Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Buhler 25 Series

-

Page 3: Table Of Contents

Service ... 20 Fluids and Lubricants ... 20 Greasing ... 20 Servicing Intervals... 21 A-Frame Adjustment ... 23 Tine Replacement ... 23 Shear Bolt ... 24 Slip Clutch ... 26 Troubleshooting ... 27 Bolt Torque 25 Series Rotary Tiller PAGE... - Page 4 Tiller Drawings and Parts List... 28 PTO (Shear Pin) Drawing & Parts List ... 33 PTO (Slip Clutch) Drawing & Parts List... 35 Gearbox Drawing & Parts List ... 37 SHIPPING KIT AND BUNDLE NUMBERS ... 38 25 Series Rotary Tiller...

-

Page 5: Warranty

25 Series Rotary Tiller WARRANTY POLICY Buhler Manufacturing products are warranted for a period of twelve (12) months (90 days for commercial application) from original date of purchase, by original purchaser, to be free from defects in material and workmanship under correct, normal agricultural use and proper applications. -

Page 6: Introduction

Buhler Farm King has a collection of rotary tiller models to suit your garden and landscaping needs. The 25 Series Tiller attaches to the 3-point hitch as well as our Cat. 1 Quick Hitch and is designed to fit a variety of tractors from 12 hp to 25 hp. Tilling widths range from 36”... -

Page 7: Safety

This signal word is to be limited to the most extreme situations, typically for machine components that, for functional purposes, cannot be guarded. SAFETY Make these practices a working part of your safety 25 Series Rotary Tiller... -

Page 8: General Safety

Read and understand the Operator’s Manual and all safety signs before operating, servicing, adjusting, repairing, or unplugging the equipment. Do not attempt any unauthorized modifications to your Buhler product as this could affect function or safety, and could affect the life of the equipment. -

Page 9: Service & Maintenance Safety

Carefully, press in place. Slowly peel back the remaining paper and smooth the remaining portion in place. Small air pockets can be pierced with a pin and smoothed out. STORAGE SAFETY SAFETY SIGNS 25 Series Rotary Tiller... - Page 10 25 Series Rotary Tiller SAFETY SIGN LOCATIONS – cont’d. Safety sign “A” Safety sign “B” Safety sign “C” Safety Sign “C” Replace safety signs immediately should they become damaged, torn or illegible. Obtain replacements from your authorized dealer using the part numbers shown.

-

Page 11: Assembly

Lubricate all grease points. B. After operating for 5 hours and 10 hours: Repeat items 1 through 5 of Section A. Then go to the regular service schedule as defined in Section 5. ASSEMBLY START UP MACHINE BREAK-IN 25 Series Rotary Tiller... -

Page 12: Operation

Install and secure all guards, doors and covers before starting. The four socket set screws on the inside of the PTO clutch assembly must be turned out as far as they go to engage the clutch. PRE-OPERATION CHECKLIST 25 Series Rotary Tiller... -

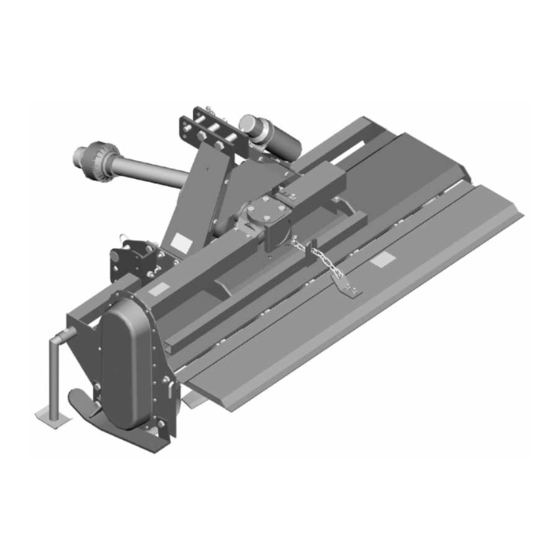

Page 13: Machine Components

OPERATION TO THE NEW OPERATOR OR OWNER The Buhler Farm King 25 Series Rotary Tiller is a machine that combines the primary and secondary tillage operation into one machine. It breaks up the soil and prepares the seed bed in one pass. Rotational power to the rotor is provided by the tractor PTO. -

Page 14: Equipment Matching

Attach the safety chains supplied with the PTO shaft, allowing sufficient slack for the Driveline during turns and operation. Check booklet attached to the PTO for instructions. EQUIPMENT MATCHING Width Horsepower 40 inches (1.0m) 4 feet (1.3m) 5 feet (1.5m) 25 Series Rotary Tiller... -

Page 15: Driveline Dimension

Measure the dimension between the locking groove on the tractor PTO shaft and the groove on the Tiller input shaft. Measure the same dimensions on the compressed driveline. If the driveline dimension exceeds the machine dimension, the driveline will have to be cut. DRIVELINE DIMENSION 25 Series Rotary Tiller... - Page 16 Be sure it telescopes freely before installing. Make sure the plastic covering shield is free to rotate on the shaft before installing on the machine. 25 Series Rotary Tiller...

-

Page 17: Attaching/Unhooking

Attach the anchor chain on the driveline shield to the frame. Use the 3 point hitch to raise the machine. Remove the blocks from under the Depth Gauge Shoes. Reverse the above procedure when unhooking from the tractor. ATTACHING/UNHOOKING 25 Series Rotary Tiller... -

Page 18: Field Operation

Buhler Farm King 25 Series Rotary Tillers are designed with the inherent flexibility of operating well in almost any kind of soil and terrain conditions. However, the operator has the responsibility of being familiar with all operating and safety procedures and following them. - Page 19 The second pass should be made at an angle to the first to give a consistent job and minimize compaction. Always remove heavy crop cover, all grass and weeds, before starting to prevent rotor plugging. FIELD OPERATION - cont'd. 25 Series Rotary Tiller...

- Page 20 Use low gear on the tractor to start the job. Increase the speed of forward travel only as the quality of the job and power available will allow. If the slip clutch slips, reduce the ground speed or raise the machine slightly out of the ground. 25 Series Rotary Tiller...

-

Page 21: Transporting

Speed vs. weight Ratio Weight of fully equipped or loaded implement(s) relative to weight of towing machine 1 to 1, or less (20 mph) 2 to 1, or less (10 mph) More than 2 to 1 25 Series Rotary Tiller... -

Page 22: Storage

If the machine cannot be placed inside, cover with a waterproof tarpaulin and tie securely in place. Store the machine in an area away from human activity. Do not allow children to play on or around the stored machine. 25 Series Rotary Tiller STORAGE... -

Page 23: Theory Of Operation

25 Series Rotary Tiller THEORY OF OPERATIONS... -

Page 24: Maintenance

Wipe grease fitting with a clean cloth before greasing, to avoid injecting dirt and grit. Replace and repair broken fittings immediately. If fittings will not take grease, remove and clean thoroughly. Also clean lubricant passageway. Replace fitting if necessary. MAINTENANCE SERVICE FLUIDS AND LUBRICANTS GREASING 25 Series Rotary Tiller... -

Page 25: Servicing Intervals

80 hours or once a season: 2. Lubricate rotor driven end bearing (1 location) 3. Lubricate rotor drive end bearing (1 location). 4. Lubricate chain drive bearing (1 location) SERVICING INTERVALS use 3 squirts only push grease in gradually 25 Series Rotary Tiller... - Page 26 SERVICING INTERVALS – cont’d. 40 Hours 1. Check gearbox oil level. Add as required 2. Add approximately 10 squirts of grease in chain case. Annually 1. Change gearbox oil. Refill with SAE 85W90 gear oil. 2. Wash machine. 25 Series Rotary Tiller...

-

Page 27: A-Frame Adjustment

Install a new replacement blade and tighten the mounting bolts to their specified torque. Lower the rear gate. Remove the blocks under the skid plates. MAINTENANCE A-FRAME ADJUSTMENT TINE REPLACEMENT 25 Series Rotary Tiller... -

Page 28: Shear Bolt

Be careful not to enlarge the holes. Install the new shear bolt and tighten. (6mm & 40mm, Gr.5) ALERT: Use only genuine Buhler Farm King parts. These shear bolts are specially designed to provide protection for the drive system. Do not install just any bolt. - Page 29 If the clutch is hot to the touch or smokes, check that the outside bolts are correctly tightened as explained in slip clutch section. If clutch still slips, linings may have to be replaced. CLUTCH MAINTENANCE 25 Series Rotary Tiller...

-

Page 30: Slip Clutch

The Buhler Farm King 25 Series Rotary Tiller moves curved Tines on a turning rotor through the ground to break it up and prepare a seed bed. It is a simple and reliable system that requires minimal maintenance. In the following section, we have listed many of the problems, causes and solutions to the problems that you may encounter. - Page 31 25 Series Rotary Tiller BOLT TORQUE...

- Page 32 25 Series Rotary Tiller 40”, 48” & 60” 25 SERIES TILLERS...

- Page 33 25 Series Rotary Tiller...

- Page 34 Always give your dealer the Model, Color and Serial Number of your machine to assist him in ordering and obtaining the correct parts. Use the exploded view and tabular listing of the area of interest to exactly identify the required part. 40'', 48'', & 60'' 25 SERIES TILLERS ITEM PART # 906290...

- Page 35 84277 1/2'' x 1 1/2'' Hex Bolt 812364 1/2'' Lock Nut 81701 3/4'' Lock Washer 84000 3/8'' B.S. Flat Washer 84072 3/8'' x 3/4'' Hex Bolt 812363 3/8'' Lock Nut 812026 5/16'' x 1'' Hex Bolt 25 Series Rotary Tiller...

- Page 36 A-Frame Top Right Hand Weldment 811790 3/4'' x 4 1/2'' Hex Bolt 81700 3/4'' Hex Nut 81568 5/16" Hex Nut 909277 Manual Holder 84048 1/2'' Flat Washer 9812433 1 1/2'' Cotter Pin 982000500 Side Stand Weldment 912301660 Snapper Clip 25 Series Rotary Tiller...

- Page 37 25 Series Rotary Tiller 25 SERIES TILLER PTO (SHEAR PIN)

- Page 38 25 SERIES TILLER PTO PARTS LIST (SHEAR PIN) ITEM PART NO. DESCRIPTION F0357 Shaft Complete 908251 Outer Half Shaft - Tractor 908252 Inner Half Shaft w/Shear - Implement 907290 Yoke RS 920-002 Ser 2 Repair Kit 920-004 Outer Tube Yoke...

- Page 39 25 Series Rotary Tiller 25 SERIES TILLER PTO (SLIP CLUTCH)

- Page 40 25 SERIES TILLER PTO PARTS LIST (SLIP CLUTCH) ITEM PART NO. F0356 908258 936515 907290 920-002 920-004 920-006 936560 936561 930-109 920-003 936503 920-013 936300 936504 936505 936506 920-015 966213 908244 936513 936508 936340 936511 936510 936507 936402 966223 936514...

- Page 41 25 SERIES TILLER GEARBOX 25 SERIES TILLER GEARBOX PARTS LIST ITEM PART NO. DESCRIPTION 912300164 Gearbox Complete 967300 Housing 967301 Hex Shaft 35.2mm Diameter 967302 Cover 110mm Diameter 967303 Snap Ring, E.35, DIN 471/2 967304 Snap Ring, I.72, DIN 472 967305 Snap Ring, I.80, DIN 472...

-

Page 42: Shipping Kit And Bundle Numbers

F0357 Options: The following is a list of options available for the Kits listed above. 902676 Adaptor kit (Cat. 1 to Cat. 0) DESCRIPTION Deck Assembly Deck Assembly Deck Assembly Deck Assembly Deck Assembly Deck Assembly 25 Series Rotary Tiller... - Page 44 (604) 864-2665 AB, Edmonton (780) 962-6991 SK, Regina (306) 781-2300 ON, Woodstock (519) 539-0435 QC, Dorion (450) 455-4840 Buhler Manufacturing 301 Mountain Street S. Morden MB. R6M 1X7 Ph.: (204) 822-4467 Fax: (204) 822-6348 www.buhler.com U.S. WAREHOUSES AR, West Memphis...

Need help?

Do you have a question about the 25 Series and is the answer not in the manual?

Questions and answers