Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for PeriBest Pumps T05

-

Page 2: Disclaimer

PeriBest Pumps S.L. provides the information in this manual "as is" and does not take any responsibility and does not give any guarantee on this manual or its content. -

Page 3: Table Of Contents

MANUAL PERIBEST T05 Contents Disclaimer ................................ 2 Contents ................................3 Safety information ............................5 Symbols ................................. 5 Pump use ..............................5 Responsibility ............................... 5 Qualification of the user ..........................6 Regulations and instructions ........................6 Safety instructions ............................7 Warranty conditions ............................9 Description .............................. - Page 4 MANUAL PERIBEST T05 Testing prior to commissioning the pump .................... 16 Maintenance ..............................17 General ................................ 17 Maintenance schedule ..........................17 Cleaning hose ............................. 18 Replacing tube ............................18 Tube unassembled ..........................18 Tube assembled ............................19 Troubleshooting ............................20 Specifications ..............................

-

Page 5: Safety Information

MANUAL PERIBEST T05 Safety information Symbols In this manual the following symbols are used: WARNING Procedures which, if not carried out with the necessary care, may result in serious damage to the hose pump or in serious bodily harm. CAUTION... -

Page 6: Qualification Of The User

MANUAL PERIBEST T05 Immediately contact your PeriBest representative, if you noticed a potential danger while using your hose pump. WARNING The user of the hose pump is always fully responsible for observing the local valid safety regulations and directives. Observe these safety regulations and directives when using the hose pump. -

Page 7: Safety Instructions

MANUAL PERIBEST T05 Safety instructions Live parts · The device must be disconnected from the power supply before it is opened · Isolate damaged faulty or manipulated devices from the mains in order to de-energise. Emergency stop switch An emergency stop switch is to be connected for the entire plant. - Page 8 MANUAL PERIBEST T05 · Do not carry out any maintenance operations or dismantle the pump without first making sure that the pipes are not under pressure and are empty or isolated. · As the peristaltic pump is volumetric and its functioning is positive displacement, it is necessary to prevent a possible overload of pressure, due to for example, the accidental closure of a valve.

-

Page 9: Warranty Conditions

If parts are used that are not PeriBest Pumps S.L. (hereafter called PeriBest) parts, every warranty becomes void. Damaged parts which are covered by the applicable warranty conditions can be returned to the manufacturer. -

Page 10: Description

Identification of the pump PeriBest pumps are identifiable by a smart NFC label located on top of the pump. On the label you can find the serial number, and a NFC device and QR code, that allow to acces to all information about the pump trough a mobile device. -

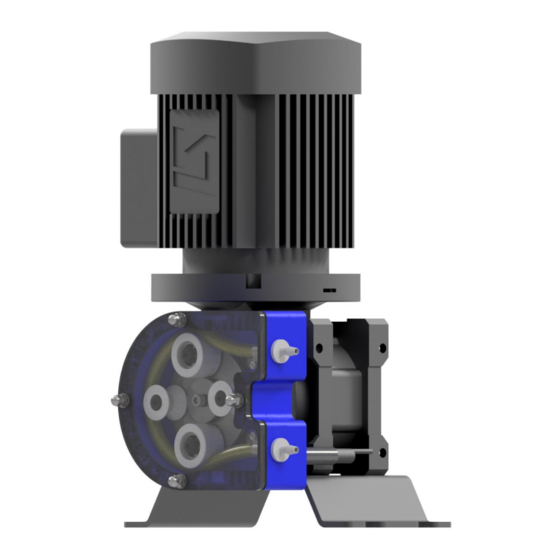

Page 11: Pump Construction

MANUAL PERIBEST T05 Pump construction 1: Cover 2: Rotor 3: Tube 4: Pump housing 5: Base plate 6: Gear reducer 7: Motor 8: Leakage sensor Pump Tubee The pump tube material should be chemically resistant with the product to be pumped. Dependent on the specific requirements of your application a corresponding pump tube must be selected. -

Page 12: Gear Box

The motors supplied are standard IEC motors with B5 flange. Tube leakage sensor Pump T05 includes a tube leakage sensor to protect internal components and avoid leaks and overpressure inside pump casing, that detect a level increase. It is needed to connect the sensor to main electrical installation before starting the pump to avoid potential damages when the tube becomes broken. -

Page 13: Transport, Storage And Elevation

MANUAL PERIBEST T05 Transport, storage and elevation Transport The pump is protected by a wooden box. All packing materials are recyclable. The pump may be transported on storage position with one roller unassembled. Check before operate the pump. Storage The pump should be in a resting position. (One roller is unassembled, and the hose should not be compressed). -

Page 14: Installation

MANUAL PERIBEST T05 Installation Unpacking and Inspection When unpacking carefully follow the instructions as given on the packaging or on the hose pump. Check that your delivery is correct and check it for any transport damage. Report any damage immediately to your PeriBest representative. -

Page 15: Maximum Connection Loads

MANUAL PERIBEST T05 OVERPRESSURE Consider the maximum permissible working pressure on the discharge Side. Exceeding the maximum working pressure may lead to serious damage to the pump. Maximum connection loads Make sure that the maximum forces on the connections are not exceeded:... -

Page 16: Comissioning

MANUAL PERIBEST T05 Comissioning Testing prior to commissioning the pump Ensure that the pump has not been damaged during transportation or storage. Immediately report any damage to the supplier. Check that the mains voltage is suitable for the motor. Ensure that the hose is suitable for the fluid to be conveyed and that it is not damaged. -

Page 17: Maintenance

MANUAL PERIBEST T05 Maintenance General WARNING Disconnect the pump from the mains. You may only carry out work on the pump after it has previously been switched off and disconnected from the mains. In case the motor is fitted with a frequency controller and has a single-phase power supply, wait two minutes to make sure that the capacitors have discharged. -

Page 18: Cleaning Hose

MANUAL PERIBEST T05 Changing lubricant. After every tube replacement, adding grease every 250 working hours. Replacing pressing rollers. Wear on the running surface. Replacing bearings. If necessary. Cleaning hose The inside of the pump hose can be easily cleaned by rinsing the pump with clean water. If a cleaning fluid is added to the water, check if the hose material is resistant to it. -

Page 19: Tube Assembled

MANUAL PERIBEST T05 5. Open the tube clamps (Part 4) that fix the tube on the connections. Once it are opened, move them out of the connection area to the centre of the pump casing. 6. Pull out the tube from the connections (a screwdriver can help to pull out the tube). Repeat this operation in both connections. -

Page 20: Troubleshooting

MANUAL PERIBEST T05 Troubleshooting Problem Possible cause Solution Pump tube has no lubricant Lubricate pump tube Increased pump Increased product temperature Reduce product temperature temperature Insufficient poor suction Check suction line for blockages conditions Pump speed too high Reduce pump speed... - Page 21 MANUAL PERIBEST T05 lifetime High pump speed Reduce pump speed the tubes High conveying temperature Reduce product temperature High operating pressure Reduce operating pressure Pump cavitation Check the suction conditions Abnormal elevation Check rollers shaft mounting temperature Unsuitable lubricant Use original lubricant...

-

Page 22: Specifications

MANUAL PERIBEST T05 Specifications Max capacity (l/h) Capacity per revolution (l/rev) 0,0042 Max. working pressure (kPa) Permissible ambient Tª (ºC) -20 a 45 Permissible product Tª (ºC) -10 a 80 Sound level at 1m (dB(A)) < 60 22 | 25... -

Page 23: Spare Parts

MANUAL PERIBEST T05 Spare parts 23 | 25... - Page 24 T05A100000 Base plate painted steel PeriBest T05 Acero pintado T05A101000 Base plate S.S. PeriBest T05 AISI-304 T05A110000 Tube Industrial Santoprene (2 bar) PeriBest T05 Santoprene T05A111000 Tube PVC (4 bar) PeriBest T05 PVC modificado T05A112000 Tube TP (4 bar)PeriBest T05 Termoplástico...

-

Page 25: Ec Declaration

Via Alemanya 11 1A – 07003 Palma de Mallorca (SPAIN) Company responsible for manufacturing and commercializing the below specified machine: PERISTALTIC PUMP Industrial range models: T05 Declare under our sole responsibility: Its conformity in accordance with all applicable provisions of the Machinery Directive (2006/42/EC), Low Voltage...

Need help?

Do you have a question about the T05 and is the answer not in the manual?

Questions and answers