales@source-mfg.com...

- Page 11 SOURCE VERSA VALVES EXPANDING GATE VALVE REFERENCE DIMENSIONS AND WEIGHTS (NON-RISING STEM) Valve Bore Flange Face to Face Bore Centerline to Bottom of Valve Bore Centerline to Handwheel Top Handwheel Diameter Number of Turns to Open/Close WT Estimated Weight Pressure...

- Page 12 SOURCE VERSA VALVES RECOMMENDED FLANGE BOLT LENGTHS & RING GASKET TYPE Recommended Bolt Lengths Stud Nominal Working Ring Gasket Bolt Size and Length Size Pressure (psi) Thread +0.125/−0 2000 5/8-11 UNC 2 1/16 3000-5000 7/8-9 UNC 10000 3/4-10 UNC BX-152...

- Page 13 X. 6.CRA material is not available for temp. Y service. NOTE 7.Source reserves the right to use material class ZZ when customers request Minimum temperature is the lowest ambient temperature to which the equipment can be materials of construction that do not comply with current NACE MR0175/ISO subjected.

- Page 14 Operating & Service Manual OPS-806 Rev. 02 EXPANDING GATE VALVE Operating & Service Manual Source Manufacturing (Shanghai) Co., Ltd 988 Xiang Jing Road, Songjiang District Shanghai 201611, P.R.China Tel: 86 21 57775088 Fax: 86 21 57775068 Email: sales@source-mfg.com...

- Page 15 This document contains Source proprietary and confidential information that is legally privileged and is intended only for the person or entity to which it is addressed and any unauthorised use is strictly...

-

Page 16: Table Of Contents

Table of Content General Information ..........................1 Installation ............................2 Unpacking ..........................2 Handling ........................... 2 Installation ..........................2 Assembly Drawing ............................2 Operation ............................. 4 Maintenance ............................4 Valve Cavity Lubrication ......................4 Stem Bearing Assembly Lubrication ..................5 Stem Packing Maintenance...................... -

Page 17: General Information

1 General Information The expanding gate valve is a unidirectional non-rising stem manual operated valve incorporating an expanding gate and seats design. The parallel expanding gate design provides a tight mechanical seal which is normally unaffected by pressure fluctuations or variations. The gate assembly uses an wedge face which is collapsed during travel. -

Page 18: Installation

2 Installation 2.1 Unpacking a) The valve is shipped in full open position with flange end protectors installed. This is to preclude debris from falling into valve cavity. b) Remove flange protectors and thoroughly inspect interior of valve and end connections for damage or foreign material. - Page 19 Operating & Service Manual OPS-806 Rev.02...

-

Page 20: Operation

3 Operation Turn the hand-wheel clockwise to CLOSE the valve until it becomes tight. Tighten securely to mechanically energize the seal. DO NOT BACK OFF THE HAND-WHEEL. Turn the hand-wheel counter-clockwise to OPEN the valve until segment is stopped by the bonnet. If necessary, with the valve fully CLOSED, cavity pressure can be relieved through the body vent fitting. -

Page 21: Stem Bearing Assembly Lubrication

this position. Inject grease into the valve cavity through the other body grease fitting. Once completion of lubrication, remove releasing tool and grease pump. Re-install grease fitting caps securely on the both fittings. CAUTION: Lubricating pressure must not exceed the rated working pressure of the valve being lubricated. -

Page 22: Draining

If necessary, repeat injection of the injectable packing until sufficient to eliminate leakage. WARNING: Always face away from the fittings during packing injection. CAUTION: Over pressurizing the injectable packing will distort packing, making the valve difficult to operate. 4.4 Draining Routine draining will reduce damage to valve caused by accumulation of foreign material in the valve body. -

Page 23: Troubleshooting

5 Troubleshooting Trouble Possible Reason Trouble Shooting Tighten the packing gland nuts Stem packing leakage Damage packing on follower plate or inject stem packing Grease fitting leakage Fitting screw loose Tighten the screw Tighten bonnet bolts as Bonnet bolts loose necessary Leakage in bonnet flange Damage to gasket... - Page 24 Operating & Service Manual OPS-811 Rev. 00 EXPANDING GATE VALVE Operating & Service Manual Source Manufacturing (Shanghai) Co., Ltd 988 Xiang Jing Road, Songjiang District Shanghai 201611, P.R.China Tel: 86 21 57775088 Fax: 86 21 57775068 Email: sales@source-mfg.com...

- Page 25 The user is the best judge when applying this procedure base on specific equipment installation and the opera- ting conditions. This document contains Source proprietary and confidential information that is legally privileged and is intended only for the person or entity to which it is addressed and any unauthorised use is strictly...

- Page 26 Table of Content General Information ..........................1 Installation ............................2 Unpacking ..........................2 Handling ........................... 2 Installation ..........................2 Assembly Drawing ............................2 Operation ............................. 4 Maintenance ............................4 Valve Cavity Lubrication ......................4 Stem Bearing Assembly Lubrication ..................5 Stem Packing Maintenance ......................

-

Page 27: General Information

1 General Information The expanding gate valve is a unidirectional rising stem manual operated valve incorporating an expanding gate and seats design. The parallel expanding gate design provides a tight mechanical seal which is normally unaffected by pressure fluctuations or variations. The gate assembly uses an wedge face which is collapsed during travel. -

Page 28: Installation

2 Installation 2.1 Unpacking a) The valve is shipped in full closed position with flange end protectors installed. b) Remove flange protectors and thoroughly inspect interior of valve and end connections for damage or foreign material. 2.2 Handling Proper lifting equipment should be provided to handle the valve. CAUTION: Do not use hand-wheels of the valve to lift the valve. - Page 29 FILENAME: 80840-R00 Operating & Service Manual OPS-811 Rev.00...

-

Page 30: Operation

3 Operation Turn the hand-wheel clockwise to CLOSE the valve until it becomes tight. Tighten securely to mechanically energize the seal. DO NOT BACK OFF THE HAND-WHEEL. Turn the hand-wheel counter-clockwise to OPEN the valve until segment is stopped by the bonnet. If necessary, with the valve fully CLOSED, cavity pressure can be relieved through the body vent fitting. -

Page 31: Stem Bearing Assembly Lubrication

Inject grease into the valve cavity through the other body grease fitting. Once completion of lubrication, remove releasing tool and grease pump. Re-install grease fitting caps securely on the both fittings. CAUTION: Lubricating pressure must not exceed the rated working pressure of the valve being lubricated. -

Page 32: Draining

WARNING: Always face away from the fittings during packing injection. CAUTION: Over pressurizing the injectable packing will distort packing, making the valve difficult to operate. 4.4 Draining Routine draining will reduce damage to valve caused by accumulation of foreign material in the valve body. -

Page 33: Troubleshooting

5 Troubleshooting Trouble Possible Reason Trouble Shooting Tighten the packing gland Stem packing leakage Damage packing nuts on follower plate or inject stem packing Grease fitting leakage Fitting screw loose Tighten the screw Tighten bonnet bolts as Bonnet bolts loose necessary Leakage in bonnet flange Damage to gasket...

Need help?

Do you have a question about the VERSA-WEDGE and is the answer not in the manual?

Questions and answers