Advertisement

Quick Links

Advertisement

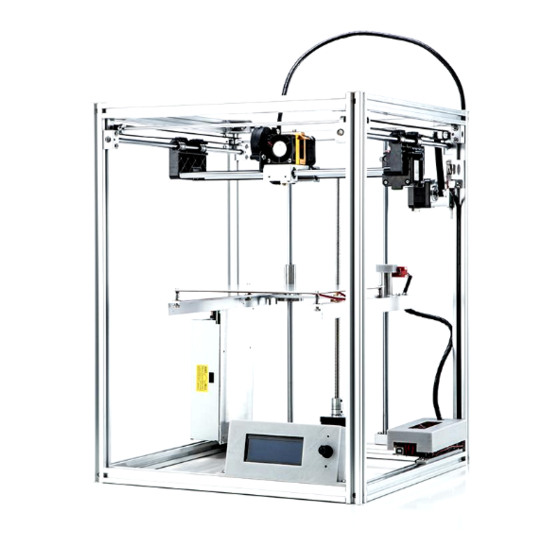

Summary of Contents for Flyingbear P902

- Page 1 ;...

-

Page 2: Table Of Contents

Catalog Ⅰ、 User notes ................... 3 Ⅱ、 Installation of software and driver............. 4 Ⅲ、 Set Printer(taking Windows 10 system as an example) ....12 Ⅳ、 Set slice software and function description ........17 Ⅴ、 Printer's connection and leveling............. 24 Ⅵ、 Print product ................... 30 Ⅶ、... -

Page 3: Ⅰ .User Notes

Ⅰ .User notes 1. This equipment is an industrial product,not a toy,please be sure to place in the area away from the kids so as not to cause damage. 2. In the working process,the nozzle and the hot bed are high temperature zone,please do not touch so as to avoid serious burns 3. -

Page 4: Ⅱ .Installation Of Software And Driver

8. The company reserves the right of final interpretation. Ⅱ .Installation of software and driver 1. Open the program Repetier-Host_1_5_5 in the folder “FlyingBear 3D Printer”... - Page 8 Install Driver...

-

Page 11: Ⅲ .Set Printer (Taking Windows 10 System As An Example)

Ⅲ .Set Printer (taking windows 10 system as an example) 1 、 Click... - Page 12 2 、 Set “ Connection ” Port :According to the ports in Device manager ( COM & LPT ) to choose, (Notice: Each computer different,my computer is COM5.) Baud Rate : fill in “ 250000 ” Other parameters remain the same.

- Page 13 3 、 Set “Printer” Reference temperature: Print PLA Extruder temperature : 205 ℃ around Bed temperature : 65 ℃ around Print ABS Extruder temperature : 230 ℃ around Bed temperature : 80~100 ℃ around Other parameters remain the same.

- Page 14 4 、 Set “ Extruder ” Number of Extruder : 1 Name : P9.2-0.4 Diameter : default it is 0.4,Please fill in it according to your nozzle’s diameter. Other parameters remain the same.

- Page 15 5 、 Set “ Printer Shape ” Printer : FlyingBearP902 X Max : 220 Y Max : 220 Bed Left : 10 Bed Front : 0 Print Area Width : 220 Print Area Depth : 220 Print Area Height : 275(Notice:The actual size is 280,but due to each customer’s installation is different,it...

-

Page 16: Ⅳ .Set Slice Software And Function Description

Ⅳ .Set slice software and function description 1 、 Click “ Slicer ” ---Choose “ Sli3r ” ---Click “ Configuration ”, Open Slic3r... - Page 17 2 、“ Print Settings ” parameter introduction ColiDo Best : thickness 0.15mm , Suitable for printing small model and exquisite model ColiDo draft : thickness 0.3mm , Suitable for fast printing ColiDo standard : thickness 0.2mm , Suitable for printing large models ColiDo standard ABS :...

- Page 18 3 、“ Filament Settings ” parameter setting “ Filament ” parameter Please fill parameter according to the picture,do not leave any of them...

- Page 19 “ Cooling ” parameter Please fill parameter according to the picture,do not leave any of them...

- Page 20 Click “ save ” Pop-up window “ Save Preset ” , Enter the name FlyingBear PLA-60 ” “ Click “ OK ” to save...

- Page 21 4 、“ Printer Settings ” parameter setting parameter ① “ General ” and “ Custom G-code ” remain the same ②“ Extruder 1 ” fill in the parameter according to the picture. “ Nozzle diameter ” default it to 0. 4...

- Page 22 Click save Pop-up window: “ Save Preset ” , Enter the name: “ FlyingBearP902 ” Click “ OK ” to save...

-

Page 23: Ⅴ、 Printer's Connection And Leveling

Ⅴ .Printer's connection and leveling(important) 1.Set the connection of printer,use a usb to connect the computer,and then right-click “This PC”.Choose the “properties” first,then choose “Device”.When appear “Ports ( COM & LPT ) ”,it means that the installation of drive is successful.But if there is a exclamation mark ,it means that the drive of your computer need to update .Please download and update your computer’s drive until the exclamation mark disappear.When become the following picture that means the drive is installed successful. - Page 25 2 、 Open software “ Print-Rite CoLiDo Repetier-Host ” Click “Connect”...

- Page 26 After successful connection, the temperature will displayed below the window. Control X/Y/Z motor to move by Can make X/Y/Z go back to home...

- Page 27 3 、 Leveling printer(very very important!!) Step 1:control the printer’s x/y/z axis back to home by LCD black knob : press to determined ,turn left or right is to choose. Press the knob and choose “ Prepare ” . Press the knob and choose “ Auto home ” to make X/Y/Z axis go back to home.

- Page 28 Step 2:Squeeze each corner of the printing bed, and tighten each wing nut to reduce the distance between hot bed to a minimum. Step 2:Repeat the first step, and then check the distance between the nozzle and the hot bed,if the distance is too large ,adjust the limit screw of Z-axis to make the distance less than 1mm.

- Page 29 Step 4:With the printer powered off, Manually move the Extruder to one corner of the Heated Print Bed to check the distance between the nozzle and Heated Print Bed. Rotate the wing nut to raise the Heated Print Bed.The distance between the Extruder and bed should be 0.1mm or roughly the thickness of an A4 sheet of paper.

-

Page 31: Ⅵ .Print Product

Attention:The hot bed needs to paste the masking tape or painted with the self-adhesive before printing. 1、Introduction of using SD card to print Click the botton , load the folder “ Test Model ” in “ FlyingBear 3D Printer... - Page 32 After load the “Test Model”,Click the slicer, all parameters must be filled according to the diagram,then click “ Slice with Slic3r ”...

- Page 33 After slice is done,Click “Save to File” to save the file in SD card.

- Page 34 After insert the SD card into LCD,choose “Prepare”----”Auto home” Choose “Prepare”---”Preheat PLA”----”Preheat PLA” Choose “ Print from SD ” ----- ” Test Model ” Then wait a moment,after the heating process all finished,it will begin to print.

- Page 35 Printing different models need different skills.If you want to print a very fine looking model,you need to continue to explore yourself for a period of time.Next,introduce the skills of printing vase for you. Step 1.Open the model folder “vase1” in “FlyingBear 3D Printer”. Step 2. Copy the model "vase 1" into the SD card and then start printing.

-

Page 36: Ⅶ .Maintenance

Ⅶ .Maintenance 1.When your machine is running with noise and vibration,you need to clean up the slide rod and drop a little oil until the slide rod can slide smoothly.If the sound is stable and the vibration is regular,you can ignore it. 2.The filament is not easy to plastify again after high temperature decomposition and cooling.So we recommend that at the end of print,you should use a small wire to clean the nozzle.This is a basic maintenance to the 3D printer.

Need help?

Do you have a question about the P902 and is the answer not in the manual?

Questions and answers