Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for ReDeTec ProtoCycler

- Page 1 Operations Manual Rev. 1.3...

-

Page 2: Table Of Contents

4.2 Initial Extrusion Steps for both Manual and Automatic: ................18 4.3 Automatic Extrusion ........................... 19 4.3.1 Automatic Extrusion Steps ........................19 4.4 Manual Extrusion ............................22 4.4.1 Manual Extrusion Steps: ........................22 5.0 Intro to the ProtoCycler Purge Procedure (PPP)....................24 5.1 Purging ............................... 24 Page 1 of 28... - Page 3 5.1.1 Short Purge ............................24 5.1.2 Disco Purge ............................25 5.3 Purge Tips ..............................25 6.0 Congratulations! ............................. 26 7.0 Appendix ................................ 27 Page 2 of 28...

-

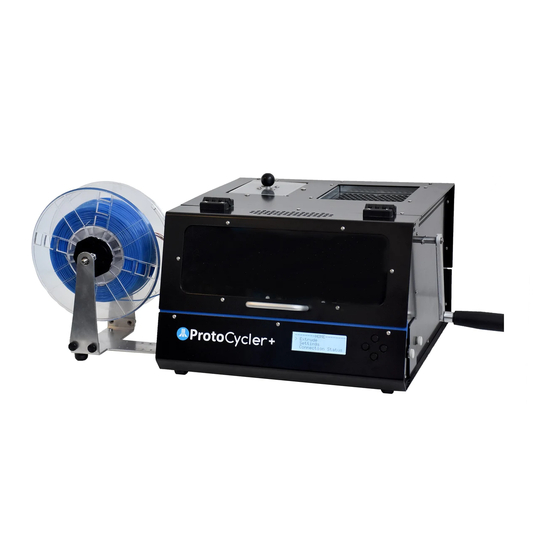

Page 4: Introduction To The Protocycler

1.0 Introduction to the ProtoCycler Welcome and thank you for joining the ProtoCycler community! ProtoCycler is designed to provide an easy to use experience and automatically take care of the extrusion process for you, using an advanced control system to monitor and control operation. -

Page 5: Extrusion Safety

For instance PVC will release chlorine gas and under no circumstances should you try to extrude it with the ProtoCycler. ABS on the other hand is commonly used in 3D printing – but, for safety reasons, still requires proper ventilation to the outside. - Page 6 Figure 2: Above shows general overviews of the left and right sides, respectively, of the ProtoCycler Figure 3: Above shows a general overview of the user interface (UI) of ProtoCycler. TODO FIX THIS Figure 4: From left to right - Nozzle Screen, Nozzle Breaker Plate, Nozzle Cap.

-

Page 7: Grinding

2.0 Grinding 2.1 Grinder Operation The ProtoCycler must be powered on at all times to operate the grinder! The grinder relies on an electromagnet interlock that engages the grinder drive train only when supplied with power. The electromagnet is calibrated to disengage the interlock at set torque limit value to prevent damage to the gear train. -

Page 8: Sorting Ground Material

1. The appropriate pellet size that can be used in your ProtoCycler’s Extruder is 0.125" to 0.2" in diameter. Pellets that do not fit in this size range will not pass through the Extruder Hopper Filter. Particles over 0.2"... -

Page 9: Important Things To Know Before Extruding

Figure 5: Shows the puller idler wheel spring engaged (left image), and disengaged (right image). 3.2 Cleanliness It is important to make sure your device is clean before use. We make sure to thoroughly clean each ProtoCycler before shipping, but over time dust can accumulate. Before extruding, inspect your extruder hopper for dust and other contaminants. -

Page 10: Plastic Care: Dry Vs Wet - Clean Vs Dirty

Make sure your drying system is already preheated before starting the timer for the drying times stated in Table 1. Note, ReDeTec currently supports PLA and ABS. If you have a specific plastic type and grade that you would like us to focus on next, please do not hesitate to reach out to us with requests. -

Page 11: Opaque Vs Transparent Plastic

For a naturally transparent plastic such as PLA, colorants must be added to make the filament opaque. Included with ProtoCycler is a sample of colorants to use with the included plastic, and additional colorants may be purchased from ReDeTec along with plastic pellets. - Page 12 Figure 7: Spooler parts bundle and spooler base shown pulled out from its recess. The following illustrations in Fig 8 below outline how to assemble the spooler and correspond to the set of written instructions that follow it. Page 11 of 28...

- Page 13 Figure 8: Step by step numbered illustrative guide to assembling the spooler. Page 12 of 28...

-

Page 14: Spooler Assembly Instructions

ProtoCycler is aligned and tested for performance before shipping, but sometimes things are bumped and moved between when the ProtoCycler ships to the next time it is turned on again by you, the owner. Taking care and patience to assure your light guides are properly aligned will pay off in the long run. -

Page 15: What You Need To Check Light Guide Alignment

• ReDeTec uses a 1.83mm and a 2.56mm dowel to align the light guides, but you can use anything close within +/- 0.1mm. The larger dowel size is used for the sensor closest to the nozzle, and the smaller dowel size is used for the sensor closest to the puller wheel. -

Page 16: Step 1 - Adjusting The Sensor Height

- dark green line). These lines being flat at a value of 255 (with a small amount of “drop-off” on the right) is a good sign that your light guides are well aligned. If the light guides are lower than 255 or have severe angle to them, such as Fig 10b below, alignment is required. -

Page 17: Step 2 - Evenly Lighting The Sensor

Figure 11: UI Thumbscrews for adjusting the height position of the photoresistors. 2. Typically the puller sensor’s photoresistor will be positioned all the way at the bottom range of its movement for best results. It has been adjusted this way from the factory, and should not need adjustment! 3. -

Page 18: Step 3 - Calibrating The Readings

3.6.5 Step 3 - Calibrating the readings 1. Finally, we need to ensure the light guide readings are accurate. This is where we’ll use the dowels. The procedure is the same for both the puller and nozzle sensor, with minor differences that will be noted as required. -

Page 19: Extrusion Operational Instructions

4.0 Extrusion Operational Instructions 4.1 Overview Now that we are all tuned up and have assured our ProtoCycler is clean and diameter sensors are aligned, we can extrude filament! We will guide you through Automatic Mode Extrusion and Manual Mode. -

Page 20: Automatic Extrusion

4.3 Automatic Extrusion ProtoCycler comes with two preloaded extrusion profiles - PLA and ABS. It is important that you have the most recent firmware and EEPROM loaded onto your ProtoCycler for these profiles to work optimally. Automatic mode also allows you to upload and run your own custom profiles via the PCC. - Page 21 “Spooler Ready”. The fan speed will reduce to allow the filament to soften to a point that it is able to start spooling. Using the yellow handle snips that come with every ProtoCycler, snip the excess filament that has been extruding off the front side of your UI. Now feed the filament through the spreader guide. See Figure 16 for reference.

- Page 22 steady state while spooling. At which point the puller wheel speed and fan speed will constantly adapt to changes in output and disturbances to the system to maintain consistent filament diameter. Note: For best results, close the door to the UI to avoid any cross-wind affecting your filament output - i.e. if a cross-wind cools the filament at the nozzle too quickly, the puller wheel won’t be able to draw-down the filament to its desired final diameter.

-

Page 23: Manual Extrusion

2. Note that there are lot of different things happening in automatic extrusion, and you have to set and control all of them in manual mode. It is not easy! Please ensure you have fully read and understood the ProtoCycler Command Center Overview - particularly the sections and appendices on how to extrude manually, and what all the commands do - before attempting manual extrusion on your own. - Page 24 Prep a piece of tape to fasten the filament to the spool. Using the yellow handle snips that come with every ProtoCycler, snip the excess filament that has been extruding off the front side of your b) Now feed the filament through the spreader guide. See Figure 16 for reference.

-

Page 25: Intro To The Protocycler Purge Procedure (Ppp)

All temperature settings for purging are found in the Appendix, Section 7.0 of this document. 5.1.1 Short Purge 1. Power on your ProtoCycler and connect to the PCC software. Pour the new plastic you wish to extrude into your Extruder Hopper. While connected to the PCC begin manual extrusion. -

Page 26: Disco Purge

5.1.2 Disco Purge Disco Purging means we are going to thermal cycle the ProtoCycler to help transition from one material to another. It is strongly recommended to remove nozzles for the duration of a disco purge and replace it only when purging is complete with a new nozzle. -

Page 27: Congratulations

6.0 Congratulations! As with any process there is a bit of a learning curve, and the ProtoCycler is a complex system to learn inside and out. Making it to the end of this instructions manual and learning all of its ins and outs hopefully means we are well underway to producing your very own filament. -

Page 28: Appendix

7.0 Appendix Table 1: Below summarizes possible purge scenarios, their respective temperature settings, and what type of purge they require. Old Material to New Material Purge Nozzle Nozzle Removal Preheat Temperature Purge Temperature [C] Notes be Purged to be Primed Type State Temperature [C]... - Page 29 Cross reference materials High temperature extrusion temperatures when material preheat purging dissimilar materials. If temperature minus the minimum extrusion High temperature 25C. temperature for the high material extrusion High temperature temperature material is higher temperature minus High Temperature can vary minimum extrusion than the maximum extrusion Disco...

Need help?

Do you have a question about the ProtoCycler and is the answer not in the manual?

Questions and answers