Summary of Contents for Lonza ARCH CCH A300N

- Page 1 CCH Feeder: Operator’s Manual Model #A300N rev.7 (3/23/16) Arch Chemicals, Inc. 1200 Lower River Road, P.O. Box 800 Charleston, TN 37310-0800...

-

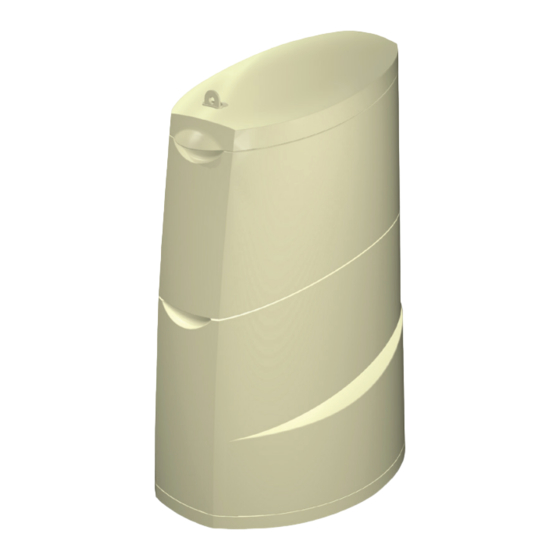

Page 2: Product Stewardship

MAKING THE WORLD A BETTER PLACE Lonza is committed to maintaining and improving our leadership in the stewardship of our products. One of our initiatives is to make health, safety, and environmental protection an integral part of a product’s life cycle –... - Page 3 The Major Components - How They Work General Principles of Operation The three main components of the CCH Feeder are An ORP controller can be used to regulate Feeder (from top to bottom) the Tablet Hopper, the Dissolving output by installing a solenoid on the inlet flow line. Cup section and the discharge tank.

-

Page 4: Specifications

Specifications CCH Feeder Operational Requirements Inlet Pressure Range 10 to 30 psi Ideal 18 psi Outlet vacuum 5-29” Hg. Operating Temperature 40° to 130º F Operational Characteristics Inlet flow (gpm) 0.1-2.0 Outlet flow (Min) 2.1 gpm Note: To Maintain NSF approval a flow indicator must be installed. Dimensions Tubing 1/2”... -

Page 5: Pre-Startup Checklist

Pre-Startup Checklist Following the procedure outlined below will ensure a smooth startup of the CCH Feeder. For seasonal operation, perform this procedure each spring. IMPORTANT!! Do NOT put tablets in the Feeder during the start-up operation. INLET WATER FLOW The inlet water flow system is designed to provide a steady sidestream of clean filtered pool water to the Feeder. -

Page 6: Start-Up Procedures

Startup Procedures After completing the PRE-START-UP CHECKLIST, Output Rate Vs Inlet Flow Rates and # of and establishing that all components of the Feeder are Cartridges filled with Tablets operating properly, your CCH Feeder is ready for start-up. 1. Refer to Charts on pages 7 and 8 to determine the Routine Maintenance of the CCH Feeder # cartridges recommended to be filled with CCH Feeder Tablets and grid type according to pool size... - Page 7 Start-up settings are based on historical data for Note: Remove unused cartridges from the Hopper average chlorine consumption in Public Pools prior to start-up and store for future use. according to pool or spa type. Outdoor Pools and Below are the feed rates for the CCH Feeder with the Spas consume considerably more chlorine than Pool different grids, flow rates and # of cartridges filled and Spas that are indoors.

- Page 8 The second calculation is for a state code that requires a specific chlorine dosage per turnover (6 hrs). Example 2: The state health code requires 10ppm (mg/l) Av. Cl. per 6 hr turnover. 24/6 = 4 turnovers per day. Therefore 10ppm x 4 = 40ppm per day chlorine dosage required. 18 lbs Av.

- Page 9 CCH Feeder Inspection and Maintenance Calcium Hypochlorite by the nature of its manufacture, contains a small amount of calcium carbonate. Proper water balance will minimize the buildup of calcium carbonate solids in the CCH Feeder, however, periodic cleaning of Feeder components is normal and recommended.

- Page 10 SECTION A. Cleaning The CCH Feeder with Muriatic Acid Inspection: The solids build-up and cleaning frequency 4. Lift the dissolving cup out of the way pouring the required for the unit will depend on the amount of contents into the base carefully. Rinse off and soak tablets used and the pool water chemistry.

-

Page 11: Section B. Troubleshooter's Guide

SECTION B. Troubleshooter’s Guide Problem Cause Solution Insufficient water flow to Check water flow through nozzles. If Rinse out dissolving cup, add 6 oz. of Feeder there is scale build-up perform solution water and 1oz. of Muriatic acid. Let sit at right until scale dissolves Inlet Shutoff Valve closed... - Page 12 CCH Feeder Detailed View Arch Chemicals, Inc. • 1200 Lower River Road • P.O. Box 800 • Charleston, TN 37310-0800 rev.7 (3/23/16)

- Page 13 rev.6 (3/23/16) Arch Chemicals, Inc. • 1200 Lower River Road • P.O. Box 800 • Charleston, TN 37310-0800...

- Page 14 CCH Feeder Diagram Descriptions Diagram Number Part Number Qty/Unit Description 79531 CCH Feeder 74712 CCH Feeder Base 74713 CCH Feeder Hopper 74714 Tablet Cartridge (priced as each) 35113 CCH Feeder Lid 74716 CCH Feeder Dissolving Cup - ASM 79806 Discharge Valve Body 79805 Discharge Valve Arm with EPDM Washer 71496...

-

Page 15: Warranty Policy

Warranty Policy CCH Feeder Commercial Pool Chlorinator Arch Chemicals, Inc. (“Arch”) warrants equipment of its manufacture and bearing its identification to be free of defects in workmanship and material. Arch’s liability under this warranty extends for a period of two (2) years (excluding electrical components which carry a 1 year warranty) from the date of installation as performed by an Authorized Commercial Dealer Representative and registered with Arch Water Chemicals via the Arch Commercial Chlorinator Warranty Registration Card. - Page 16 Lonza Emergency Action Network (LEAN) The Lonza Emergency Action Network (“LEAN”) is Arch’s emergency action system. Call the LEAN system at 1-800-654-6911) in North America, and at (Country Code for the United States) 423-780-2970 elsewhere in the world. The LEAN system is available 24 hours a day, 7 days a week for assistance with spills, injuries and emergencies of any kind.

Need help?

Do you have a question about the ARCH CCH A300N and is the answer not in the manual?

Questions and answers