Advertisement

Quick Links

OPERATING INSTRUCTIONS AND OWNER LOG BOOK

SAFETY FIRST

All our locomotives are safe to run, and will give many hours of

pleasure, providing the following safety procedures are followed: -

1.

Please read the instructions thoroughly before running for the

first time.

2.

Always do a complete refill of gas, oil and water. Never refill just

the gas to prolong the run.

3.

Never let the engine run out of water.

4.

When refilling the gas, do not have any naked flame present, and

NO SMOKING!

5.

Do not pick up the engine by the bodywork, chimney or boiler,

especially when hot.

6.

Only pick up the engine by the buffer beams and, when hot, use

old gloves or a cloth.

7.

Do not stand over the chimney. Ejected boiling water or steam

may cause serious injury.

8.

Do not open the smoke box door while the engine is alight.

ACCUCRAFT UK LTD

PO Box 394, Hereford

Herefordshire. HR1 9QN

Tel: 01981 241380

www.accucraft.uk.com

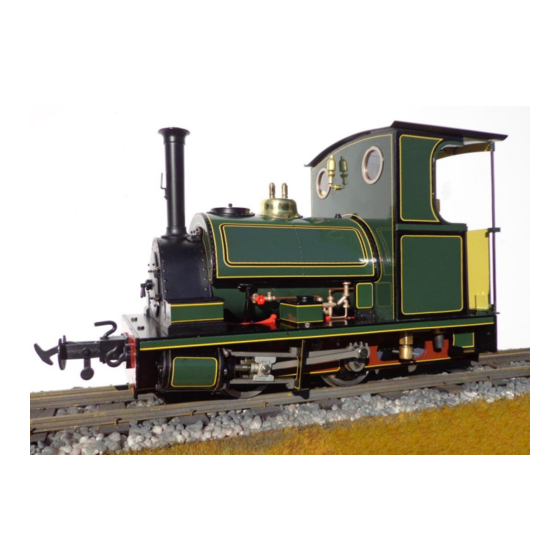

PECKETT 0-4-0ST (1:19 SCALE)

1

Advertisement

Summary of Contents for Accucraft PECKETT 0-4-0ST

- Page 1 Herefordshire. HR1 9QN Tel: 01981 241380 www.accucraft.uk.com OPERATING INSTRUCTIONS AND OWNER LOG BOOK PECKETT 0-4-0ST (1:19 SCALE) SAFETY FIRST All our locomotives are safe to run, and will give many hours of pleasure, providing the following safety procedures are followed: - Please read the instructions thoroughly before running for the first time.

- Page 2 General Hints As with all operating machinery, whether model or full size, wear will occur. In the model steam locomotive much can be done to help prolong its life and decrease the amount of time required in the workshop for servicing. Keep the engine as clean as possible, and the motion free from dirt and garden debris.

- Page 3 The boiler water filler is on the manifold on top of the firebox in the cab. The Goodall valve will allow the boiler to be topped up while in steam. The main steam regulator valve is the handle on the rear of this manifold.

- Page 4 Filling the lubricator: as you will read in the instructions for the end of the run, the lubricator should be left empty of oil and water. Fill up the lubricator with steam oil to about ¼ of an inch below the top.

- Page 5 Running When the engine has raised about 50 psi, you are ready to start running. It is advisable to run the engine in reverse first; it clears the condensed water from the cylinders best this way. Before commencing your first run of the day, it is advisable to put a cloth loosely over the chimney for a few minutes, as condensed water will be ejected from the chimney.

- Page 6 other live steam loco). When the locomotive slows as the pressure falls at the end of a run, stop the engine. If it is the last run of the day, make sure you suck out any remaining condensate. End of Run As previously mentioned, the locomotive will slow (due to pressure dropping) when the fire has gone out.

- Page 7 A Bit of History Peckett & Sons of Bristol had long been renowned for producing industrial tank engines, many of them small saddle tanks, and the ‘Cranmore’ type had its origins in an 0-4-0 saddle tank version of the special 7x10” cylinder design, Works No.1030 of 1904 Gamecock which would be later be referred to as a ‘Cranmore Class’.

- Page 8 DAMAGE WILL BE COVERED BY WARRANTY AS IT IS ATRIBUTED TO OPERATOR ERROR. AT ACCUCRAFT WE GIVE YOU THE ABILITY TO RAISE A GOOD HEAD OF STEAM BUT IT IS UP TO THE OPERATOR TO CONTROL THE GAS FLOW SO THE FIRE DOES NOT ROAR OUT OF CONTROL AND BURN IN THE SMOKE BOX.

- Page 9 This guarantee is quoted in addition to all legal rights of the purchaser under the Sale of Goods Act and shall expire two years from the date of purchase. Under no circumstances shall Accucraft UK Ltd be responsible for any consequential damages arising in regard to any Accucraft UK Ltd product...

- Page 10 Cab Operational Controls: A: Water filler (Goodall valve). F: Water gauge. B: Steam regulator. G: Reverse lever. C: Lubricator. H: Burner jet. D: Gas Filler valve. I: Pressure gauge. E: Gas Control valve. Accessories Illustrated. A. Protective gloves B. Boiler filling syringe C.

Need help?

Do you have a question about the PECKETT 0-4-0ST and is the answer not in the manual?

Questions and answers